Stator of wheel hub motor for electric vehicle

A hub motor and electric vehicle technology, applied in the field of electric vehicles, can solve problems such as messy and loose winding of enameled wires, low utilization rate of stator slots, and motor failure damage, etc., to increase the effective area, reduce the risk of high temperature failure, and reduce iron loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

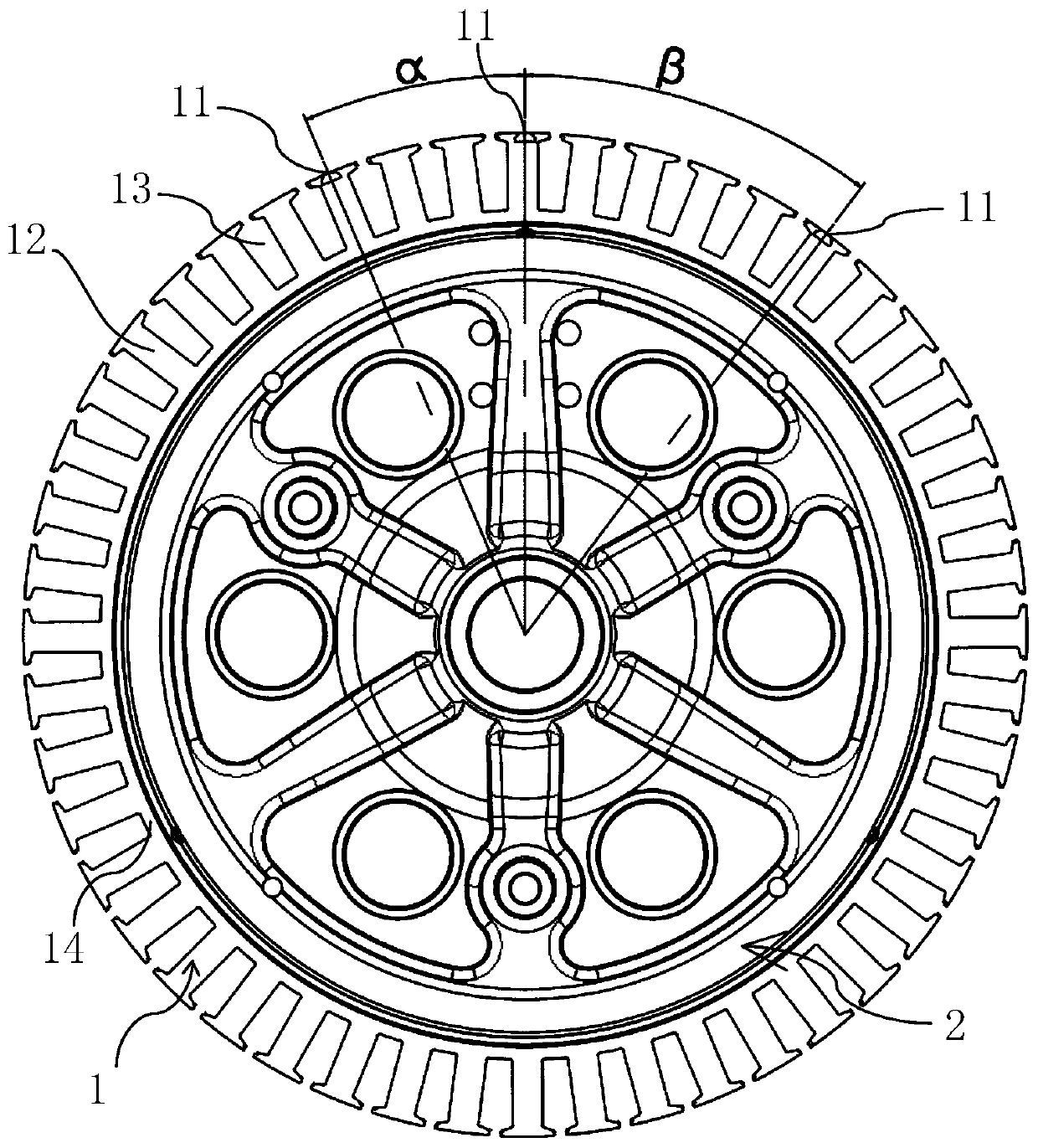

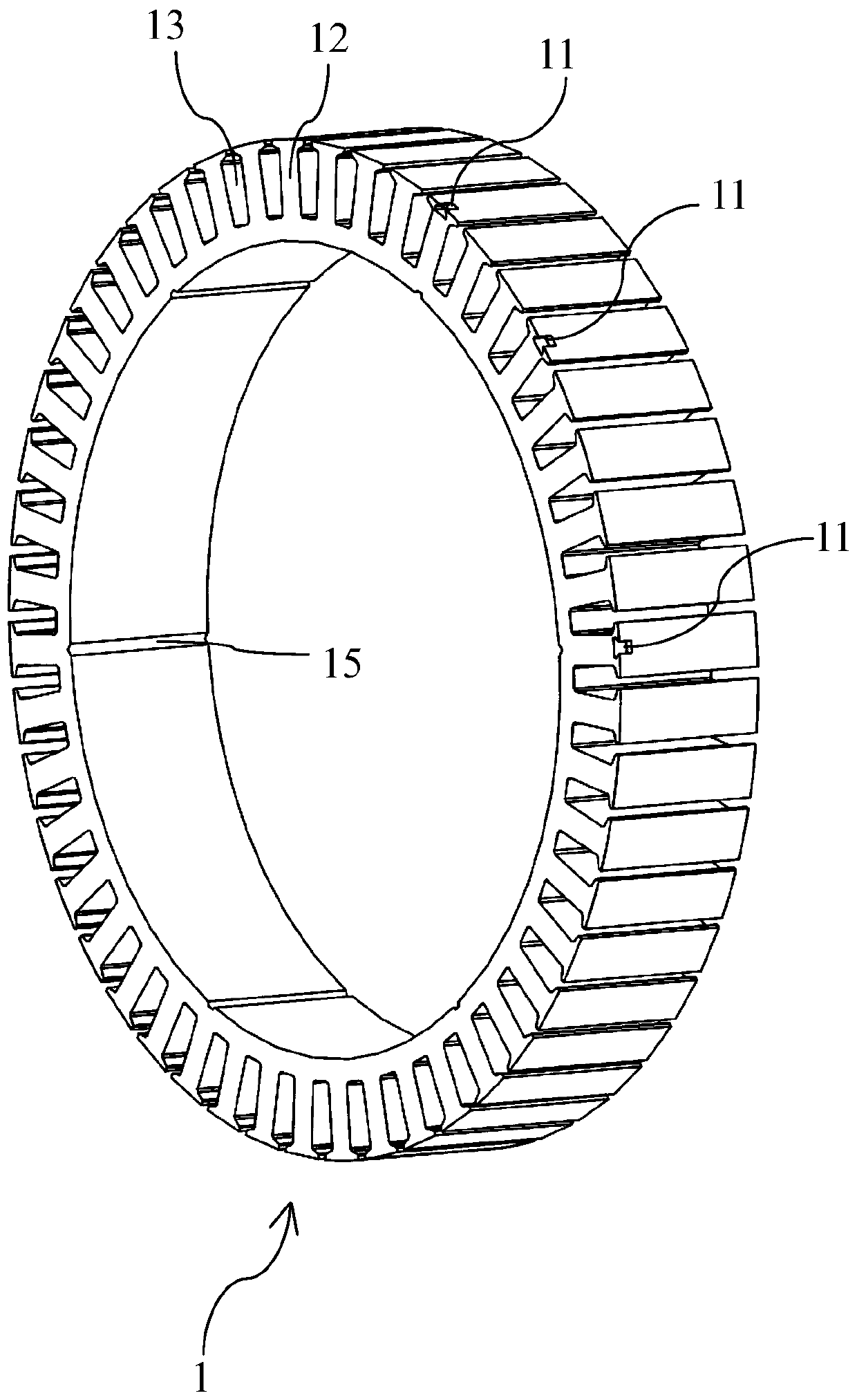

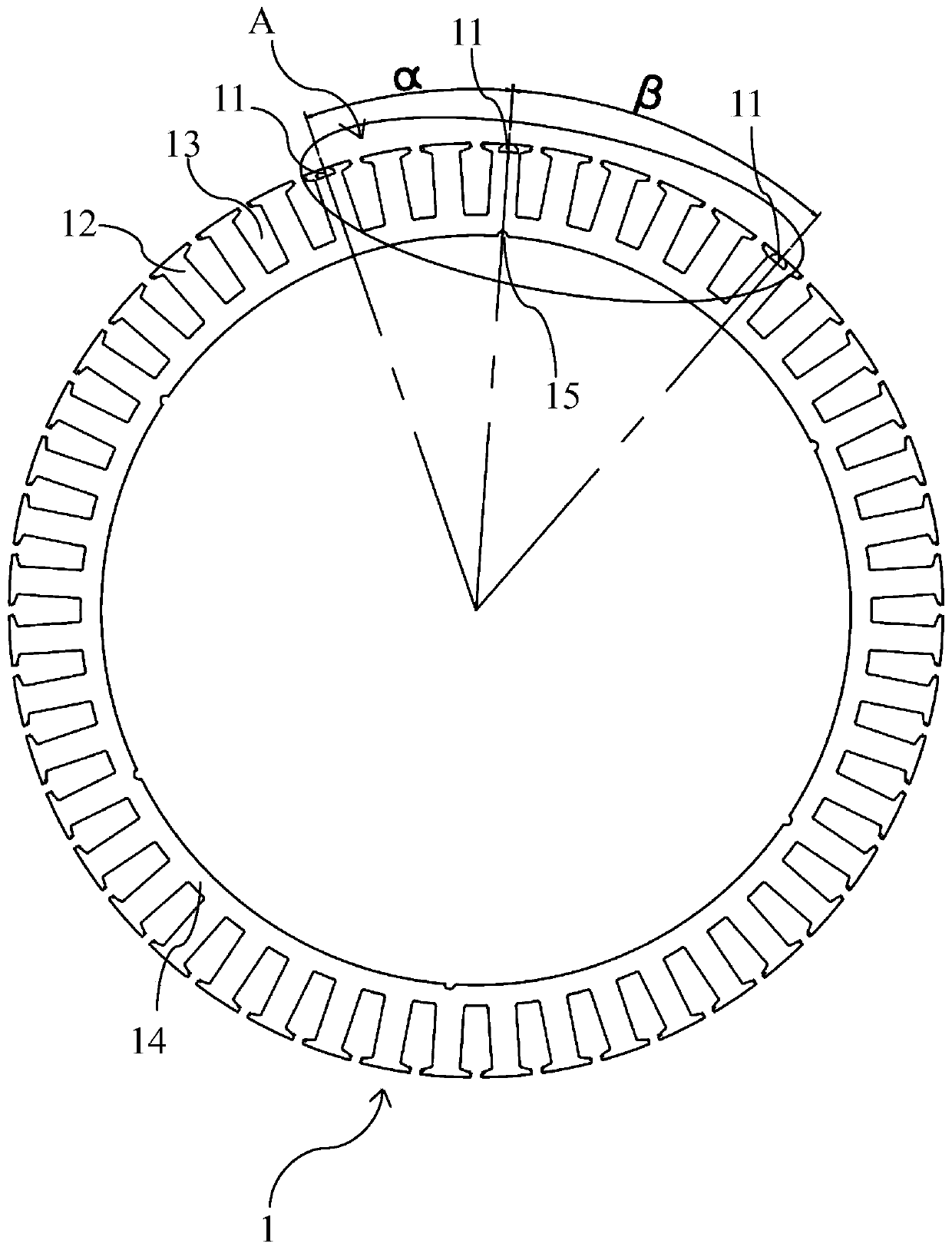

[0027] Such as Figure 1 to Figure 4As shown, the stator of a 10-inch in-wheel motor for electric vehicles provided by this embodiment includes an iron core 1 and a bracket 2, the iron core 1 is composed of ribs 12, yokes 14 and tooth grooves 13, and the iron core 1 is fixed on On the outer peripheral surface of the