Spinning method of high-viscosity polyester melts for reducing oligomers

A polyester melt and oligomer technology, used in filament forming treatment, textile and papermaking, feeding solution to spinnerets, etc. , filter hole blockage and other problems, to reduce the possibility of generation, reduce the chance of internal shear heating, reduce the effect of melt flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

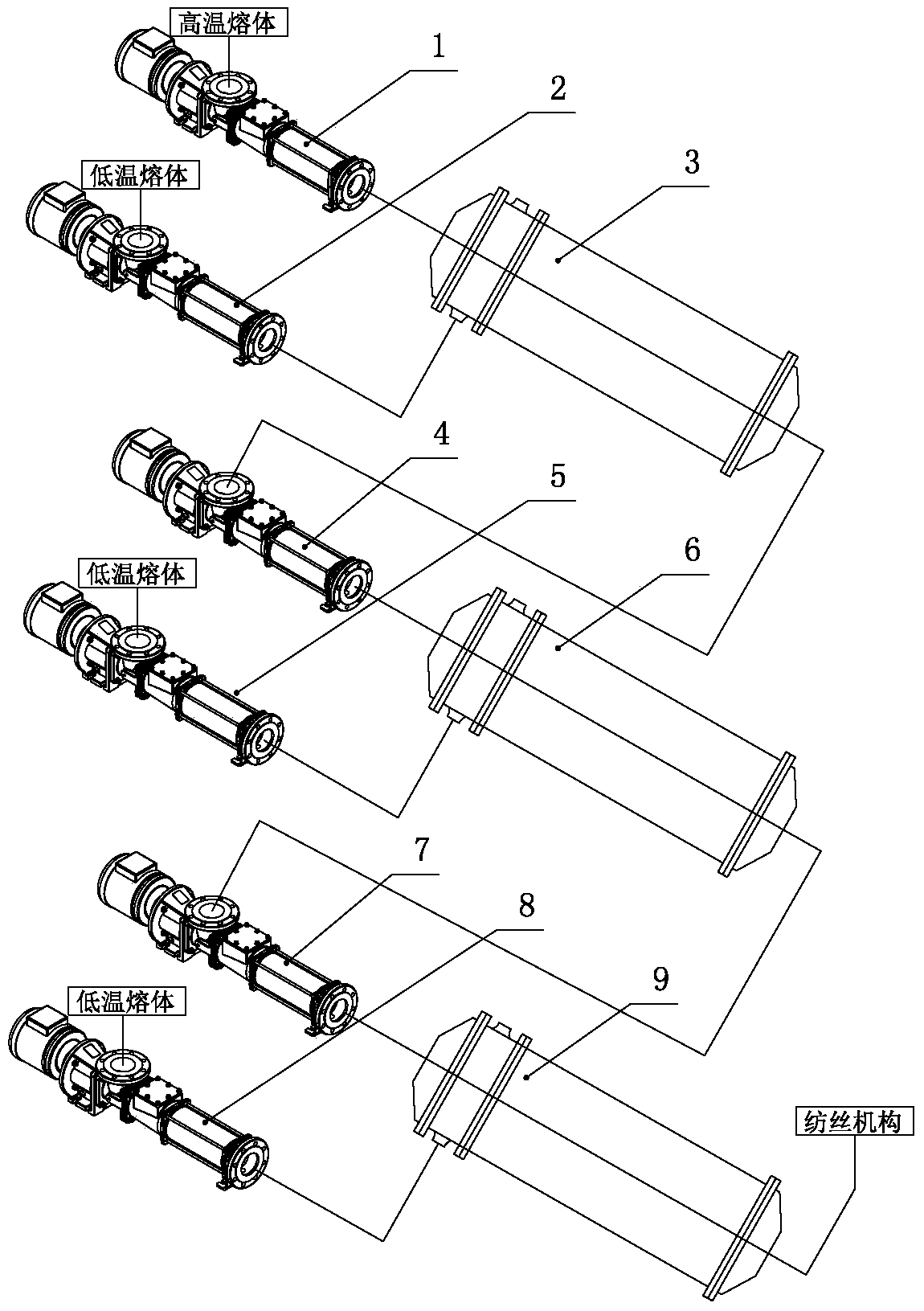

[0024] Such as figure 1 Shown, be a kind of spinning method that reduces the high viscosity polyester melt of oligomer, comprises the steps:

[0025] (1) The high-temperature melt after viscosity increase is transported to the spinning mechanism through the three-stage screw pump; the temperature of the high-temperature melt at the output end of the screw pump at each level is 285±5°C; the three-stage screw pumps are respectively the first-stage screw pump 1 , the second-stage screw pump 4 and the third-stage screw pump 7;

