Supporting floating type centrifugal spinning device and using method thereof

A centrifugal spinning, floating technology, applied in textile and papermaking, spinneret assembly, filament/thread forming, etc., can solve the problems of weak dispersion, easy stacking, and finishing loss of centrifugal spinning fibers , to achieve the effect of improving dispersibility, strong dispersibility and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

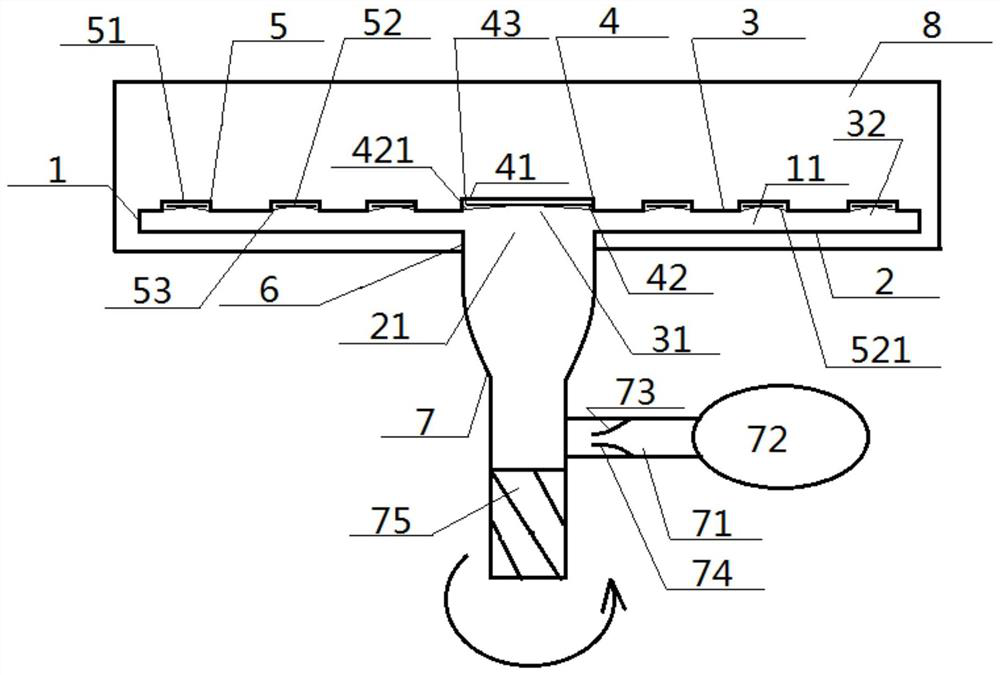

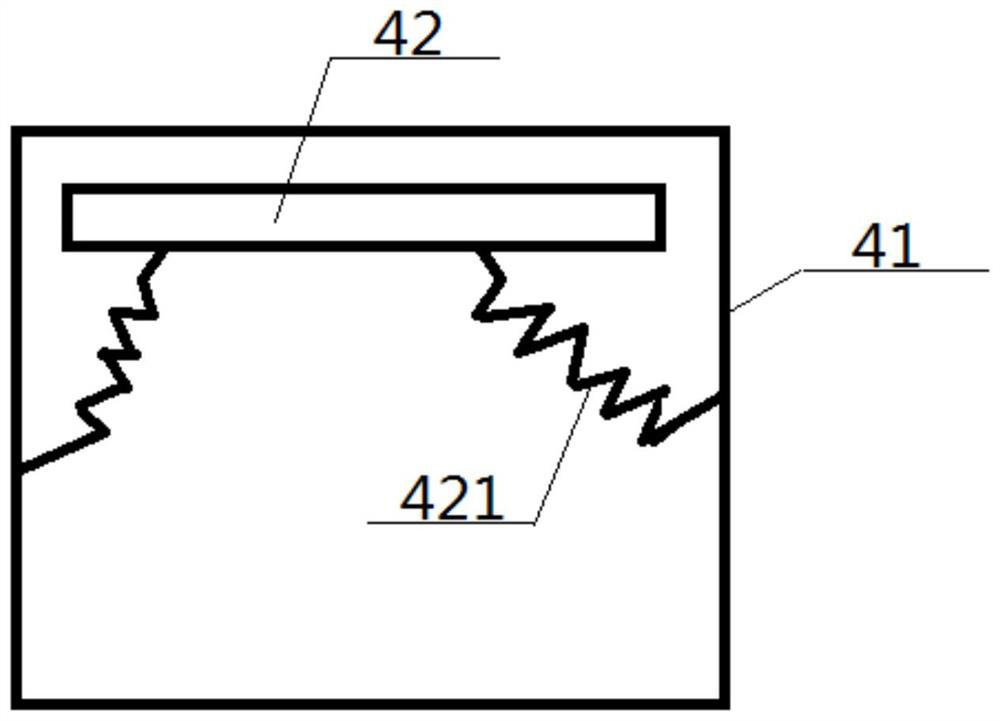

[0054] A floating centrifugal spinning device, comprising a liquid-holding bottom shell 2, a liquid-holding top shell 3, a main nozzle 4 and a plurality of secondary nozzles 5, the periphery of the liquid-holding bottom shell 2 is connected with the liquid-holding shell 1 The periphery of the top shell 3 is connected, and the liquid-holding bottom shell 2, the side enclosure shell 1, and the liquid-holding top shell 3 together form a liquid-holding inner chamber 11, and the middle part of the liquid-holding top shell 3 is provided with a main liquid port 31 and a plurality of The secondary liquid port 32, and the main liquid port 31 is in one-to-one correspondence with the main nozzle 4, and the secondary liquid port 32 is in one-to-one correspondence with the secondary nozzle 5; The bottom of cylinder 41 communicates with liquid-holding cavity 11 through main liquid port 31, and the top of main spray cylinder 41 extends upwards, and the position near its top in main spray cyli...

