Patents

Literature

54results about How to "Reduce end length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

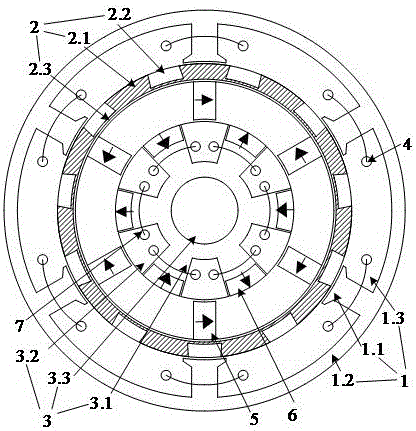

Mixed permanent magnetic pole-alternating and magnetic flux-switching memory motor and winding switching magnetism-weakening control method thereof

ActiveCN104578477ASimple structureImprove space utilizationAC motor controlMagnetic circuit stationary partsLow speedMagnetic poles

The invention discloses a mixed permanent magnetic pole-alternating and magnetic flux-switching memory motor and a winding switching magnetism-weakening control method thereof. The mixed permanent magnetic pole-alternating and magnetic flux-switching memory motor comprises a salient rotor and a stator, wherein the stator contains stator cores, aluminium-nickel-cobalt permanent magnets, neodymium-iron-boron permanent magnets, centralized armature windings and pulsed magnetism-adjusting windings; iron core edges of two adjacent outer U-shaped units and tangentially-magnetized long-stripped neodymium-iron-boron permanent magnets form a first permanent magnetic pole, while the circumferentially-inward (outward) and parallel-magnetized V-shaped embedded aluminium-nickel-cobalt permanent magnets and inner U-shaped units form a second permanent magnetic pole; mixed magnetic poles are in alternating polarity distribution; when the motor runs at a low speed, the pulsed magnetism-adjusting windings are in direct-current pulsed working state, while in a high-speed weak-magnetism area, the pulsed magnetism-adjusting windings are converted into alternating-current armature windings. Requirements on performance in a low-speed area and in the high-speed area can be met at the same time; influence of an armature reaction field on the aluminium-nickel-cobalt permanent magnets with low coercivity is small; the utilization rate of permanent magnetism, the torque density, and the reliability of system operation are high.

Owner:SOUTHEAST UNIV

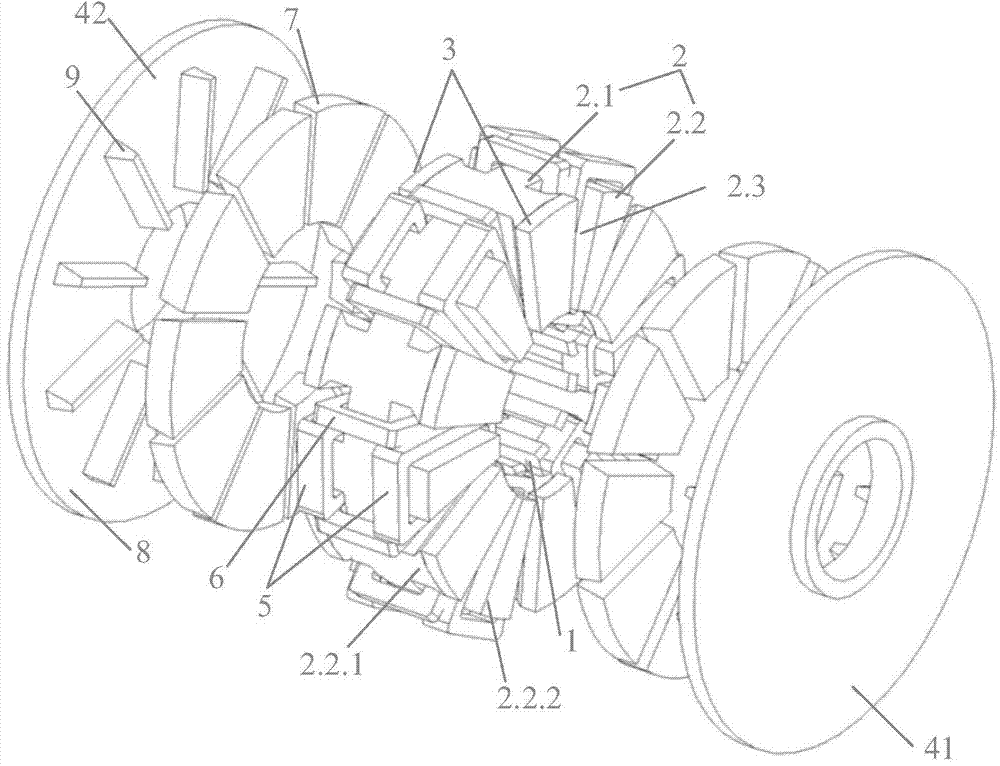

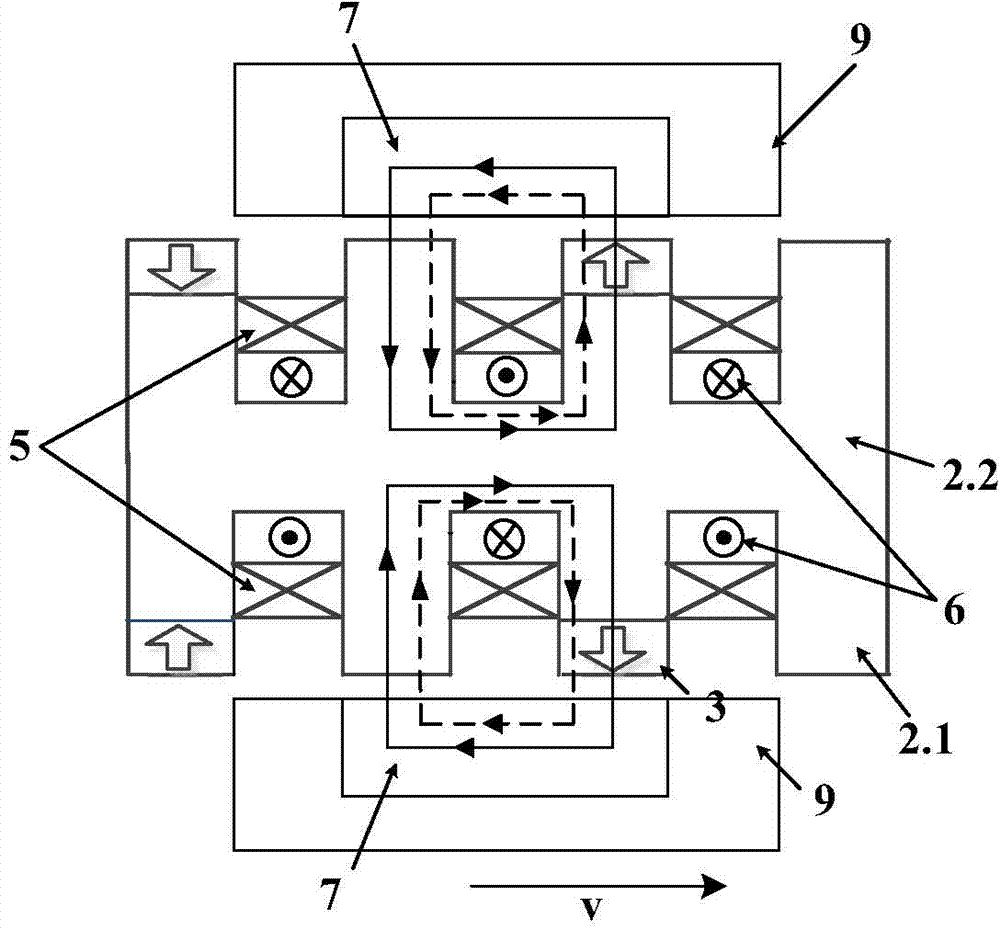

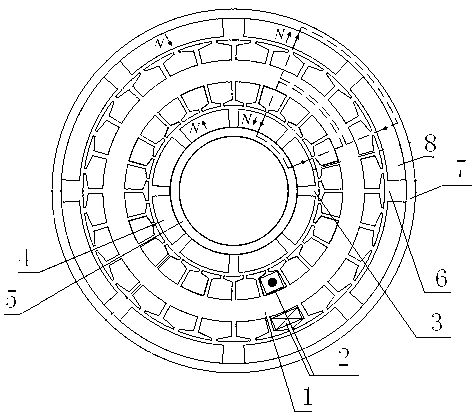

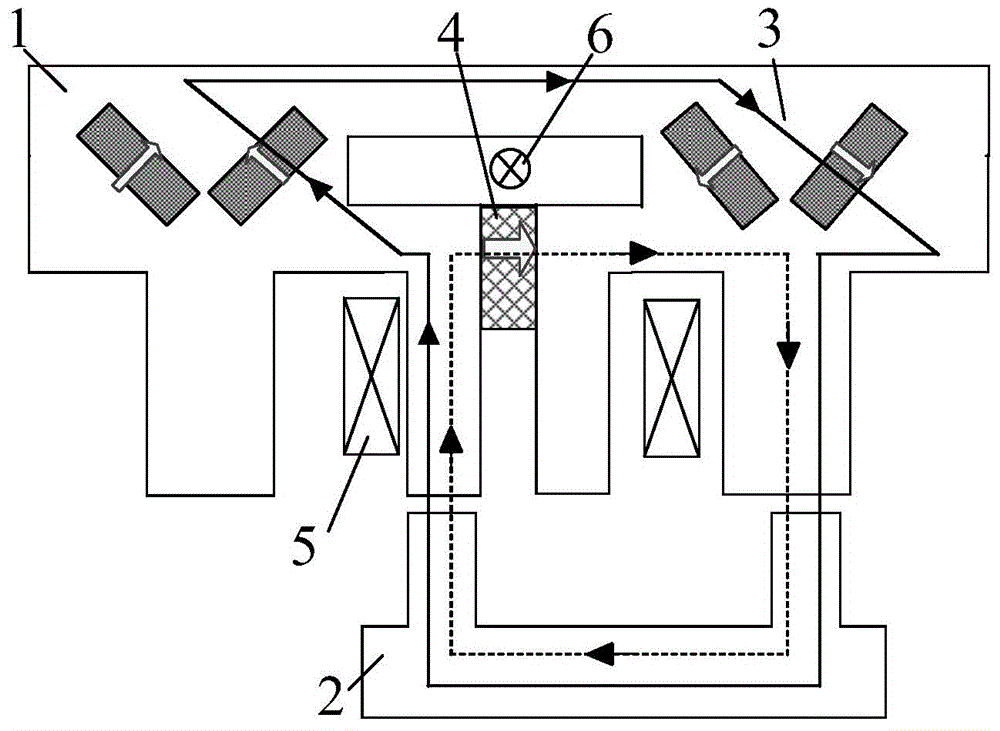

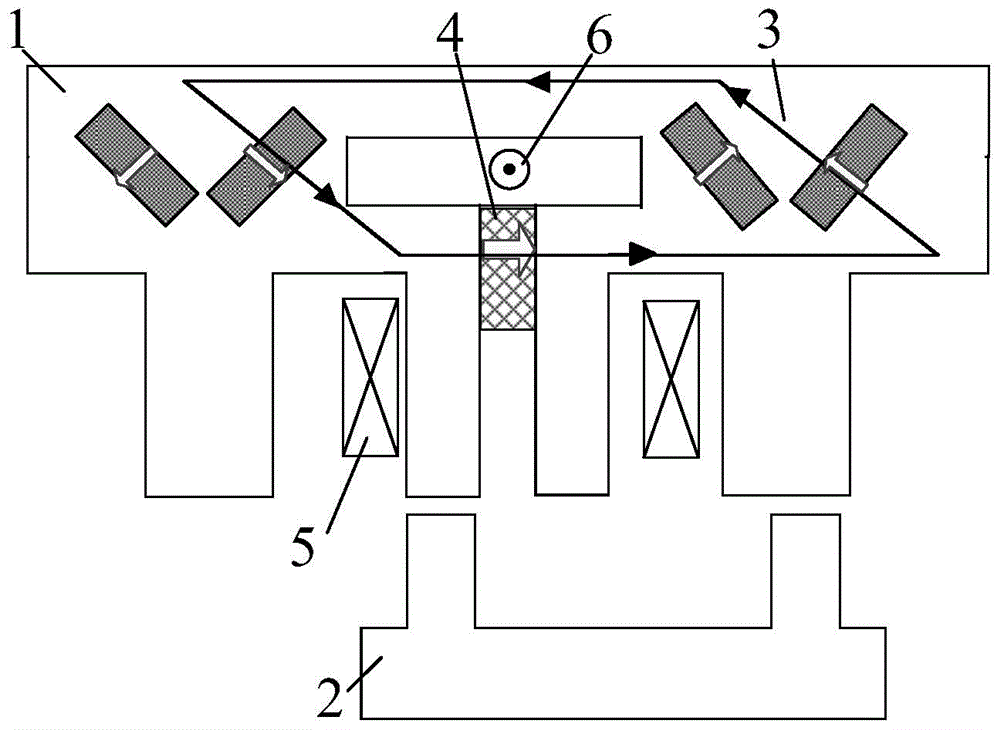

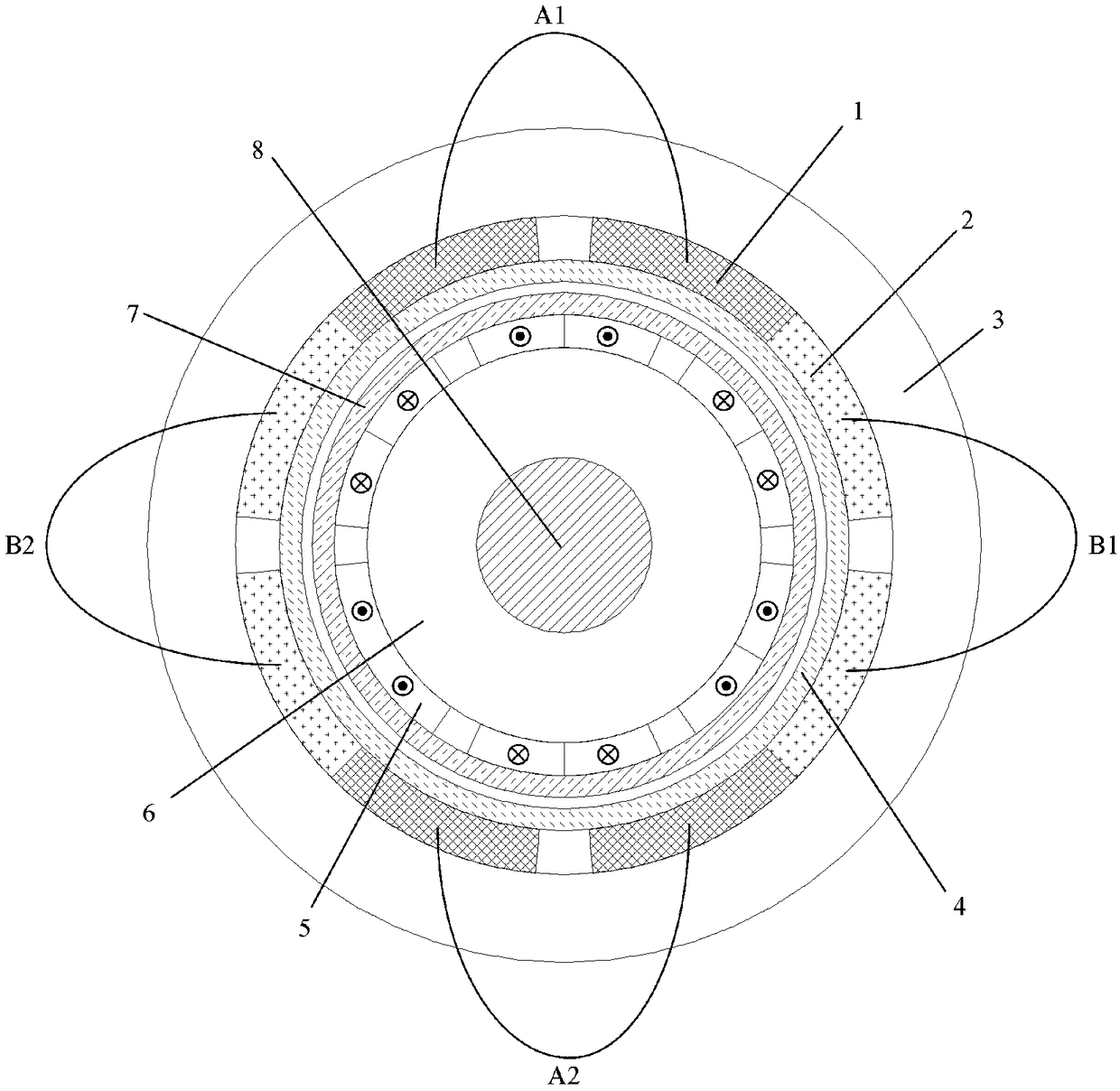

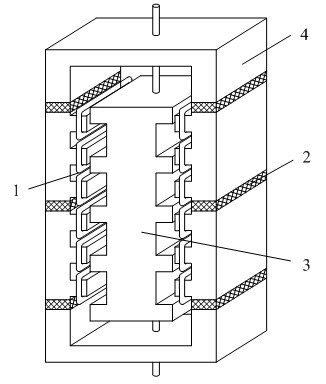

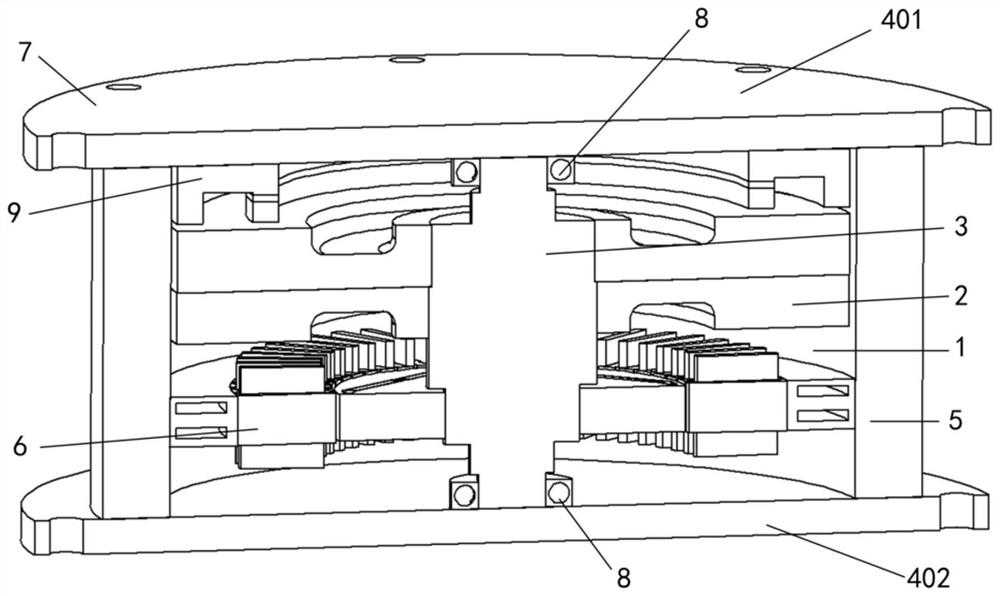

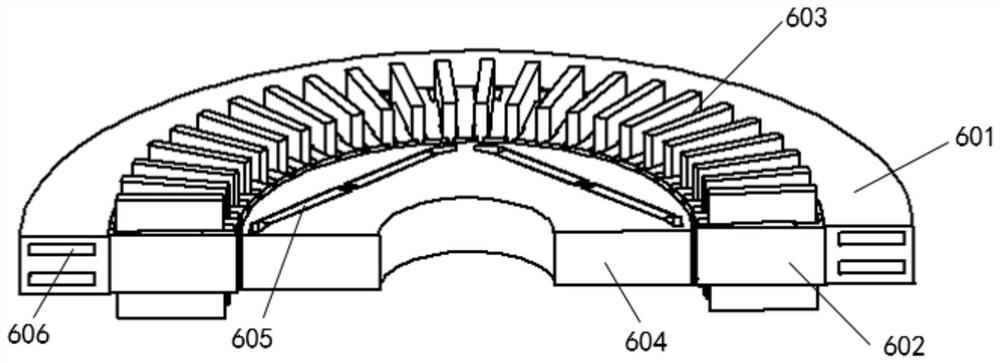

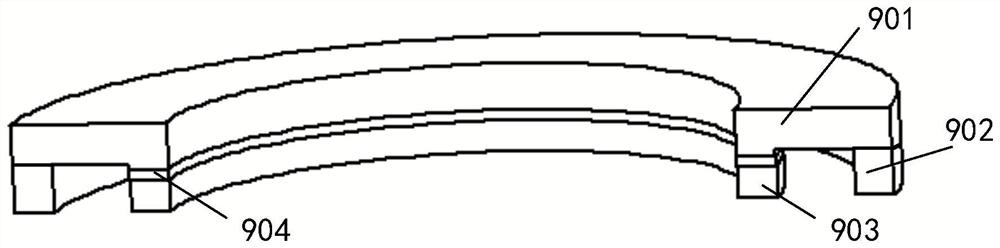

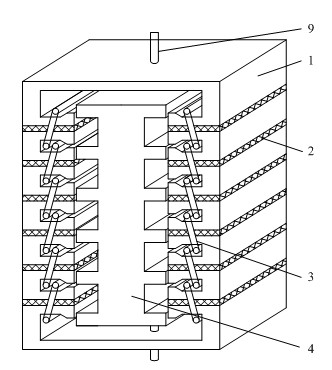

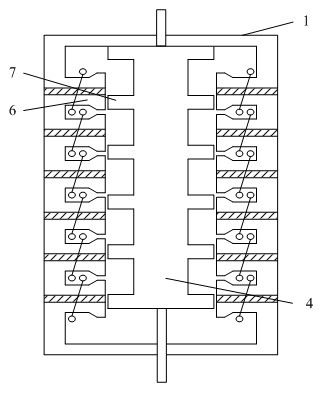

Axial magnetic field magnetic flux switching type surface-mounted permanent magnet memory motor

ActiveCN103490573ASimple structureReduce wind resistanceMagnetic circuit rotating partsMagnetic circuit stationary partsSurface mountingElectric machine

The invention discloses an axial magnetic field magnetic flux switching type surface-mounted permanent magnet memory motor. The permanent magnet memory motor comprises a first rotor (41), a second rotor (42), a stator (1) and an installing shaft, wherein the stator (1) is arranged between the first rotor (41) and the second rotor (42) and of an axial two-side symmetrical structure, the installing shaft is used for coaxially installing the stator (1), the first rotor (41) and the second rotor (42), and the stator is located between the two rotors to form an axial two-air-gap motor. The stator (1) is of the two-side symmetrical salient pole structure and comprises a stator iron core (2), a plurality of permanent magnets (3), a three-phase armature winding (5) and a single-phase pulse winding (6). The stator iron core (2) comprises a stator yoke (2.1) and stator teeth (2.2), wherein the stator teeth (2.2) protrude in the center direction of the first rotor (41) and in the center direction of the second rotor (42) respectively from the stator yoke (2.1). By the adoption of the permanent magnet memory motor, power density of the motor is improved, and the wide rotating speed operation range is possessed.

