Double-cosine air gap flux switching servo motor

A technology of air gap flux and servo motor, applied in the field of servo motor, can solve the problems of large motor cogging torque, unfavorable high-speed operation, and failure to meet the control accuracy requirements of the servo system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

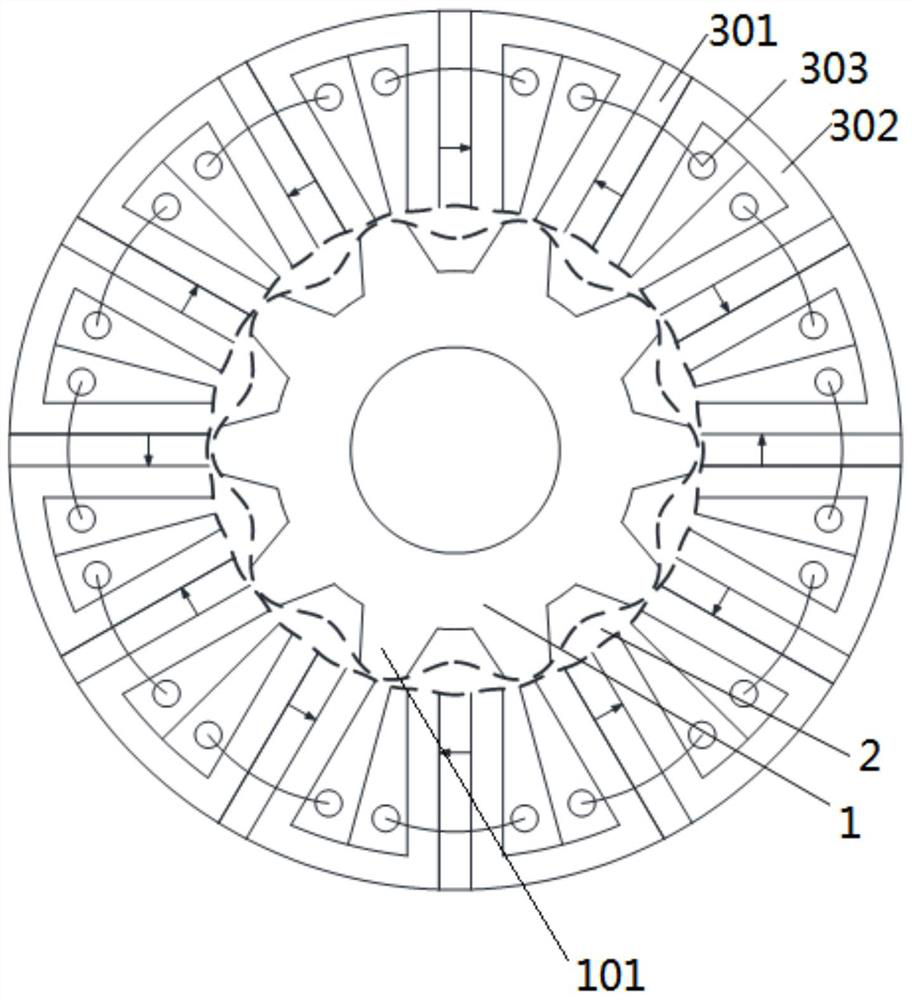

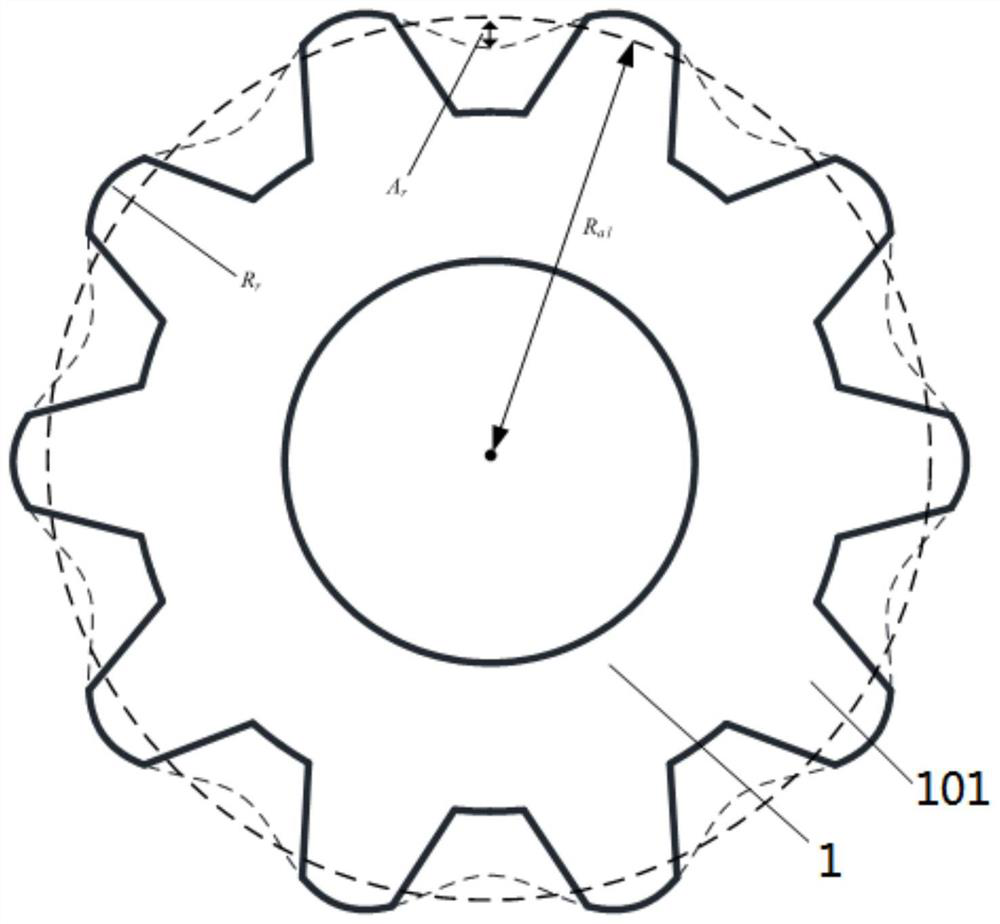

[0023] refer to Figure 1-Figure 4 , the present invention proposes a double cosine air gap flux switching servo motor, including a rotor 1 and a stator arranged outside the rotor 1, and an air gap 2 is left between the stator and the rotor 1, wherein:

