Method for alleviating coking of coke tower top oil gas pipeline

A technology for oil and gas at the top of the tower, applied in the petroleum industry, cracking, non-catalytic thermal cracking and other directions, can solve the problem that the temperature of the oil and gas at the top of the coke tower cannot be reduced, and achieve the effects of reducing the carrying capacity, reducing coking and improving the processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

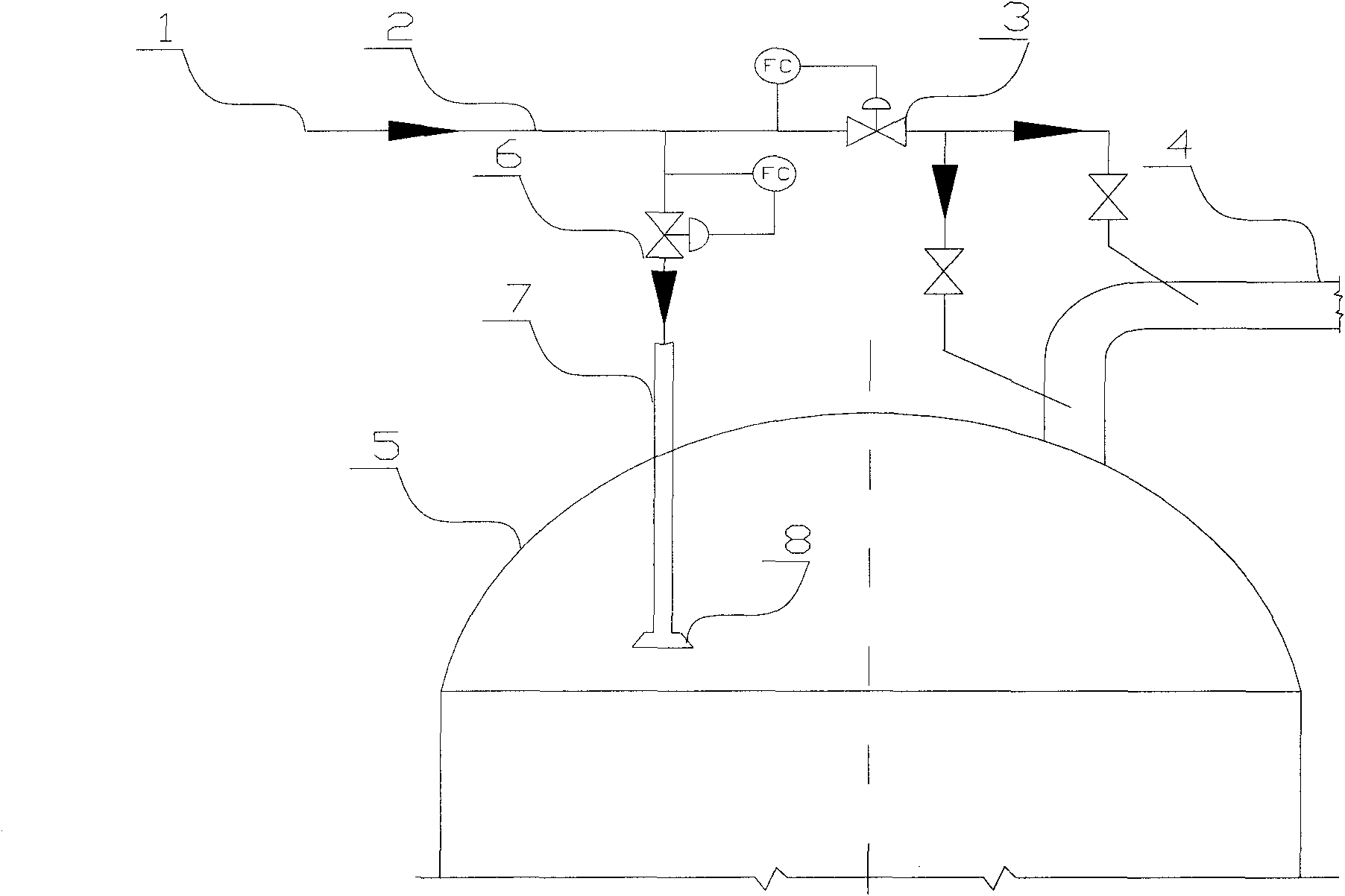

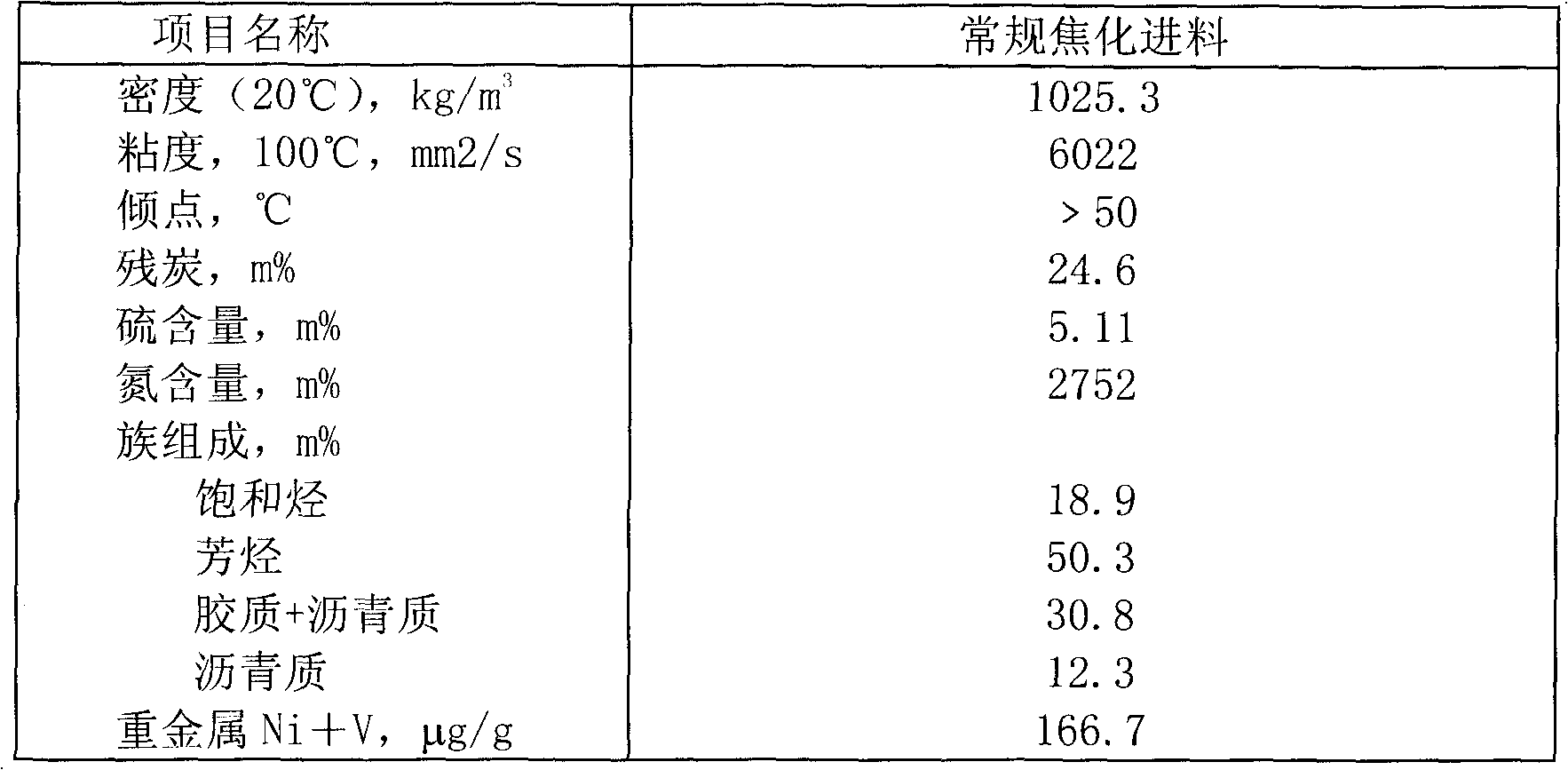

[0027] The properties of raw oil are shown in Table 1. The high-temperature material at 498°C from the radiant section of the heating furnace enters the tower from the bottom of the coke tower, and the oil and gas after entering the tower undergo coking reaction; inject an appropriate amount of quenching oil at 4m below the oil and gas outlet at the top of the coke tower, and the quenching oil comes from coking fractionation The 200°C coking wax oil in the coke tower is sprayed from three evenly distributed nozzles with droplets of 50 μm to 300 μm and covers the cross section of the coke tower. The pipeline is quenched again to 420°C by the traditional method, and then goes to the fractionation tower for fractionation. Other operating conditions and test results are shown in Table 2.

