Patents

Literature

59results about How to "Conductivity adjustable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polythiophenes having alkyleneoxythia thiophene units in electrolyte capacitors

InactiveUS7341801B2Reduce conductivityConductivity adjustableHybrid capacitor electrolytesHybrid capacitor electrodesPolymer scienceElectrolysis

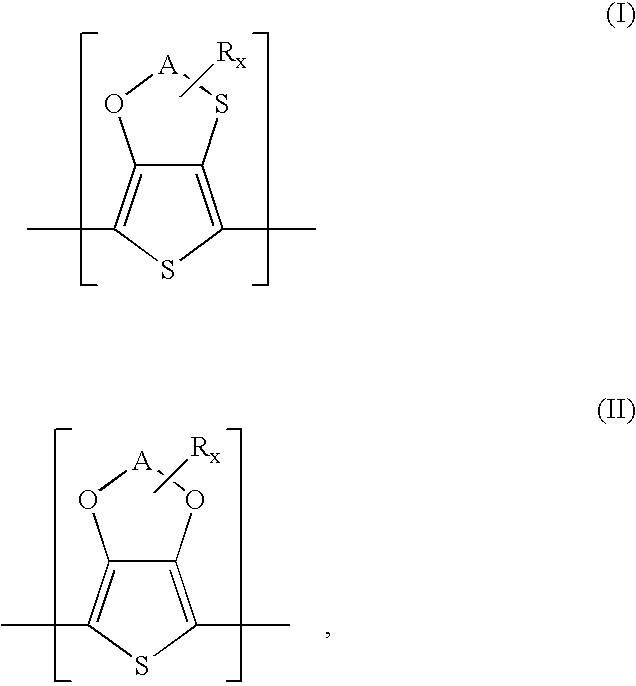

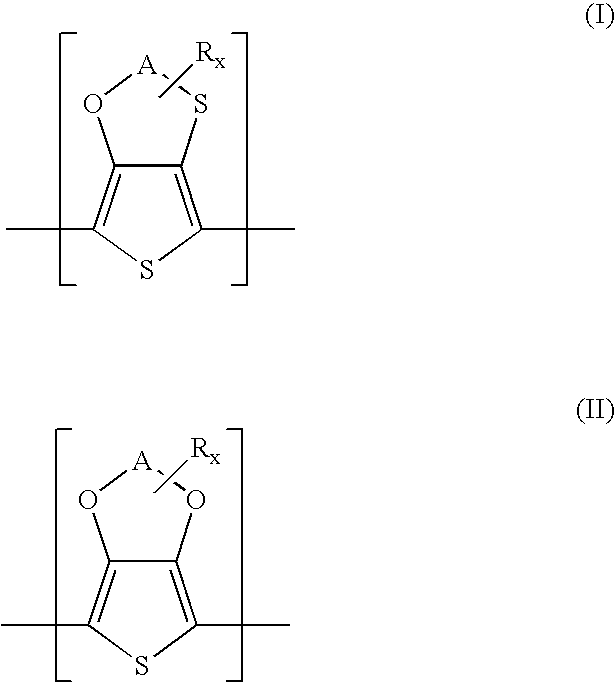

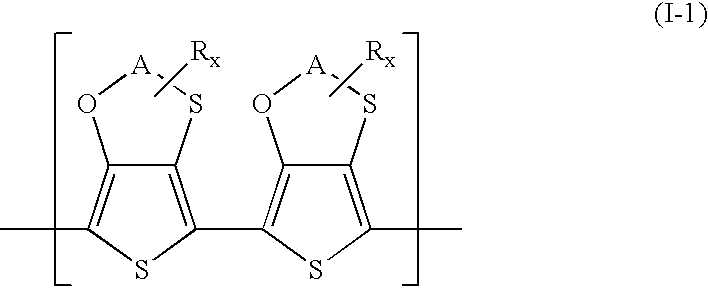

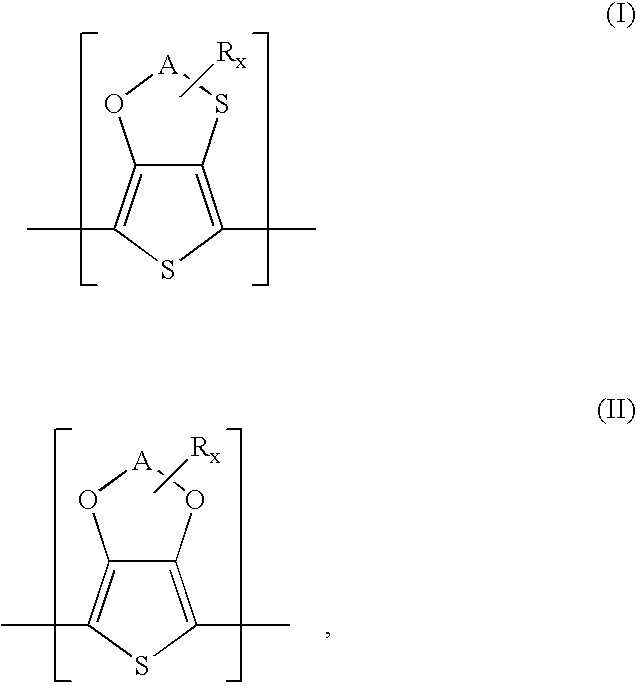

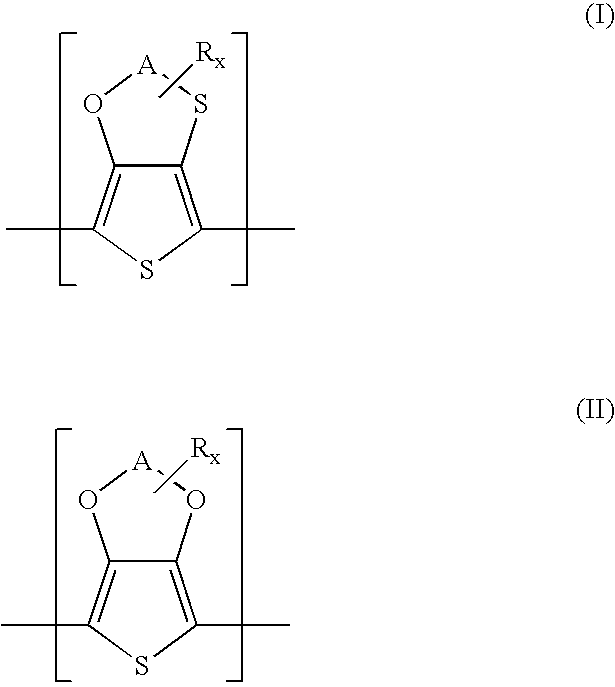

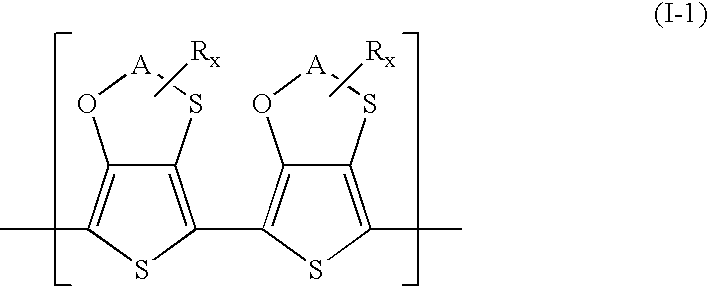

Electrolyte capacitors containing certain polythiophenes are described. More particularly, the polythiophenes have backbones containing repeating units of the following general formula (I) and / or repeating units of the following general formula (II),wherein A is, for example, a C1-C5-alkylene radical, R is, for example, a C1-C18-alkyl radical, and x is an integer from 0 to 8. Also described are dispersions comprising such polythiophenes, and the use of such polythiophenes or dispersions thereof for producing conductive layers.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

Polythiophenes having alkyleneoxythia thiophene units in electrolyte capacitors

InactiveUS20050013094A1Reduce conductivityConductivity adjustableHybrid capacitor electrolytesHybrid capacitor electrodesCapacitorPolymer chemistry

Electrolyte capacitors containing certain polythiophenes are described. More particularly, the polythiophenes have backbones containing repeating units of the following general formula (I) and / or repeating units of the following general formula (II), wherein A is, for example, a C1-C5-alkylene radical, R is, for example, a C1-C18-alkyl radical, and x is an integer from 0 to 8. Also described are dispersions comprising such polythiophenes, and the use of such polythiophenes or dispersions thereof for producing conductive layers.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

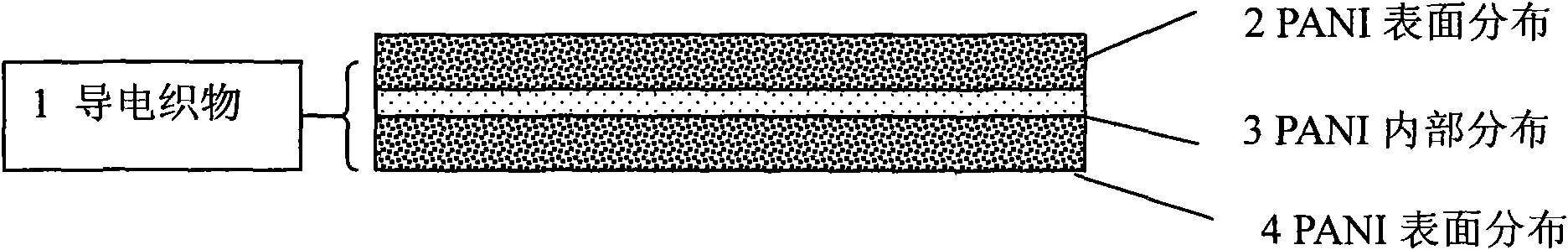

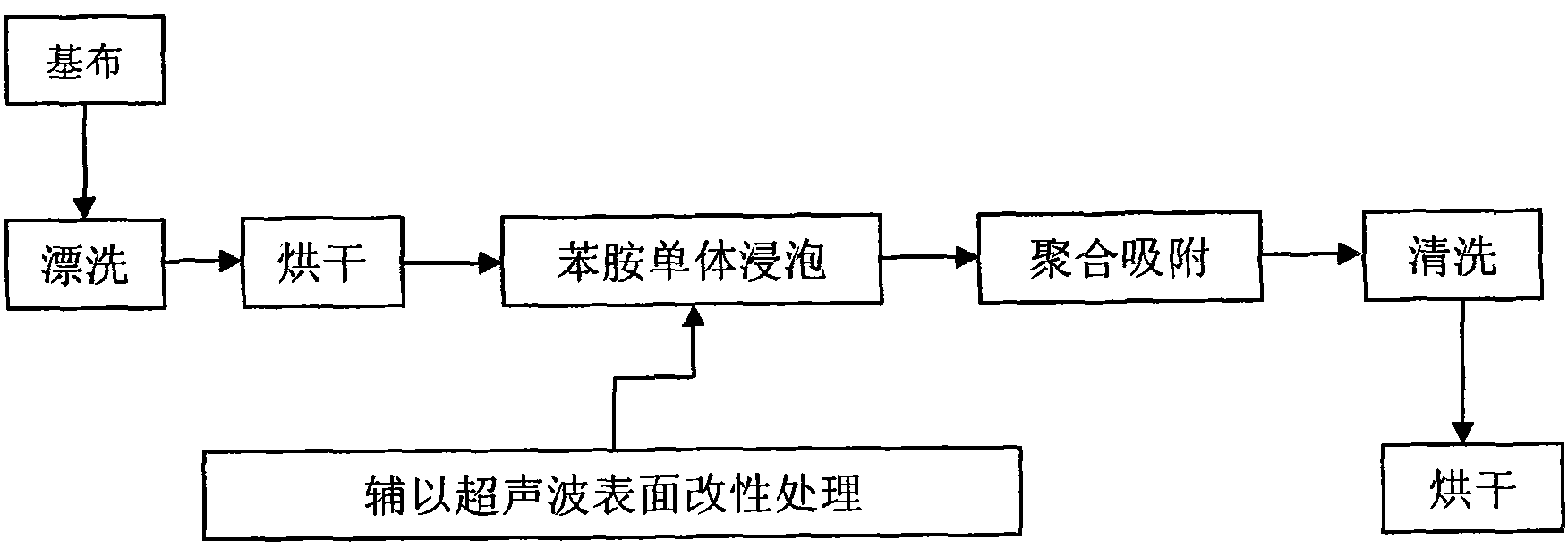

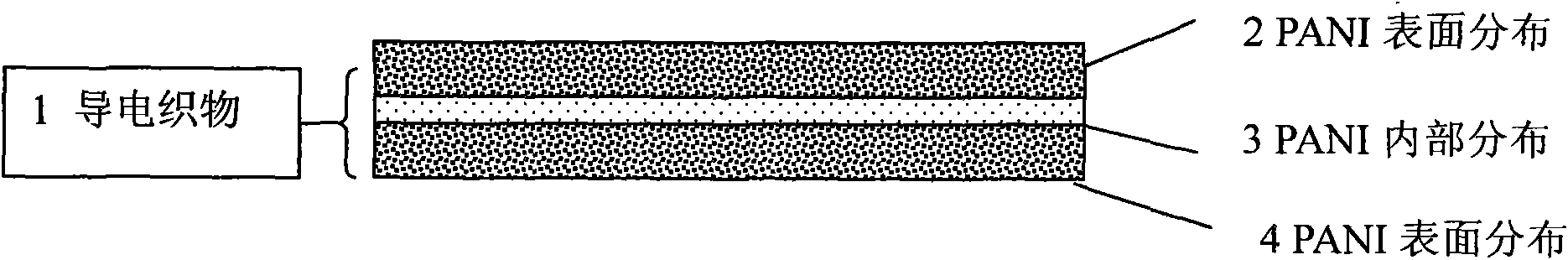

Novel method for preparing polyaniline composite conductive fabric

InactiveCN102337679AAutomatic elimination of influenceAccurate measurementPhysical treatmentFiberConductive polymer

The invention relates to a novel method for preparing a polyaniline composite conductive fabric. The novel method for preparing a polyaniline composite conductive fabric is characterized in that a conductive fabric with good conductive properties is prepared from a chemical fiber fabric as a matrix material and polyaniline as a conductive material through an in-situ polymerization method (also known as an in-situ adsorption polymerization method). The novel method for preparing a polyaniline composite conductive fabric adopts an ultrasonic dipping treatment process as an auxiliary process of a base fabric dipping process adopting aniline. Therefore, the novel method for preparing a polyaniline composite conductive fabric has good surface modification effects on a base fabric, is beneficial for depositing a conductive material on fiber surfaces of the base fabric in polymerization and enabling the conductive material to permeate into fibers of the base fabric, and improves conductivity and conductive stability. A conductive fabric prepared by the novel method has high conductivity and good environmental stability, is easy for synthesis, and keeps physical and mechanical properties belonging to fabrics on the basis of acquirement of conductive properties, wherein surface resistance R of the conductive fabric is reduced to a value of 1 to 5 kilo-ohm.