[0024] The rotor 1 is evenly provided with a plurality of salient pole teeth 101 along the circumference of the section, and the end of the salient pole teeth 101 away from the rotor 1 is in an arc-shaped structure. The rotor-side boundary of the air gap is in the shape of a cosine curve, and the cosine curve function of the rotor-side boundary of the air gap is R r (θ) = R a1 +A r *cos(P r *θ), where: R a1 Starting radius of the cosine curve representing the side boundary of the air gap rotor, A r Amplitude of the cosine curve representing the air gap rotor side boundary; P r Indicates the number of salient pole teeth 101.

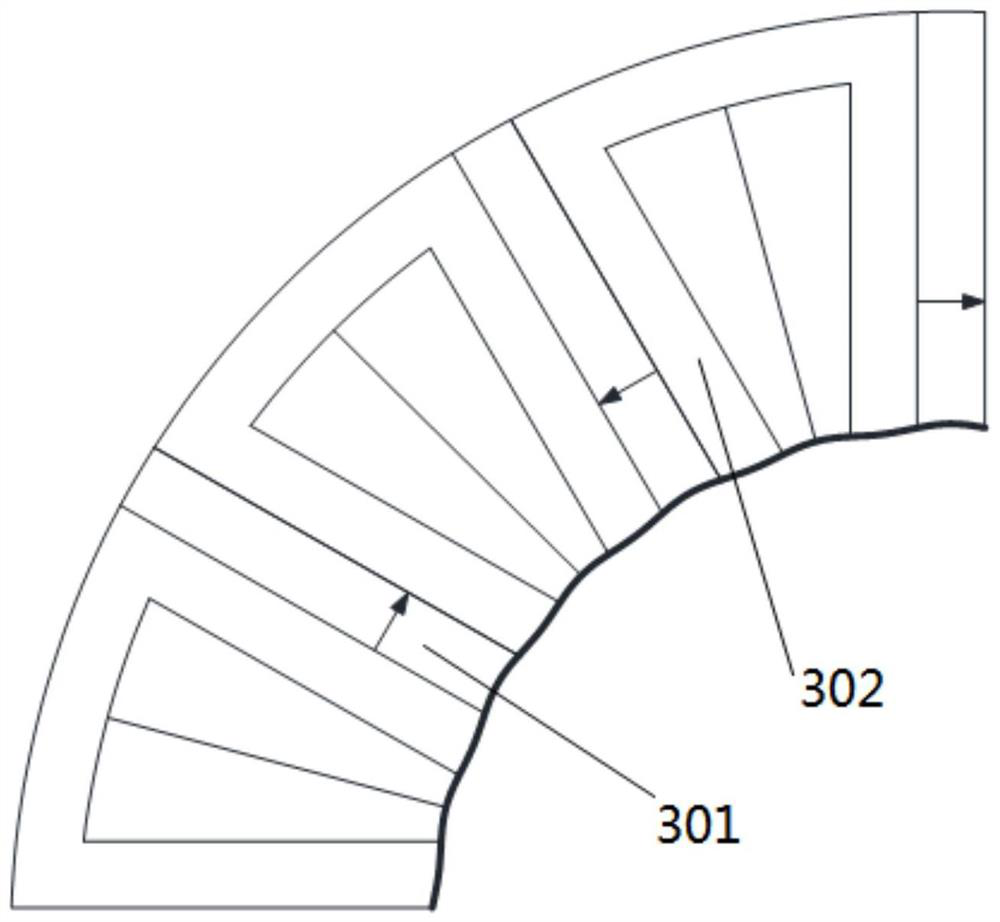

[0025] The stator includes permanent magnets 301, stator cores 302 and stator windings 303. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com