Titanate having a nanometer structure and preparing method and application thereof

A nanostructure, titanate technology, applied in the field of materials, can solve the problems of environmental pollution, high concentration of corrosive alkali, high synthesis cost, etc., and achieve the effects of easy control of process parameters, simple preparation process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

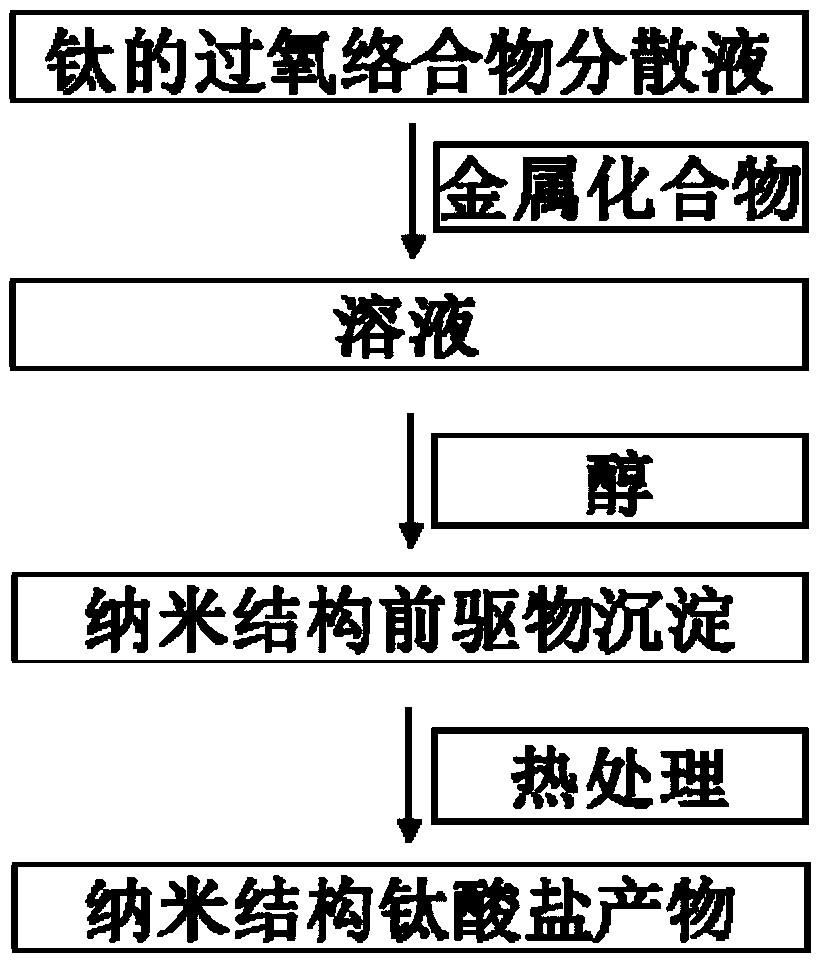

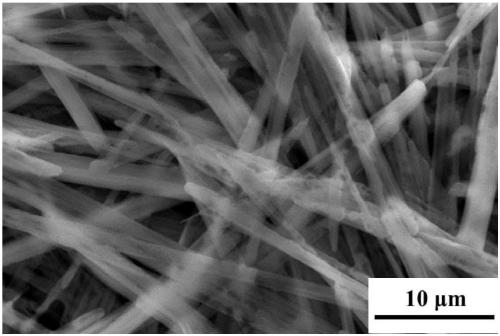

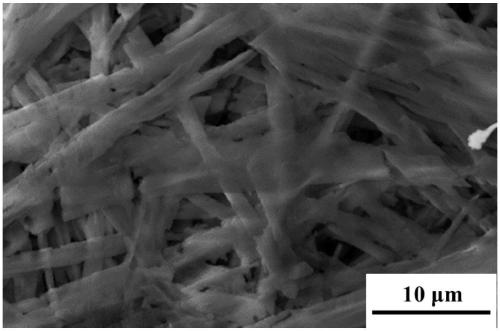

[0066] according to figure 1 According to the process, 4 grams of titanium isopropoxide is dispersed in 100 milliliters of water under stirring conditions, and then 8 milliliters of 30% hydrogen peroxide is added and stirred to form a titanium-containing peroxo complex suspension. Next, add 10 grams of sodium hydroxide to the above-mentioned peroxo complex suspension, and stir to form a light yellow transparent solution. Next, 30 ml of ethanol was slowly added to the above transparent solution at room temperature, and after stirring, a one-dimensional nanowire-shaped precursor precipitate was obtained, and the sodium titanate precursor precipitate was obtained by filtration separation. The SEM image is as follows figure 2 shown. Subsequently, the precursor was precipitated and dried, and then heated at 300 degrees Celsius for 24 hours to obtain a one-dimensional nanowire-shaped sodium titanate product. The SEM image is as follows image 3 shown. Figure 4 It is a graph of ...

Embodiment 2

[0068] according to figure 1 In the process described above, under stirring conditions, 3 g of titanium isopropoxide is dispersed in 100 ml of water, and then 6 g of urea peroxide is added, and stirred to form a titanium-containing peroxo complex suspension. Next, add 8 grams of sodium oxide to the above-mentioned peroxo complex suspension, and stir to form a light yellow transparent solution. Next, 10 ml of isopropanol was slowly added to the above transparent solution at room temperature, and the precursor precipitate was obtained after stirring. The sodium titanate precursor precipitate was obtained by suction filtration, and its SEM image was basically the same as figure 2 Consistent with that shown. Subsequently, the precursor was precipitated and dried, and then heated at 450 degrees Celsius for 4 hours to obtain a sodium titanate product, whose SEM image was basically the same as image 3 Consistent with that shown.

Embodiment 3

[0070] according to figure 1 According to the process, 1 g of tetrabutyl titanate was dispersed in 100 ml of water under stirring conditions, and then 2 ml of hydrogen peroxide with a concentration of 30% was added, and stirred to form a titanium-containing peroxo complex suspension. Next, add 2 grams of sodium peroxide and 3 grams of sodium chloride to the suspension of the above-mentioned peroxo complex, and stir to form a light yellow transparent solution. Next, 30 ml of methanol was slowly added to the above transparent solution at room temperature, and the precursor precipitate was obtained after stirring. The sodium titanate precursor precipitate was obtained by centrifugation, and its SEM image was basically the same as figure 2 Consistent with that shown. Subsequently, the precursor was precipitated and dried, and then heated at 900 degrees Celsius for 1 hour to obtain the sodium titanate product, whose SEM image was basically the same as image 3 Consistent with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com