Owner:WUYI UNIV

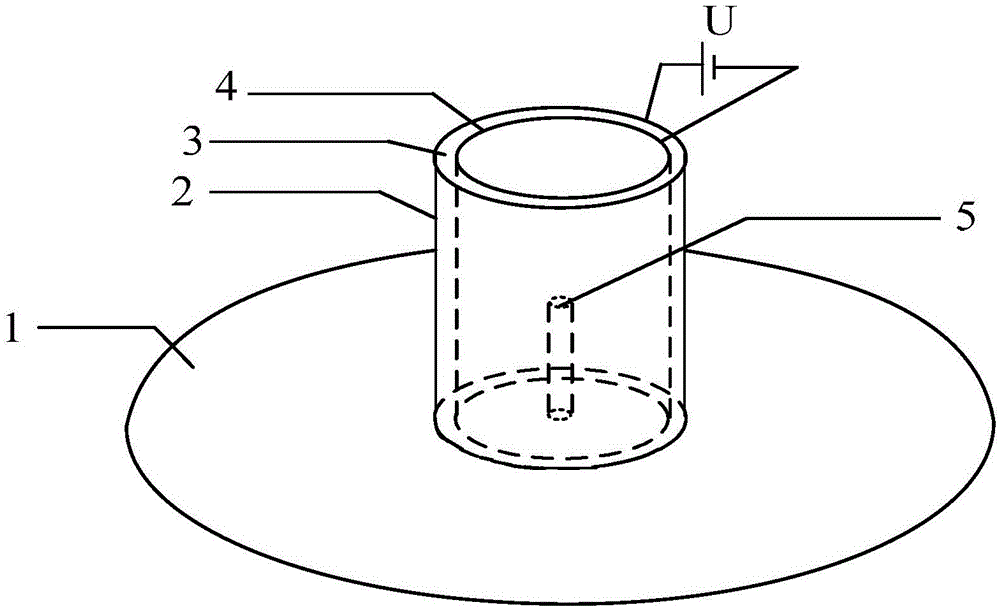

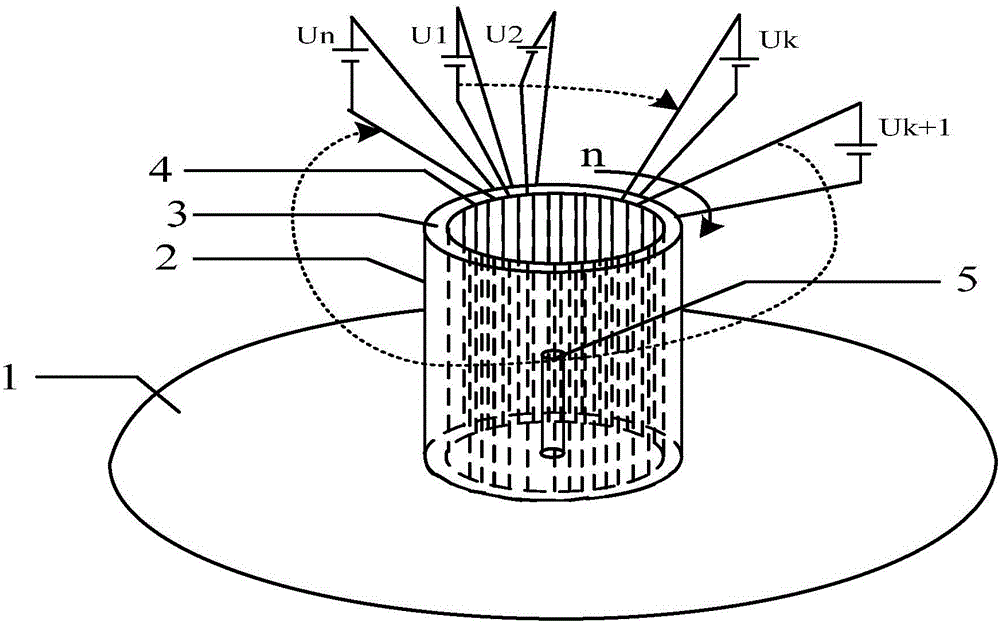

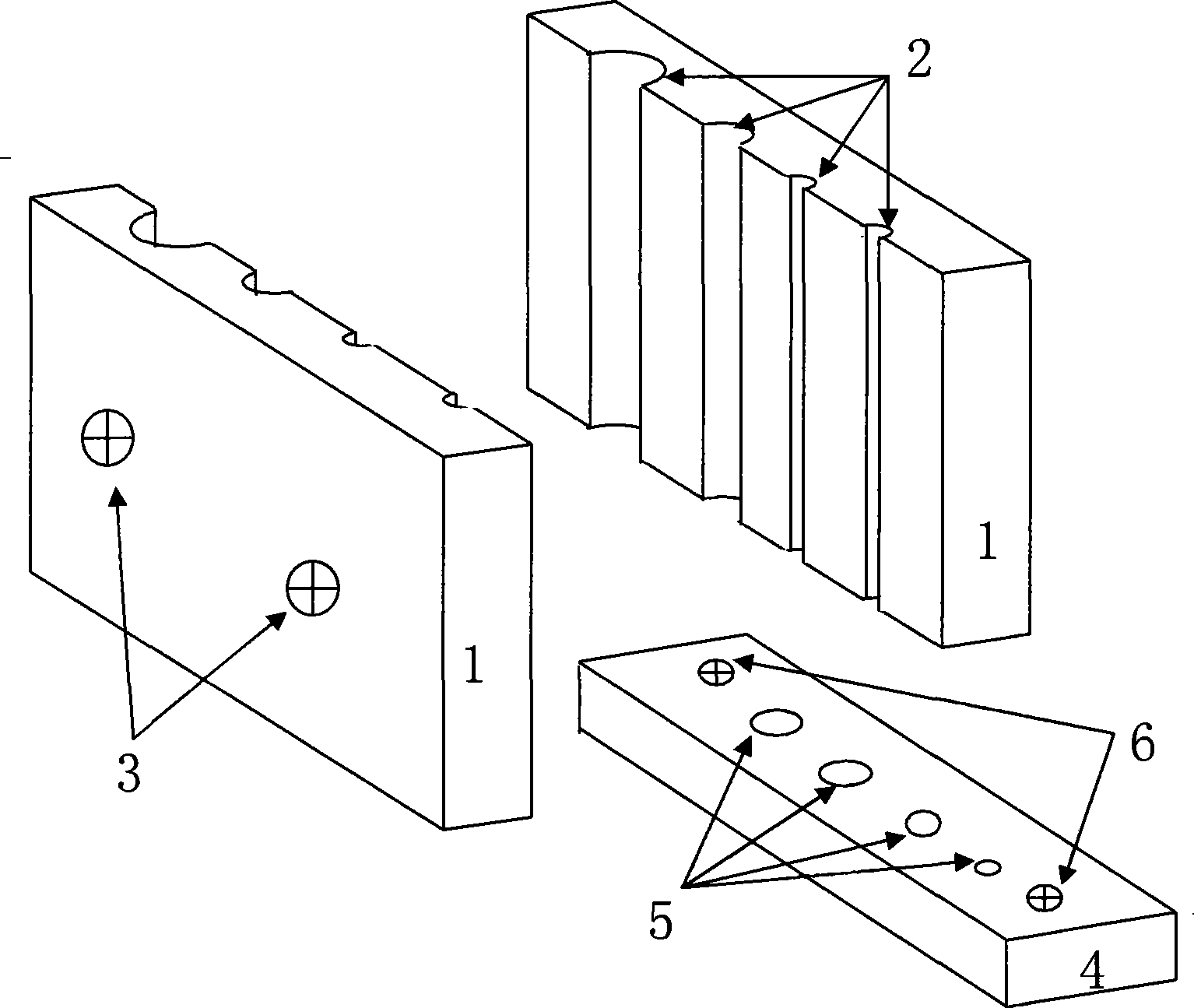

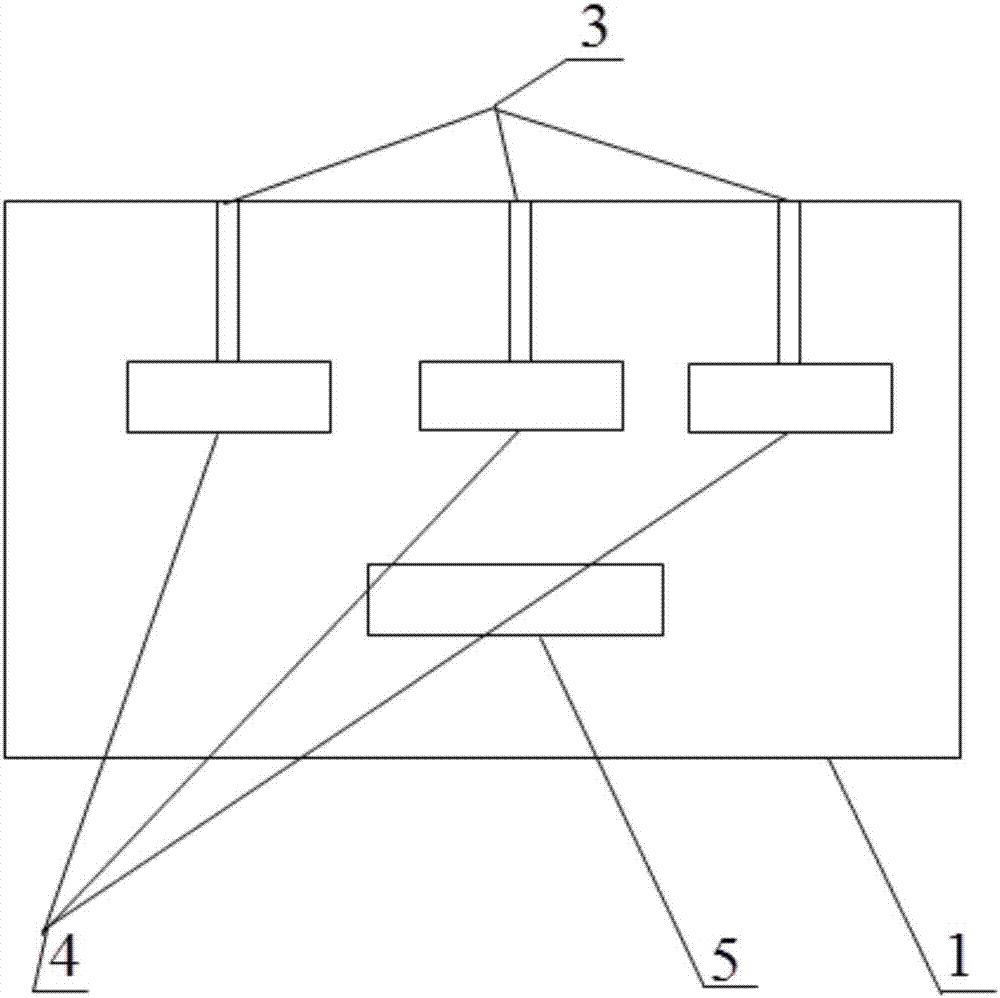

Reconfigurable antenna based on graphene coating

ActiveCN105161832AAchieve broadbandAchieving UWBRadiating elements structural formsDielectricReconfigurable antenna

The invention discloses a reconfigurable antenna based on a graphene coating. The reconfigurable antenna comprises an antenna body which comprises a ground plate and a monopole erected on the ground plate. The antenna body further comprises a dielectric sleeve which is thoroughly through and shaped like a hollow cylinder. The dielectric sleeve is positioned on the group plate and at the outer periphery of the monopole. One of inner and outer side surfaces of the dielectric sleeve is coated with a grapheme coating, and the other is coated with a silicon coating. Each of the graphene coating and the silicon coating is connected with one end of external offset voltage, and a certain gap is reserved between the graphene coating or the silicon coating connected with the anode of the external offset voltage and the ground plate. The external offset voltage is controlled by dividing the graphene coating and the silicon coating into multiple blocks, so that the antenna is enabled to have characteristics of wide band, reconfigurable frequency and / or reconfigurable radiation pattern.