Owner:SOUTHEAST UNIV

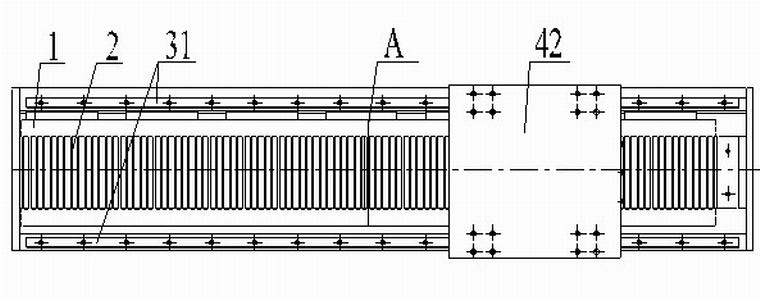

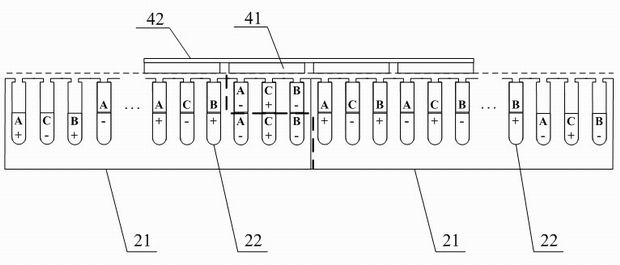

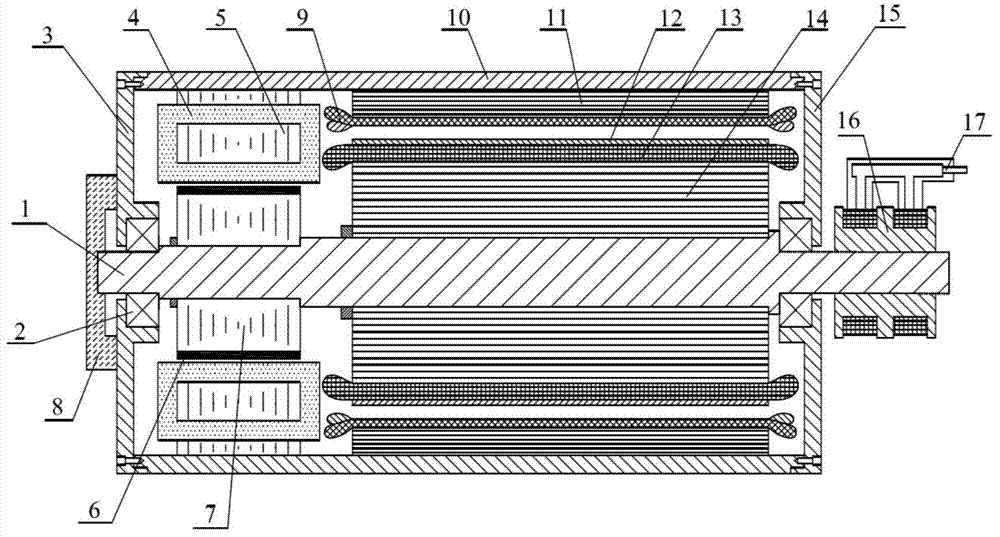

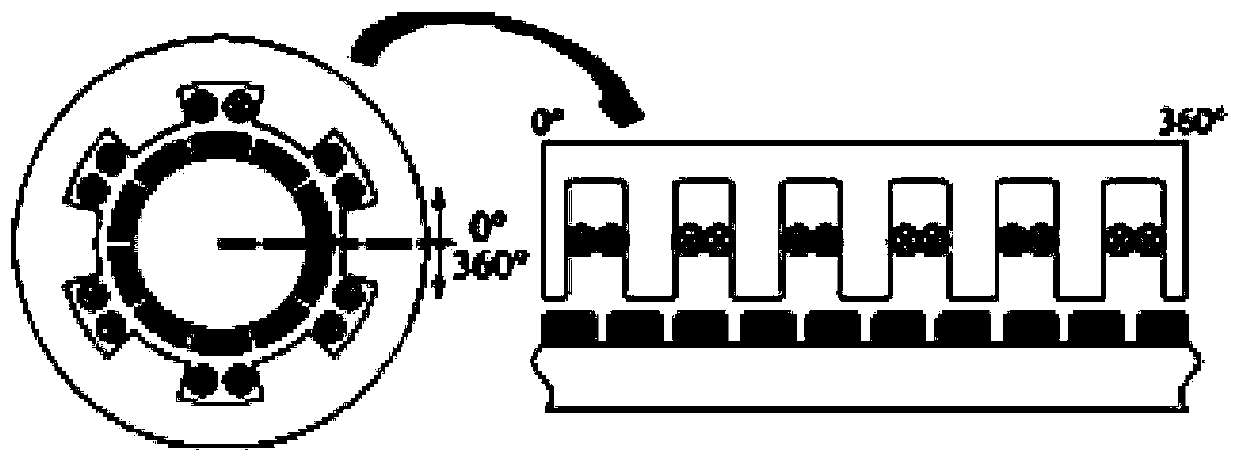

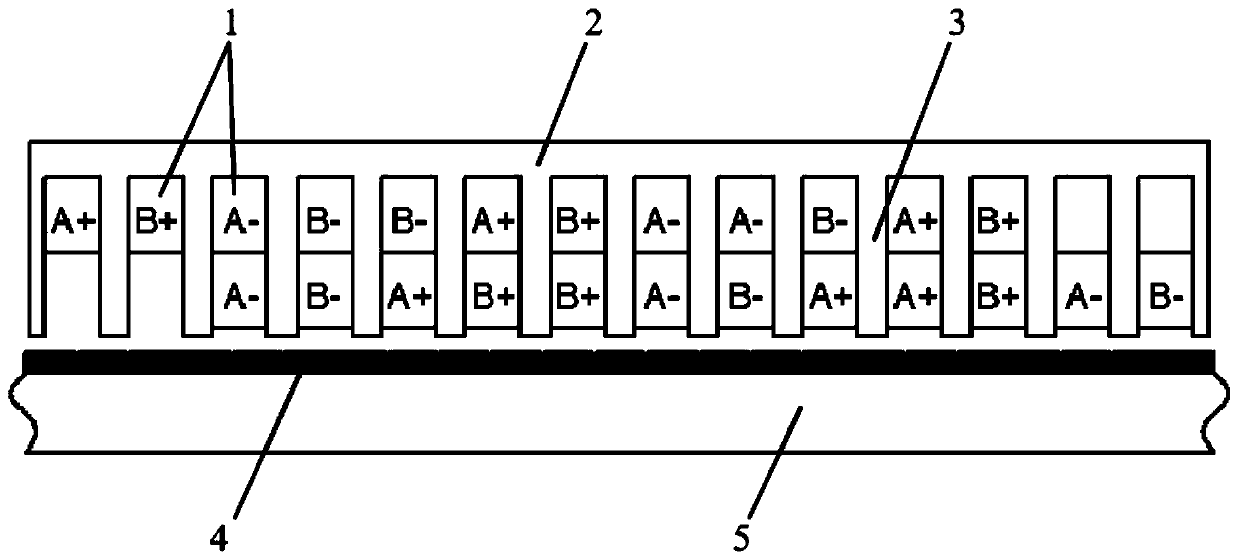

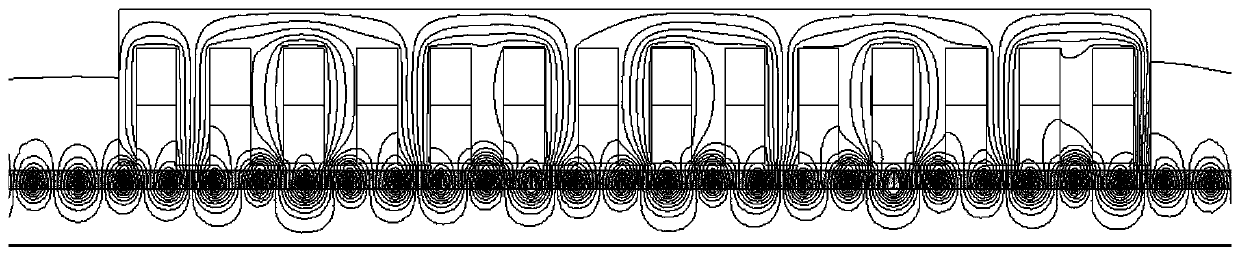

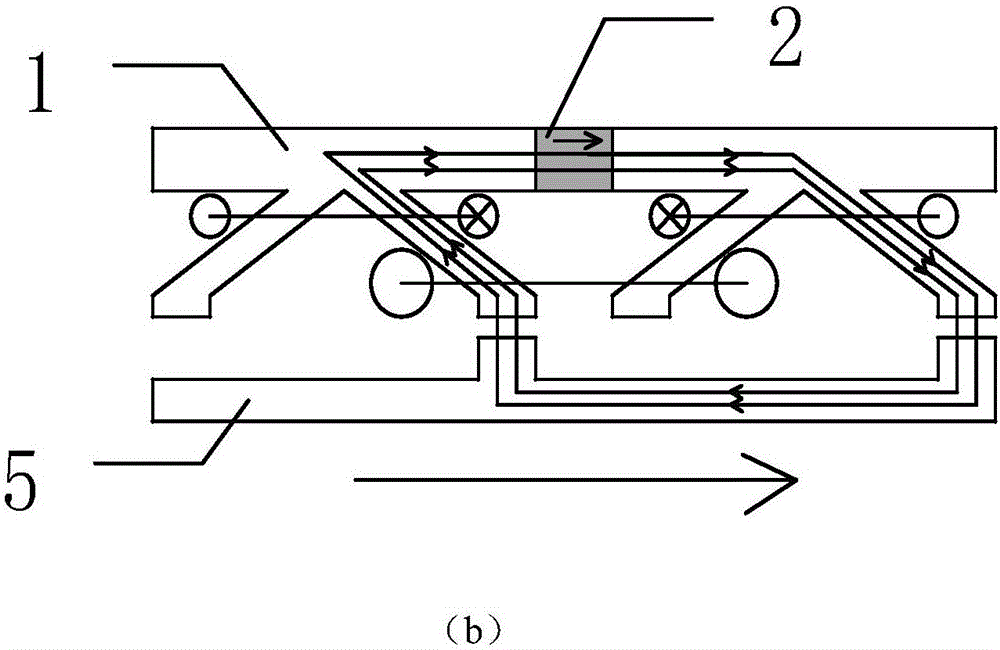

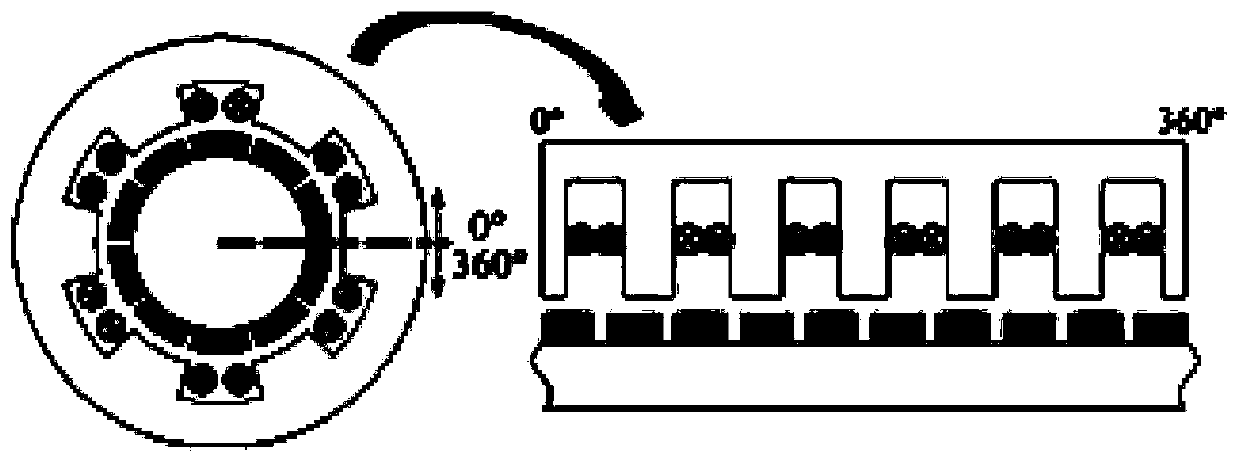

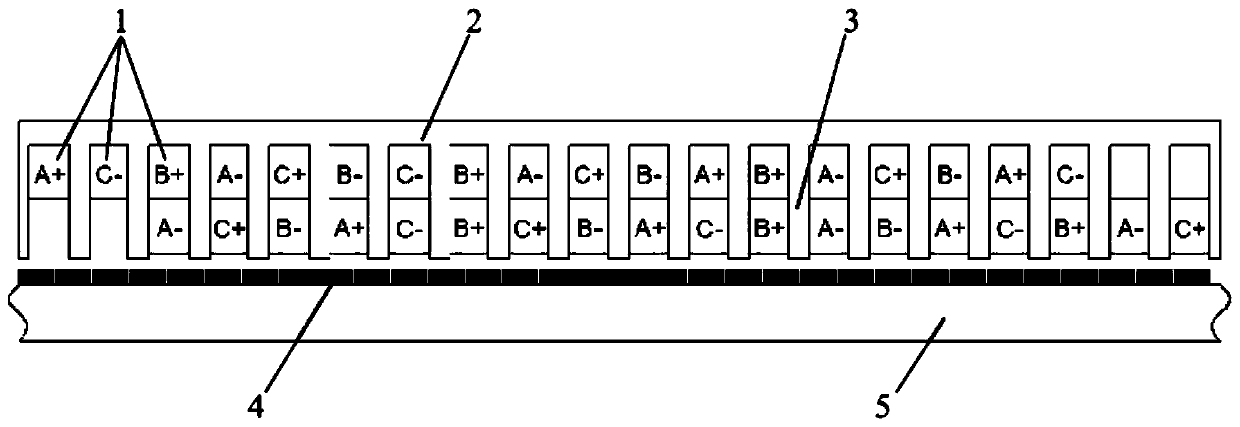

Concentrated-winding multi-segment permanent magnet synchronous linear motor

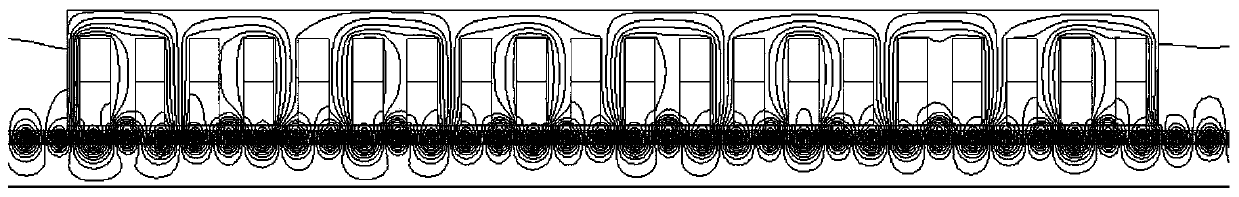

InactiveCN101777821AIncrease thrust densityReduce lossPropulsion systemsWindings conductor shape/form/constructionPermanent magnet synchronous motorPermanent magnet synchronous generator

The invention discloses a concentrated-winding multi-segment permanent magnet synchronous linear motor, which belongs to the technical field of liner motors and solves the problem of low system operation efficiency of the traditional primary dynamic magnetic steel type permanent magnet synchronous linear motor of which the rotor windings are electrified at the same time. In the concentrated-winding multi-segment permanent magnet synchronous linear motor, an armature is arranged in the middle of the upper surface of a machine seat; a pair of guide rails is arranged on two sides of the armature on the upper surface of the machine seat; the pair of the guide rails are in sliding fit connection with a pair of sliding blocks which are fixedly connected with a rotor body; a plurality of pairs of permanent magnets are arranged on the inner surface of the rotor body along a motion direction in one row and a plurality of columns; air gaps are reserved between the permanent magnets and the armature; a plurality of segments of armature cores are sequentially and closely connected in the motion direction of the rotor body; the armature cores adopt a tooth slot structure; a segment of armature winding is embedded in the tooth slot of each segment of armature core; each segment of armature winding is a concentrated winding; and two adjacent segments of armature windings are overlapped to be embedded on the end part of each segment of armature core, wherein the length of the overlapped area is equal to the pitch, which is 1, of the windings. The motor is applicable to heavy-load propulsion systems.

