Fluid distribution method for rapid-cooling heat exchanger

A quenching heat exchanger and fluid distribution technology, applied in the direction of heat exchanger shell, fluid circulation arrangement, refrigerator, etc., can solve the problems of long residence time, uncontrollable adiabatic residence time, etc., to improve the utilization rate and slow down the rising rate. , Improve the effect of operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

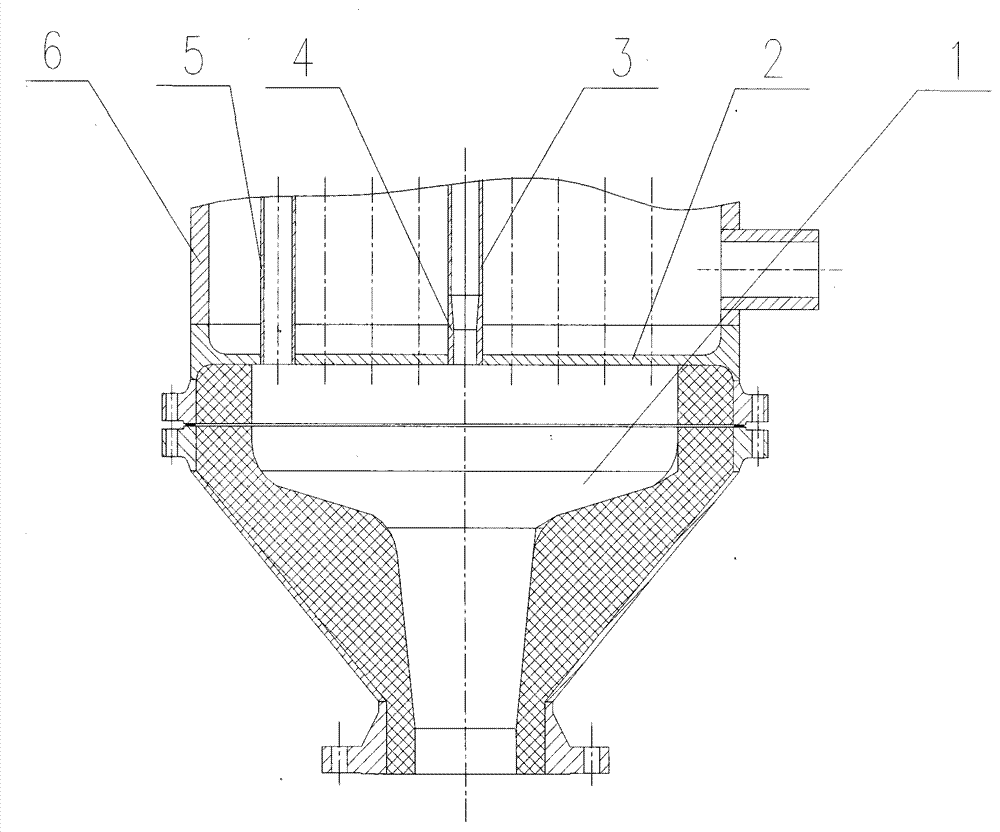

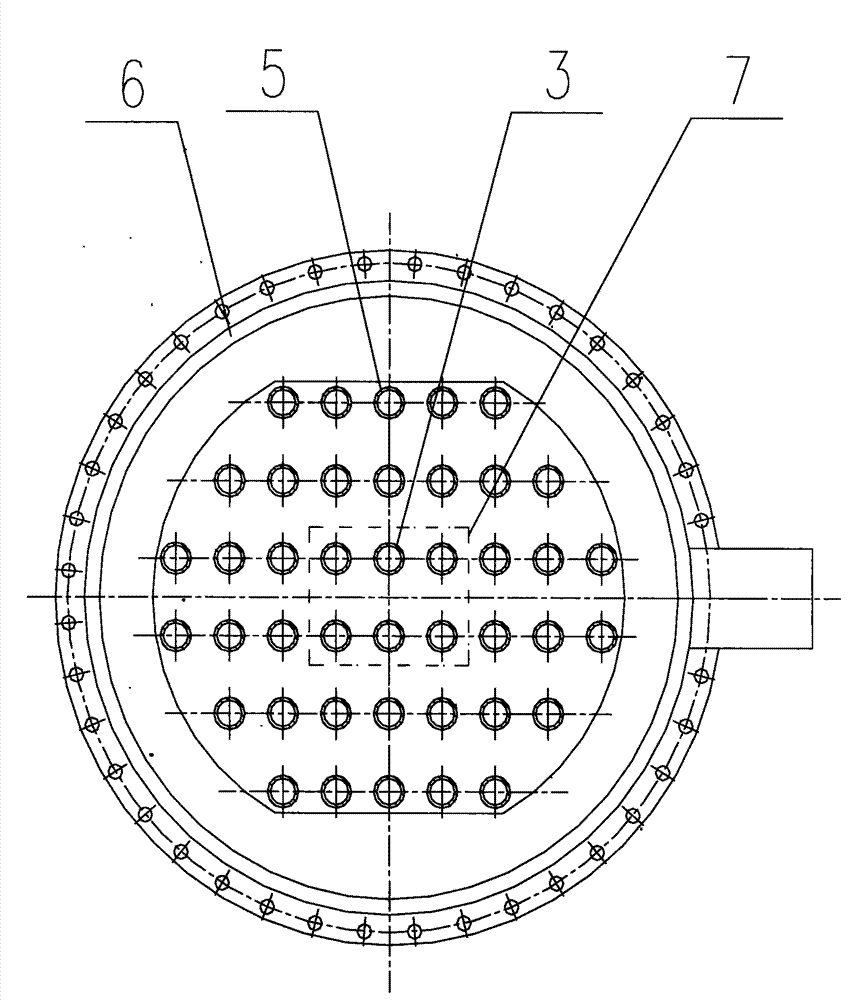

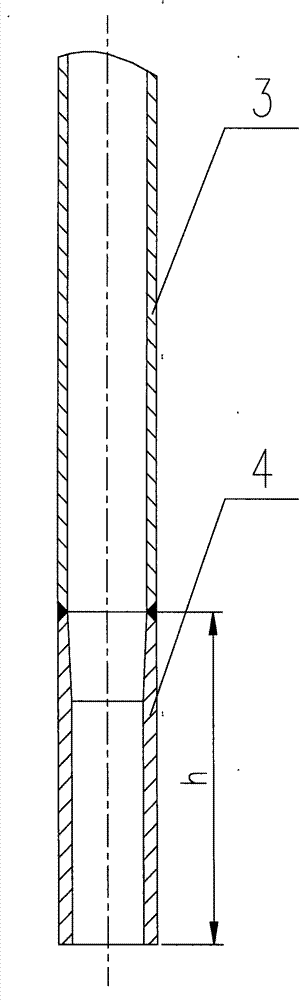

[0021] refer to Figure 1 ~ Figure 3 , a fluid distribution system of a quenching heat exchanger includes a quenching heat exchanger inlet channel 1, an inlet tube plate 2, a central heat exchange tube 3, a short flow equalizing tube 4, surrounding heat exchange tubes 5, a cylinder 6 and other components. The central heat exchange tube 3 is composed of two tubes, the entrance is a short flow equalizing tube 4, and the exit is a section of equal diameter tube. The two are butt welded to form a complete central heat exchange tube 3 after welding. The inner diameter of the short flow equalizing tube 4 is smaller than the inner diameter of the equal-diameter tube of the central heat exchange tube 3 , and the inner diameter of the equal-diameter tube at the outlet of the central heat exchange tube 3 is the same as that of the surrounding heat exchange tubes 5 .

[0022] The following specific examples were simulated and calculated by computational fluid dynamics (CFD). There are 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com