Birotor permanent magnet motor applied to wind power generation

A permanent magnet motor and double rotor technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of no further research and verification in engineering practice of operation reliability, complex wind turbine system, bulky filter inductor, etc., to achieve improved The effect of copper wire utilization, material cost reduction, and small volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

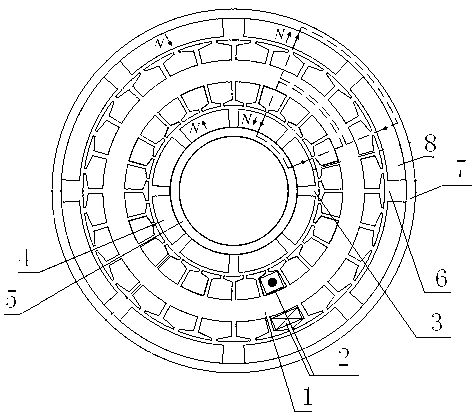

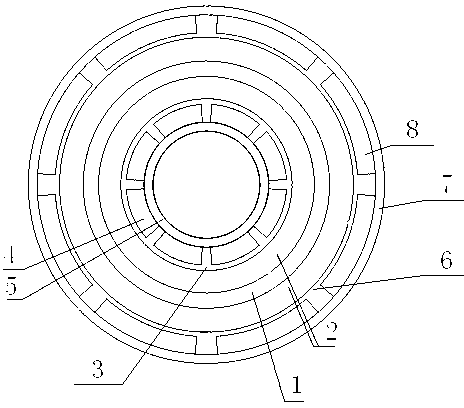

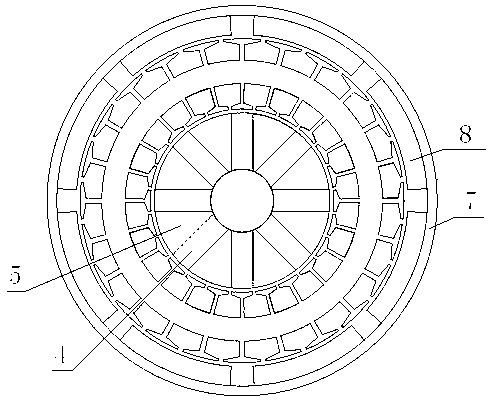

[0024] The invention is a double-rotor permanent magnet motor applied to wind power generation, which is suitable for a wide wind speed range, and its structure includes a motor stator and an inner and outer rotor of the motor. The motor stator includes stator core 1 and stator winding 2; the inner rotor of the motor includes inner rotor iron core 5 and inner rotor permanent magnet 4, and the outer rotor of the motor includes outer rotor iron core 7 and outer rotor permanent magnet 8; There is an inner air gap 3 between them, and an outer air gap 6 between the outer rotor and the stator. The inner and outer air gaps of the motor are respectively formed between the inner and outer rotors and the stator, and the formation of double air gaps increases the effective air gap area of the motor.

[0025] The stator core and rotor core are composed of silicon stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com