Owner:HARBIN INST OF TECH

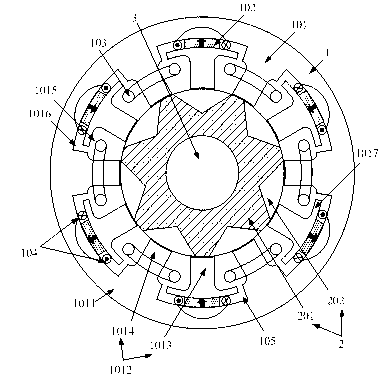

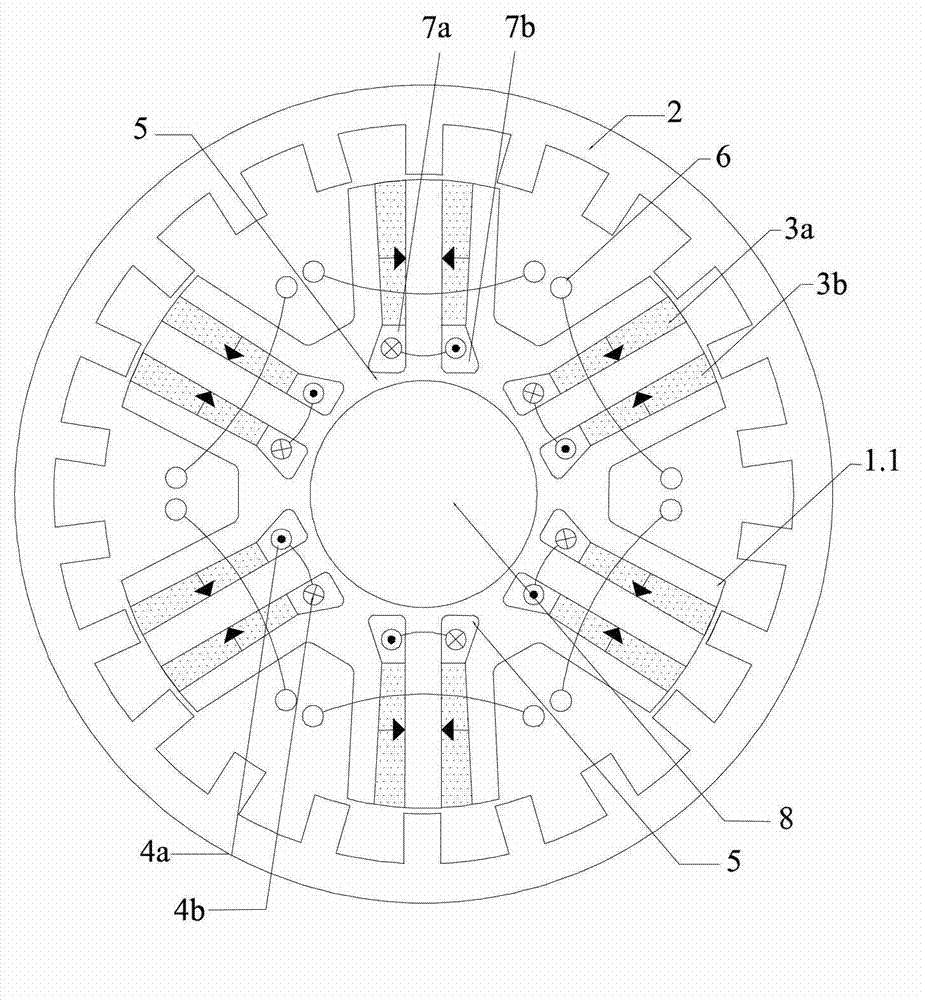

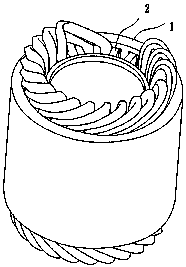

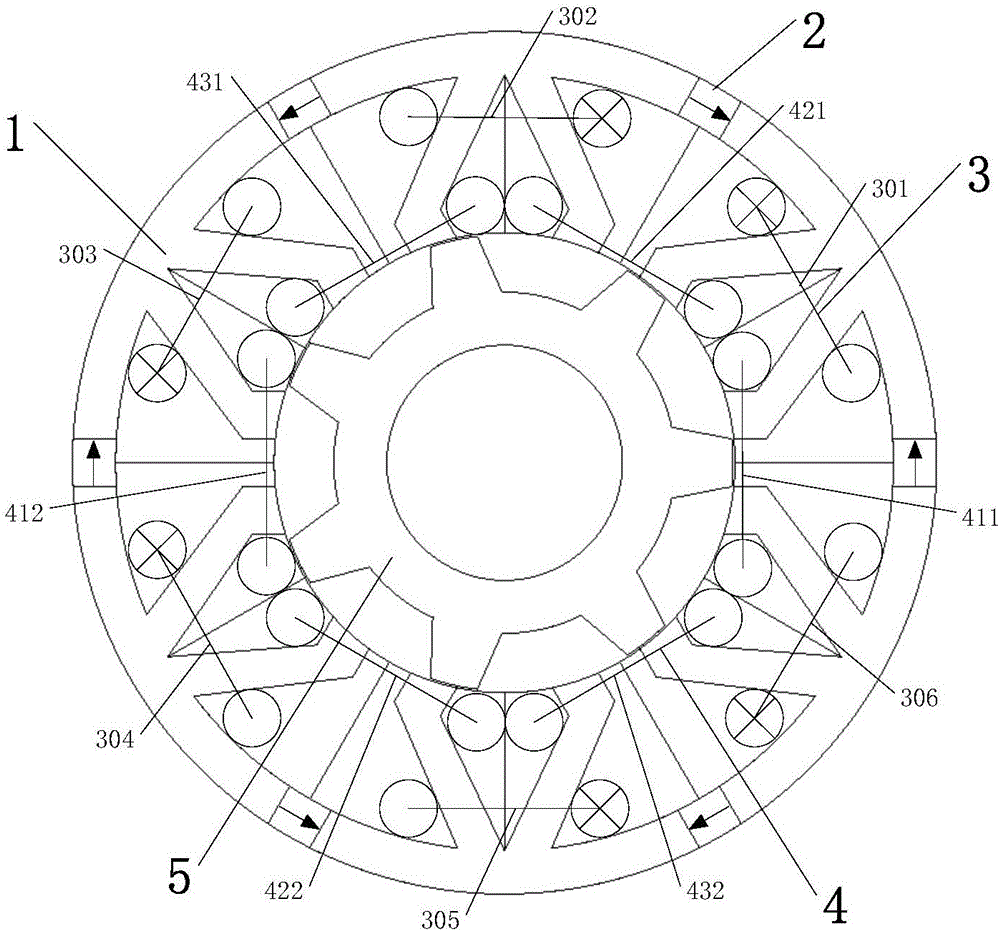

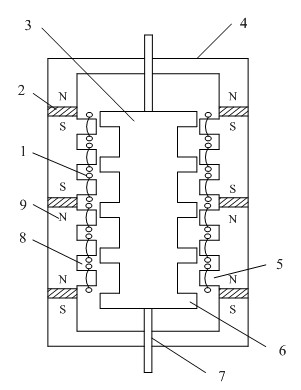

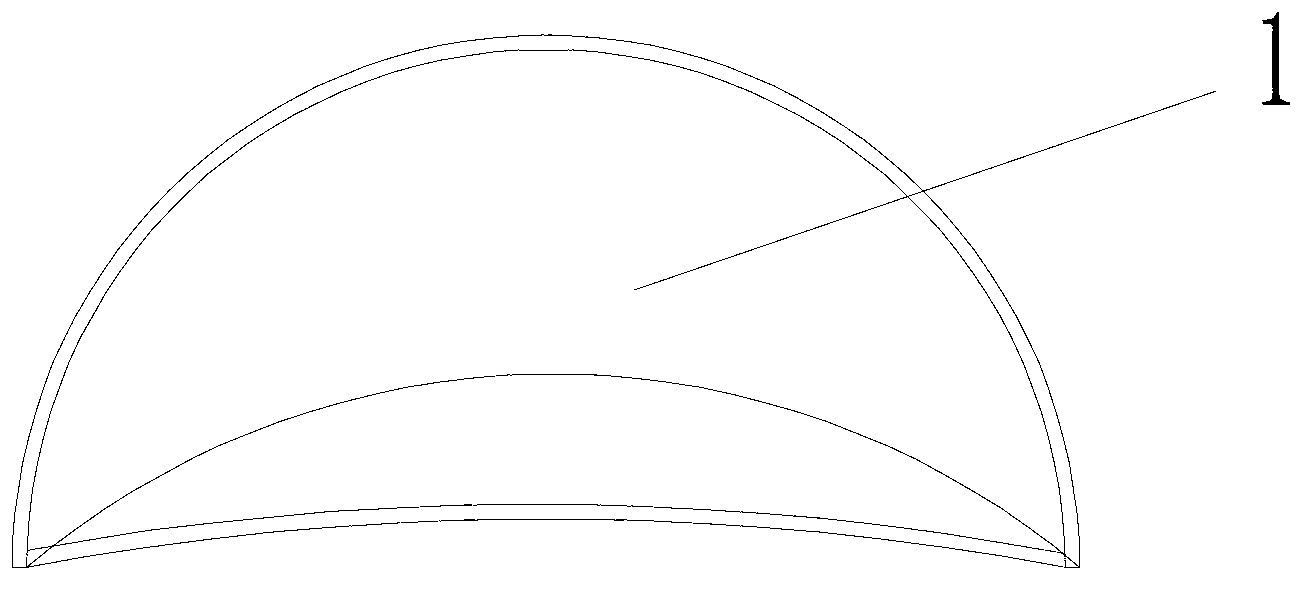

Built-in permanent magnet memory motor of magnetic flux switching type

InactiveCN103199661ASimple structureReduce wind resistanceMagnetic circuit rotating partsSynchronous machine detailsMechanical reliabilityElectric machine

The invention discloses a built-in permanent magnet memory motor of a magnetic flux switching type. The permanent magnet memory motor comprises a casing, a stator, a rotor and a rotating shaft, wherein the stator is a cylinder with a through hole and is formed by a star-shaped magnetic isolation block with a center through hole and partitioned rotor iron core discs; the rotating shaft is fixedly connected in the center through hole of the magnetic isolation block; and the partitioned rotor iron core discs are shaped like a fan and are uniformly distributed at the circumference of the rotor as well as fixedly connected to the outer surface of the magnetic isolation block. The stator comprises a stator iron core, permanent magnets, three-phase armature windings and pulse windings, wherein the stator iron core comprises a stator yoke and stator teeth formed by permanent teeth and armature teeth; the permanent magnets are shaped like a tile and radially magnetized, so that magnetic leakage factors are small; the magnetization directions of the two adjacent permanent magnets are opposite; the three-phase armature windings are wound on the armature teeth; and the pulse windings are wound on the permanent magnets. According to the permanent magnet memory motor, the weak magnetic ability and the rotation speed running range of the motor can be improved; and the no-load air gap magnetic field can be adjusted. In addition, the permanent magnet memory motor disclosed by the invention is strong in mechanical reliability, thereby being suitable for high-speed running.

