A new system for separation and purification of hydrophobic eutectic solvent of weak protic acid and method for purifying weak protic acid

A deep eutectic solvent, separation and purification technology, applied in the fields of biology and chemical industry, can solve the problems of difficult separation of impurity organic acids, affecting the purity of lactic acid, etc., and achieve the effect of high recovery rate, less pollution and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

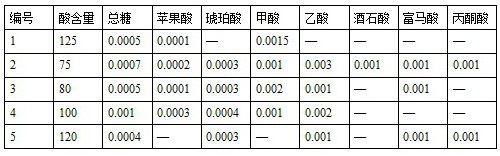

[0056] A new system of hydrophobic deep eutectic solvent separation and purification of weak protic acid A method for extracting high-purity L-lactic acid from L-lactic acid fermentation broth, the content of L-lactic acid in the fermentation broth is 210g / L (the ratio of L-lactic acid and heteroacids The ratio of the amount and concentration of substances is 25:1), take 1L of fermentation broth, add a compound containing oxygen atoms as electron-donating atoms to the reaction solution at a volume ratio of 1:1, and a carbon atom apart from each other, such as 400 mL 3-( 4-Hydroxy-phenyl)-3-oxo-pentyl propionate, add 300 mL of liquid paraffin, 300 mL of isododecanol as a deep eutectic solvent accelerator, the temperature is 30 ° C, the stirring speed is 400 rpm, and the The time is 30 minutes. After testing, 85% of the lactic acid in the fermentation broth is transferred from the water phase to the hydrophobic deep eutectic solvent system. When analyzing the hydrophobic deep eut...

Embodiment 2

[0058] A method for extracting citric acid from citric acid fermentation broth by a new system for separation and purification of weak protonic acid in a hydrophobic deep eutectic solvent. The content of citric acid in the fermentation broth is 110g / L (the ratio of citric acid to miscellaneous acids is 20:1), 1L of fermentation broth. Add a compound containing oxygen atom as an electron-donating atom to the reaction solution at a volume ratio of 1:1, and a compound with two carbon atoms apart from each other, such as 350mL 3-hydroxybenzyl amyl succinate, add 300mL liquid paraffin, and a deep eutectic solvent to promote 350g isohexadecanol at 30°C, the stirring speed is 400 rpm, and the stirring time is 30min. After testing, 83% of the citric acid in the fermentation broth is transferred from the water phase to the hydrophobic deep eutectic solvent system. The concentration ratio of citric acid and heteroacids in the hydrophobic deep eutectic solvent system is 180:1. After anal...

Embodiment 3

[0060] A method for extracting malic acid from malic acid fermentation broth by a new system for separation and purification of weak protonic acid in a hydrophobic deep eutectic solvent. The content of malic acid in the fermentation broth is 87 g / L (the ratio of the concentration of malic acid to miscellaneous acids is 23:1), 1L of fermentation broth. Add a compound containing oxygen and nitrogen atoms as electron-donating atoms to the reaction solution at a volume ratio of 1:1, and a carbon atom is separated from each other, such as 500 mL, N, N-dibutyl-3-oxoisobutyroxime, add 300 mL Liquid paraffin, deep eutectic solvent accelerator undecone 200 mL, at 30 ° C, stirring speed of 400 rpm, stirring time 30 min. After testing, 80% of the malic acid in the fermentation broth was transferred from the water phase to the hydrophobic deep eutectic solvent system. The ratio of the concentration of malic acid to the heteroacid in the hydrophobic deep eutectic solvent system is 150:1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com