Owner:GUILIN UNIV OF ELECTRONIC TECH

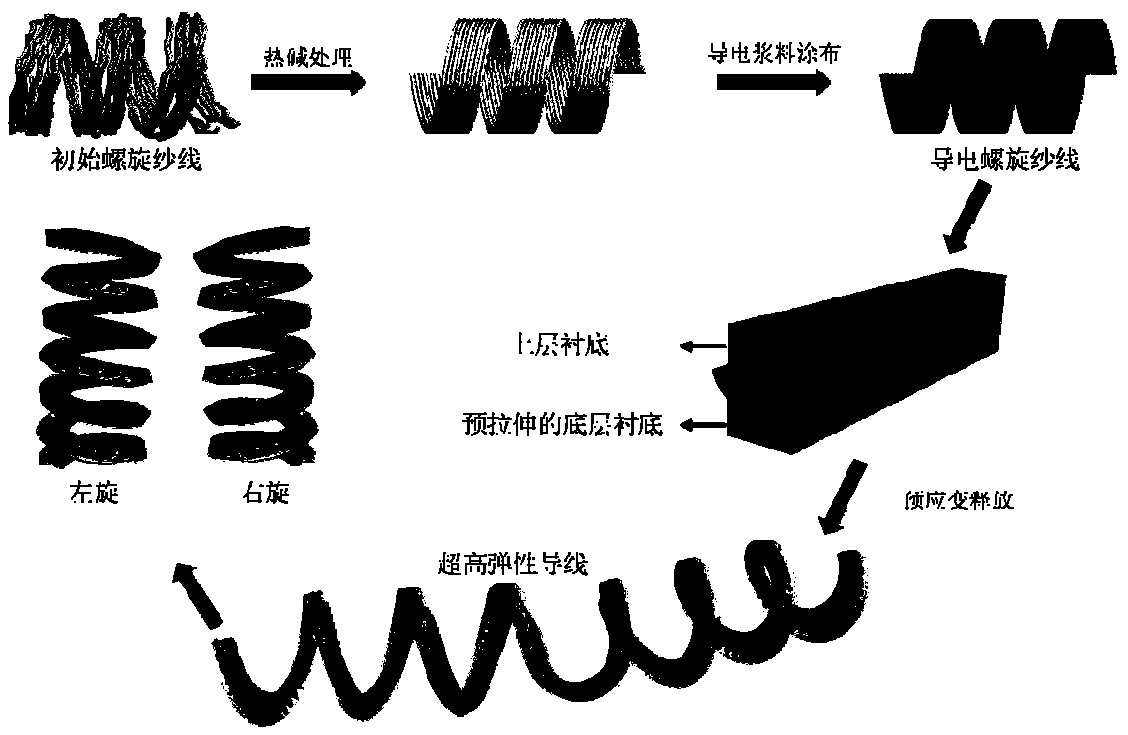

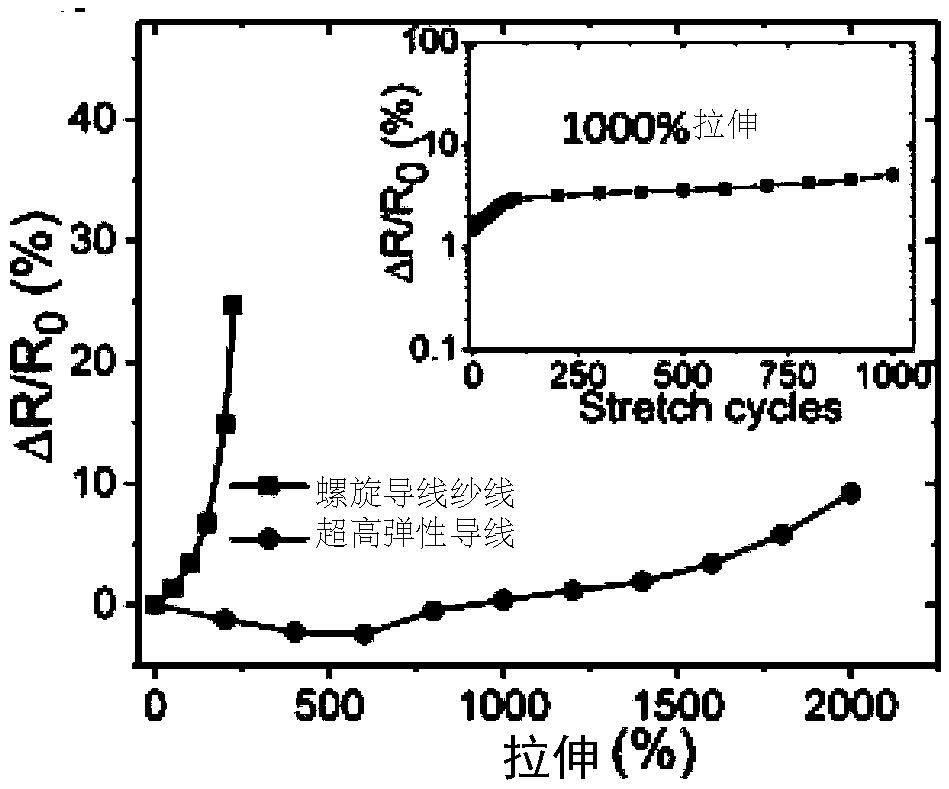

Ultrahigh-elasticity wire and preparation method thereof

ActiveCN108520795ANovel preparation methodEasy to prepareExtensible conductorsExtensible conductor cablesFiberElastic substrate

The invention provides an ultrahigh-elasticity wire and a preparation method thereof. The ultrahigh-elasticity wire is in a helical structure, and the ultrahigh-elasticity wire comprises a bottom elastic substrate, flexible conductive fibers adhered to the surface of the bottom elastic substrate and in a helical structure, and a flexible filling substrate embedded in the flexible conductive fibers.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Electroconductive plastic with high electrical conductivity and preparation method thereof

InactiveCN102212244AConductiveEvenly dispersedNon-conductive material with dispersed conductive materialPolymer scienceFiltration

The invention provides an electroconductive plastic with high electrical conductivity and a preparation method thereof. The electroconductive plastic is composed of a plastic matrix, electroconductive polyaniline, a dispersant and an antioxidant. The preparation method comprises the following steps: 1. synthesis of the electroconductive polyaniline: adding aniline to distilled water on the basis of using an inorganic acid as a doping agent, dissolving ammonium persulfate in the distilled water to obtain an ammonium persulfate solution, dropwise adding the ammonium persulfate solution at a constant speed, carrying out suction filtration, washing and drying; and 2. preparation of the electroconductive plastic: firstly adding a plastic matrix resin and the dispersant to a mixing roll, mixingfor some time; then adding the plastic matrix resin; then adding polyaniline until the two components are completely mixed to obtain a mixture; introducing the mixture to a mold, hot-pressing; and cooling to room temperature. According to the invention, a hot-melting and blending method is utilized to prepare the electroconductive plastic with high electrical conductivity. The obtained electroconductive plastic can be used for overcoming the defects that the existing electroconductive plastic has large filling amount of electroconductive filler, poor compatibility of the filler and the plastic matrix and the like, the volume conductivity of the electroconductive plastic provided by the invention can be adjusted within a large range, and the retention rates of original mechanical properties and processing properties of the plastic base body are high.