Embodiment 2

[0057] Basic content is the same as embodiment 1, the difference is:

[0058] Both the main support wire 421 and the secondary support wire 521 are made of metal or elastic plastic. Preferably, both the main support wire 421 and the secondary support wire 521 are metal spring wires. Further preferably, both the main floating sheet 42 and the secondary floating sheet 52 are made of metal material or high temperature resistant plastic.

Embodiment 3

[0060] Basic content is the same as embodiment 1, the difference is:

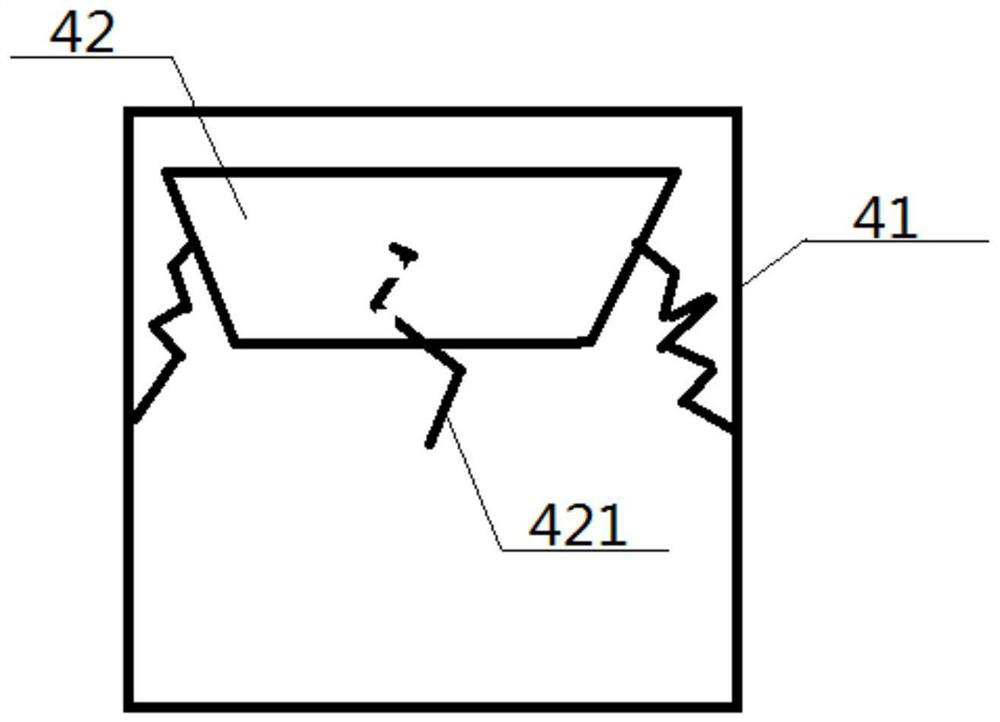

[0061] The main floating plate 42 has the same structure as the secondary floating plate 52, and both include a floating plate bottom plate 44 and a plurality of floating plate nozzles 45 arranged thereon; the floating plate bottom plate 44 is provided with a plurality of floating plate through holes 441, the floating nozzle 45 includes a spray nozzle 451 and a top opening 452 and a bottom opening 453 provided at both ends of the spray nozzle. The middle spray tube 451 communicates with the floating plate through hole 441 through the plate spray bottom opening 453 . The middle tube 451 of the sheet spray is a truncated conical structure with a narrow top and a wide bottom. The area of the top opening 452 of the sheet spray is smaller than the area of the bottom opening 453 of the sheet spray.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com