Novel semi-continuous high-speed spinning machine

A semi-continuous, spinning machine technology, applied in the field of spinning equipment, can solve the problems of inability to increase the spinning speed and insufficient thread response, and achieve the effects of convenient individual speed increase, easy control, and simplified transmission structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

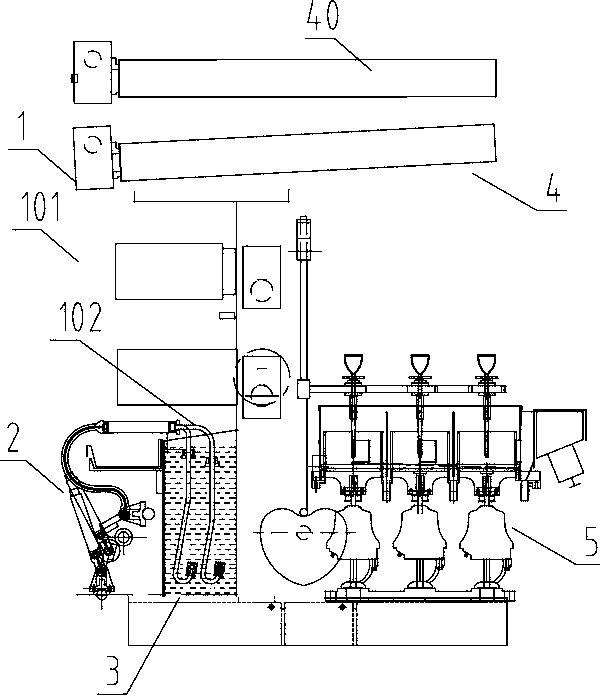

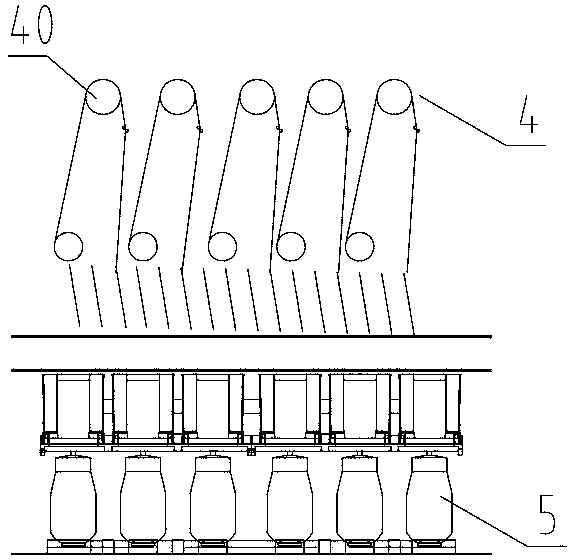

[0089] Such as Figure 7 , Figure 8 with Figure 10 As shown, the semi-continuous high-speed spinning machine provided in this embodiment includes a frame 1, a glue supply device 2, a filament forming device 3, a spinning device 4, and a winding device 5, and the spinning device 4 includes a spinning device There are three spinning rolls 40, the spinning rolls 40 are arranged transversely to the operating surface of the spinning surface, and the spinning rolls 40 are parallel to each other.

[0090] Such as Figure 9 As shown, the operating surface of the spinning surface is a horizontal working surface located in the spinning surface area, and the horizontal arrangement of the spinning roller 40 relative to the operating surface of the spinning surface means that when the spinning worker faces the winding device, the spinning roller 40 is installed horizontally relative to spinning workers.

[0091] There are three spinning rolls 40 , which are drafting roll 404 , coagul...

Embodiment 2

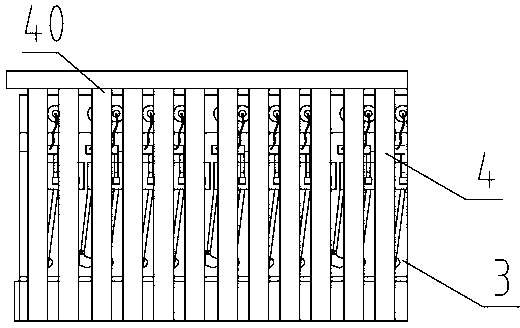

[0098] Such as Figure 11 As shown, this embodiment is basically the same as Embodiment 1, except that the spinning roll 40 is arranged obliquely from one end to the other relative to the horizontal plane. The spinning roll 40 has a length of 1400 mm and a diameter of 100 mm.

Embodiment 3

[0100] This embodiment is basically the same as Embodiment 1, and the difference is: among the three spinning rollers 40, one of the spinning rollers 40 is connected to a driving device alone, and the other two spinning rollers 40 are connected to a driving device; the length of the spinning rollers 40 is 800mm , with a diameter of 50mm. Of course, it is also possible that the three spinning rollers 40 are all connected to one driving device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com