Owner:HARBIN ENG UNIV

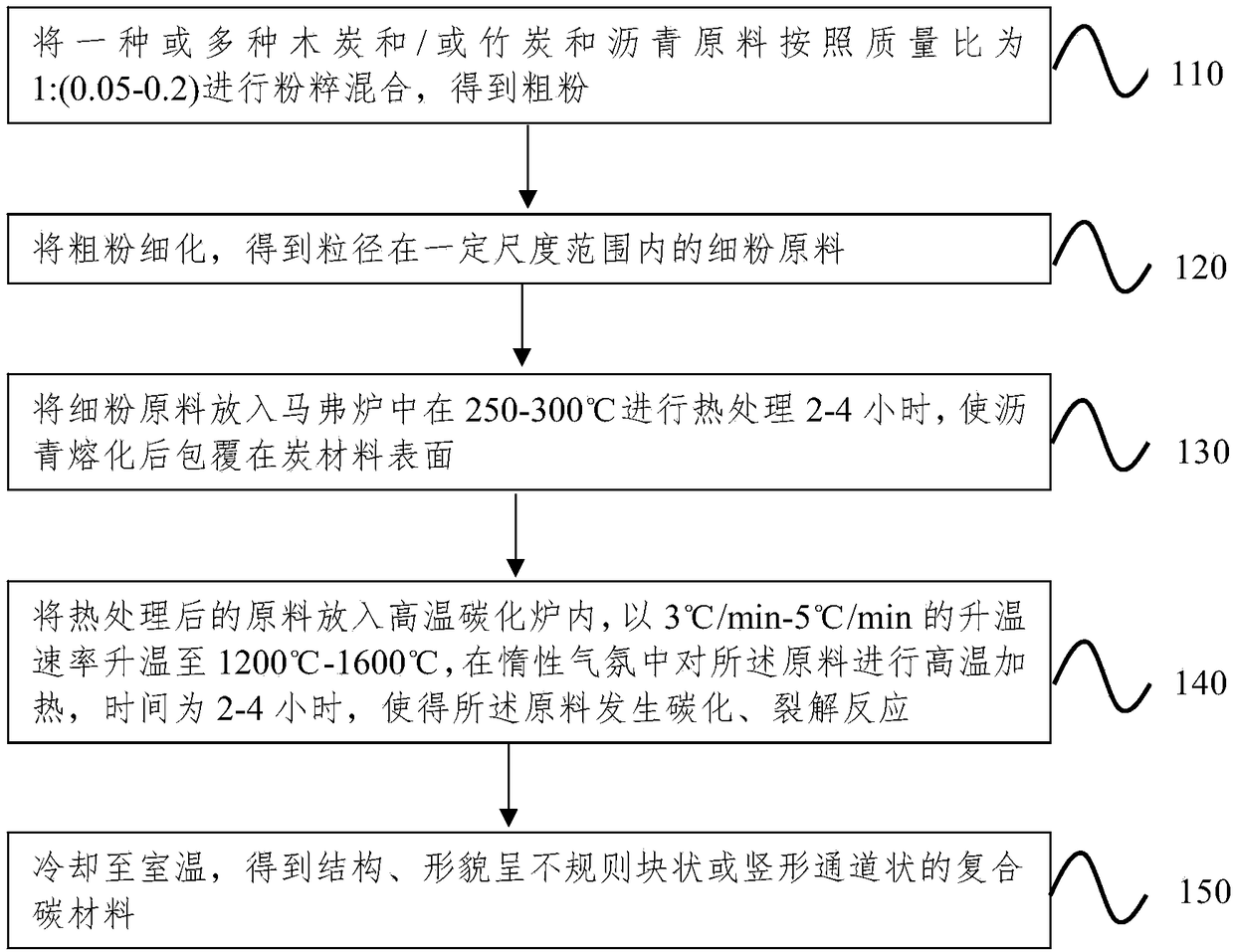

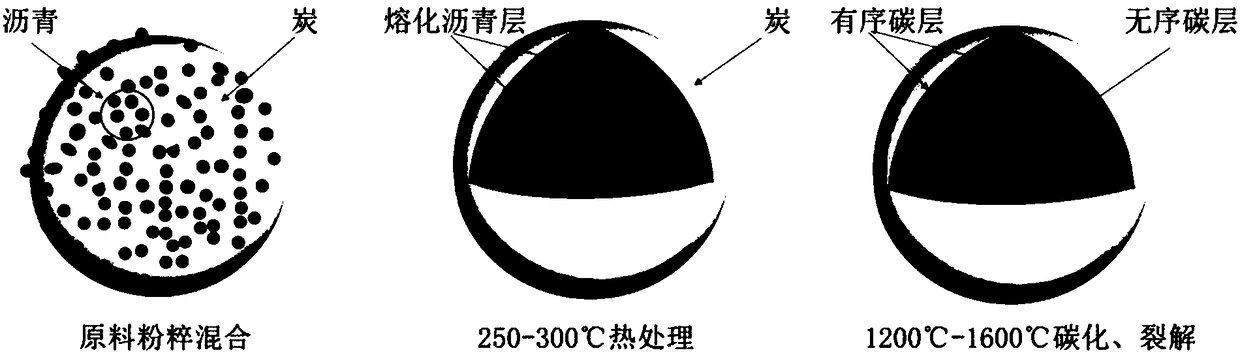

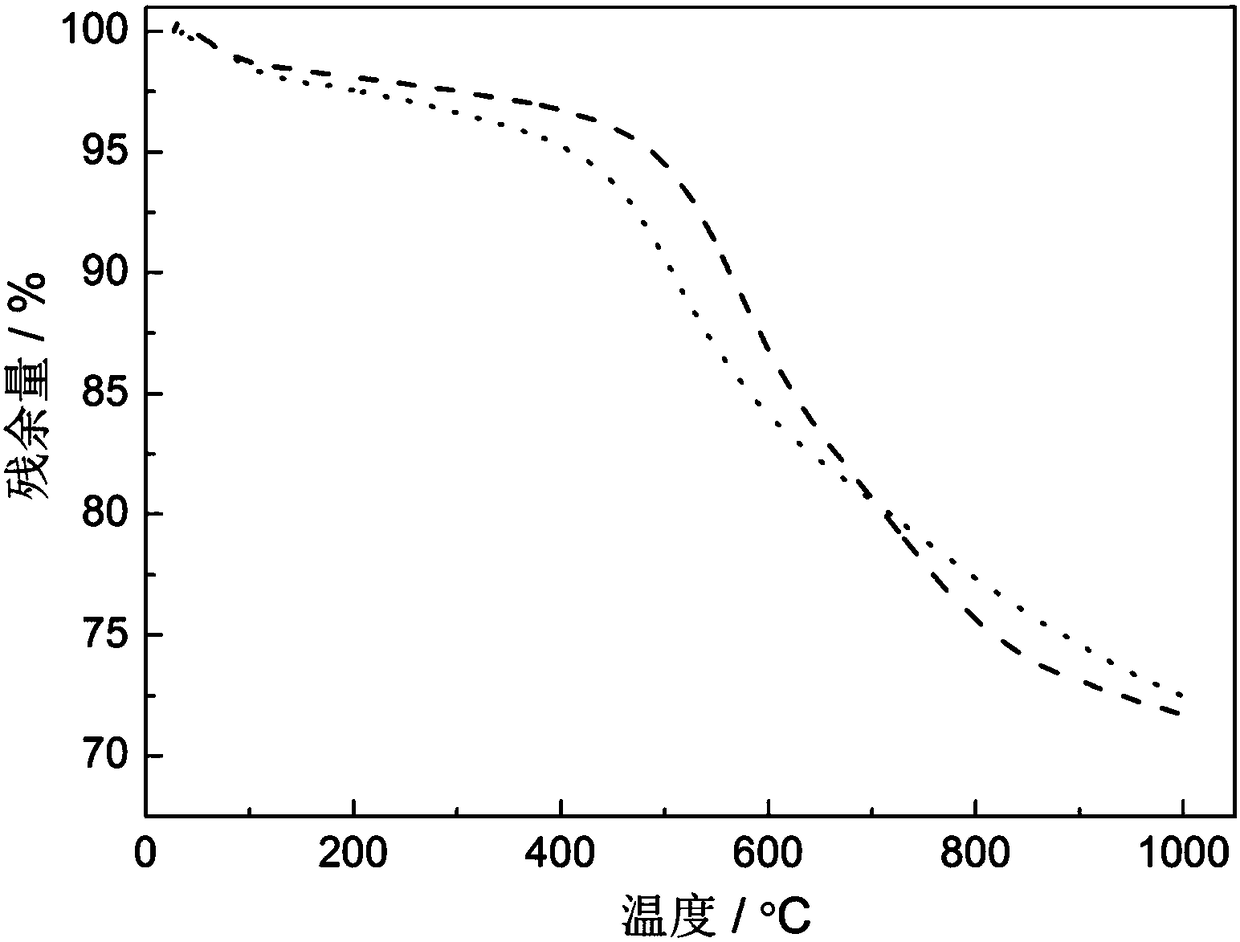

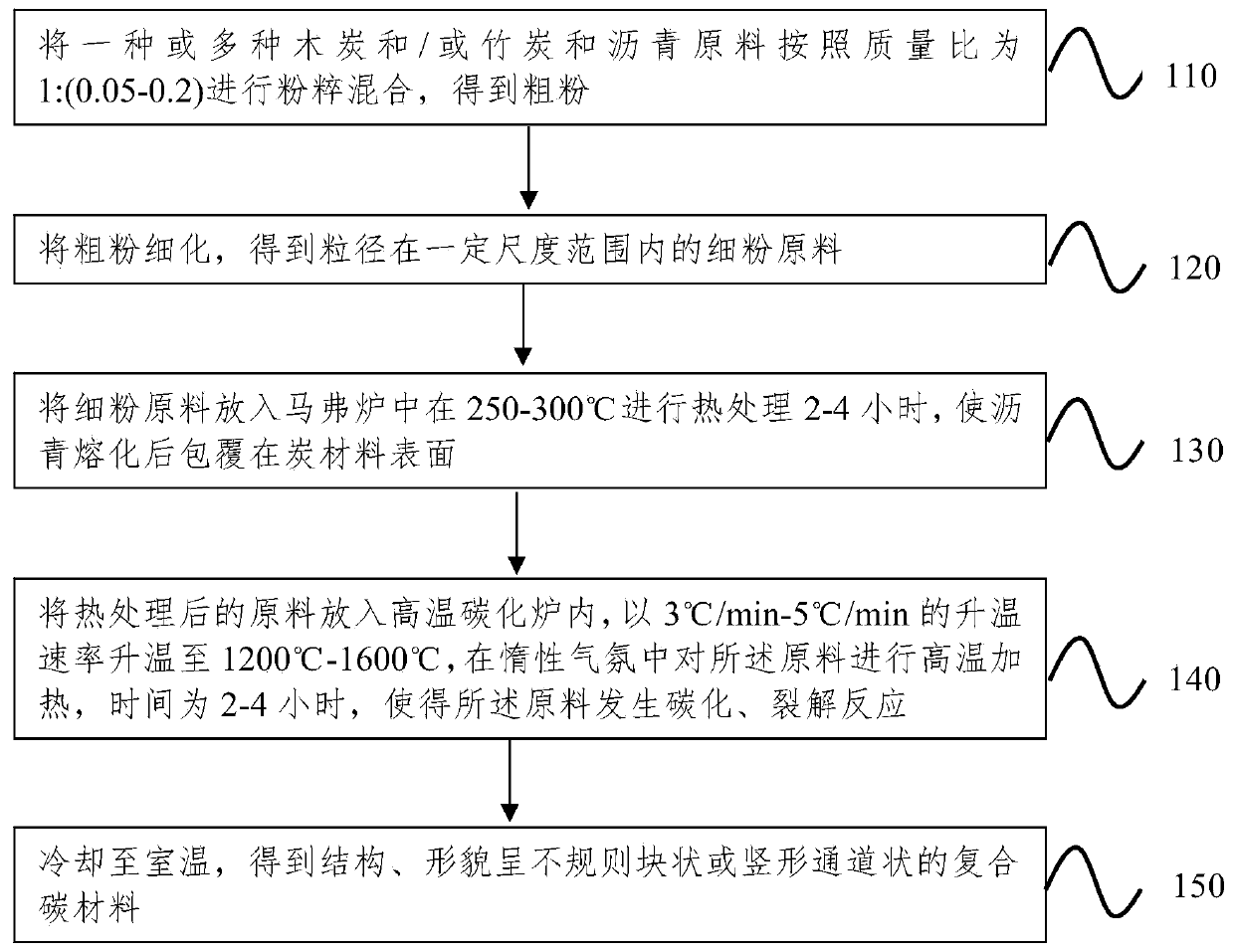

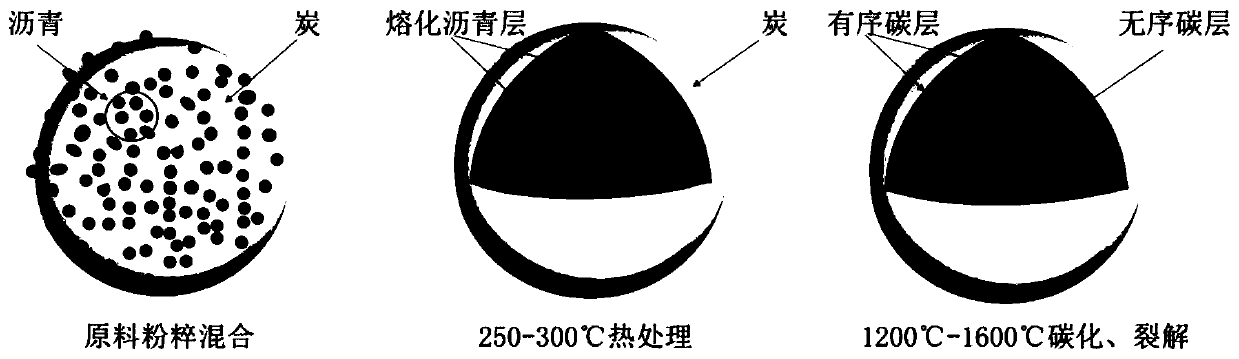

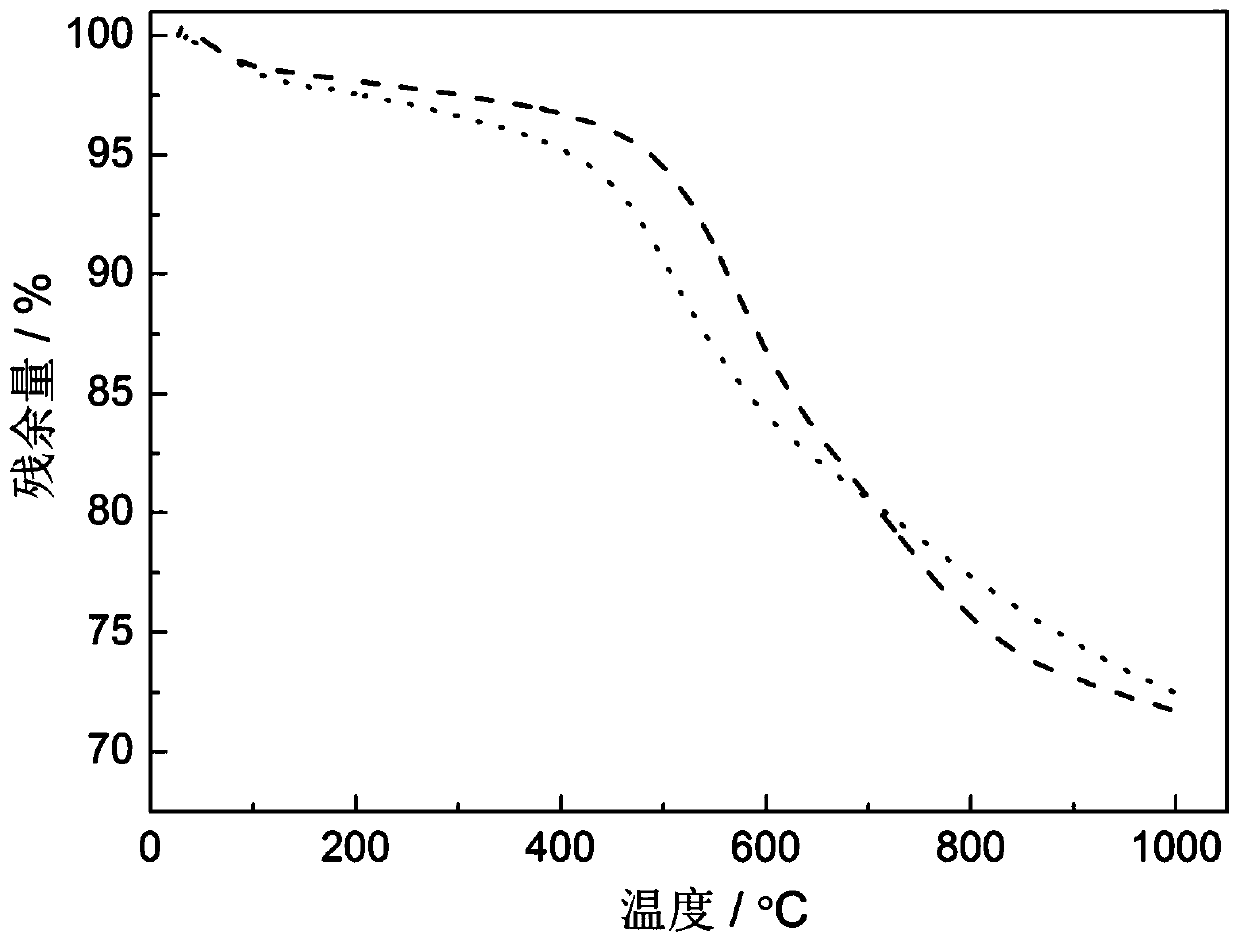

Sodium ion battery negative electrode material based on carbon material and pitch and preparation method and application thereof

ActiveCN109148838AWork lessIncrease energy densityCell electrodesSecondary cellsActivated carbonElectrical battery

The invention discloses a sodium ion battery negative electrode material based on carbon material and pitch and a preparation method and application thereof, wherein the sodium ion battery negative electrode material is a composite carbon material of which the surface is coated with pitch-based ordered carbon structure and appearance is an irregular block shape or vertical channel shape. The carbon material and the pitch are used as precursor raw materials, the pitch is melted and coated on the surface of the carbon material by heat treatment in the air after mechanical mixing, and then the pitch and the carbon material are carbonized and cracked in an inert atmosphere at the same time to obtain a composite carbon material with a surface orderly structure and an internal disorderly structure; Wherein the kind of charcoal comprises charcoal and bamboo charcoal, the charcoal comprises one or more mixtures of white charcoal, black charcoal, activated carbon and machine charcoal, the bamboo charcoal comprises one or more mixtures of carbonized materials of bamboo, pale bamboo, bitter bamboo, thunder bamboo and yellow bamboo, and the pitch is one or more mixtures of coal tar pitch, petroleum pitch and natural pitch.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI +1

Preparation method of polyacrylonitrile electromagnetic shielding nanocomposite

The invention discloses a preparation method of a polyacrylonitrile electromagnetic shielding nanocomposite. Firstly, silver nitrate, carbon nano tubes, dispersing agents and polyacrylonitrile serve as raw materials to be dissolved in dimethylformamide to carry out solution mixing, then after hydrostomia on a substrate, drying is carried out under 120-190 DEG C, film shaping is carried out, meanwhile the silver nitrate is degraded into nano-silver particles to be dispersed in a composite system, and finally a composite material formed by the nano-silver particles, the carbon nano tubes, the dispersing agents and the polyacrylonitrile is formed. According to the preparation method, the nano-silver / carbon nano tubes / polyacrylonitrile material is simple in preparation process, no complex equipment is needed, forming processing and shielding functions are completed at a time, and electromagnetic shielding performance is stable and reliable; and due to the advantages of light weight, easy processing in various shapes, good size stability, adjustable conducting performance in a wide range, and the like, the material has wide application in the fields of static electricity prevention, microwave absorption, electromagnetic shielding, electrochemistry, and the like.

