Linear permanent magnet motor operating mechanism of high-voltage circuit breaker

A high-voltage circuit breaker and operating mechanism technology, which is applied to the field of linear permanent magnet motor operating mechanisms, can solve the problems of difficulty in meeting the long-stroke opening and closing operation requirements of the high-voltage circuit breaker, the short stroke of the permanent magnet mechanism, and the difficulty in guaranteeing the opening and closing operation. , to reduce the risk of irreversible demagnetization, increase the magnetic field density, and increase the torque density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

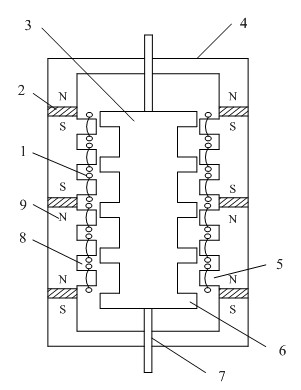

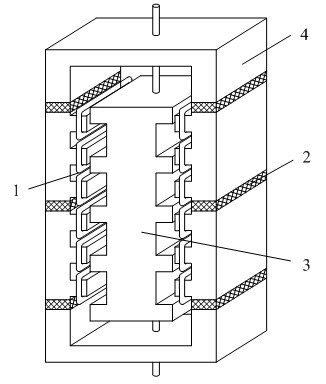

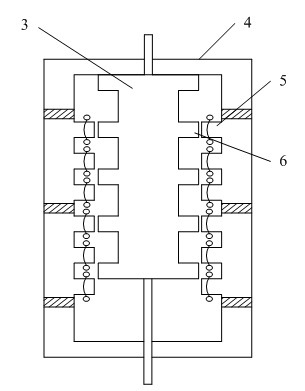

[0021] Depend on figure 1 It can be seen that a linear permanent magnet motor operating mechanism for a high-voltage circuit breaker includes a stator core 4, a mover core 3, a drive rod 7, and a permanent magnet 2. The stator core 4 is a box, and the mover core 3 is placed In the stator core 4, the drive rods 7 arranged at both ends of the mover core 3 pass through the shells at both ends of the stator core 4 and can move up and down. The side walls of the stator core 4 are provided with permanent magnets 2, and the poles of the upper and lower adjacent permanent magnets opposite, that is, the polarities of the opposite faces of the upper and lower adjacent permanent magnets are the same, such as figure 1 As shown in , the N poles to N poles, S poles to S poles of the adjacent permanent magnets up and down, and the permanent magnets on the left and right sides of the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com