Owner:SOUTHEAST UNIV

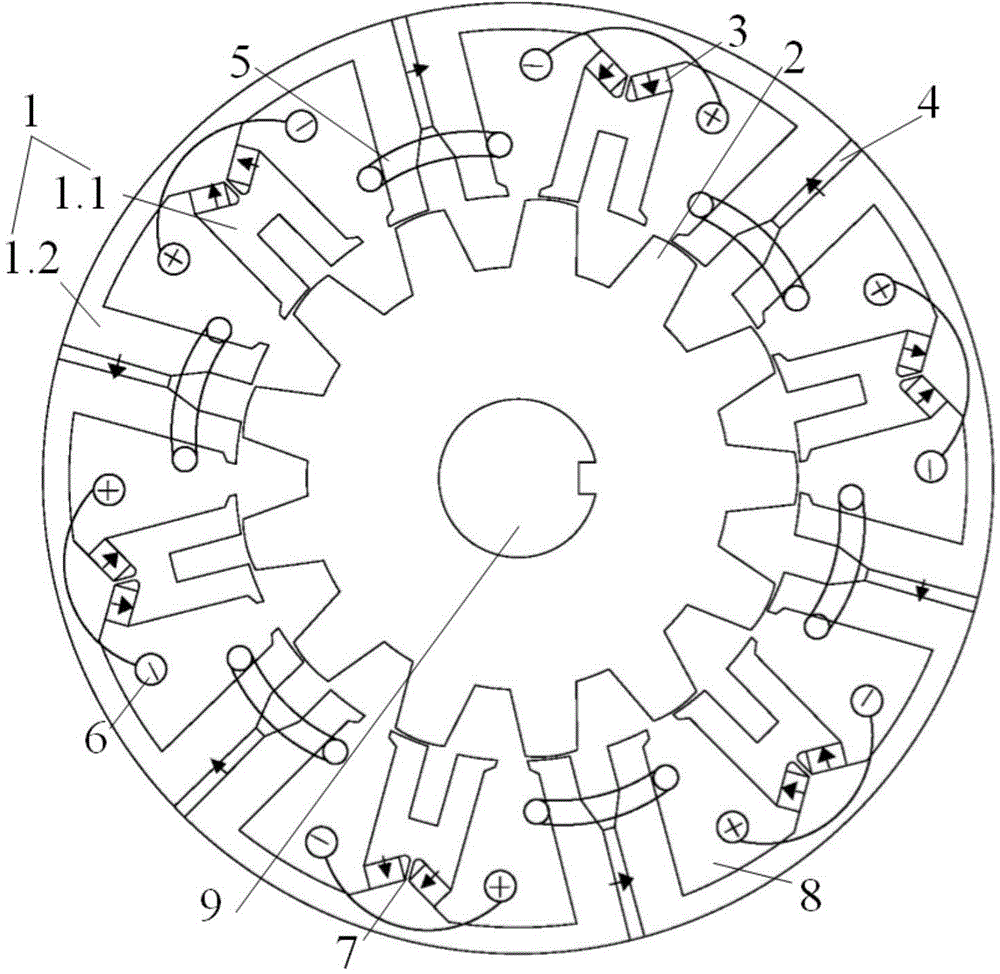

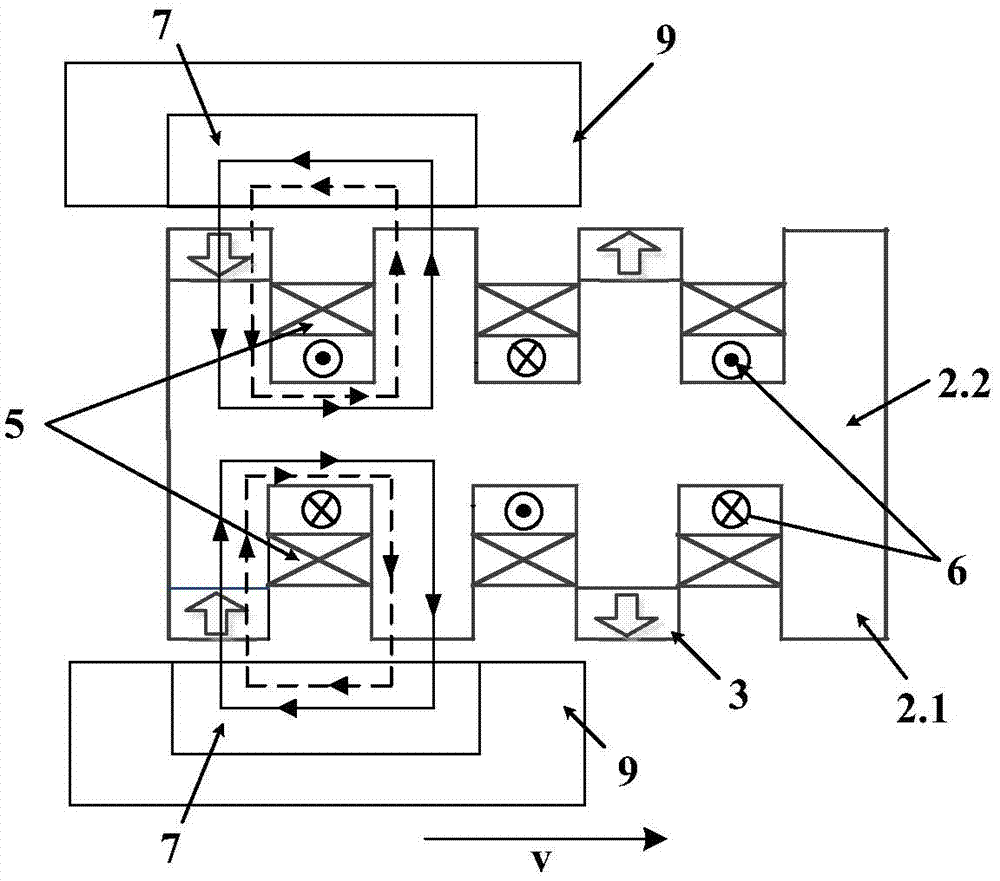

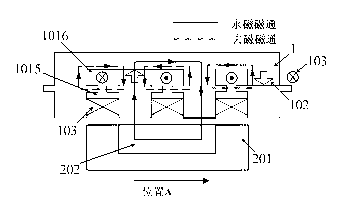

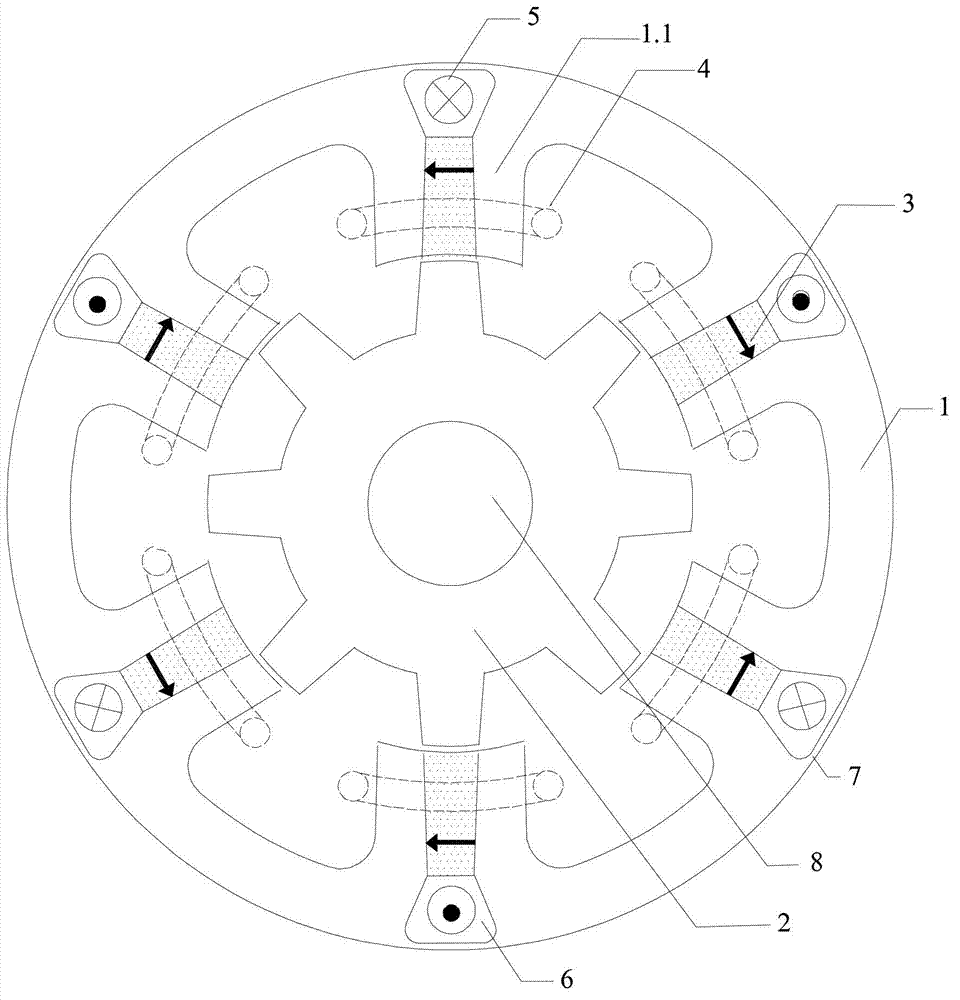

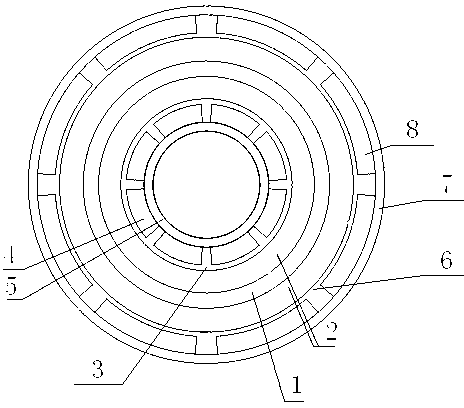

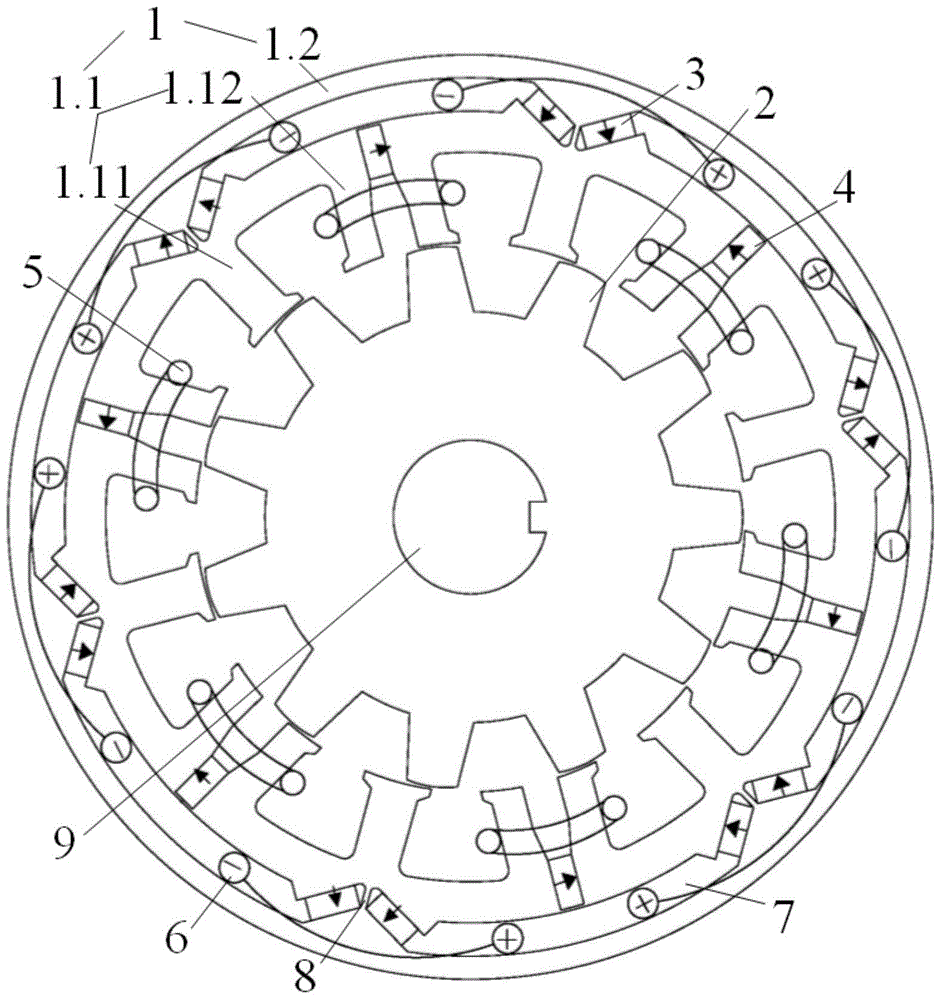

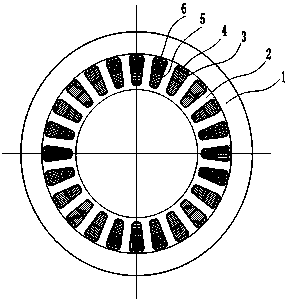

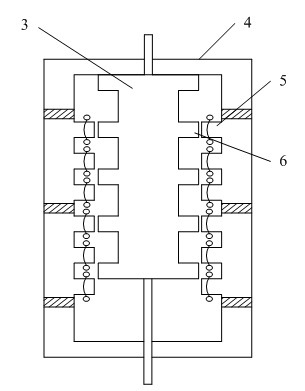

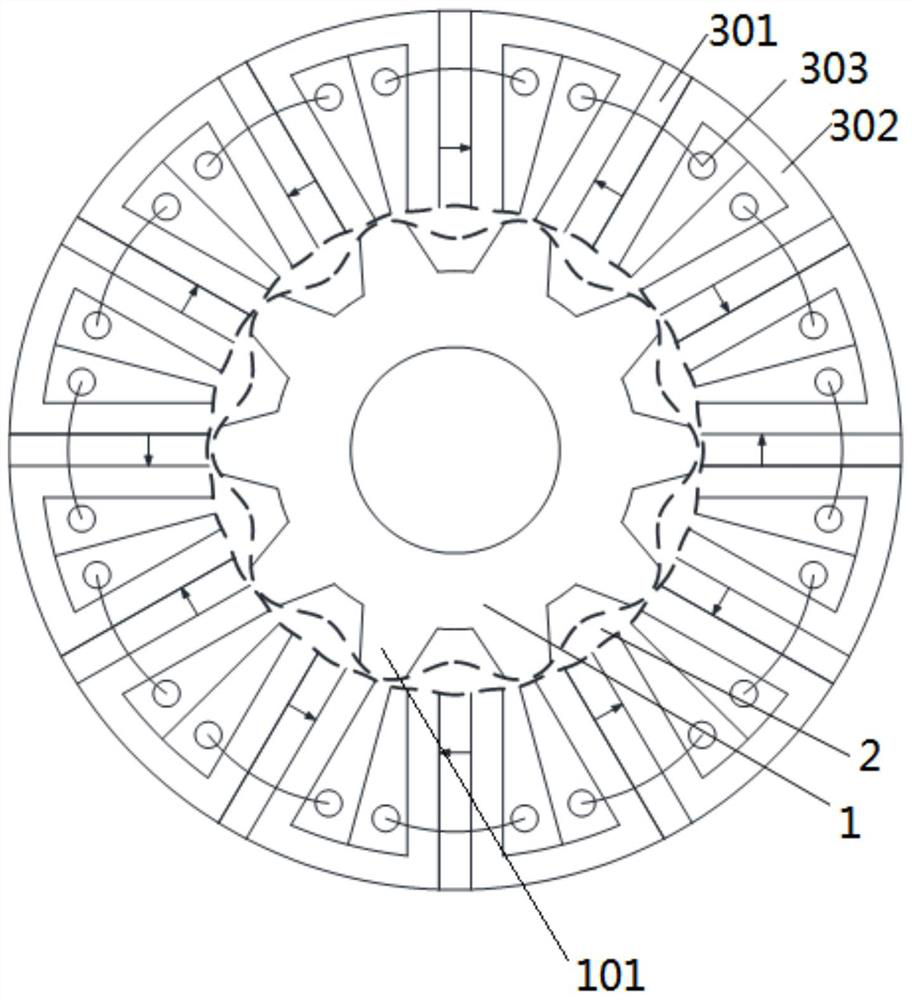

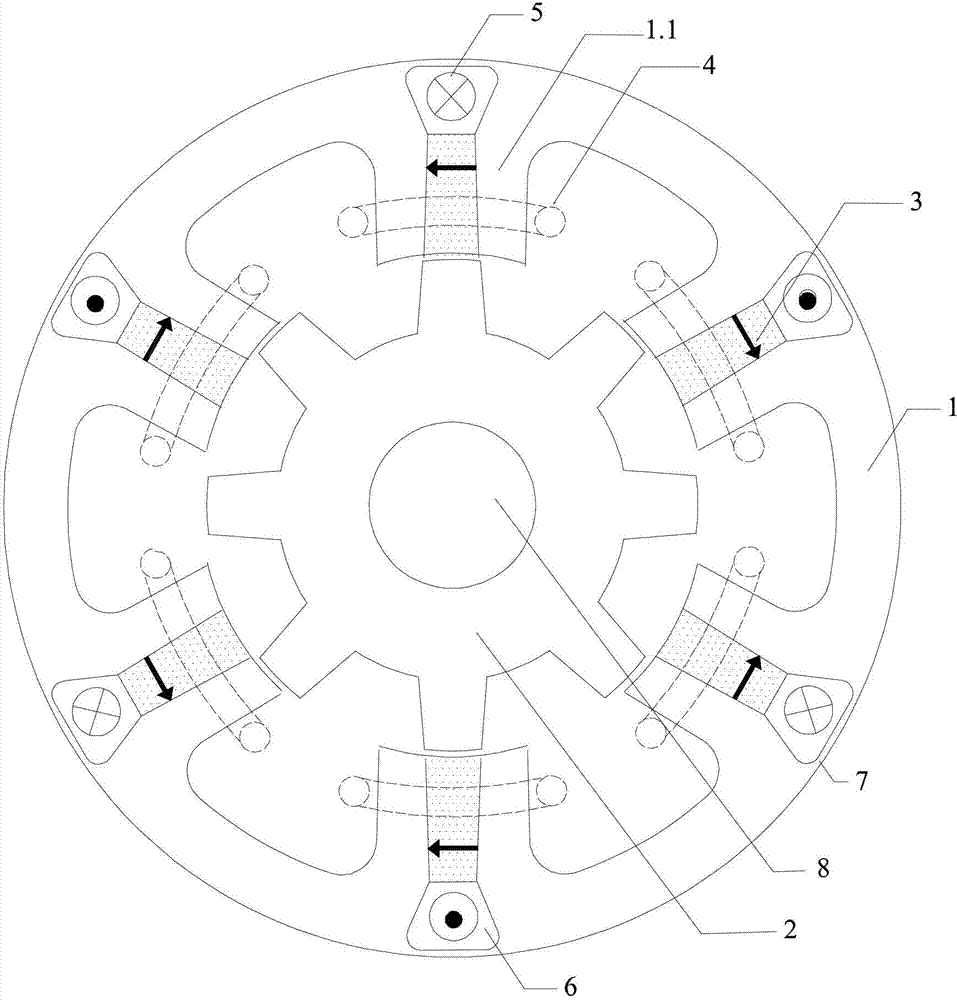

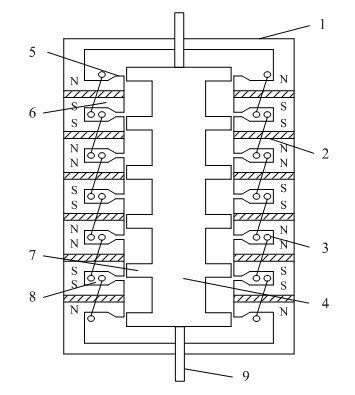

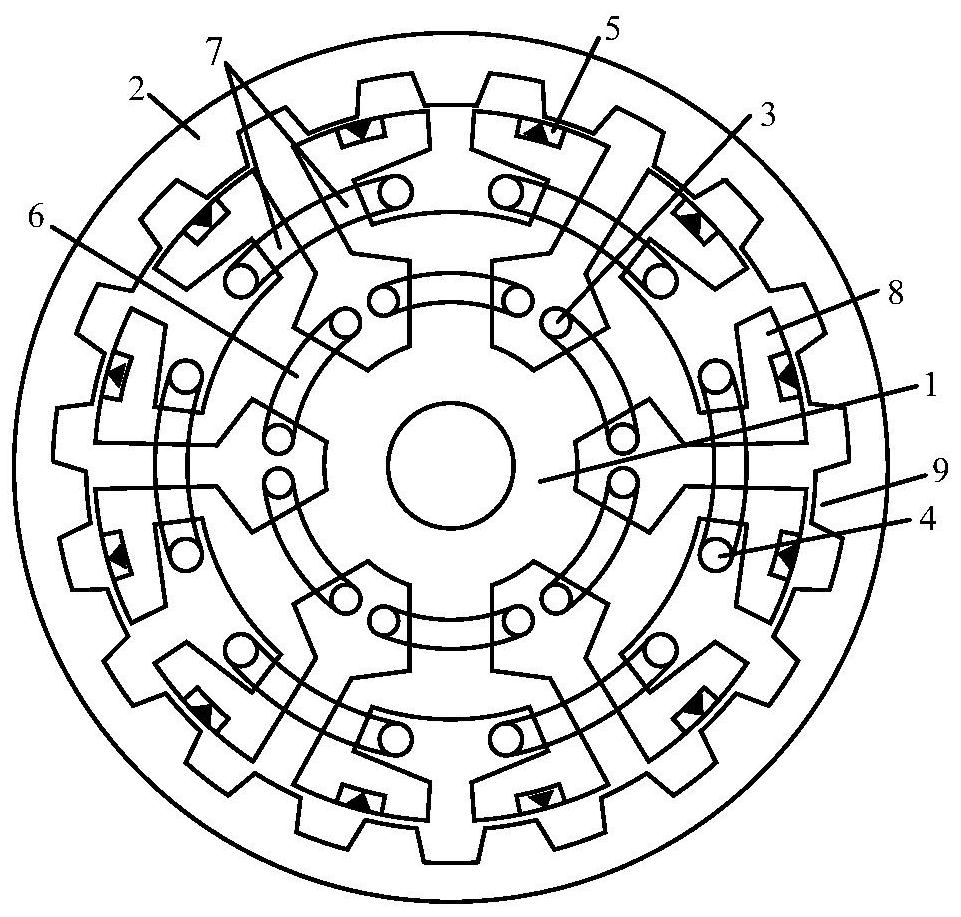

Magnetic flux switching type permanent magnet memory motor

ActiveCN103051139ASimple structureStable structureSynchronous machinesMagnetic circuit stationary partsElectric machineMemory motor

The invention discloses a magnetic flux switching type permanent magnet memory motor comprising an enclosure, a stator contained in the enclosure, a rotor (2) and a non-magnetic rotary shaft (8). The magnetic flux switching type permanent magnet memory motor is characterized in that the stator (1) is arranged at the outer part of the rotor (2); the rotor (2) is fixedly arranged on the non-magnetic rotary shaft (8) and is in a convex pole type; the rotor (2) comprises a rotor main body part and rotor teeth which protrude from the main body part to a direction which is far away from the center of the rotor; the stator comprises a stator iron core (1), a permanent magnet (3), a three-phase armature winding (4) and a pulse winding (5); the stator iron core (1) comprises a plurality of stator yokes and stator teeth (1.1) which protrude from the stator yokes to the direction of the center of the stator iron core; and the three-phase armature winding (4) is wound on the stator teeth (1.1). According to the magnetic flux switching type permanent magnet memory motor disclosed by the invention, a motor no-load gap magnetic field is adjustable, and the weak magnetism capability and the rotary speed operation speed of the motor are improved; and meanwhile, the torque and the power density of the motor are improved and the copper consumption of the motor is reduced.

Owner:SOUTHEAST UNIV

Birotor permanent magnet motor applied to wind power generation

InactiveCN103269140AIncrease the number of winding coilsImprove power densityDynamo-electric machinesWind drivenThermodynamics

The invention discloses a birotor permanent magnet motor applied to wind power generation. Rotors of the birotor permanent magnet motor comprise an inner rotor and an outer rotor. A stator comprises a stator core and a stator winding, wherein the inner rotor and the outer rotor share the stator, and the stator winding is wound on the stator core. The inner rotor is arranged inside the stator, an inner air gap is formed between the inner rotor and the stator, and the inner rotor comprises an inner rotor permanent magnet and an inner rotor core. The outer rotor is arranged outside the stator, an outer air gap is formed between the outer rotor and the stator, and the outer rotor comprises an outer rotor core and an outer rotor permanent magnet of which the surface is attached to the inner surface of the outer rotor core. The inner rotor and the outer rotor are fixedly connected and rotate synchronously. The magnetizing direction of the inner rotor permanent magnet and the magnetizing direction of the outer rotor permanent magnet are opposite. An inner magnetic circuit and an outer magnetic circuit are parallel and are closed through the stator core shared by the inner magnetic circuit and the outer magnetic circuit. The back-to-back annular winding can effectively reduce copper loss of the motor, enlarge an effective air gap area of the motor, and strengthen power generation capacity of a wind driven generator at a low wind speed.

Owner:JIANGSU UNIV

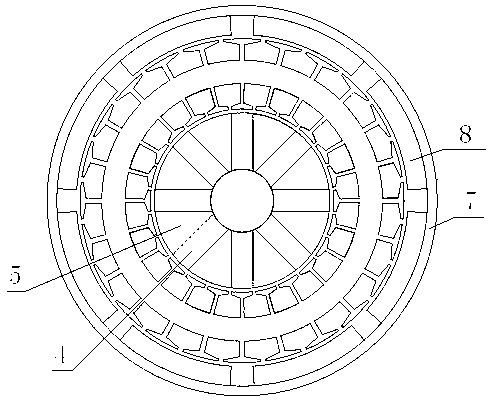

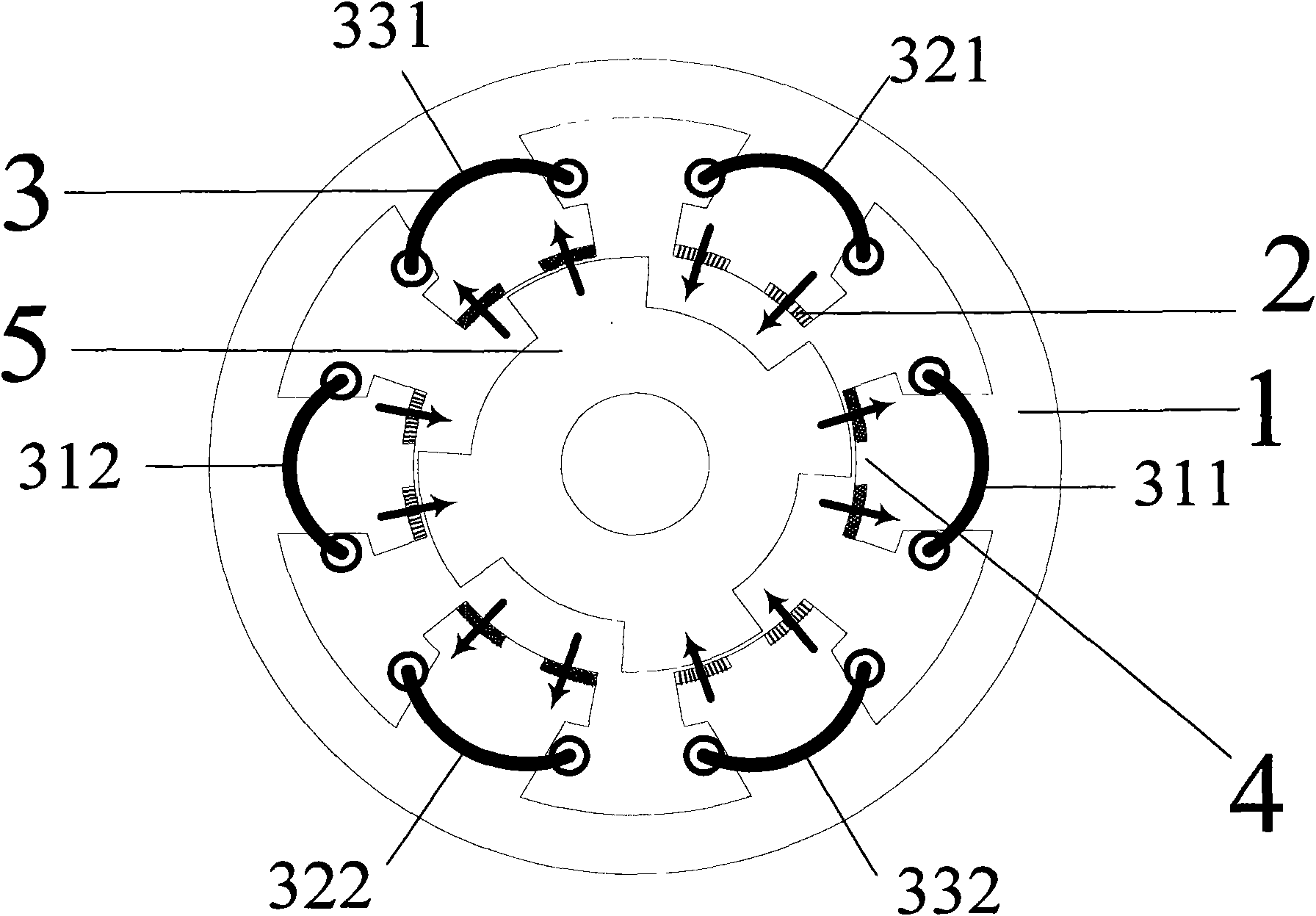

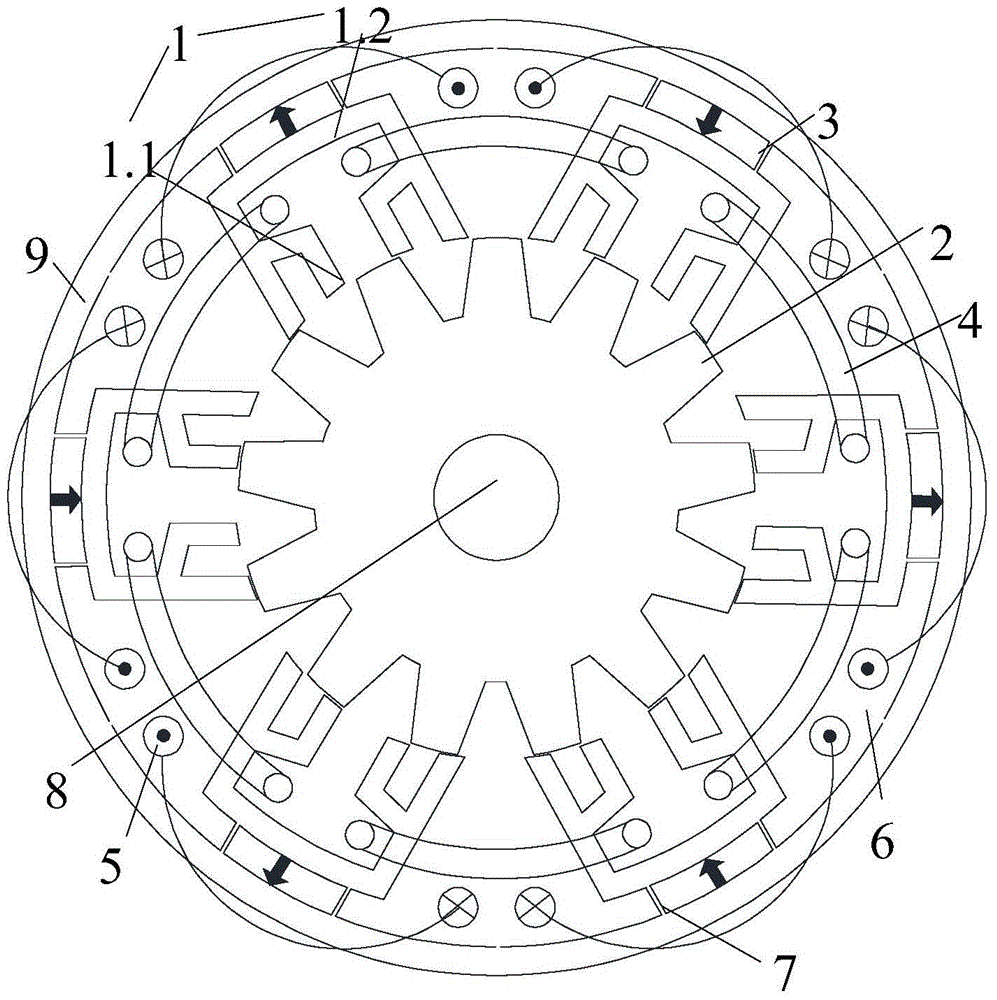

Magnetic gear type double-stator hybrid permanent magnet memory motor

InactiveCN105141092ASimple structureImprove space utilizationMagnetic circuit rotating partsMagnetic circuit stationary partsEpoxyElectric machine

The invention discloses a magnetic gear type double-stator hybrid permanent magnet memory motor. The motor comprises an external stator, a rotor and an internal stator which are coaxially arranged and sleeved from outside to inside in turn. The external stator comprises armature iron core teeth, stator yokes and armature windings which are arranged on the armature iron core teeth. The internal stator comprises an internal stator iron core provided with internal slots, neodymium iron boron permanent magnets, aluminum nickel cobalt permanent magnets and pulse magnetic regulating windings which are arranged in the internal slots of the internal stator. The two types of co-excitation permanent magnets are arranged in a "U" shape. The number of single permanent magnets on the internal stator is equal to that of external stator armature teeth. The whole rotor has an annular cup-shaped structure. Rotor iron blocks are fixed in a non-magnetic-conductive epoxy resin sleeve. The rotor iron blocks are connected via magnetic conductive bridges. Disadvantages that a conventional single stator has multiple internal excitation sources which are mutually hindered in space and torque density is relatively low can be solved. Besides, high power density is realized by arrangement of double-stator hybrid permanent magnets, and residual magnetization intensity and magnetization direction of the permanent magnets are regulated by applying pulse current so that motor magnetic field high-efficiency regulation is realized, and rotating speed operation range is enhanced.