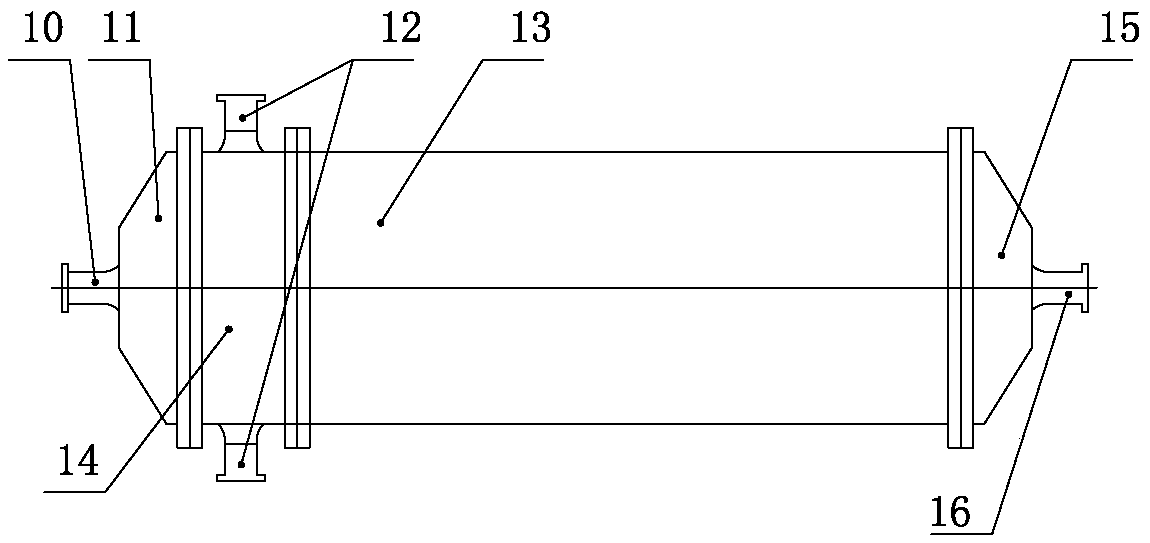

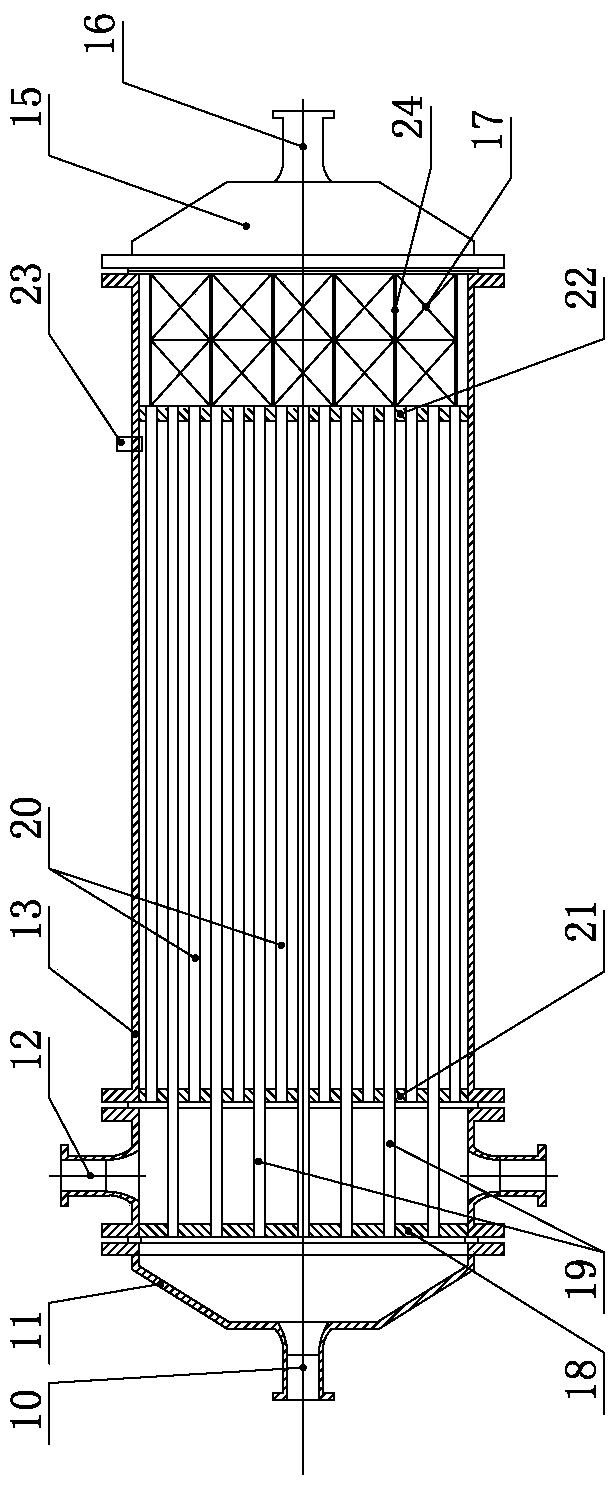

[0026] (2) Install a mixer after each stage of the multi-stage screw pump, specifically: the outlet of the first-stage screw pump 1 is connected to the high-temperature melt inlet 10 of the first-stage mixer 3, and the mixed output of the first-stage mixer 3 Port 16 is connected to the inlet of the second-stage screw pump 4, the outlet of the second-stage screw pump 4 is connected to the high-temperature melt inlet 10 of the second-stage mixer 6, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com