Embodiment 2

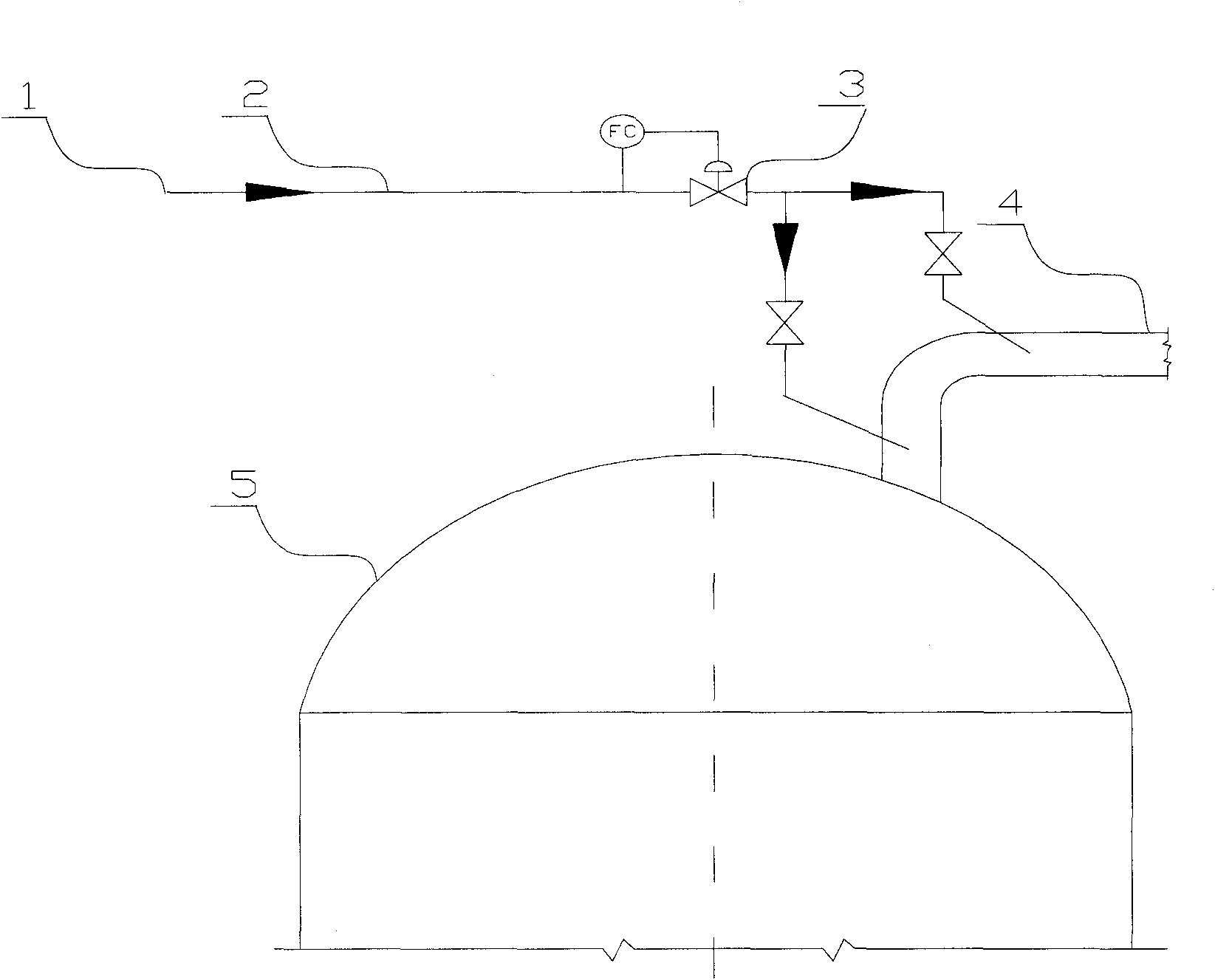

[0031] The raw material oil property is with embodiment 1. The high-temperature material at 498°C from the radiant section of the heating furnace is fed from the upper part of the coke tower, and the feed is dispersed to the tower wall at 0.3m below the tangential height of the coke tower through the distributor and enters the tower in a swirling manner. After entering the tower Coking reaction of the oil and gas in the coke tower; inject an appropriate amount of quenching oil at 2.5m below the oil and gas outlet at the top of the coke tower. Droplets spray out and cover the cross-section of the coke tower, and the temperature of the oil and gas exiting the tower after quenching is 441°C; the oil and gas exiting the tower is quenched to 423°C by traditional methods on the outlet pipeline, and then goes to the fractionating tower for fractionation. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com