Rutile metatitanic acid and titanium dioxide, and preparation methods thereof

A technology of rutile type and metatitanic acid, which is applied in the preparation of titanium compounds, the preparation of chlorides, chemical instruments and methods, etc., to achieve the effects of avoiding product sintering, low hydrolysis temperature, and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

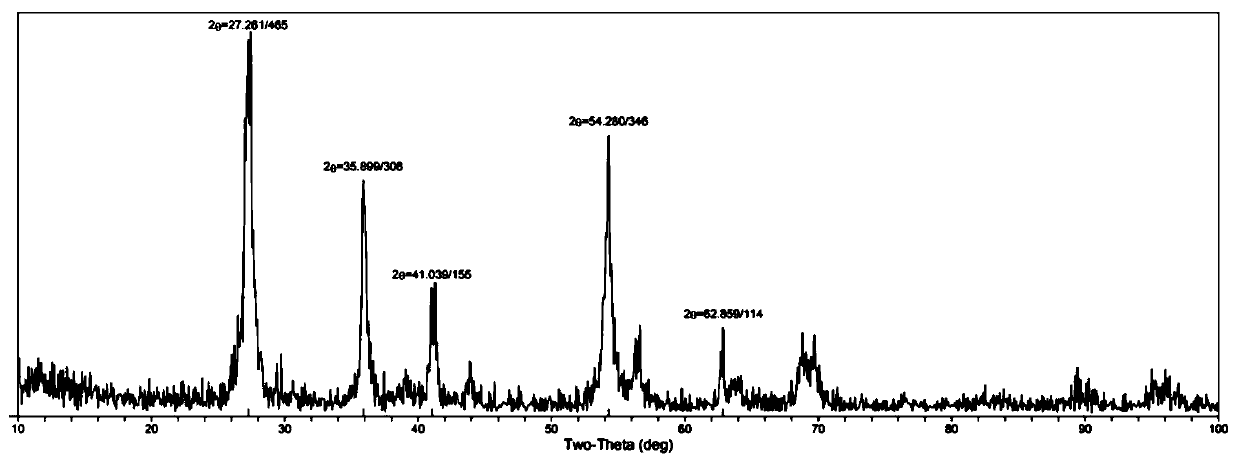

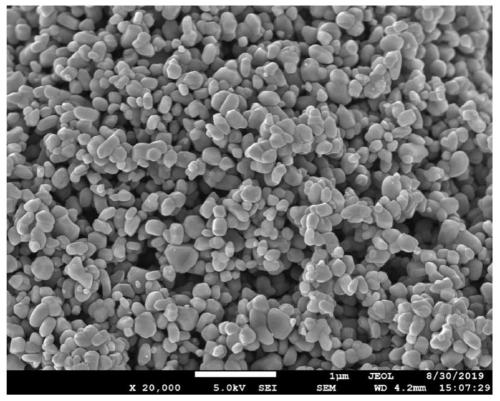

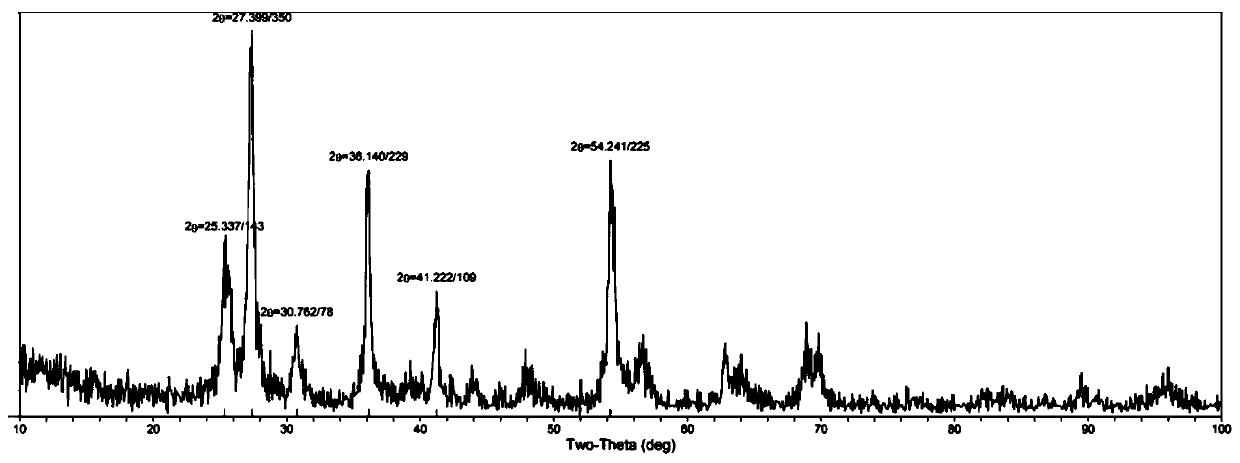

Image

Examples

preparation example Construction

[0058] A kind of preparation method of rutile type metatitanic acid provided by the embodiment of the present invention comprises:

[0059] The mixed solution of the seed crystal solution and the ferrotitanium solution is hydrolyzed and kept at 90-100° C. to obtain a mixed solution containing metatitanic acid, ferrous chloride and hydrochloric acid; the seed crystal solution is obtained from the ferrotitanium solution Part of it is obtained by aging at 90-100°C, the iron ions in the ferrotitanium solution are all ferrous ions, and the Ti in the ferrotitanium solution 4+ The content of TiO 2 Calculated as 100-200g / L, the iron-titanium ratio in the ferrotitanium solution is 0.1-0.3.

[0060] Iron-to-titanium ratio in the application refers to the mass of ferrous ions and titanium (in the form of TiO 2 count) mass ratio.

[0061] The above method belongs to the liquid phase hydrolysis method, which has lower energy consumption compared with the hydrochloric acid method. Under ...

Embodiment 1

[0109] (1) Add 32% hydrochloric acid and ilmenite into the reaction kettle according to the acid / mineral mass ratio of 5:1, feed hydrogen chloride gas to make the pressure in the system 1MPa higher than the atmospheric pressure, react at 80°C for 5 hours, and the reaction ends Afterwards, the insoluble matter was removed by filtration to obtain solution A0;