Owner:HENAN UNIV OF URBAN CONSTR

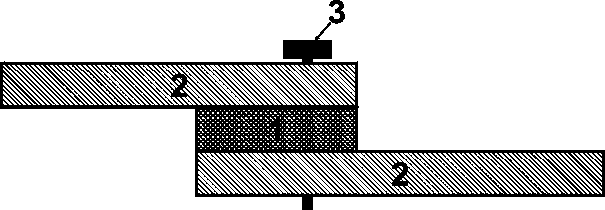

Preparation method of double layer electrochemical working electrode with shielding outer layer

InactiveCN101241098ASpecial structureImprove electromagnetic shielding performanceMaterial electrochemical variablesEpoxyCarbon nanotube

The present invention provides a preparation method of double electrochemistry working electrode structure with shielding crust. Epoxy on outside is used as substrate based on the inner layer as preparation working electrode, and carbon nano-tube is used as conductive filler to process a choiceness Hertzian waves shielding layer. The said working electrode has special structure, dielectric property and strong electromagnetic shielding effectiveness, at the same time, has merits of light quality, adjustable conductivity, strong high temperature oxidation resistance and good stability. In addition, the said working electrode is a working electrode with electromagnetic shielding technique, which is convenient for operation of electrochemistry test and is a promising electromagnetic shielding technique, and has widely use value and application prospect in electrochemistry field.

