High efficieng electric machine

A high-efficiency, motor stator technology, applied in the shape/style/structure of the winding conductor, can solve the problems of weakening the ability of magnetic potential harmonics, excessively long stator winding materials, etc. The effect of saving magnet wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

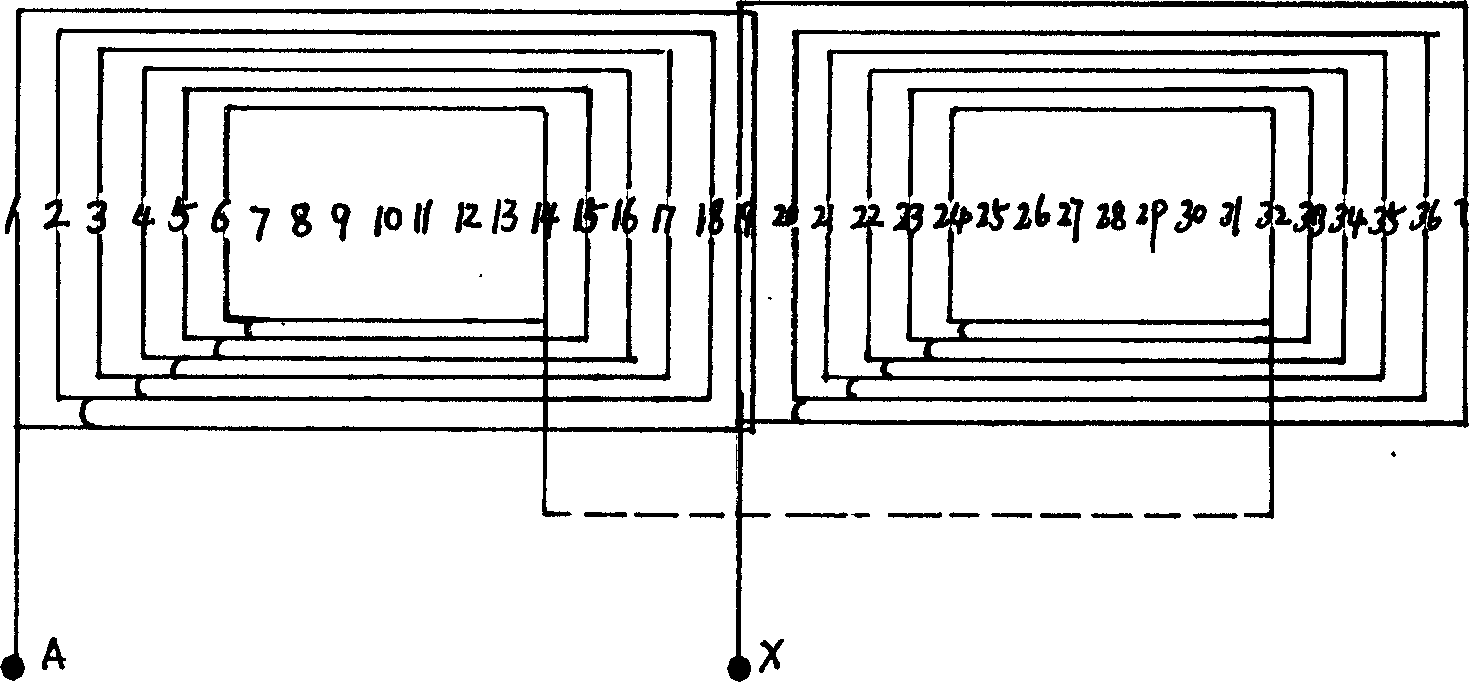

[0007] like figure 1 As shown, the number of stator slots of the motor is 36, and the number of poles is a modified three-phase concentric double-layer winding of a 2-pole, 3-phase motor. The turns ratio from the large circle to the small circle is distributed according to 1:2:3:2. The fundamental winding coefficient Kapl=0.8665, the total harmonic content is 0.89%, and the fundamental winding coefficient Kapl=0.9095 of the conventional winding, the harmonic content is 0.64%. The content is greatly reduced, which can save a lot of electromagnetic wires and electromagnetic materials, and the economic efficiency is very obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com