Primary permanent-magnet vernier linear motor and segmenting method therefor

A linear motor, primary technology, used in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of increasing thrust, space conflicts between permanent magnets and windings, etc., to prevent motor overheating, avoid space conflicts, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

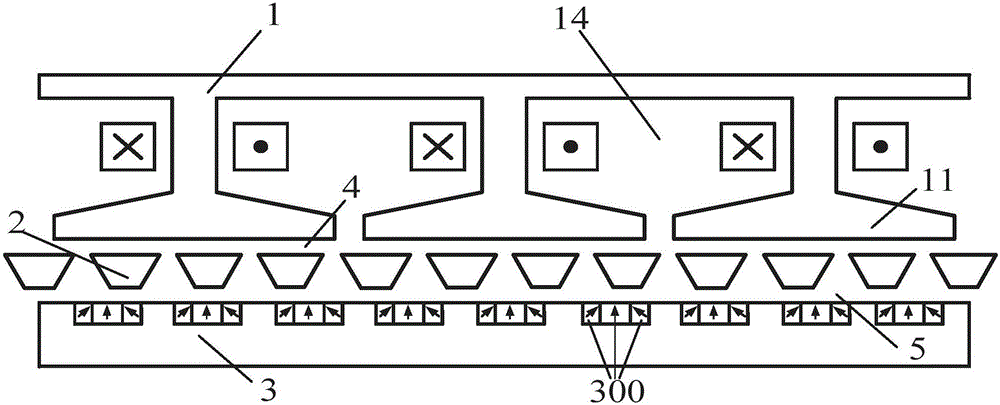

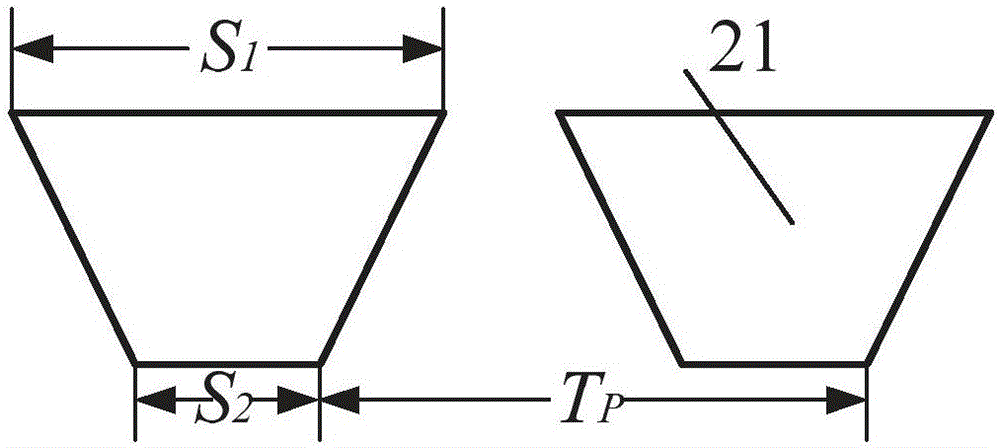

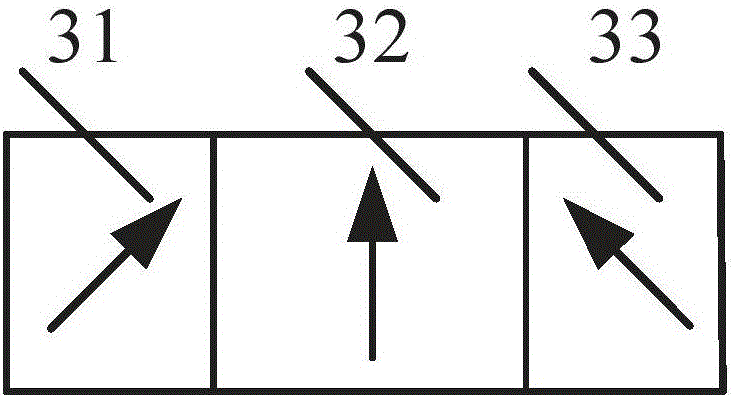

[0033] refer to figure 1 , the present invention is a method for increasing the thrust density of primary permanent magnet motors, including five parts: primary A1, secondary 2, primary B3, air gap A4, and air gap B5. There is an air gap between primary A1 and secondary 2 A4, there is an air gap B5 between primary B3 and secondary 2. The slot 14 of the primary A1 is used to place the winding. Primary A1 and primary B3 move in a straight line in the same direction and at the same speed, and secondary 2 is fixed. For the specific structure and proportional relationship of secondary 2, see figure 2 .

[0034] The primary A1 is slotted to form an alveolar structure, and the slot 14 is used to place windings, and the type of windings can be concentrated or distributed windings. Groove 14 can adopt various groove types, select according to specific needs. The yoke of the primary A1 provides the main flow path of the magnetic flux, and its thickness can be determined by the spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com