Owner:SOUTHEAST UNIV

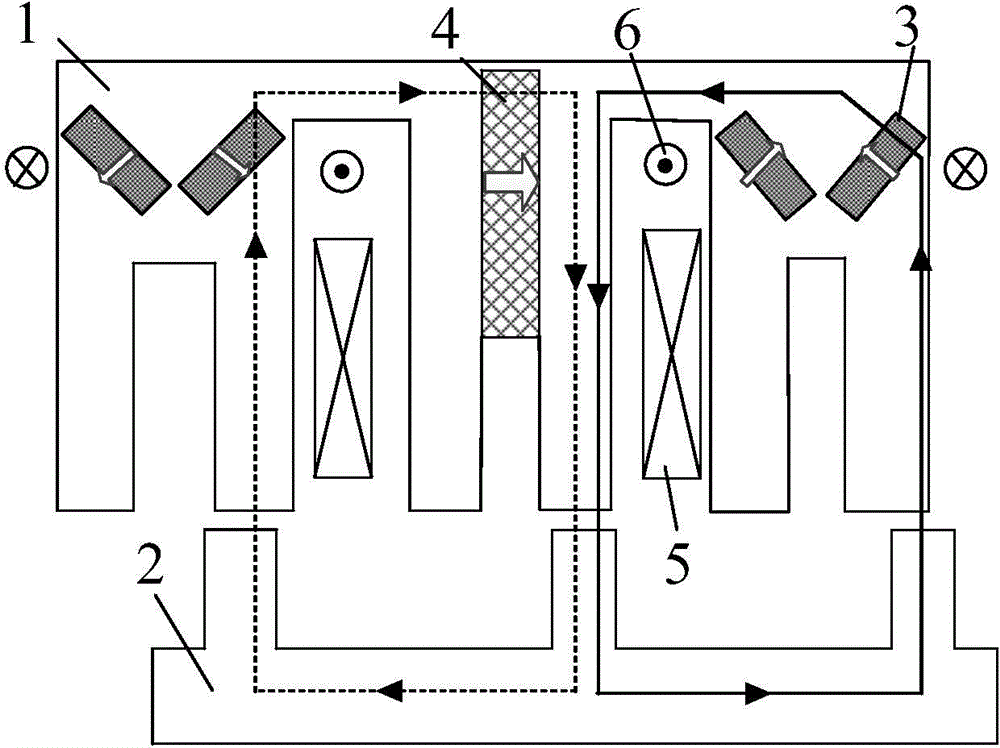

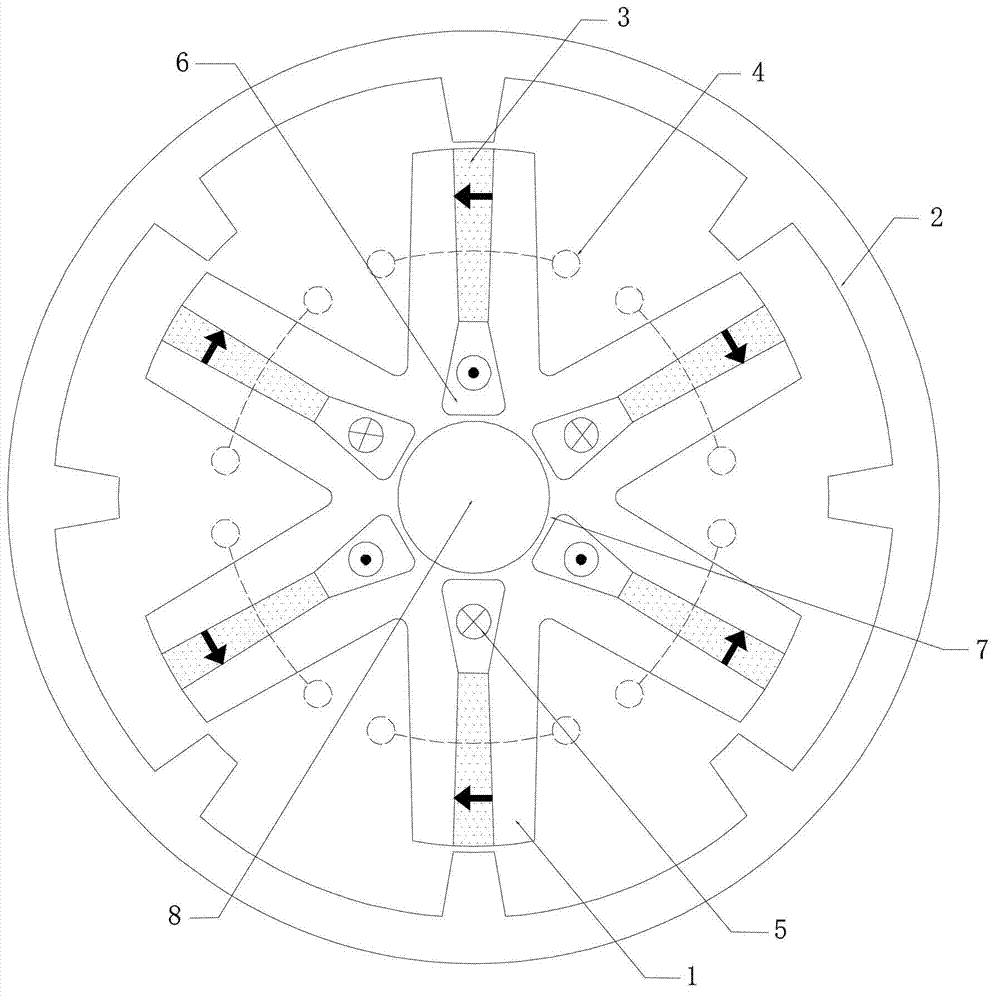

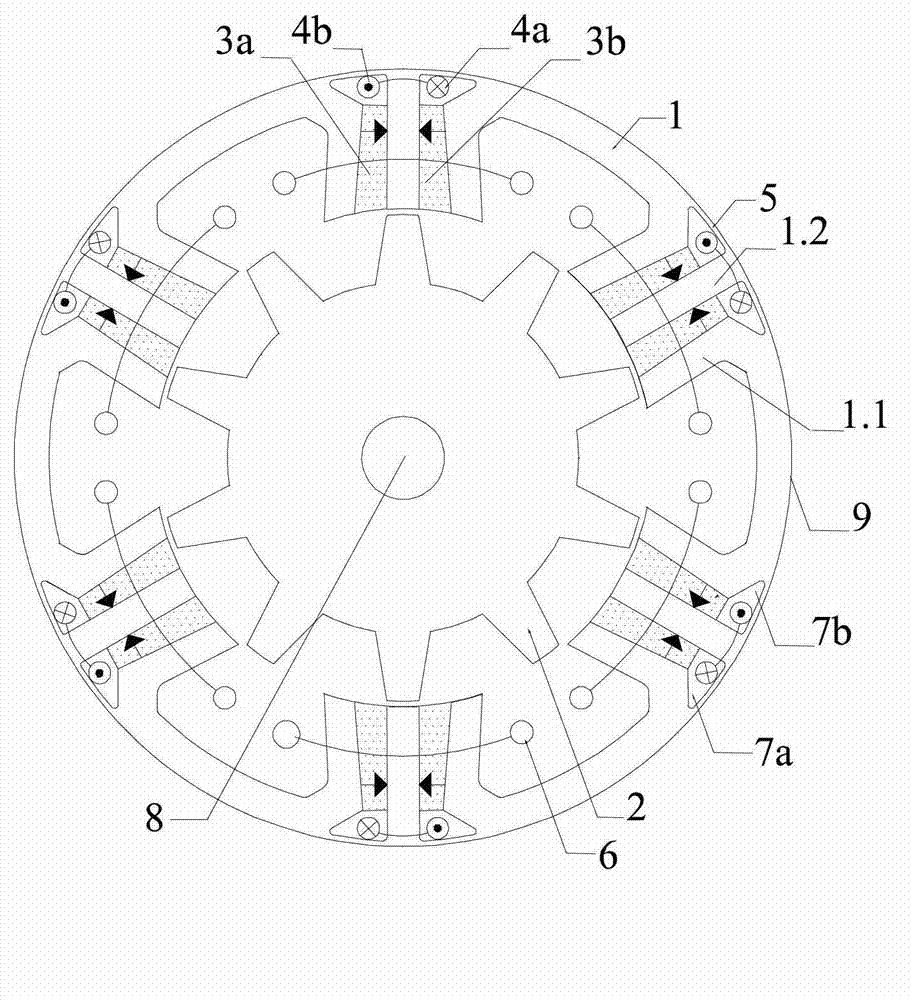

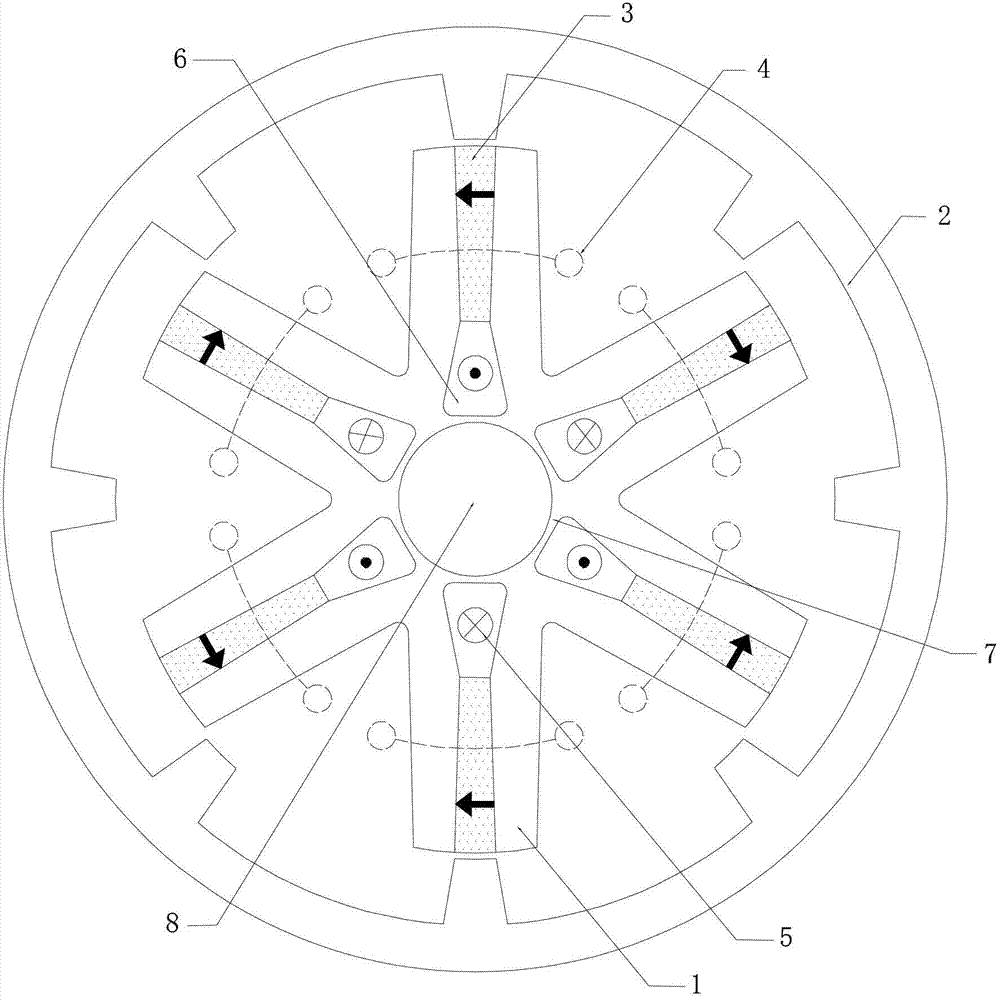

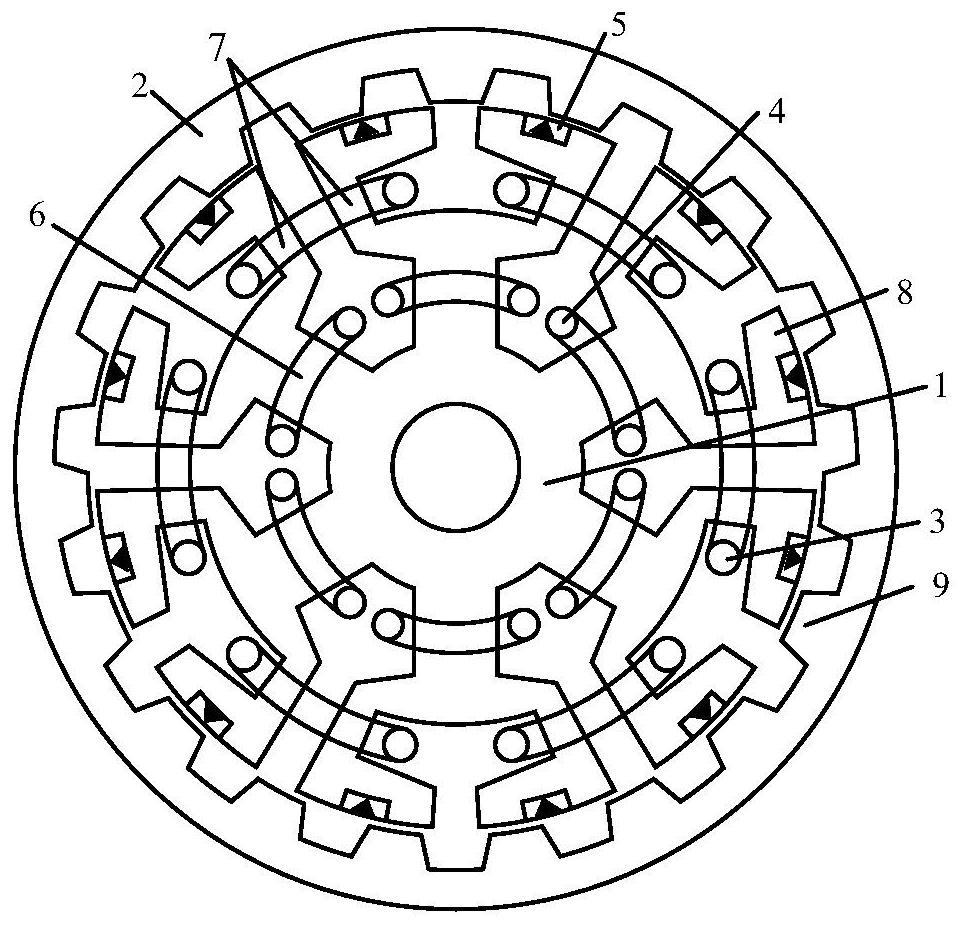

Magnetism-gathering-type magnetic flux switching permanent magnet memory motor

InactiveCN103078466ASimple structureStable structureMagnetic circuit stationary partsWindings conductor shape/form/constructionCopper lossPulse current

The invention discloses a magnetism-gathering-type magnetic flux switching permanent magnet memory motor, which comprises a stator, a rotor (2) and an un-conducted magnetic shaft (8), wherein the stator (1) is arranged outside the rotor (2); the rotor (2) is fixed on the un-conducted magnetic shaft (8) and is in a salient pole type; the stator comprises a stator core (1), a first permanent magnet (3a), a second permanent magnet (3b), a three-phase armature winding (6), a first pulsed winding (4a) and a second pulse winding (4b); the stator core (1) comprises a plurality of stator yokes and stator teeth protruding to the center direction of the stator core from the stator yokes; and a stator slot is formed between the adjacent stator teeth. With the adoption of the magnetism-gathering-type magnetic flux switching permanent magnet memory motor, the residual magnetization of the permanent magnet is adjusted through applying pulse current to a pulse winding; a motor no-load air-gap field can be adjusted; the weak magnetic ability of the motor and the rotating speed operation range are improved; and meanwhile, the torque and power density of the motor can be effectively improved through magnetism-gathering-type armature teeth, and the copper loss of the motor is reduced.

Owner:SOUTHEAST UNIV

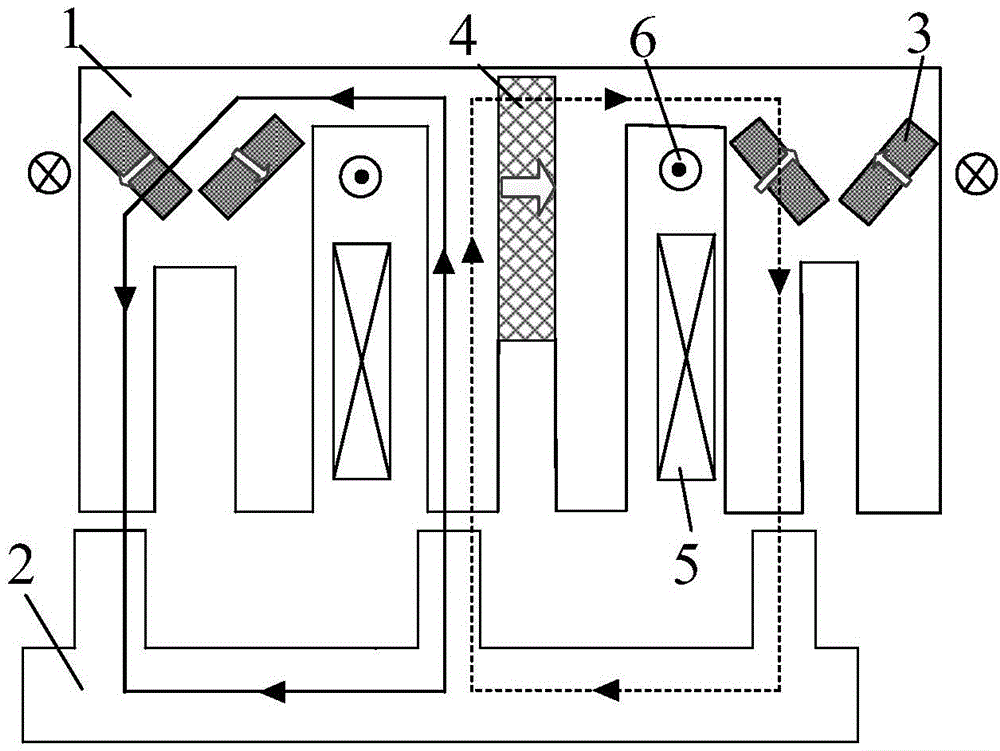

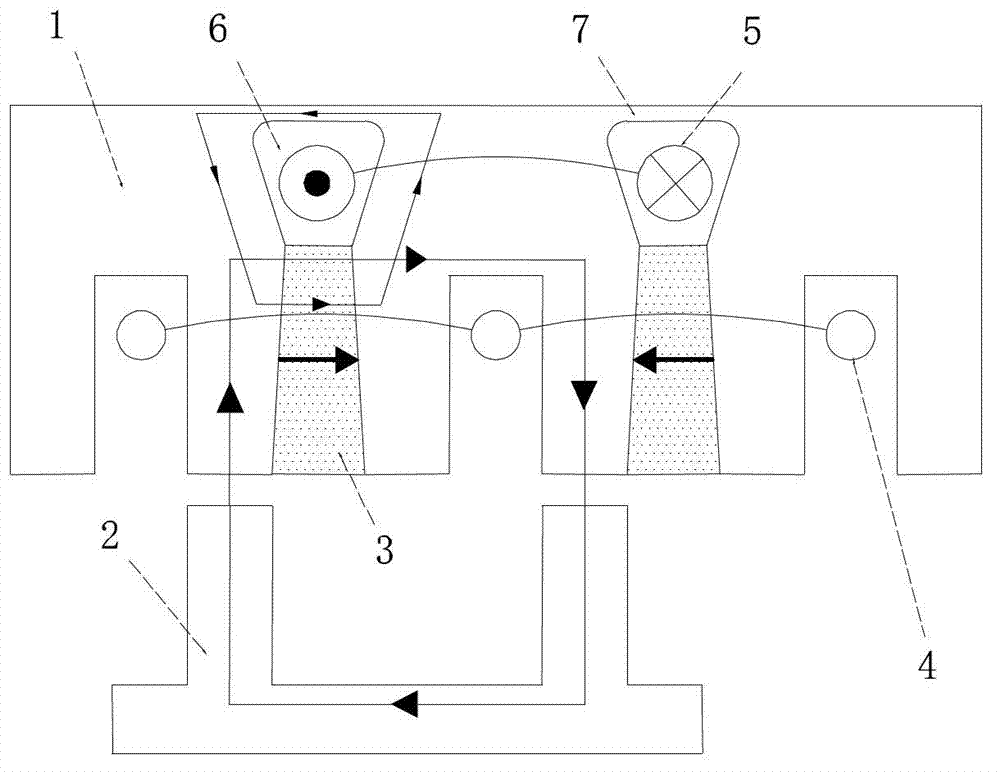

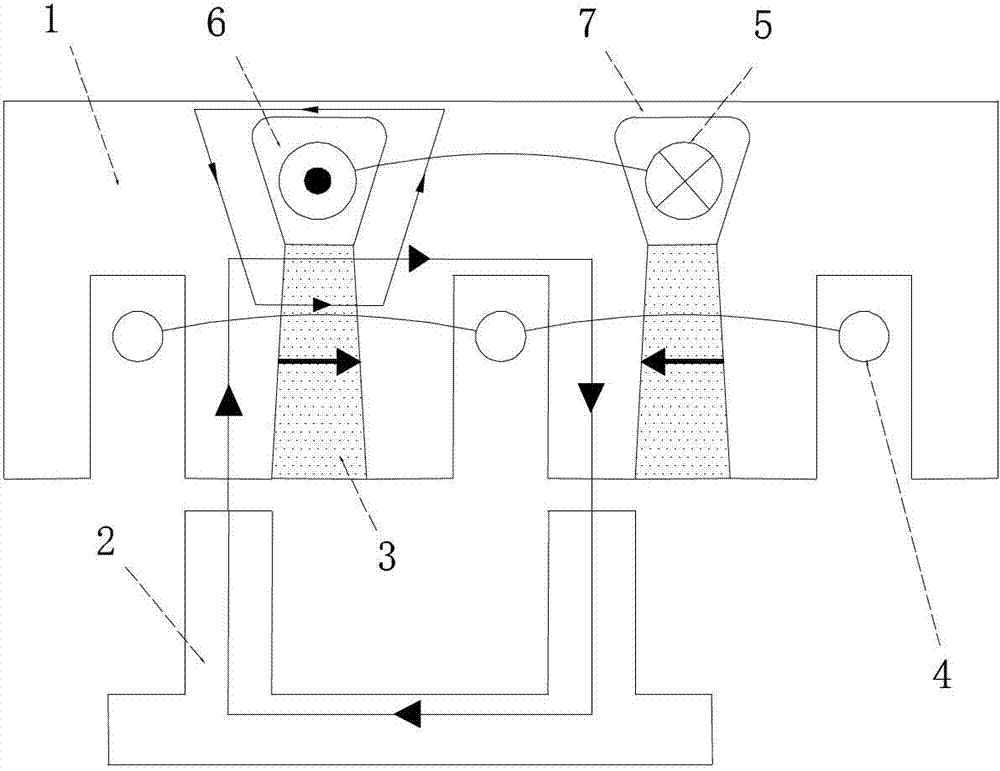

E-shaped stator core flux switching type hybrid permanent magnet memory motor

InactiveCN104410180ASimple structureStable structureMagnetic circuit stationary partsElectric machineMemory motor

The invention discloses an E-shaped stator core flux switching type hybrid permanent magnet memory motor and belongs to the field of flux-adjustable permanent magnet motors. Both rotor and stator cores of the motor adopt a salient pole structure. A stator of the motor comprises six E-shaped stator cores, V-shaped aluminum-nickel-cobalt permanent magnets, tangential-magnetizing rectangular neodymium iron boron permanent magnets and a whole layer of stator yokes, wherein adjacent neodymium iron boron permanent magnets with opposite polarities are inlaid between the two adjacent E-shaped stator cores, and a three-phase concentrated winding armature winding is wound across a sandwich-shaped unit composed of the core edges of adjacent E-shaped stator units and the neodymium iron boron permanent magnets; a groove between two adjacent V-shaped aluminum-nickel-cobalt permanent magnets is used for placing a concentrated single-phase pulse winding. The E-shaped stator core flux switching type hybrid permanent magnet memory motor greatly alleviates a space conflict between electromagnetic loading in the stator cores and pulse magnet-adjustment capacity, can realize flexible online magnet adjustment and has little loss of excitation, the torque density and the force and energy expression of the motor can be improved, and the fault-tolerant fault operation ability is good.

