Concentrated-winding multi-segment permanent magnet synchronous linear motor

A permanent magnet synchronous linear and concentrated winding technology, applied in the shape/style/structure of winding conductors, electrical components, electromechanical devices, etc., can solve problems such as low system operation efficiency, reduce losses, reduce cogging positioning force and edge positioning force, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

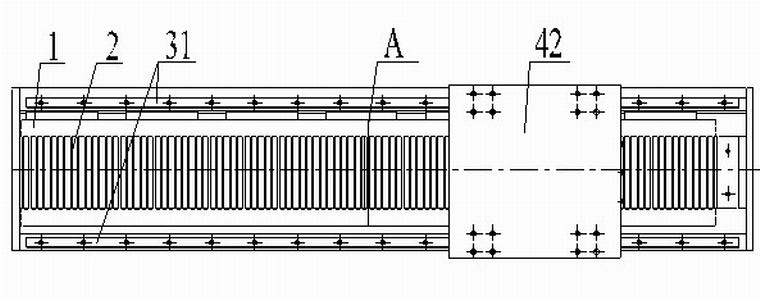

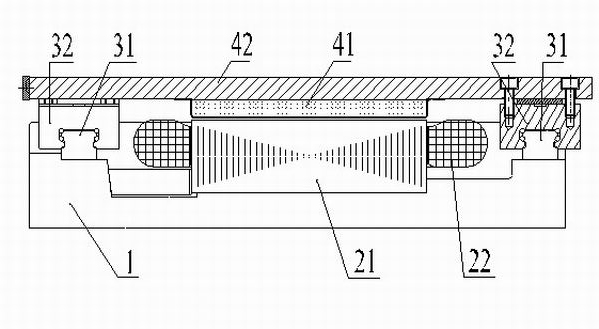

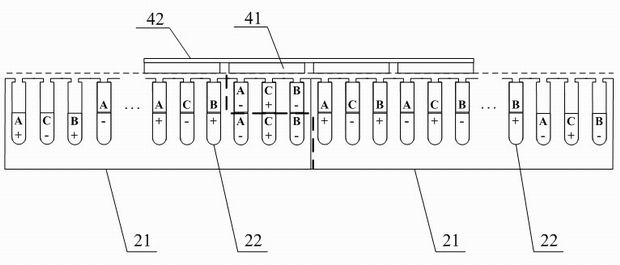

[0010] Specific implementation mode one: the following combination Figure 1 to Figure 4 Describe this embodiment, this embodiment includes machine base 1, armature 2, a pair of guide rails 31, a pair of sliders 32, many pairs of permanent magnets 41 and mover body 42,

[0011] The armature 2 is arranged in the middle of the upper surface of the base 1, and a pair of guide rails 31 are arranged on both sides of the armature 2 on the upper surface of the base 1, and a pair of guide rails 31 are slidably connected with a pair of sliders 32. The block 32 is fixedly connected with the mover body 42, and a plurality of pairs of permanent magnets 41 are arranged in a row and multiple columns on the inner surface of the mover body 42 along the movement direction, and there is an air gap between the permanent magnets 41 and the armature 2;

[0012] The armature 2 is composed of a multi-section armature core 21 and a multi-section armature winding 22. The multi-section armature core 21...

specific Embodiment approach 2

[0014] Specific implementation mode two: the following combination Figure 6 and Figure 7 Describe this embodiment, the difference between this embodiment and Embodiment 1 is that the permanent magnet 41 is a rectangular permanent magnet, the magnetization direction of the rectangular permanent magnet is perpendicular to the mover body 42, and the magnetization direction of the adjacent rectangular permanent magnets is opposite; The width L of the rectangular permanent magnet m The value range is L m =(0.75~0.9)τ p , where τ p is the pole pitch of the rectangular permanent magnet. Other components and connections are the same as those in Embodiment 1.

[0015] In this embodiment, the permanent magnet 41 adopts a rectangular permanent magnet, and grooves are arranged on the surface of the moving sub-body 42 , the rectangular permanent magnet is surface-attached in the groove of the moving sub-body 42 , and N and S poles are arranged alternately. The width of the permanen...

specific Embodiment approach 3

[0016] Specific implementation mode three: the following combination Figure 8 and Figure 9 Describe this embodiment. The difference between this embodiment and Embodiment 1 or 2 is that the permanent magnet 41 is a rectangular permanent magnet, and the surface of the permanent magnet 41 on the side of the air gap is a convex arc surface. The permanent magnets 41 are magnetized radially, and the magnetization directions of adjacent permanent magnets 41 are opposite. Other compositions and connections are the same as those in the first or second embodiment.

[0017] The permanent magnet 41 in this embodiment adopts a convex arc surface structure, which is attached to the moving body 42, and the N and S poles are arranged alternately. This structure is conducive to the formation of a sinusoidal magnetic field in the air gap, effectively reducing the motor teeth The positioning force and thrust fluctuation of the groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com