Owner:佛山中科先创电子科技有限公司

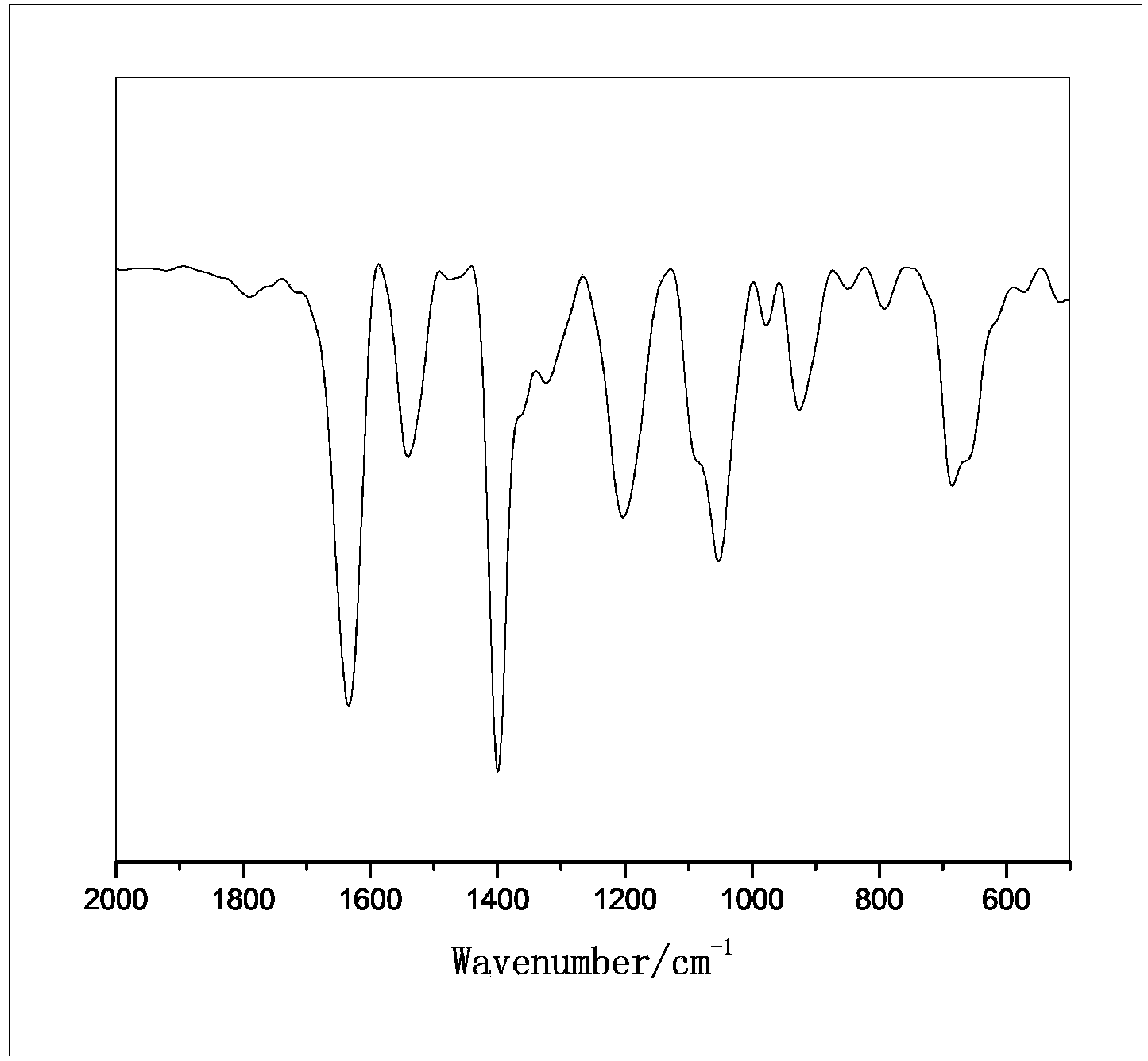

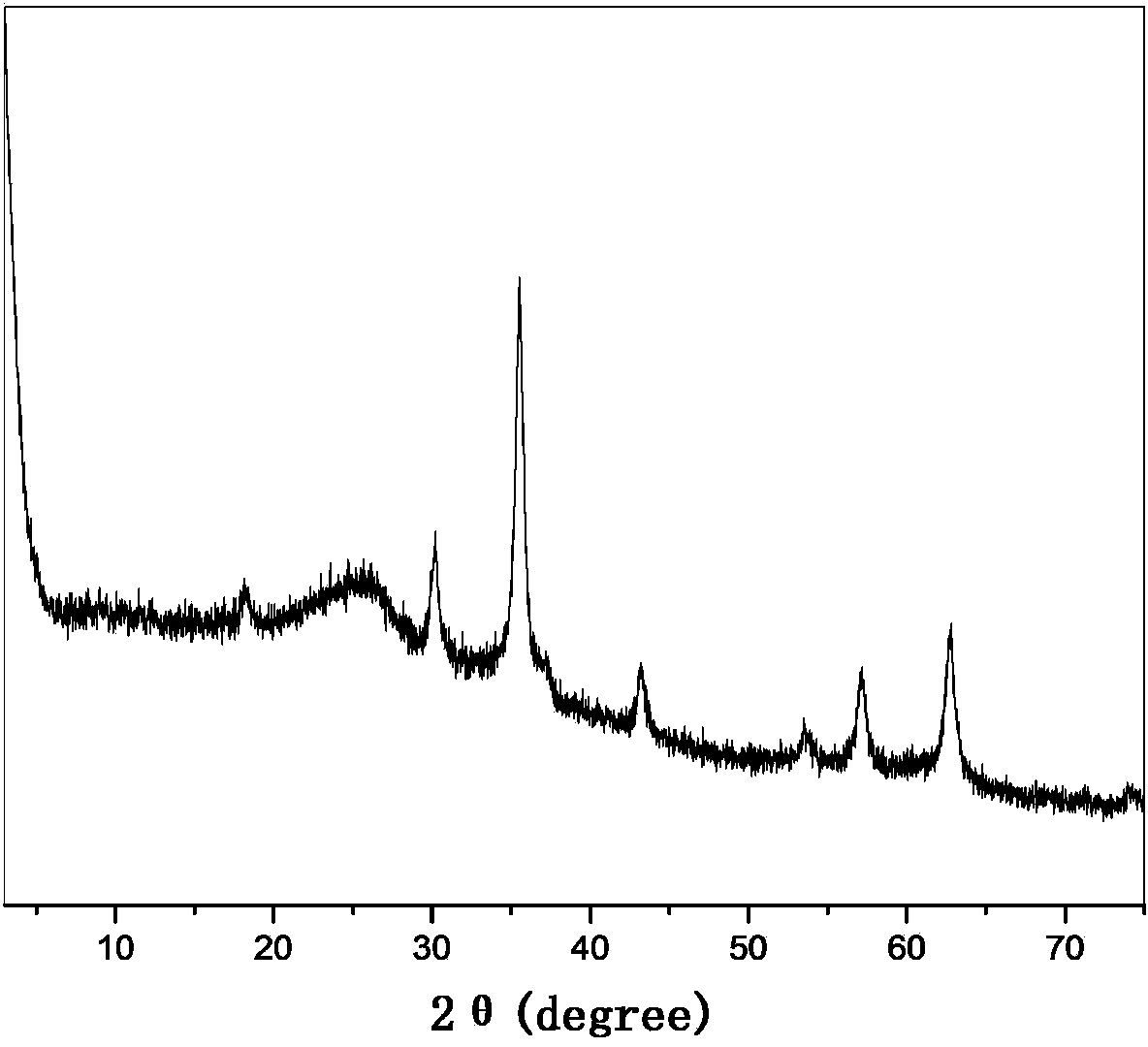

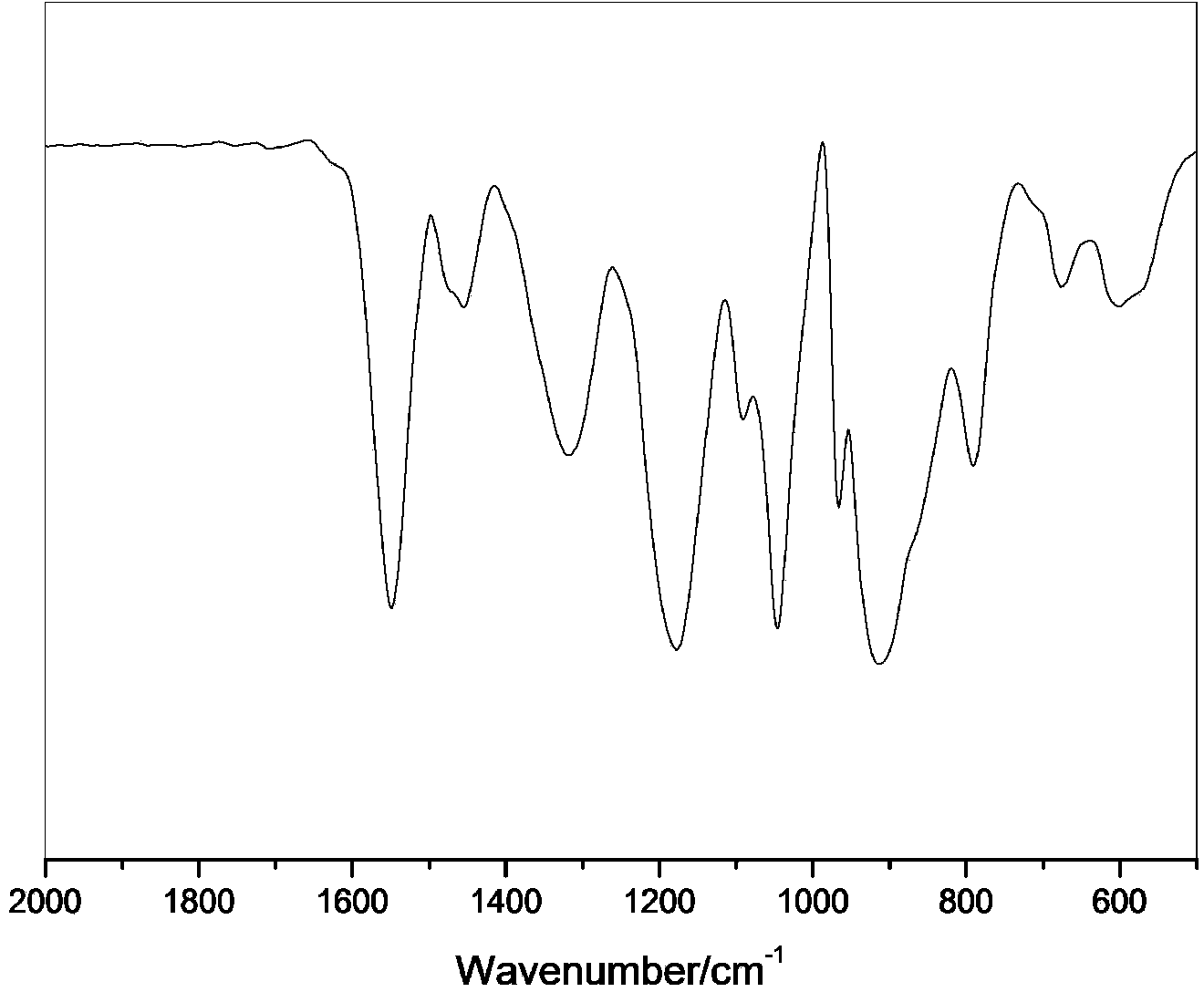

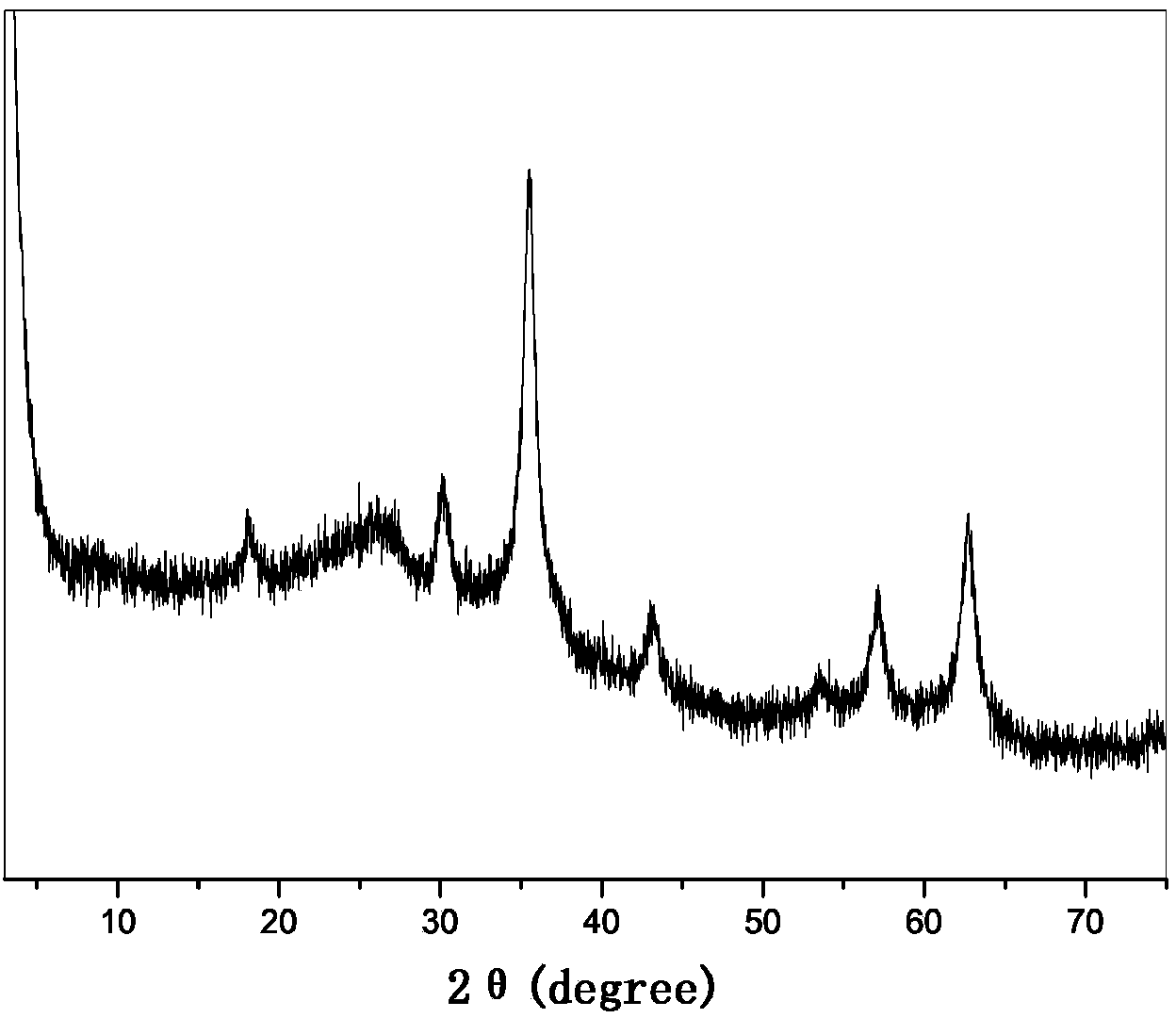

Polypyrrole-PEDOT/Fe3O4 compound and preparation method thereof

The invention relates to a Polypyrrole-PEDOT / Fe3O4 compound with the characteristic of microwave absorption and a preparation method of the Polypyrrole-PEDOT / Fe3O4 compound. The preparation method includes the steps of preparing white emulsion, adding ferrous chloride, adding ferric chloride, carrying out washing and drying, and the like. The absorption frequency band of the compound prepared according to the method can be adjusted by changing the thickness of the compound, the microwave absorption frequency band is obviously broadened, and good wave absorption performance is achieved. In the preparation process, electromagnetic parameters can be adjusted by changing temperature and the use number of oxidizing agents, and the method is of great significance in broadening the microwave absorption frequency band of the compound and preparing novel wave absorption materials.

Owner:OCEAN UNIV OF CHINA

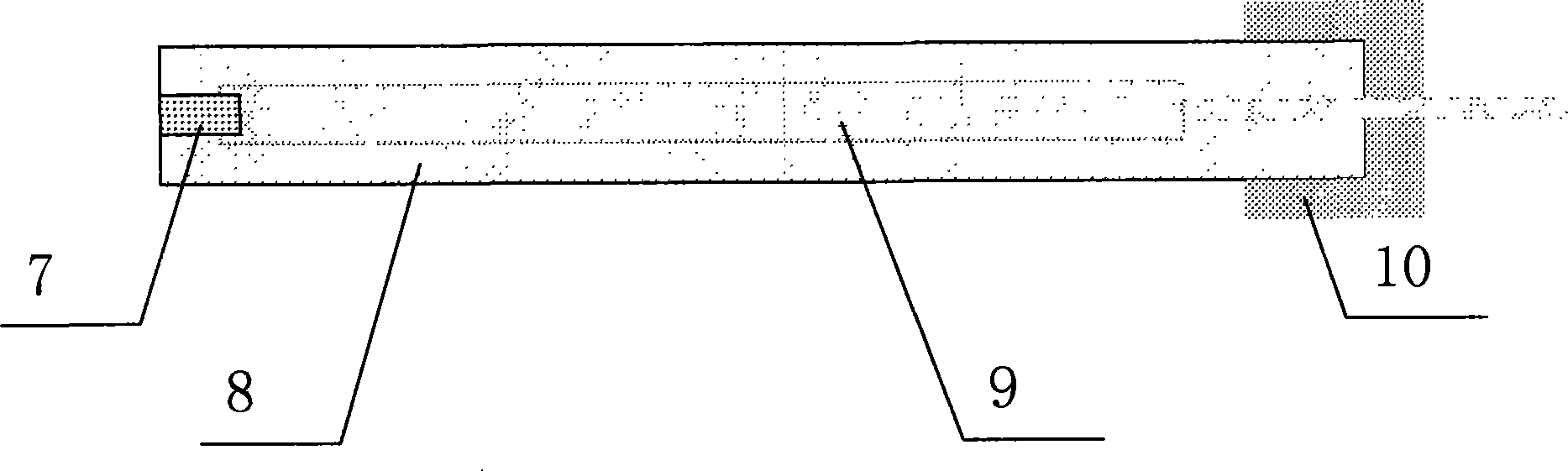

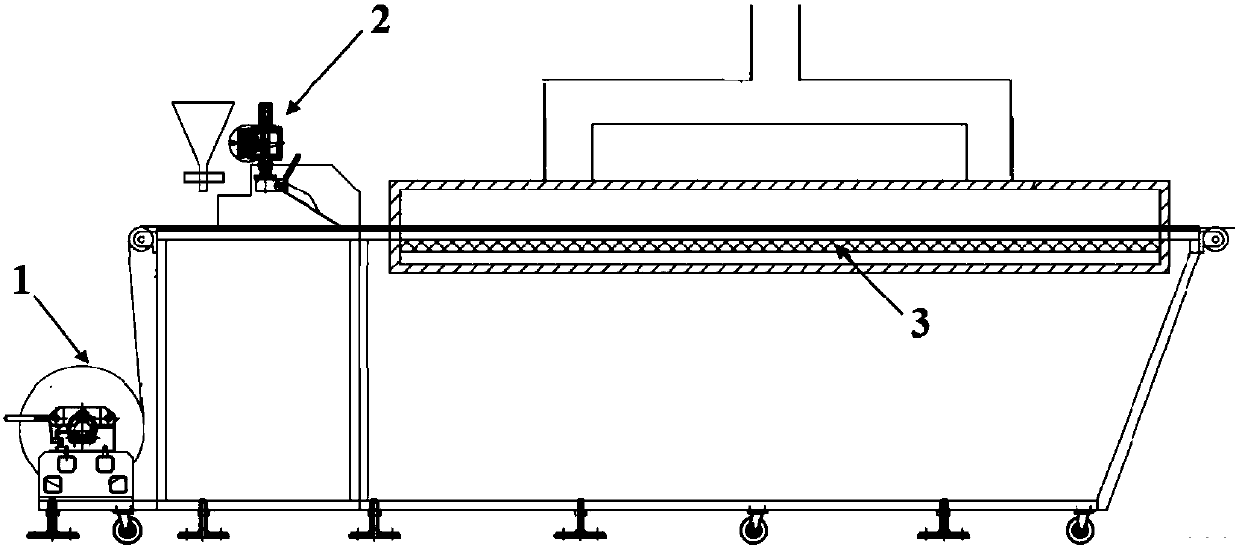

Continuous preparation method of graphene film prereg

The invention relates to a continuous preparation method of a graphene film prereg, and belongs to the technical field of functional materials. The graphene film prereg takes a resin adhesive film anda graphene film as the raw materials and is prepared through the hot melting process, the resin adhesive film is coated with a resin at the breadth of 100-1400 mm at the surface density of 10-100 g / m<2> on release paper, the resin is one of epoxy resin, phenolic resin, unsaturated polyester, polyurethane, bismaleimide resin and polyimide resin; the graphene film is a film having a three-dimensional network structure or a porous structure and is prepared by taking graphene as the main material, and the material composition of the graphene film is determined according to the use function of thegraphene film prereg. The continuous preparation of the method leads to the advantage of high yield of the graphene film prereg, and the heavy demand of the practical application is well met. The most crucial point of the method is the continuous preparation of the graphene film.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Heat-generating composite material of graphene and bimetallic nanowires and preparation method thereof

The invention discloses a heat-generating composite material of graphene and bimetallic nanowires and a preparation method thereof, wherein the heat-generating composite material includes preparationraw materials and a preparation method. The preparation raw materials comprise the following components: graphene oxide, copper nanowires, and silver, platinum, gold or palladium noble metal salts. The highly conductive nano component with stable structure is obtained by composting of the bimetallic nanowires and graphene oxide. At the same time, graphene oxide is easy to disperse in a polymer phase, a complicated and energy-consuming dispersion treatment means is avoided, the introduction of a dispersant is not needed, the preparation process is greatly simplified, the processing cost is low,and the heat-generating material can be produced in large quantities; the time of the prepared heat-generating material required to be heated to a stable value in a range of 10-220 V is less than 300s, and the stable temperature can be regulated in a range of 0-200 DEG C through voltage. The electrical conductivity of the prepared heat-generating composite material can be adjusted in a range of0.1-10 S / cm. The prepared heat-generating composite material is suitable for use as a warm-keeping material, also can be used as a temperature control material, and has broad application prospects.