Owner:SOUTHEAST UNIV

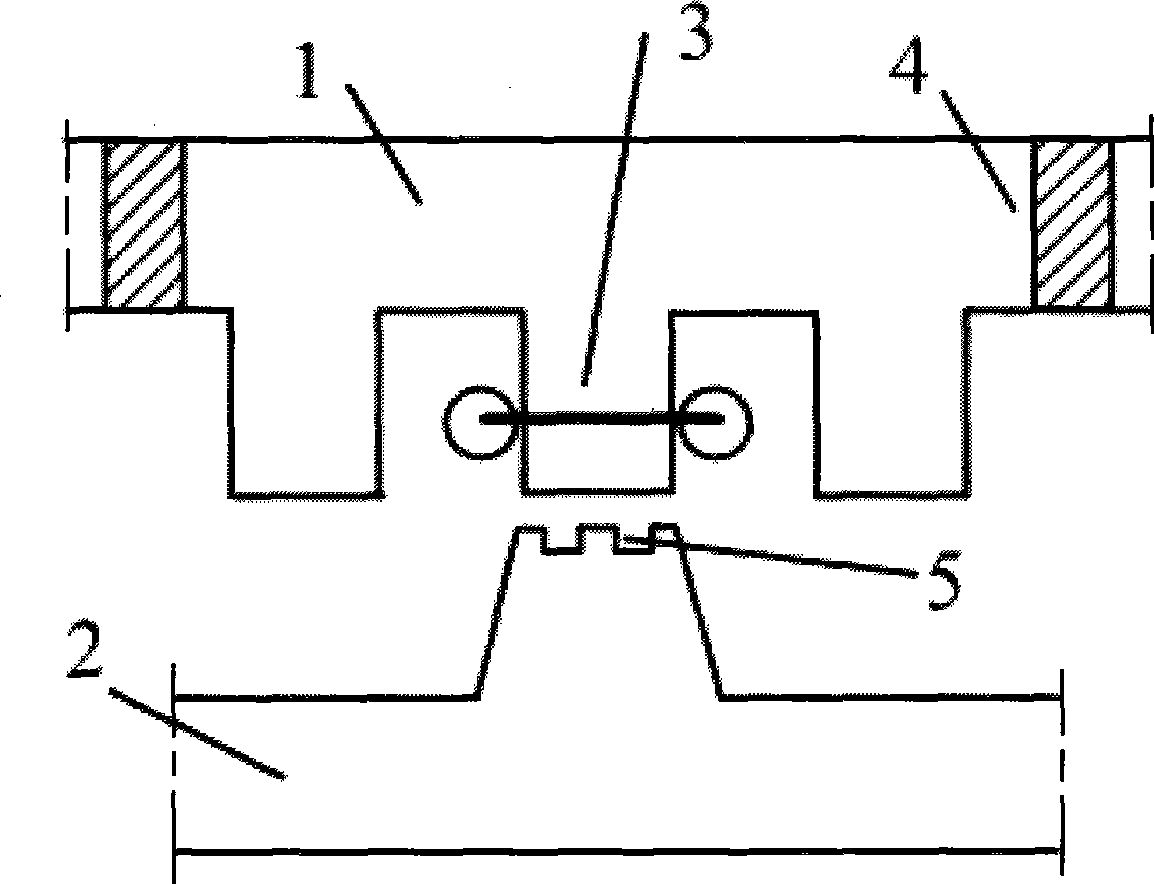

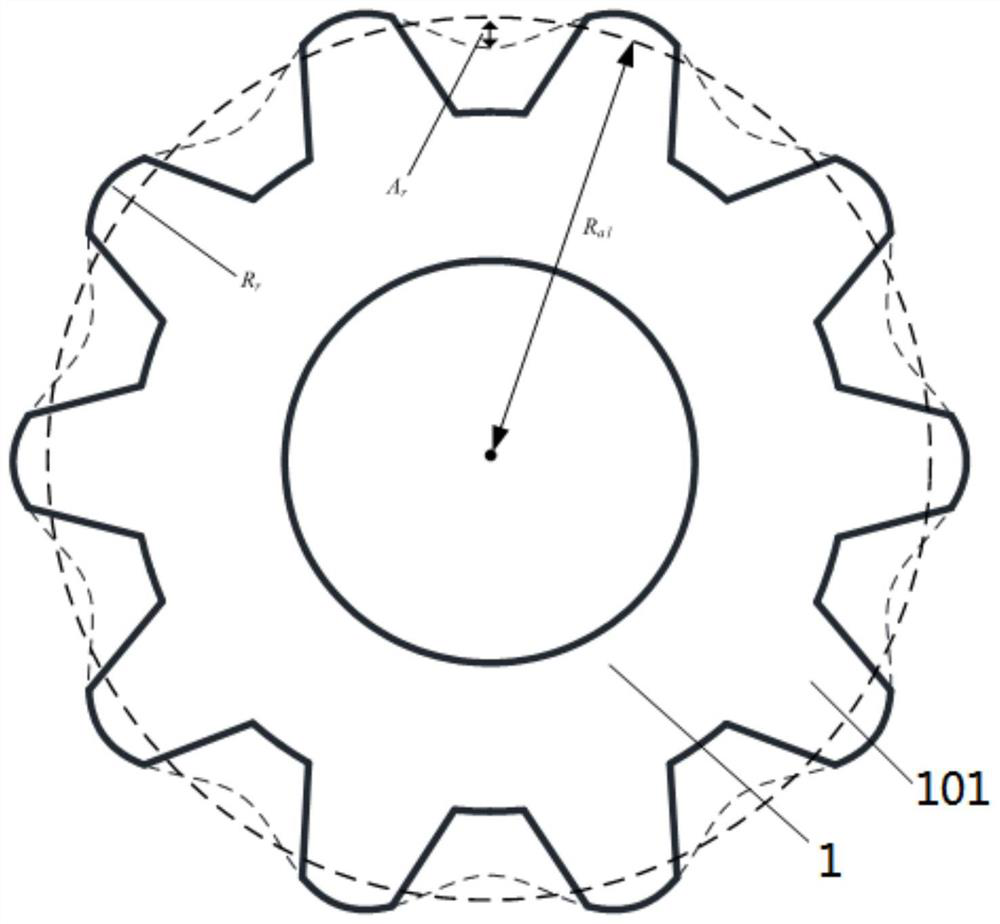

Stator surface mounted doubly salient permanent magnet motor with auxiliary salient pole

ActiveCN101651371AImprove cooling conditionsSimple and strong structureMagnetic circuit rotating partsMagnetic circuit stationary partsConstant powerSurface mounting

The invention relates to a stator surface-mounted doubly salient permanent magnet motor with an auxiliary salient pole which has simple and firm structure, and constant power, wide speed-regulation operation range and higher power density; the motor comprises a stator (1) and a rotor (5), the rotor (5) is arranged at the inner part or outer part of the stator (1), the stator (1) and the rotor (5)are in a doubly salient structure, and a concentrated winding (3), a permanent magnet (2) and an auxiliary salient pole (4) are arranged on the stator (1), wherein, each concentrated winding coil of any one phase of the concentrated winding (3) is arranged in an iron core groove of the stator (1), and the coils of each a phase winding are connected serially or in parallel; the permanent magnet (2)is arranged on the salient pole of the stator (1), the outer surface of each stator tooth, facing to air gap, is mounted with two permanent magnets (2), and the polarity of two magnetic steels, belowthe same tooth, is the same, and the magnetism of the magnetic steel, below the adjacent stator tooth, is opposite.

Owner:SOUTHEAST UNIV

Combined permanent magnet brushless motor stator and manufacturing method thereof

PendingCN110011436AReduce NVHIncrease profitMagnetic circuit stationary partsManufacturing stator/rotor bodiesBrushless motorsCircular surface

The invention provides a combined permanent magnet brushless motor stator and a manufacturing method thereof. A stator core is formed by a tooth part iron core formed by winding and a yoke part iron core, the tooth part iron core is located inside, the yoke part iron core is located outside, an inner circular surface of the tooth part iron core has no notch, a winding is placed into a groove froman outer circular surface or is wounded tooth by tooth, a tooth part winding is sleeved in the yoke part iron core to form a stator assembly after being manufactured, the invention is suitable for a fractional slot winding is also suitable for a distributed winding, the iron core has no slot and almost has no cogging torque, the motor running performance is good, the material utilization rate is high, the design is optimized and flexible, the motor efficiency and specific power are easy to improve, and the automatic production is easy to achieve.

Owner:杨世国

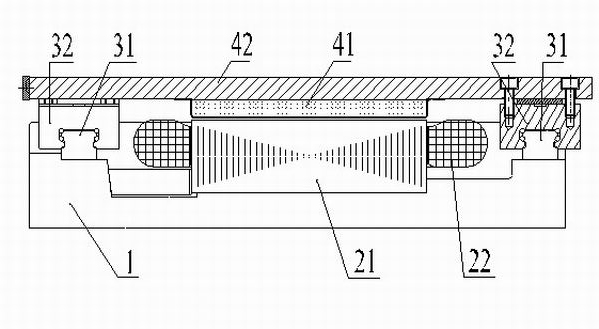

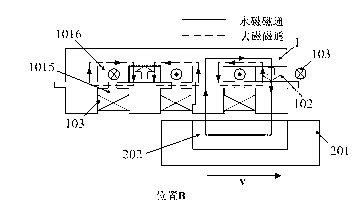

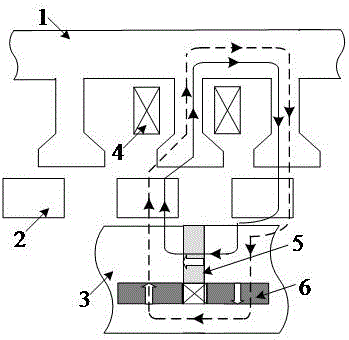

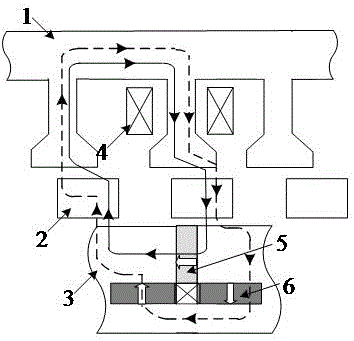

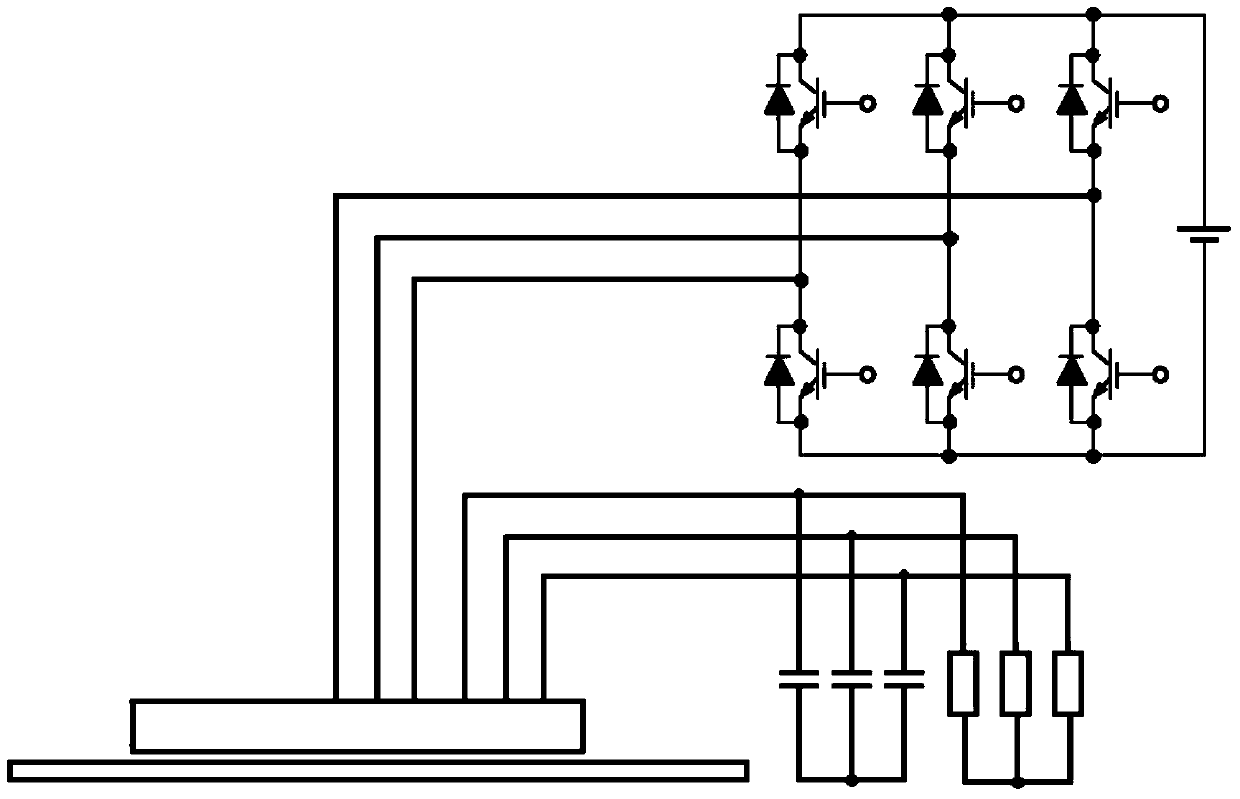

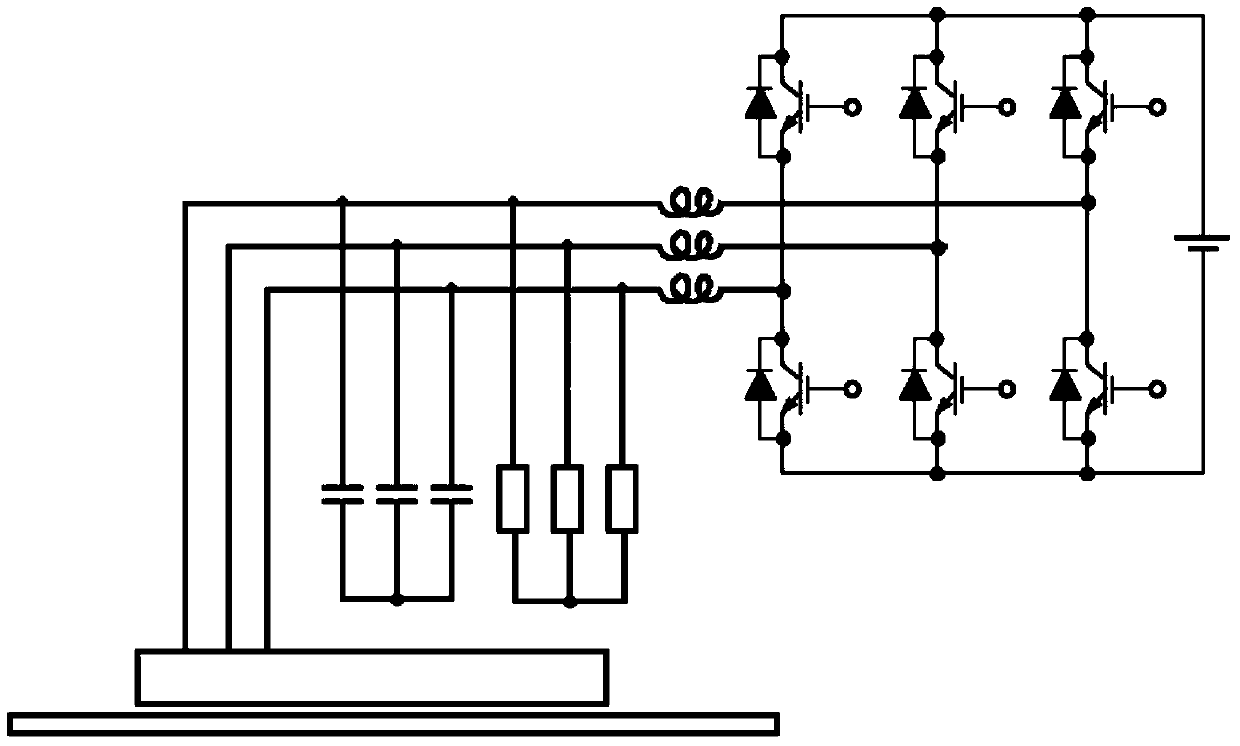

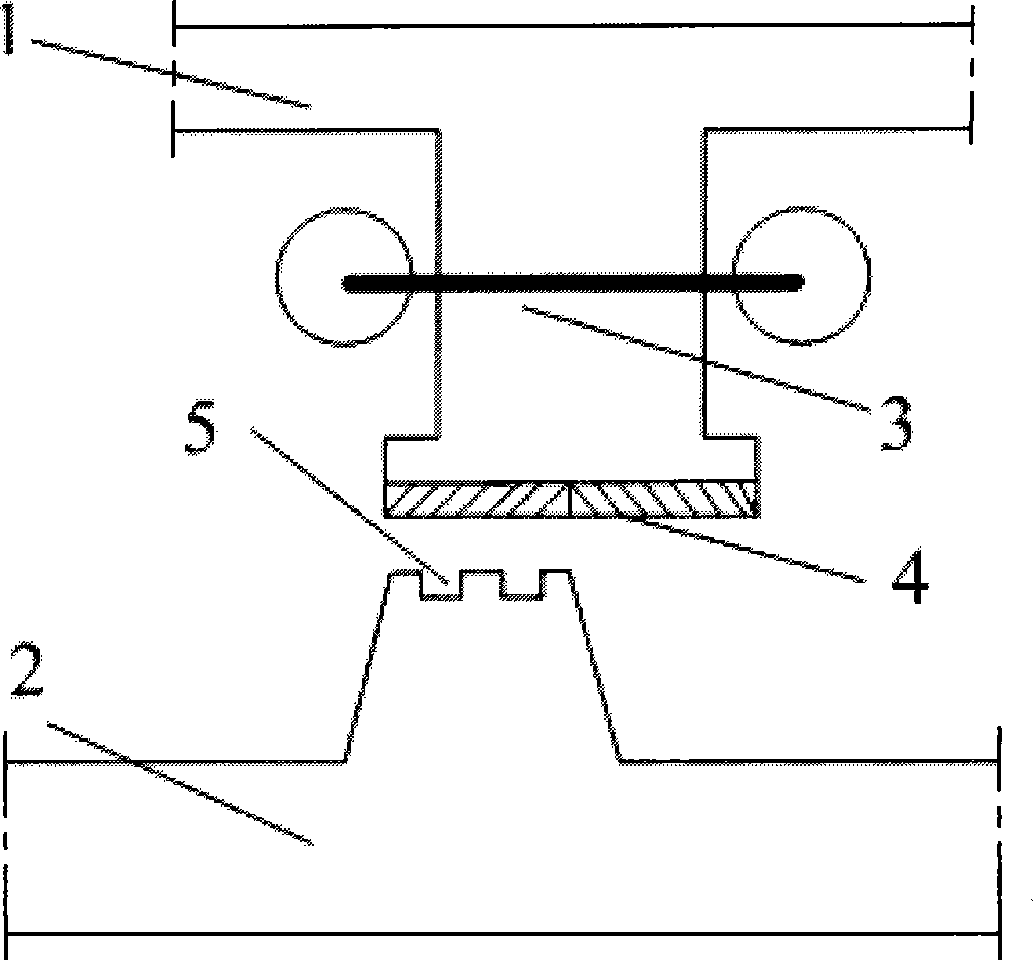

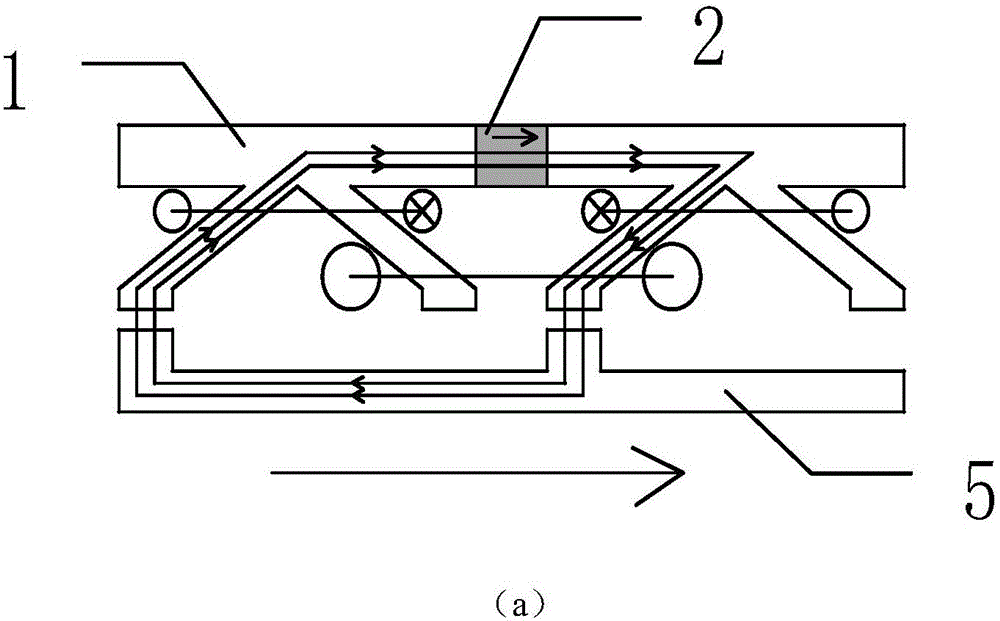

Electromagnetic brake linear motor system and control method thereof

ActiveCN103762821AReduce end lengthReduce size and weightAssociation with control/drive circuitsAC motor controlElectromagnetic brakeEngineering

The invention relates to an electromagnetic brake linear motor system and a control method of the electromagnetic brake linear motor system, and belongs to the field of motors. A primary iron core of a linear motor in the system is in the shape of a flat plate, the output end of a primary winding is connected with a multi-phase energy absorbing resistor set in parallel, or two multi-phase winding sets are adopted for the primary winding, one multi-phase winding set is connected with the multi-phase energy absorbing resistor set in parallel, and the other multi-phase winding set is connected with an inverter. The control method includes the steps that when the relative speed between a motor and a stator of the linear motor is intermediate speed or high speed, frequency and phase of output current of the inverter are controlled so as to ensure that the linear motor works in a power generation braking mode; when the relative speed between the motor and the stator of the linear motor is low speed, frequency and phase of output current of the inverter are controlled so as to ensure that the linear motor works in a reverse braking mode. The electromagnetic brake linear motor system and the control method of the electromagnetic brake linear motor system are suitable for train braking systems in the rail transit field, motive power machine testing and brake systems of liner driving devices like lifting devices and recreation facilities.

Owner:HARBIN INST OF TECH

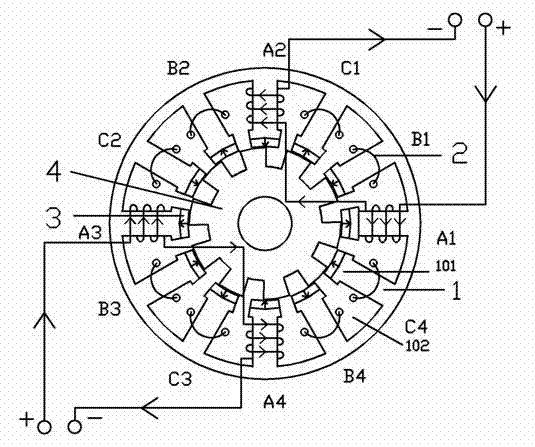

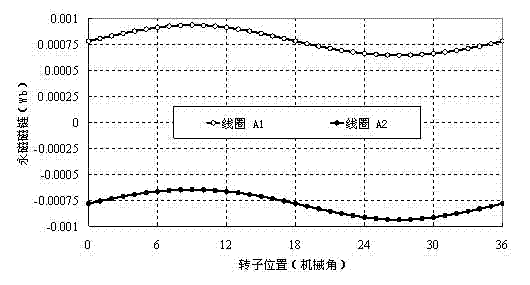

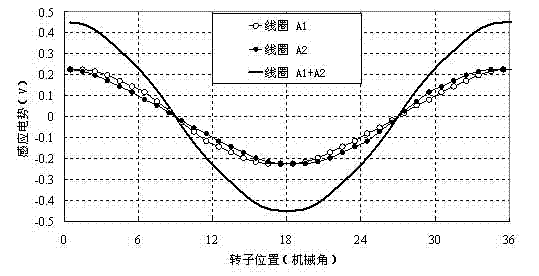

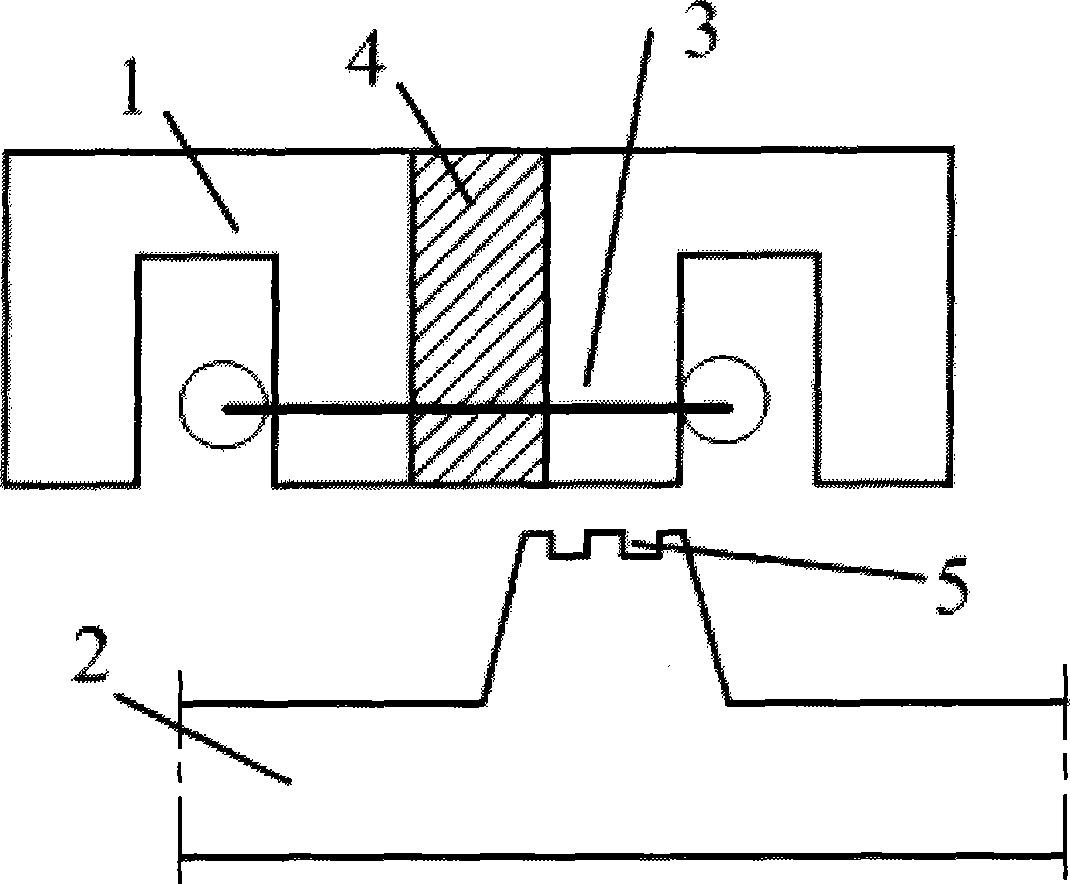

Stator surface-mounted doubly salient permanent-magnet motor with complementary winding magnetic paths

InactiveCN102403857AImprove cooling conditionsSimple and strong structureSynchronous machinesWindings conductor shape/form/constructionElectric machineDoubly salient

This invention designs a stator surface-mounted doubly salient permanent-magnet motor with complementary winding magnetic paths, which comprises a stator (2) and a rotor (4), wherein the rotor (4) is located on the interior or exterior of the stator (1); the stator (1) is a salient pole structure and is provided with stator teeth (101) protruded out of a yoke part; armature winding slots (102) are formed between the stator teeth; the stator teeth (101) and the armature winding slots (102) are distributed in an alternation manner; integrated armature windings (2) and permanent magnets (3) are arranged on the stator (1), wherein the permanent magnets (3) are arranged on the stator teeth (101) and are located on an air gap between the stator (2) and the rotor (4); the integrated armature windings (2) are arranged on the stator teeth (101) of the stator (1); and the motor disclosed by this invention is simple and firm in structure and has strong torque output capacity and large power density.

