Production method for liquid dispersion of titanium oxide particles

A manufacturing method and technology of titanium oxide, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve problems such as impaired transparency of alcohol dispersions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

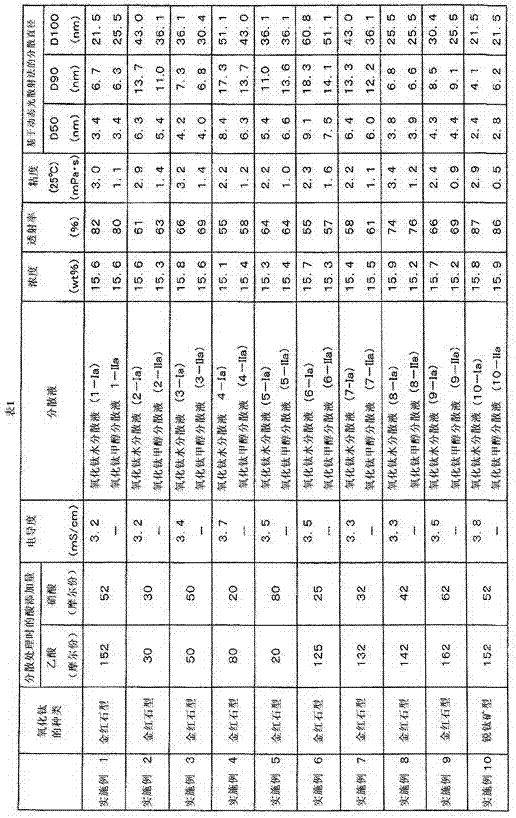

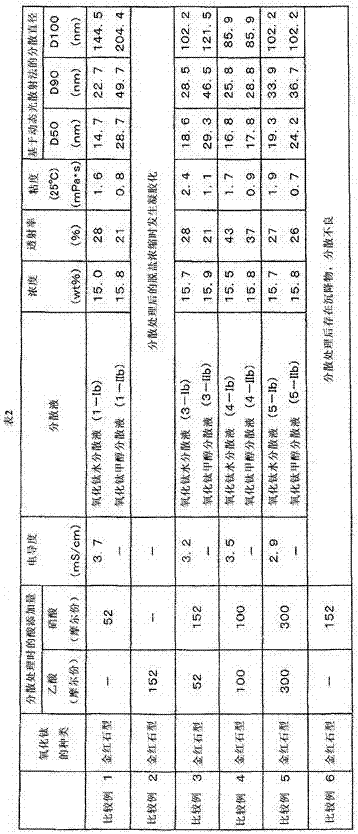

[0062] Hereinafter, although this invention is demonstrated in detail based on an Example, this invention is not limited to these Examples at all.

[0063] Hereinafter, "Microza" manufactured by Asahi Kasei Chemical Co., Ltd. (model: ACP-1010D, fractional molecular weight: 13000) was used for ultrafiltration. The dispersion diameter of the titanium oxide particles in the dispersion liquid was measured by a dynamic light scattering method (UPA-UT manufactured by Nikkiso Co., Ltd.).

[0064] Regarding the total light transmittance of the dispersion liquid of titanium oxide particles, using a haze meter (NDH4000 manufactured by Nippon Denshoku Industries Co., Ltd.), ion-exchanged water was filled into a cuvette with an optical path length of 10 mm, and the light transmittance was measured ( blank value) T 0 , similarly fill the cuvette with dispersion liquid and measure the light transmittance T, with (T / T 0 )×100 to find out.

[0065] Viscosity was measured with a tuning-fork...

reference example 1

[0068] (Adjustment of aqueous slurry A of rutile-type titanium oxide particles)

[0069] Into a separable flask equipped with a reflux device, 3 L of an aqueous solution of titanium tetrachloride adjusted so that the concentration of chloride ions is 2.3 mol / L and the concentration of titanium ions is 50.7 g / L in terms of titanium oxide is charged at 70° C. It heated for 3 hours and hydrolyzed to obtain an aqueous slurry containing the precipitated rutile-type titanium oxide particles. (first process)

[0070] Use glass fiber filter paper with a collection diameter of 300 nm to filter the above water slurry to remove unreacted titanium tetrachloride and dissolved components. The titanium oxide particles obtained in this way were slurried twice in water, and an aqueous sodium hydroxide solution was added to the obtained water slurry until the pH of the above water slurry reached 7.0. Filtration and washing with fiber filter paper. At this time, when the rutile-type titanium ...

Embodiment 1

[0074] To the aqueous slurry A of rutile-type titanium oxide particles obtained in Reference Example 1, 152 molar parts of acetic acid and 52 molar parts of nitric acid were added relative to 100 molar parts of titanium oxide to perform degumming, and then water was added to make the slurry The material is diluted in such a way that it reaches 50g / L in terms of titanium oxide.

[0075] 2L of the aqueous slurry thus obtained was subjected to a wet dispersion treatment for 18 hours using a circulation type bead mill "Ultra Apecks Mill UAM-05" manufactured by Kotobuki Kogyo Co., Ltd. to obtain an aqueous dispersion of rutile-type titanium oxide particles. . In the above-mentioned wet dispersion treatment, zirconia beads with a diameter of 30 μm were used, and the rotational speed of the bead mill was set at 2940 rpm.

[0076] Concentrate the aqueous dispersion of the rutile-type titanium oxide particles until the content of the rutile-type titanium oxide particles reaches 15% by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com