Owner:芦露华

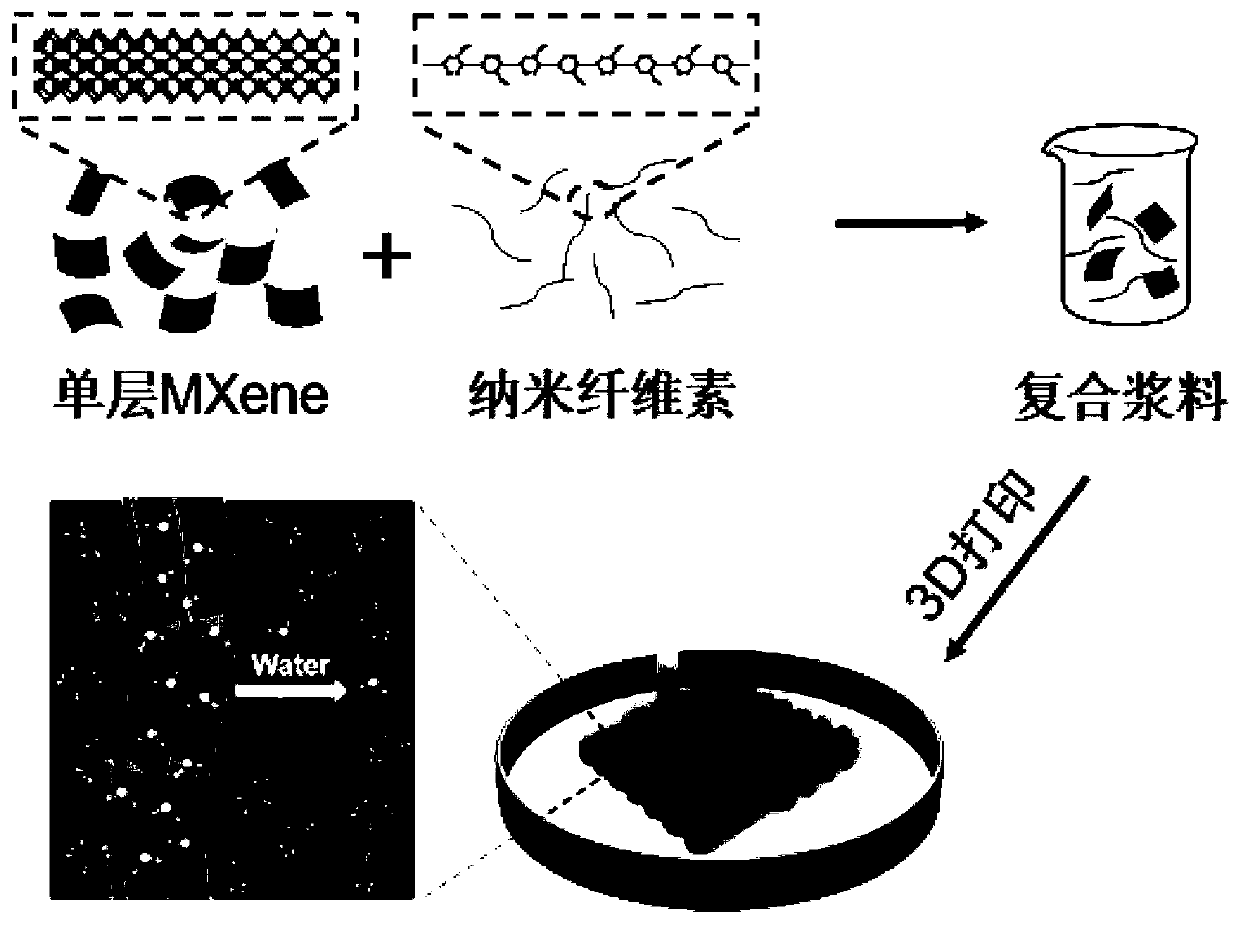

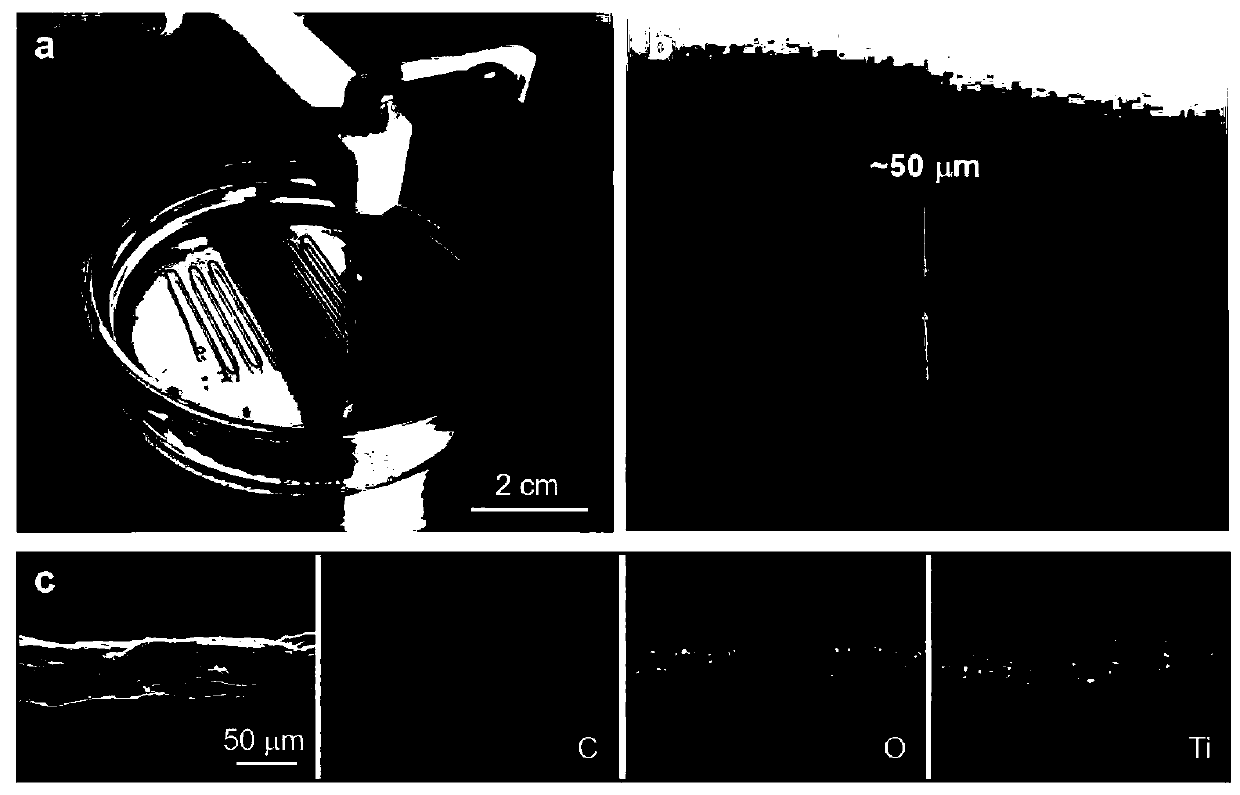

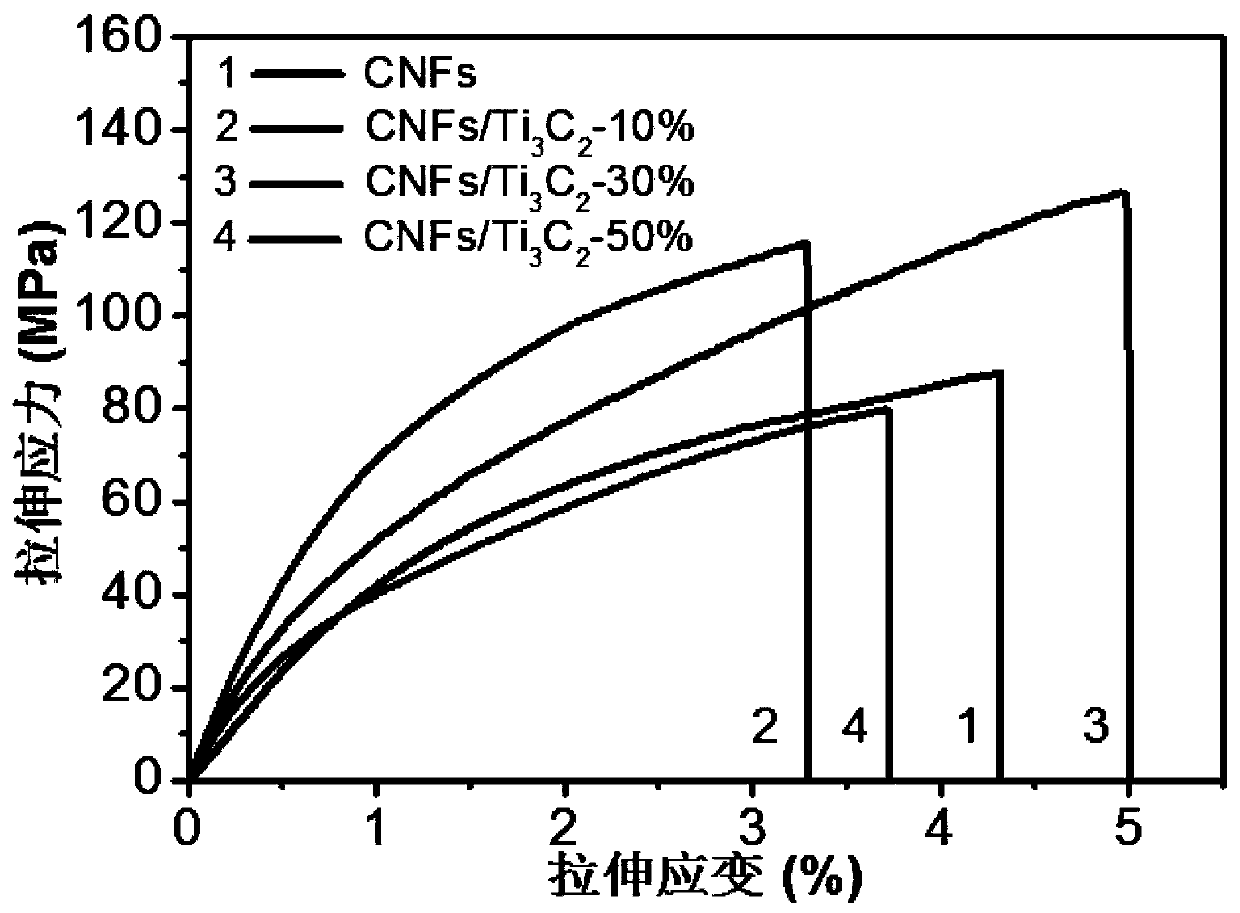

Multifunctional intelligent fiber or fabric

ActiveCN110528101AVersatilityOvercome single functionElectroconductive/antistatic filament manufactureMonocomponent cellulose artificial filamentFiberPolymer science

The invention relates to a multifunctional intelligent fiber or fabric. The multifunctional intelligent fiber or fabric is obtained by directly extruding a mixed sizing agent containing oxidized nanocellulose and a MXene material into a solvent for forming; the weight ratio of the oxidized nanocellulose to the MXene material in the mixed sizing agent is 9:1-3:7, preferably 7:3-1:2, and more preferably 1:1.

Owner:SHANGHAI TENTH PEOPLES HOSPITAL

Coating material and prepn. thereof

This invention discloses a stannic oxide / antimony oxide coating nanomaterial, which comprises stannic oxide 70-90 wt.%, antimony oxide 0.5-20 wt.%, zinc oxide 0.5-18 wt.% and rare earth compounds 0.001-1 wt.%. The coating nanomaterial is manufactured by dissolving the raw materials, adding ammonia solution for hydrolysis, filtering, performing azeotropic distillation, washing with alcohol, drying, sintering, shearing and ultrasonically dispersing. This invention utilizes controllable precipitation method to manufacture ATO monodispersed powders, and applies the slurry of the powders to the matrix, which is then subjected to thermal treatment at lower than 300 deg.C to form films. The coating nanomaterial has adjustable light transmittance and electric conductivity according to different requirements, thus is suitable for large-area coating.

