Long-stroke linear permanent magnet motor operation mechanism of high-voltage breaker

A high-voltage circuit breaker and operating mechanism technology, applied in the field of high-voltage circuit breaker long-stroke linear permanent magnet motor operating mechanism, can solve the problem that it is difficult to meet the long-stroke opening and closing operation requirements of high-voltage circuit breakers, the opening and closing operation is difficult to guarantee, and the permanent magnet The short stroke of the mechanism can reduce the risk of irreversible demagnetization, improve the torque density, and achieve the effect of strong magnetic concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

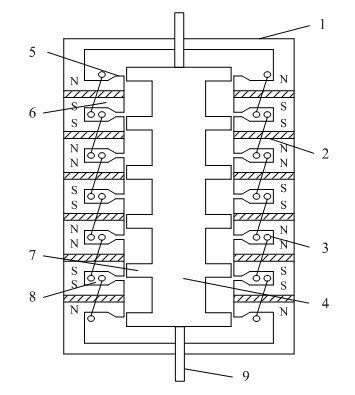

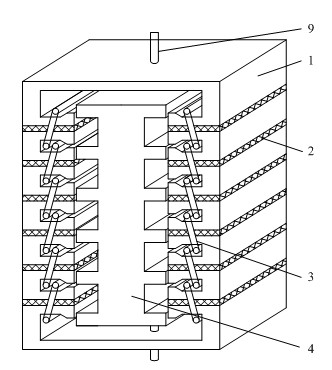

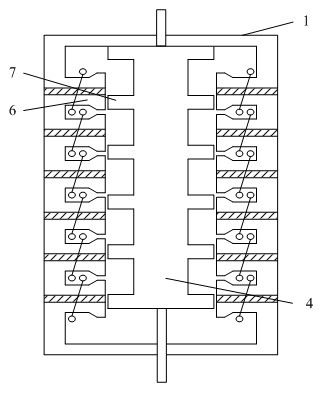

[0021] Depend on figure 1 It can be seen that an operating mechanism of a long-stroke linear permanent magnet motor for a high-voltage circuit breaker includes a stator core 1, a mover core 4, a driving rod 5, and a permanent magnet 2. The stator core 1 is a box body, and the mover core 4 is placed In the stator core 1, the drive rods 5 arranged at both ends of the mover core 4 pass through the casings at both ends of the stator core 1 and can move up and down. The inner side wall of the stator core 1 is provided with a stator salient pole 6, and the inside of the stator salient pole The permanent magnet 2 is set, and the polarities of the upper and lower adjacent permanent magnets are opposite, that is, the polarities of the opposite surfaces of the upper and lower adjacent permanent magnets are the same, as figure 1 As shown in , the upper and lower permanent magnets a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com