[0110] (2) Add iron powder to A0, react at 60°C for 1 hour to obtain solution A1, control Ti 3+ The concentration of TiO 2 Calculated as 1g / L;

[0111] (3) Pass hydrogen chloride gas into the solution A1, so that the concentration of hydrochloric acid in the solution is raised to 12mol / L, adopt vacuum crystallization to control the iron-titanium ratio in the solution to be 0.2, and separate to obtain solution A2;

[0112] (4) Add solution A2 to the iron-titanium co-extractor according to O / W=1:1, use 60% trioctylphosphine oxide diluted with kerosene (that is, the ratio of trioctylphosphine oxide to kerosene mass is 1.5:...

Embodiment 2

[0119] (1) Add 45% hydrochloric acid and ilmenite into the reaction kettle according to the acid / mineral mass ratio of 2:1, feed hydrogen chloride gas to make the pressure in the system 0.1MPa higher than the atmospheric pressure, and react at 70°C for 10 hours. After the end, remove the insoluble matter by filtration to obtain solution A0;

[0120] (2) Add iron sheets to A0, react at 70°C for 30 minutes to obtain solution A1, and control Ti 3+ The concentration of TiO 2 Calculated as 2g / L;

[0121] (3) Pass hydrogen chloride gas into solution A1, so that the concentration of hydrochloric acid in the solution is raised to 14mol / L, adopt vacuum crystallization to control the iron-titanium ratio in the solution to be 0.3, and separate to obtain solution A2;

[0122] (4) According to O / W=2:1, the solution A2 is added to the iron-titanium co-extractor, and 50% trioctylphosphine oxide diluted with kerosene is used for extraction to obtain the iron-titanium extract solution A3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com