Owner:SOUTHEAST UNIV

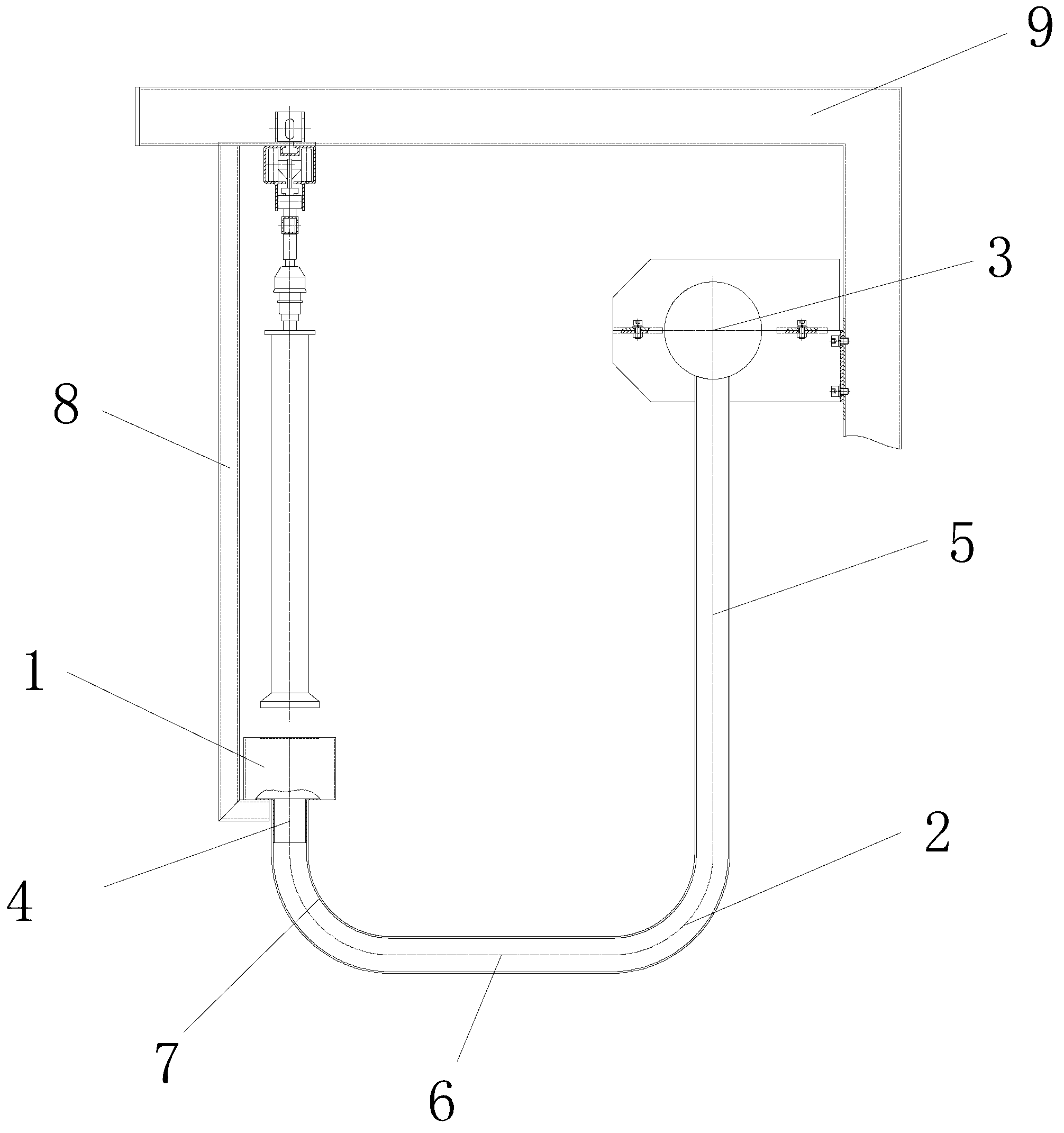

Integrated compensation pulse generating set

InactiveCN103501100AImprove coaxialityShorten the axial lengthMechanical energy handlingSynchronous motorPermanent magnet synchronous motor

The invention relates to an integrated compensation pulse generating set and belongs to the field of a motor and a pulse power. The invention aims to solve the problems of large volume and poor reliability of a current compensation pulse generating set. The integrated compensation pulse generating set comprises an enclosure, a compensation pulse generator, an electric motor and a rotating spindle; both a rotor of the compensation pulse generator and a rotor of the electric motor are fixed on the rotating spindle; both a stator of the compensation pulse generator and a stator of the electric motor are fixed on the inner surface of the enclosure; the electric motor is a high-speed permanent-magnet synchronous motor; and the compensation pulse generator is a hollow-core AC (Alternate Current) compensation pulse generator. The integrated compensation pulse generating set is suitable for a compensation pulse generating set in a small movable electromagnetic transmitting device.

Owner:HARBIN INST OF TECH

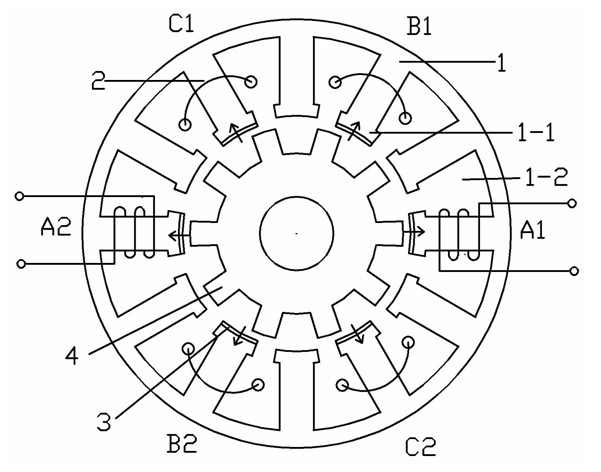

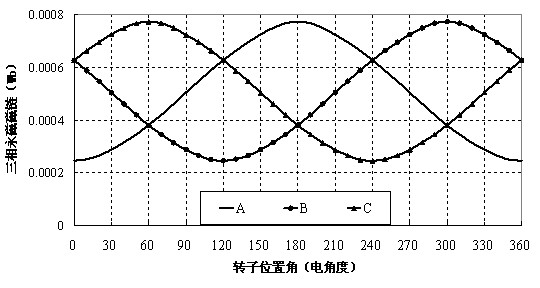

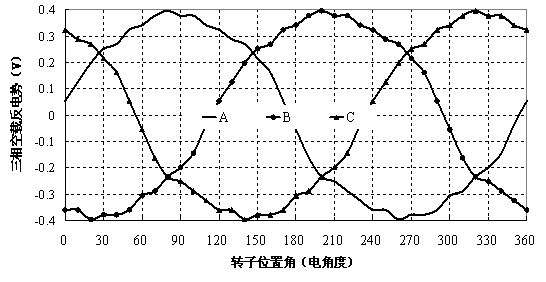

High-reliability half stator-tooth winded stator-surface mounted permanent magnet motor

InactiveCN102611219AImprove cooling conditionsGreat effortWindingsMagnetic circuit rotating partsElectric machineSurface mounting

The invention relates to a high-reliability half stator-tooth winded stator-surface mounted permanent magnet motor which comprises a stator (1) and a rotor (4). The rotor (4) is arranged inside or outside the stator (1). The high-reliability half stator-tooth winded stator-surface mounted permanent magnet motor is characterized in that: the stator (1) is in a salient pole structure and provided with stator teeth (1-1) which protrude from a yoke part; armature winding slots (1-2) are formed among the stator teeth (1-1), the stator teeth (1-1) and the armature winding slots (1-2) are distributed alternatively, the stator (1) is provided with a centralized armature winding (2) and permanent magnets (3), and only half of the stator teeth (1-1) are winded by armature winding coils and provided with the mounted permanent magnets so that half of permanent magnets is saved and the areas of the armature winding slots are increased. Only half of the stator teeth (1-1) are dotted with the permanent magnets (3), and the magnetizing directions of the permanent magnets (3) are same between the gap of the stator (1) and the rotor (4). The centralized armature winding (2) is arranged on the stator teeth (1-1) of the stator (1) provided with the permanent magnets. The high-reliability half stator-tooth winded stator-surface mounted permanent magnet motor has the advantages of simple and firm structure, strong torque output capacity, large power density and high reliability.

Owner:SOUTHEAST UNIV

Fractional-pole two-phase vernier permanent magnet linear motor

ActiveCN110855119AIncreased Design FreedomReduce control difficultyMagnetic circuit rotating partsMagnetic circuit stationary partsPull forceElectric machine

The invention discloses a fractional-pole two-phase vernier permanent magnet linear motor, which comprises an armature winding, a primary iron core yoke part, a primary iron core tooth part, permanentmagnet poles and a secondary iron core. The permanent magnet poles are uniformly distributed on the secondary iron core in an array manner, and the polarities of adjacent permanent magnet poles are opposite; the armature winding, the primary iron core yoke part and the primary iron core tooth part form a motor primary; the permanent magnet poles and the secondary iron core form a motor secondary;an air gap exists between the linear motor primary and the linear motor secondary, and the motor primary and the linear motor secondary can move relative to each other. According to the invention, the constraint that the number of effective permanent magnet poles in a traditional vernier permanent magnet linear motor is an even number is canceled, and a fractional pole concept is provided, so that the number of effective permanent magnet poles of the permanent magnet linear motor can be fractional, possible pole slot matching schemes are expanded, and the design freedom degree of the linear motor is improved. According to the invention, while the high thrust density characteristic of the vernier permanent magnet linear motor is maintained, the horizontal thrust fluctuation and the longitudinal magnetic tension fluctuation are reduced, thereby helping to improve the control precision and the response speed of the motor.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for reducing positioning torque of stator permanent magnetic type electric machine based on rotor auxiliary slot

InactiveCN101488678ASimple and strong structureCompact structureMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineEngineering

The invention discloses a method for reducing the locating moment of a permanent-magnet type motor of a stator based on an auxiliary groove of a rotor. The auxiliary groove is arranged on the rotor to increase upper harmonic component generated by magnetic conductance of an air gap tooth space, so that the fundamental frequency of the generated locating moment is increased, while the amplitude is correspondingly reduced. As the dimension of the auxiliary groove of the rotor is optimally designed, the idle load electric potential of the motor can be guaranteed when the locating moment is reduced, and the performance index such as torque output capability and the like can not be influenced. In the structure, the invention maintains the advantages of being compact and simple, good in robustness and suitable for high speed running of the permanent-magnet type motor of the stator; the volume of the motor is not needed to be additionally increased, and on the contrary, the magnet core quantity of the rotor can be reduced. Compared with other ways used for reducing the locating moment, the technical method is simple, convenient and effective, has low cost and is especially suitable for the permanent-magnet type motor of the stator, thus the type of motor has better application prospect in the fields such as a direct drive type aerogenerator, hybrid vehicle, etc.

Owner:环一军

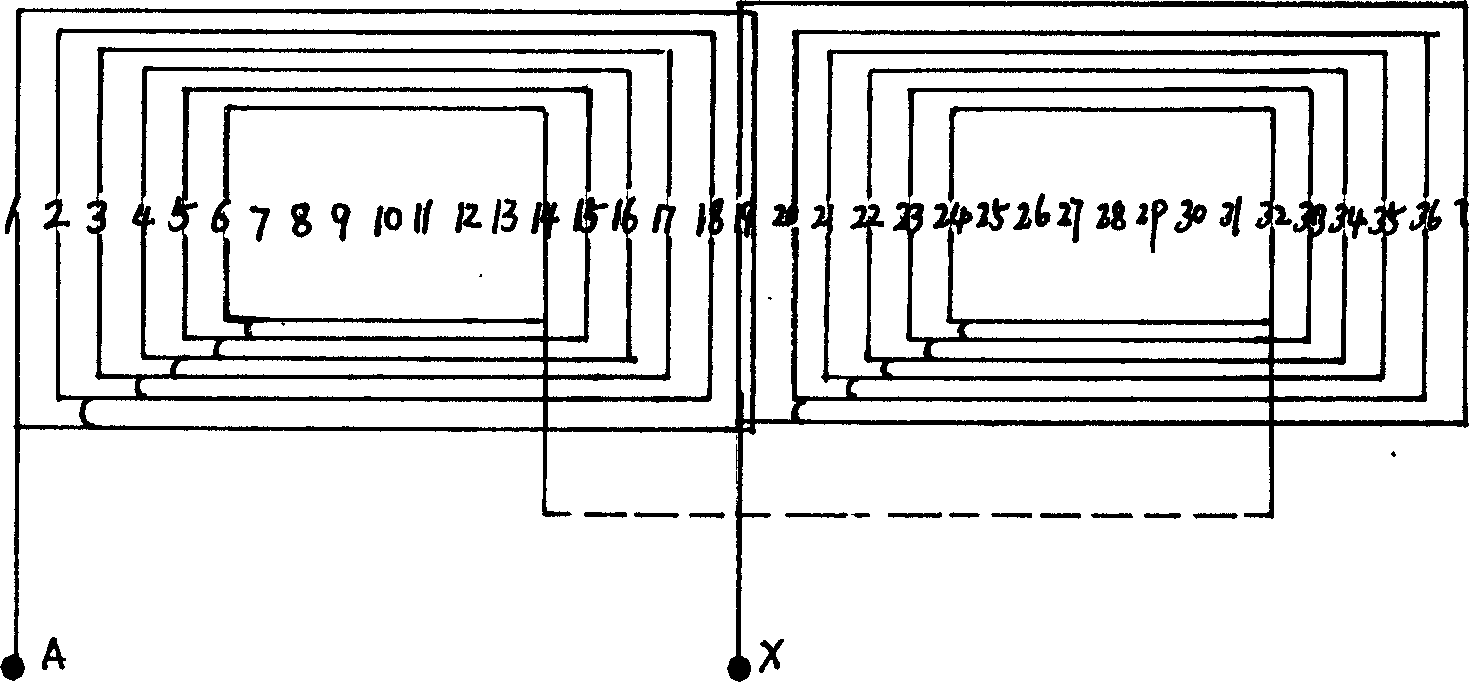

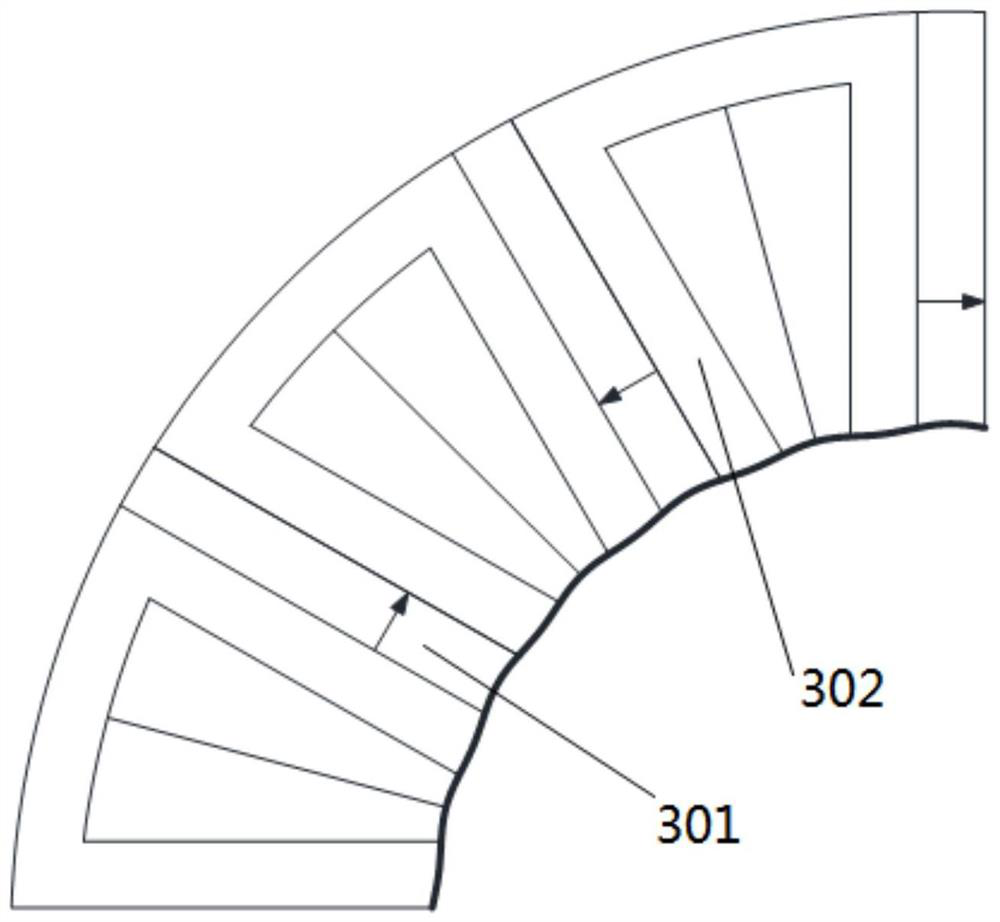

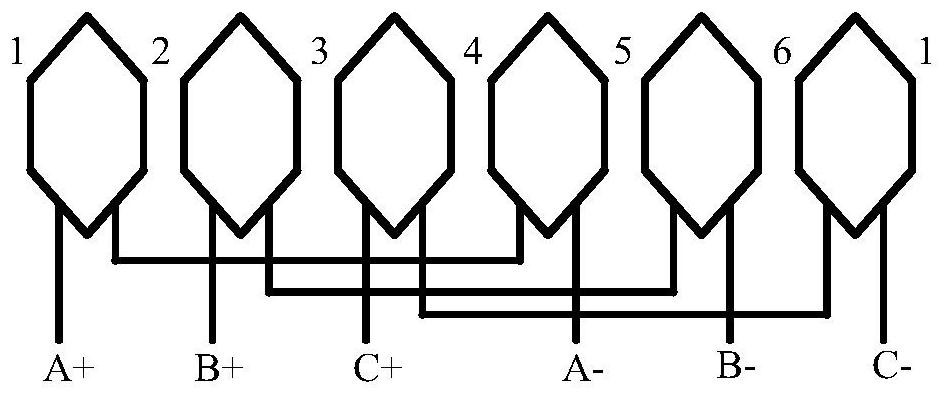

A two-phase fractional slot air core compensation pulse generator

ActiveCN109038903AImproved discharge output capabilityAvoiding Overlap ProblemsWindings conductor shape/form/constructionElectricityBasket winding

A two-phase fractional slot air core compensation pulse generator including stator and rotor, the stator comprises a two-phase armature winding, A 90 DEG electric angle difference exists between thattwo-phase armature winding, the two-phase armature winding consists of two coils, All coils of the two-phase winding are concentric centralized windings, all the coils of the two-phase winding are uniformly distributed in the stator space, the coils of different phases are staggered, and there is no gap between two adjacent coils, A rotor includes an excitation winding, the excitation winding consists of six excitation coils, the above-mentioned pulse generator is a pulse generator with two phases, Four-slot, six-poles, and satisfies the slot pole number combination constraint condition of fractional slot winding with pitch of 1, thus avoiding the cross-overlap problem of the ends of different phase coils of the traditional distributed winding, greatly reducing the manufacturing difficultyof the stator winding of the air-core pulse generator, and the discharge output capability of the motor can be effectively improved.

