Production method of superfine high count yarn

A production method and high-slender technology, applied in the field of yarn production, can solve the problems of economical constraints, labor cost and lack of advantages, etc., and achieve the effect of improving spinning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

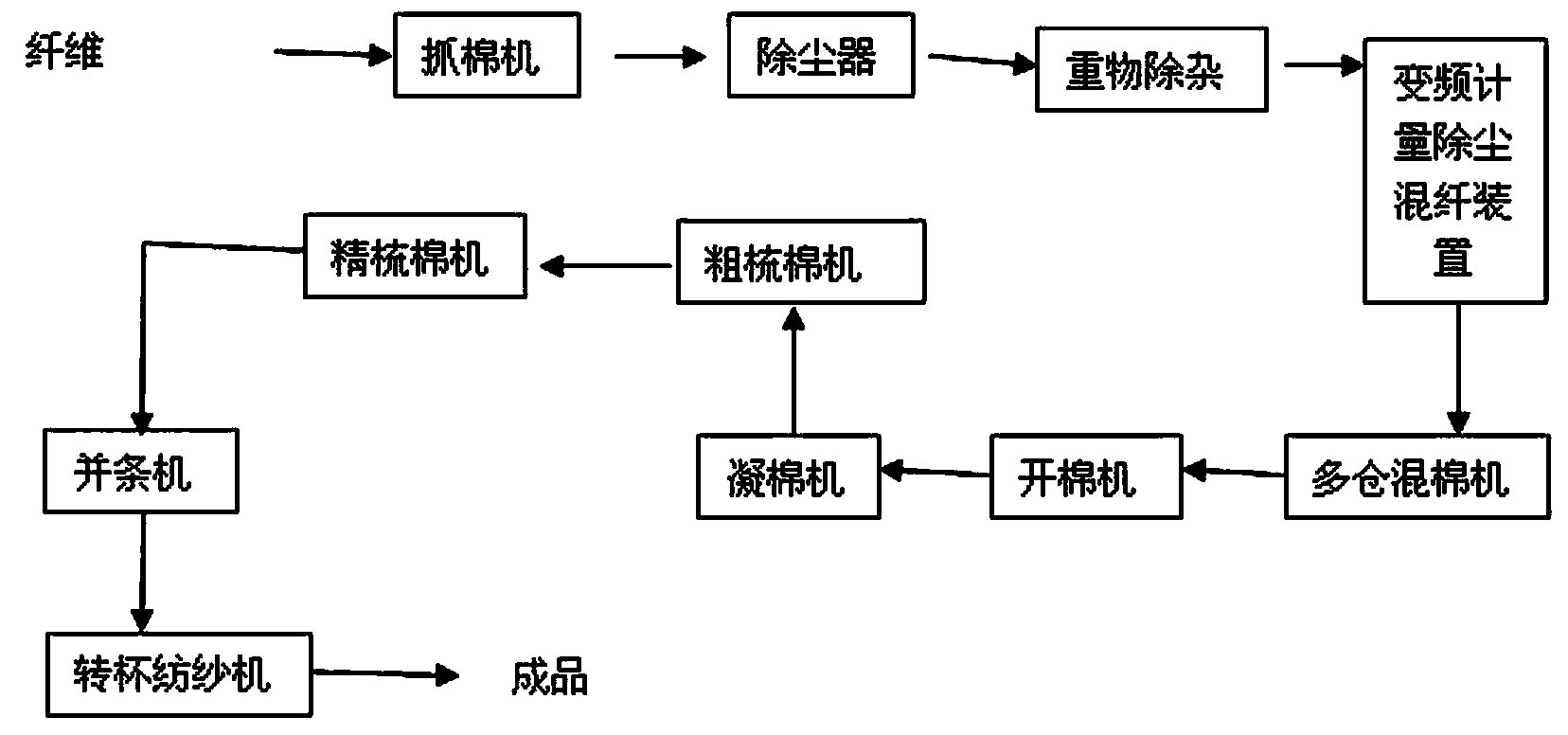

Method used

Image

Examples

Embodiment 1

[0040] Spinning 40 s super fine high count yarn

[0041] Step 1. Arrange the modal fiber bales with a fineness of 1.0dtex, a length of 32mm, and a dry strength of 2.5cN / dtex on the cotton path, and the fiber bales are grasped and loosened into small pieces and small fiber bundles by the plucking machine, and the process is completed. Grabbing process;

[0042] Step 2, dedusting the small fiber bundles in the step 1 on the conveying pipeline by blowing air, using the heavy object removal process to remove heavy objects with a specific gravity greater than the small fiber bundles, and completing the dust removal and heavy object removal processes;

[0043] Step 3, tearing the small cellulose through step 2 into single fibers with a cotton opener, and completing the cotton opening process;

[0044] Step 4, the monofilament in the step 3 is carried out impurity-gathering with the condensing machine, completes the condensing process;

[0045] Step 5. Use a carding machine to str...

Embodiment 2

[0051] Spinning 45 s super fine high count yarn

[0052] Step 1. Arrange the modal fiber bales with a fineness of 0.99dtex, a length of 35mm, and a dry strength of 3.5cN / dtex on the cotton path, and the fiber bales are grasped and loosened into small pieces and small fiber bundles by the catching machine, and the completion Grabbing process;

[0053] Step 2, dedusting the small fiber bundles in the step 1 on the conveying pipeline by blowing air, using the heavy object removal process to remove heavy objects with a specific gravity greater than the small fiber bundles, and completing the dust removal and heavy object removal processes;

[0054] Step 3, tearing the small cellulose through step 2 into single fibers with a cotton opener, and completing the cotton opening process;

[0055] Step 4, the monofilament in the step 3 is carried out impurity-gathering with the condensing machine, completes the condensing process;

[0056] Step 5. Use a carding machine to straighten an...

Embodiment 3

[0062] spinning 50 s super fine high count yarn

[0063] Step 1. Arrange the modal fiber bales with a fineness of 0.9dtex, a length of 35mm and a dry strength of 3.0cN / dtex on the cotton path, and the fiber bales are grasped and loosened into small pieces and small fiber bundles by the catching machine, and the completion Grabbing process;

[0064] Step 2, dedusting the small fiber bundles in the step 1 on the conveying pipeline by blowing air, using the heavy object removal process to remove heavy objects with a specific gravity greater than the small fiber bundles, and completing the dust removal and heavy object removal processes;

[0065] Step 3, tearing the small cellulose through step 2 into single fibers with a cotton opener, and completing the cotton opening process;

[0066] Step 4, the monofilament in the step 3 is carried out impurity-gathering with the condensing machine, completes the condensing process;

[0067] Step 5. Use a carding machine to straighten and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com