bracket 2, the center of the bracket 2 is welded with a shaft sleeve, and the axial end of the iron core 1 is provided with a number of Hall slots for installing Hall elements, and the inner peripheral surface of the iron core 1 is provided with several anti-rotation recesses Slot 15, anti-rotation ribs and anti-rotation grooves 15 are provided on the outer circumference of the bracket 2 for corresponding cooperation to form a circumferential positioning and anti-rotation connection pair. Copper wire windings are placed in the cavity of the tooth groove 13, and the copper wire windings are arranged in a clockwise direction. Or wind around the tooth bar 12 in a coun...

Embodiment 2

[0037] The technical solutions in this embodiment are mostly the same as those in Embodiment 1. This embodiment only describes the different parts in detail, and the parts that are the same as those in Embodiment 1 will not be repeated here.

[0038] Such as figure 1 and image 3 As shown, the outer diameter of the iron core 1 is 208-215mm. Preferably, the outer diameter of the iron core 1 is 209-211mm. More preferably, the outer diameter of the iron core 1 is 209-210mm. In this embodiment, the outer diameter of the iron core 1 is The outer diameter is 210.2~210.5mm.

[0039] The rib 12 of the iron core 1 has a width of 5-8 mm, the thickness H2 of the tooth lip of the iron core 1 is 0.5-2 mm, and the yoke 14 of the iron core 1 has a thickness of 3.5-6 mm. Preferably, the rib 12 of the iron core 1 has a width of 5.5~7mm, the thickness H2 of the tooth lip of the iron core 1 is 0.8~1.5mm, the thickness of the yoke 14 of the iron core 1 is 4.5~5mm, more preferably, the width of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com