Owner:THE UNIV OF NOTTINGHAM NINGBO CHINA

Hybrid excitation type magnetic flux switching motor with K-shaped stator cores

ActiveCN106451834ASimple structureCompact structureMagnetic circuit stationary partsWindings conductor shape/form/constructionElectric machineExcitation current

The invention discloses a hybrid excitation type magnetic flux switching motor with K-shaped stator cores, and belongs to the technical field of fabrication of a motor. Permanent magnets, armature windings and single-phase excitation windings are arranged at a stator part, stator cores are in K shapes, each permanent magnet is embedded between adjacent stator cores, the armature windings are three-phase concentrated windings which are wound at inner sides of stator teeth of adjacent K-shaped stator cores at two sides of each permanent magnet in a bridging way, the single-phase excitation windings are wound at outer sides of two stator teeth of each K-shaped stator core in a bridging way, and no permanent magnet and no winding are arranged at a rotor part. The hybrid excitation type magnetic flux switching motor is compact, simple and firm in structure, the no-load magnetic flux of the magnetic flux switching motor is maintained to be dual-polarity characteristic, meanwhile, a hybrid excitation function is achieved, the magnetic flux switching motor has relatively high torque output capability and relatively high power density, the regulation range of an air-gap magnetic field is broaden by adjusting an excitation current, and the magnetic flux switching motor is good in magnetic regulation performance.

Owner:JIANGSU UNIV

Linear permanent magnet motor operating mechanism of high-voltage circuit breaker

InactiveCN102157310AControl speedSimple structureSwitch power arrangementsProtective switch operating/release mechanismsElectric machineElectrical polarity

The invention relates to a linear permanent magnet motor operating mechanism of a high-voltage circuit breaker, comprising a stator core, a rotor core, drive rods and permanent magnets, wherein the stator core is a box body; the rotor core is arranged in the stator core; the drive rods arranged on both ends of the rotor core penetrate through shells positioned on the upper and the lower ends of the rotor core and can move up and down; the side wall of the stator core is provided with the permanent magnets; upper and lower adjacent permanent magnets are opposite in polarity; the permanent magnets positioned on the left and the right edges of the box body are same in polarity placement directions; stator salient poles with the number of integral multiples of a phase number are arranged on the inner side wall of the stator core and between the two adjacent permanents and are provided with armature coils; the outer side wall of the rotor core is provided with rotor salient poles; when therotor core is positioned on a highest position, the stator salient pole positioned on the uppermost end of the stator core just faces to the rotor salient poles; and when the rotor core is positionedon a lowest position, the stator salient pole positioned on the lowest end of the stator core just faces to the rotor salient poles.

Owner:SOUTHEAST UNIV

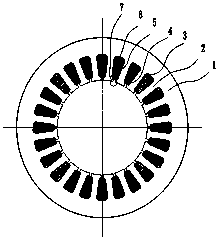

High efficieng electric machine

InactiveCN1619917AReduce end lengthLow costWindings conductor shape/form/constructionElectric machineHarmonic

A high efficient motor contains three-phase concentric double layer winding with natural number rule turn ratio which greatly reduces magnetic potential harmonic content, reduces end length of stator winding and improves electromagnetic noise, temperature rising, vibration and efficiency.

Owner:TELLHOW SCI TECH CO LTD

Broken end suction device of tail yarn removing machine

The invention discloses a broken end suction device of a tail yarn removing machine. The broken end suction device comprises a broken end suction component and a driving unit, wherein the driving unit comprises a driving motor and a fan; the driving motor and the fan are both arranged in the tail yarn removing machine; the broken end suction component comprises a suction nozzle and a first suction pipe; one end of the first suction pipe is fixedly connected with the suction nozzle, and the other end of the first suction pipe is communicated with a second suction pipe on the tail yarn removing machine; and the second suction pipe is connected with an exhaust opening of the fan. The broken end suction device can suck the broken ends on a spool under the condition that the tail yarn spool moves; the cotton yarns are snapped under the combined action of suction force and pulling force; the broken end length of the tail yarn is reduced; the tail yarn removing machine can conveniently search the tail yarn broken ends; and the tail yarn removing efficiency is improved.

Owner:CMT HICORP MACHINERY QINGDAO

Double-cosine air gap flux switching servo motor

PendingCN112821700AImprove cooling conditionsAttenuation of air gap magnetic field harmonicsSynchronous machine detailsMagnetic circuit stationary partsEngineeringHarmonics

The invention provides a double-cosine air gap magnetic flux switching servo motor which comprises a rotor and a stator arranged outside the rotor. An air gap is reserved between the stator and the rotor, and the rotor side boundary and the stator side boundary of the air gap are in a cosine curve shape. According to the present invention, the rotor side boundary and the stator side boundary of the air gap are all cosine curve shapes, so that air gap magnetic field harmonic waves generating cogging torque can be effectively weakened, then the cogging torque is reduced, the torque fluctuation is reduced, and meanwhile the sufficient output torque is guaranteed.

Owner:SOUTHEAST UNIV

Odd-pole three-phase linear permanent-magnet vernier motor

ActiveCN110798045AIncreased Design FreedomReduced horizontal electromagnetic thrust fluctuationsPropulsion systemsPull forceElectric machine

The invention discloses an odd-pole three-phase linear permanent-magnet vernier motor, comprising an armature winding, a primary iron core yoke part, a primary iron core tooth part, permanent magnet poles and a secondary iron core, wherein the permanent magnet poles are uniformly distributed on the secondary iron core in the form of an array, and the polarities of adjacent permanent magnet poles are opposite; the armature winding, the primary iron core yoke part and the primary iron core tooth part form a motor primary stage; the permanent magnet poles and the secondary iron core form a motorsecondary stage; and an air gap exists between the linear motor primary stage and the linear motor secondary stage, and the linear motor primary stage and the linear motor secondary stage can move relative to each other. According to the invention, the constraint that the number of effective permanent magnet poles in a traditional linear permanent-magnet vernier motor is an even number is eliminated, and the concept of odd poles is provided, so the number of the effective permanent magnet poles of the linear permanent-magnet motor can be an odd number, a possible pole groove matching scheme isexpanded, and the design freedom degree of the linear motor is improved; and while the high thrust density characteristic of the linear permanent-magnet vernier motor is maintained, and the horizontal thrust fluctuation and the longitudinal magnetic tension fluctuation of the linear permanent-magnet vernier motor are reduced, so the control precision and the response speed of the motor are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

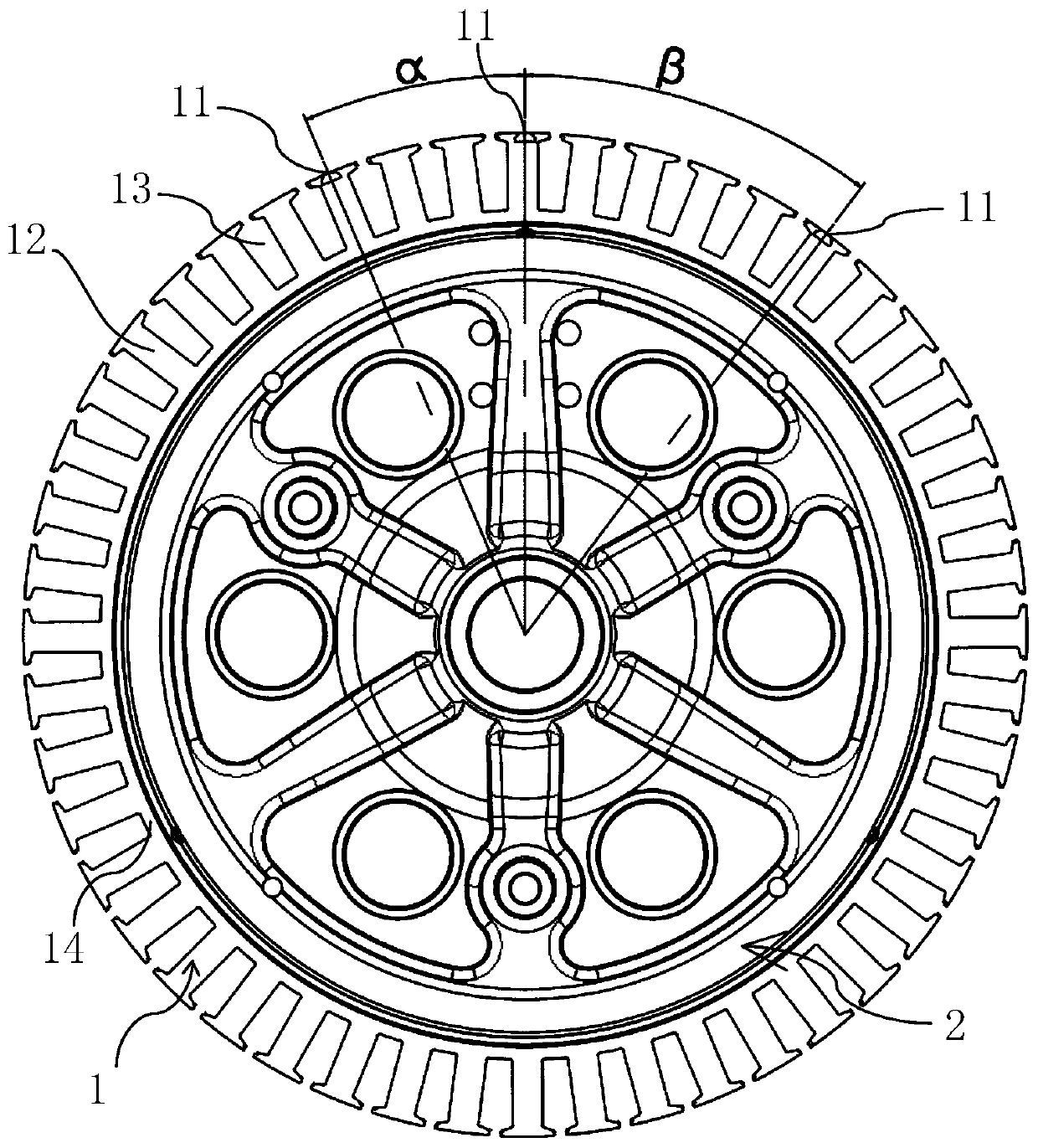

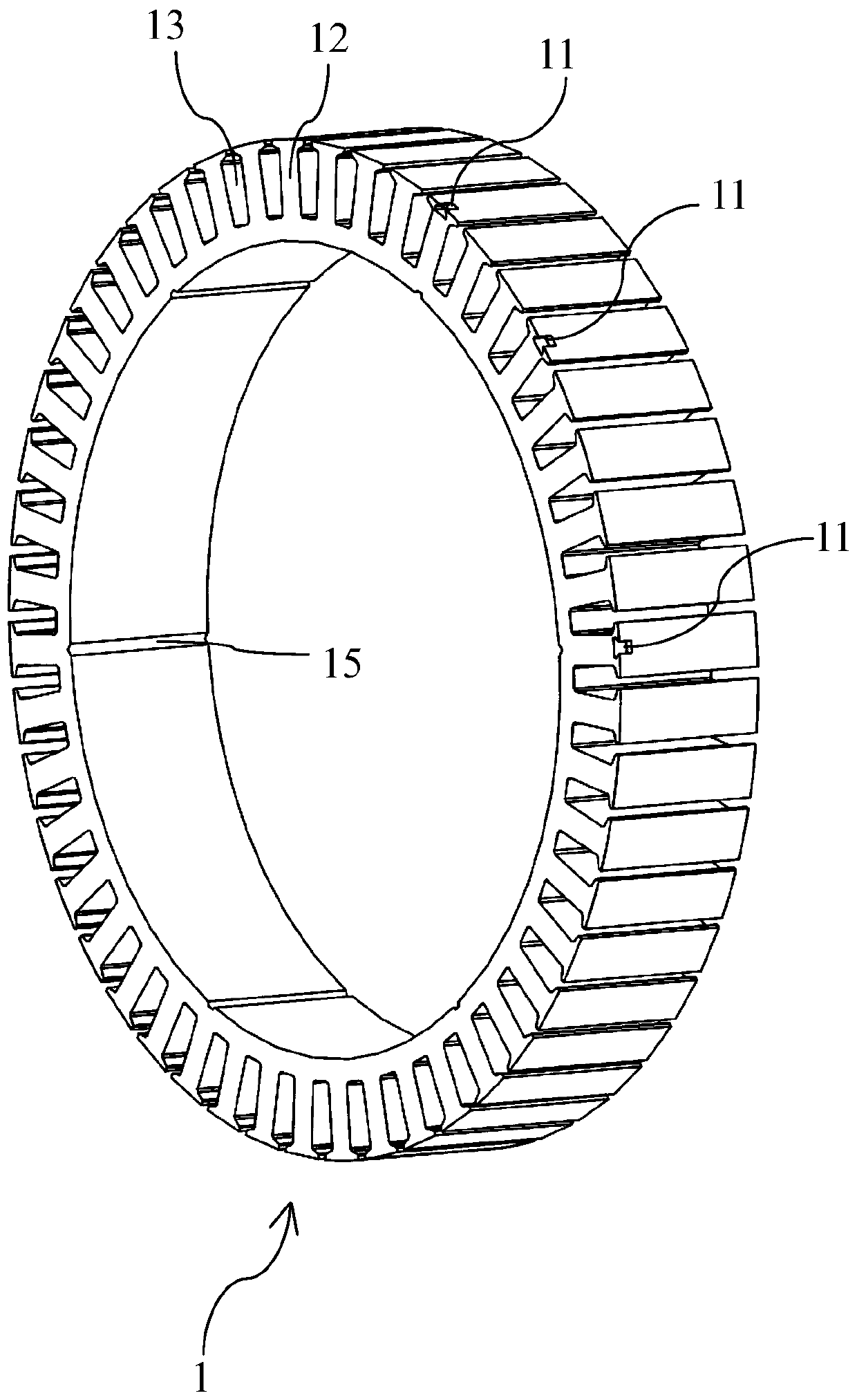

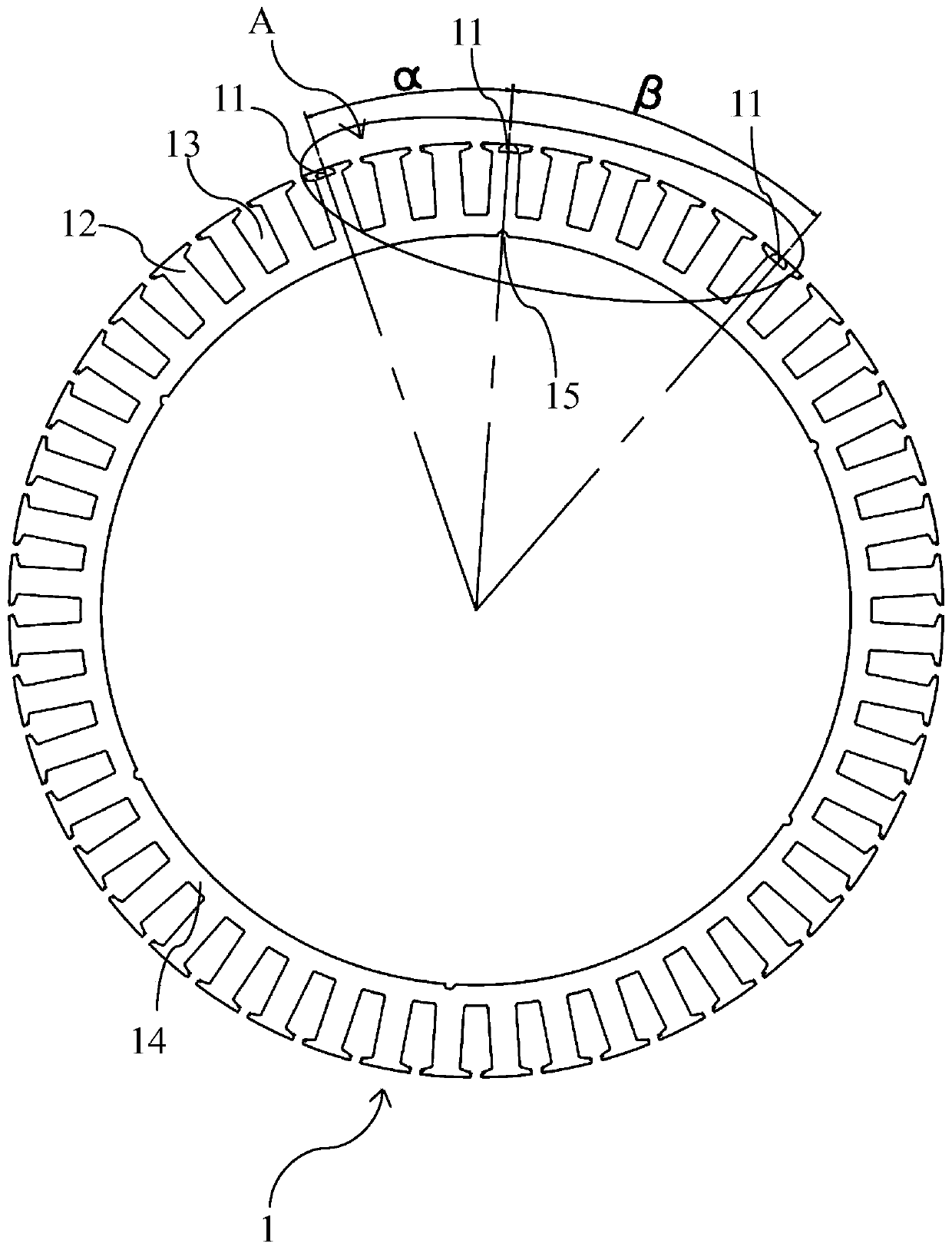

Stator of wheel hub motor for electric vehicle

PendingCN111463925AImprove installation accuracyImprove accuracyElectric machinesMagnetic circuit stationary partsElectric machineElectric cars

The invention relates to a stator of a wheel hub motor for an electric vehicle, which comprises an iron core and support, wherein the iron core is composed of tooth ribs, a yoke part and tooth grooves, the iron core is arranged on the outer side of the support, at least three Hall grooves are formed in the end part of the same side of the iron core, the three Hall grooves are located on the toothribs of the iron core and are distributed in a circumferential manner, the symmetrical center lines of the three Hall grooves are intersected in pairs, the symmetrical center line of the middle Hall groove in the three Hall grooves and the symmetrical center lines of the Hall grooves located on the two sides of the middle Hall groove form an included angle [alpha] and an included angle [beta] respectively, the number of tooth grooves of the iron core is 48, the included angle [alpha] ranges from 22 degrees to 26 degrees, and the included angle [beta] ranges from 36 degrees to 40 degrees. The stator has the advantages that the tooth groove structure is optimized, the position of each Hall groove is reasonably arranged, the precision of a motor commutation point is improved, the problem thata groove opening Hall is difficult to install and prone to deviation is solved, the stator adapts to a single-wire multi-turn winding process, a magnetic circuit is optimized, the motor efficiency isimproved, a groove wedge is removed, and the stator groove utilization rate is increased.

Owner:TAIZHOU JINYU ELECTROMECHANICAL

Magnetic flux switching type permanent magnet memory motor

ActiveCN103051139BSimple structureStable structureSynchronous machinesMagnetic circuit stationary partsElectric machineMemory motor

The invention discloses a magnetic flux switching type permanent magnet memory motor comprising an enclosure, a stator contained in the enclosure, a rotor (2) and a non-magnetic rotary shaft (8). The magnetic flux switching type permanent magnet memory motor is characterized in that the stator (1) is arranged at the outer part of the rotor (2); the rotor (2) is fixedly arranged on the non-magnetic rotary shaft (8) and is in a convex pole type; the rotor (2) comprises a rotor main body part and rotor teeth which protrude from the main body part to a direction which is far away from the center of the rotor; the stator comprises a stator iron core (1), a permanent magnet (3), a three-phase armature winding (4) and a pulse winding (5); the stator iron core (1) comprises a plurality of stator yokes and stator teeth (1.1) which protrude from the stator yokes to the direction of the center of the stator iron core; and the three-phase armature winding (4) is wound on the stator teeth (1.1). According to the magnetic flux switching type permanent magnet memory motor disclosed by the invention, a motor no-load gap magnetic field is adjustable, and the weak magnetism capability and the rotary speed operation speed of the motor are improved; and meanwhile, the torque and the power density of the motor are improved and the copper consumption of the motor is reduced.

Owner:SOUTHEAST UNIV

A multi-tooth permanent magnet embedded flux switching memory motor

ActiveCN103501063BSimple structureStable structureMagnetic circuit rotating partsSynchronous machine detailsThree-phaseNon magnetic

Owner:SOUTHEAST UNIV

Compact flywheel energy storage battery

ActiveCN113991933AShorten the axial lengthCompact structureElectrical storage systemMechanical energy handlingCircular discMagnetic bearing

The invention discloses a compact flywheel energy storage battery, and belongs to the technical field of electric energy storage. The battery comprises: an energy storage flywheel which is formed by stacking at least one hollow flywheel disc on a flywheel rotating shaft; an upper end cover and a lower end cover which are respectively arranged on the upper side and the lower side of the energy storage flywheel; a machine shell which is fixed between the upper end cover and the lower end cover, wherein the machine shell, the upper end cover and the lower end cover form a vacuum cavity; a high-speed motor which is arranged between the upper end cover and the energy storage flywheel or between the energy storage flywheel and the lower end cover; and a mechanical bearing and a permanent magnet bearing. The high-speed motor is fixed on the stepped rotating shaft and is provided with an annular water channel. The axial length of the flywheel energy storage battery is reduced, the structure is compact, simple and reliable, and the material consumption is reduced. In the same vacuum cavity, more hollow flywheel discs can be stacked to form a flywheel energy storage battery with larger capacity; and different flywheel energy storage batteries can form a flywheel energy storage battery pack with larger capacity and larger power through flanges arranged on the upper end cover and the lower end cover.

Owner:HUAZHONG UNIV OF SCI & TECH

Long-stroke linear permanent magnet motor operation mechanism of high-voltage breaker

ActiveCN102157309AControl speedSimple structureSwitch power arrangementsProtective switch operating/release mechanismsElectric machineElectrical polarity

The invention provides a long-stroke linear permanent magnet motor operation mechanism of a high-voltage breaker. Long-stroke linear permanent magnet motor operation mechanism of high-voltage breaker is characterized in that the operation mechanism comprises a stator core, a rotor core, a driving rod and a permanent magnet, wherein the stator core is a box body; the rotor core is disposed in the stator core; the driving rod disposed at two ends of the rotor core passes through the upper and lower end shells of the stator core and can move up and down; the inner side wall of the stator core isprovided with a stator salient pole; the permanent magnet is disposed in the stator salient pole; the polarities of the upper and lower adjacent permanent magnets are opposite; the polarity arrangingdirections of the permanent magnets at left and right sides of the box body are the same; the stator salient pole is provided with an armature coil; the top part of the stator salient pole is provided with a pole shoe; the outer side wall of the rotor core is provided with a rotor salient pole; when the rotor core is located at the highest position, the lower half section of the stator salient pole at the uppermost end of the stator core faces the rotor salient pole; when the rotor core is located at the lowest position, the upper half section of stator salient pole at the lowest end of the stator core faces the rotor salient pole.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com