Owner:CENT SOUTH UNIV

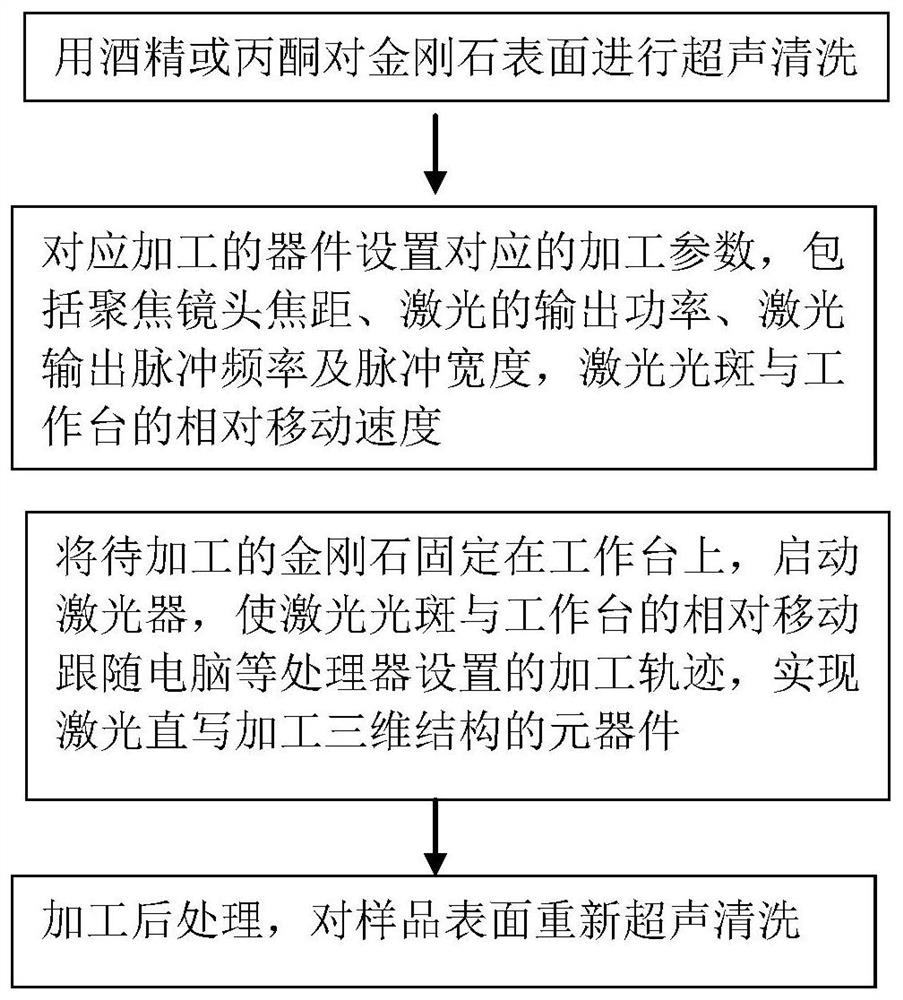

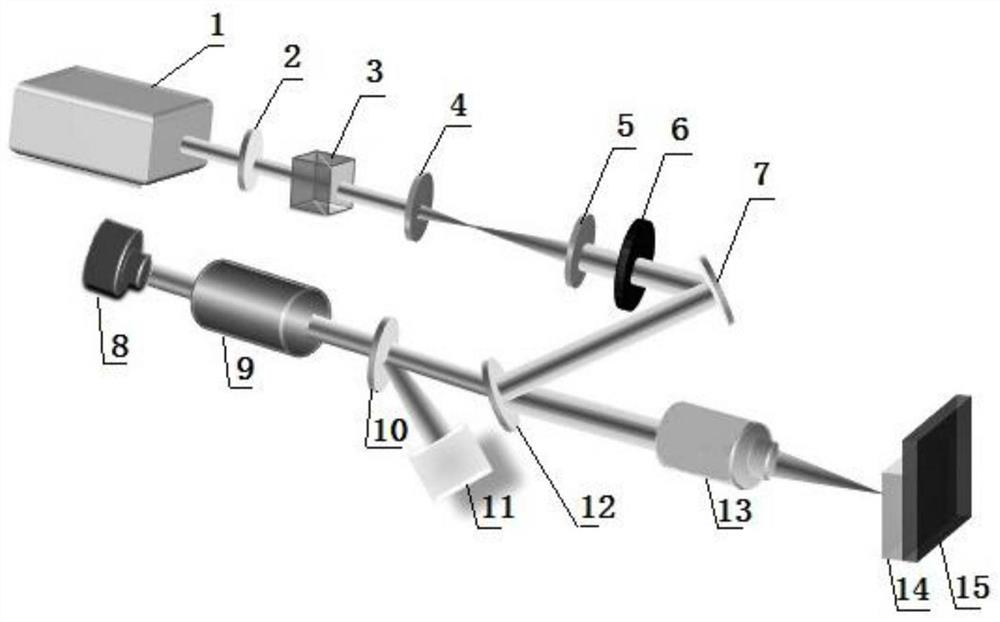

Component prepared from laser processing diamond material and preparation method of component

InactiveCN112828449AChange conductivityImprove thermal conductivityLaser beam welding apparatusOptical radiationCapacitance

The invention discloses a method for preparing a component by processing a diamond material through laser. The method adopts following devices: a laser device, a light beam shutter for controlling the output of the laser device, and a workbench for placing a diamond, a focusing lens is arranged between a laser head of the laser device and the workbench; laser emitted by the laser device is irradiated on the diamond through the focusing lens; the laser is focused on the surface or inside the diamond by controlling the relative movement of a laser spot and the workbench; and the diamond material in a laser radiation area is converted into a graphite phase and an amorphous carbon phase by adjusting the output power of the laser device, the pulse repetition frequency of laser output and the three-dimensional moving speed of the laser spot relative to the workbench, and the conductivity and the electromagnetic wave transmittance of the material in the laser radiation area are changed. The invention further discloses a component prepared by the method. Various devices such as an electromagnetic wave modulator, a resistor and a capacitor which are freely designed can be processed on the surface and the interior of the diamond.

Owner:TIANJIN UNIV

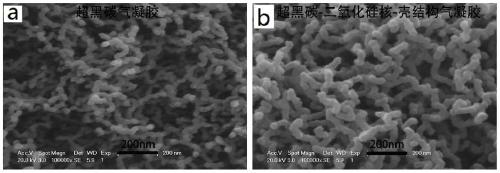

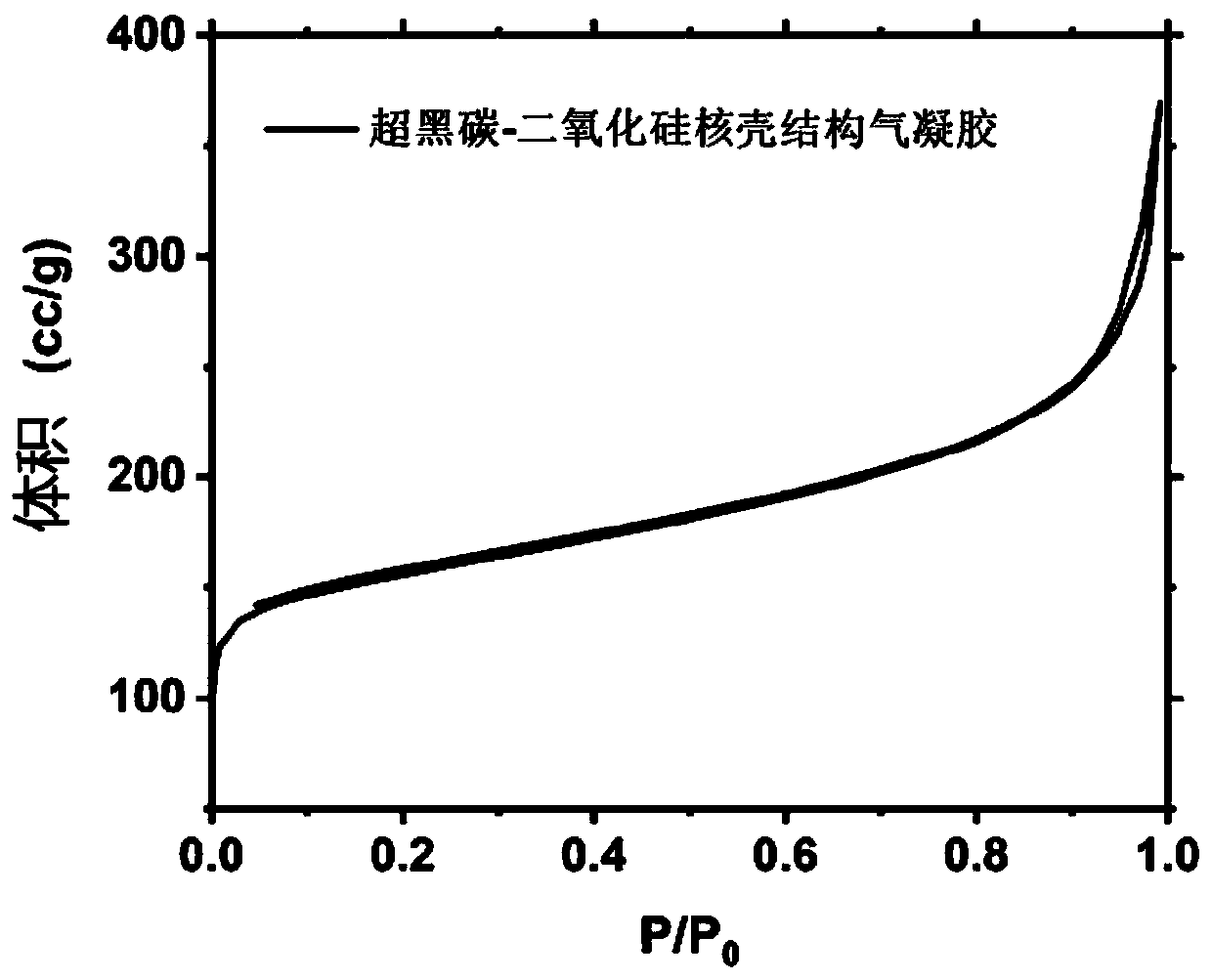

Ultra-black carbon-silica core-shell structure aerogel and preparation method thereof

InactiveCN110467174AEnhanced light absorptionImprove conductivityMaterial nanotechnologySilicaCarbonizationAbsorption rate

The invention relates to an ultra-black carbon-silica core-shell structure aerogel and a preparation method thereof, wherein the core is an ultra-black carbon aerogel, and the surface of the core is coated with silica by using a chemical vapor deposition method to form a shell. The preparation method comprises: preparing a resorcinol-formaldehyde aerogel by using a sol-gel technology, and carryingout high-temperature carbonization treatment on the resorcinol-formaldehyde aerogel to obtain an ultra-black carbon aerogel; and forming a silica shell with a nano-scale thickness on the surface of the ultra-black carbon aerogel by using a chemical deposition method to obtain the ultra-black carbon-silica core-shell structure aerogel. Compared with the aerogel in the prior art, the aerogel of thepresent invention has low electrical conductivity of 0.021 ms / mm, has high light absorption rate, has an average absorption of more than 98.6% at a wave band of 400-2000 nm, and further has advantages of simple reaction process, low overall cost, low density, high yield, adjustable electrical conductivity and the like.

Owner:TONGJI UNIV

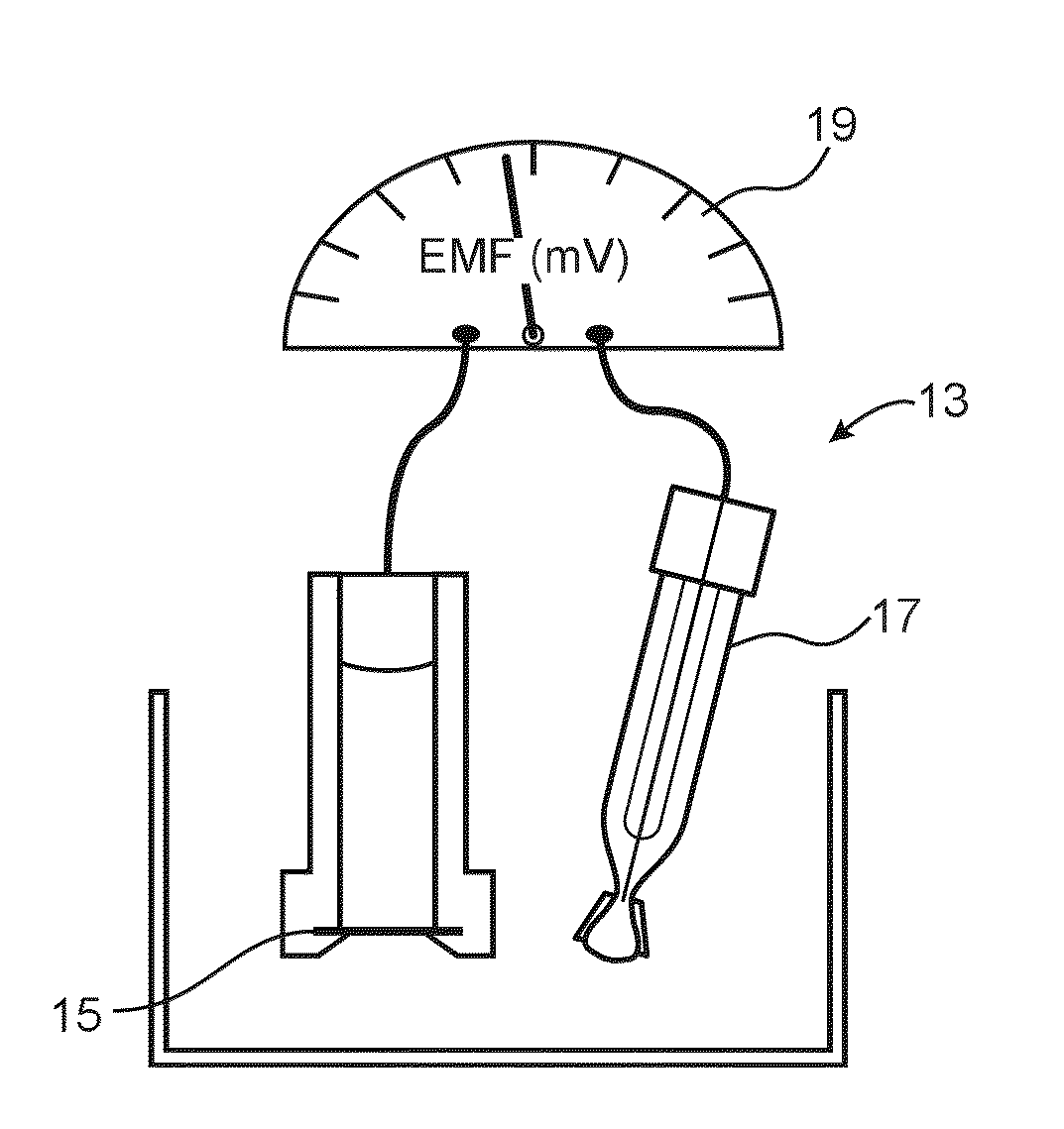

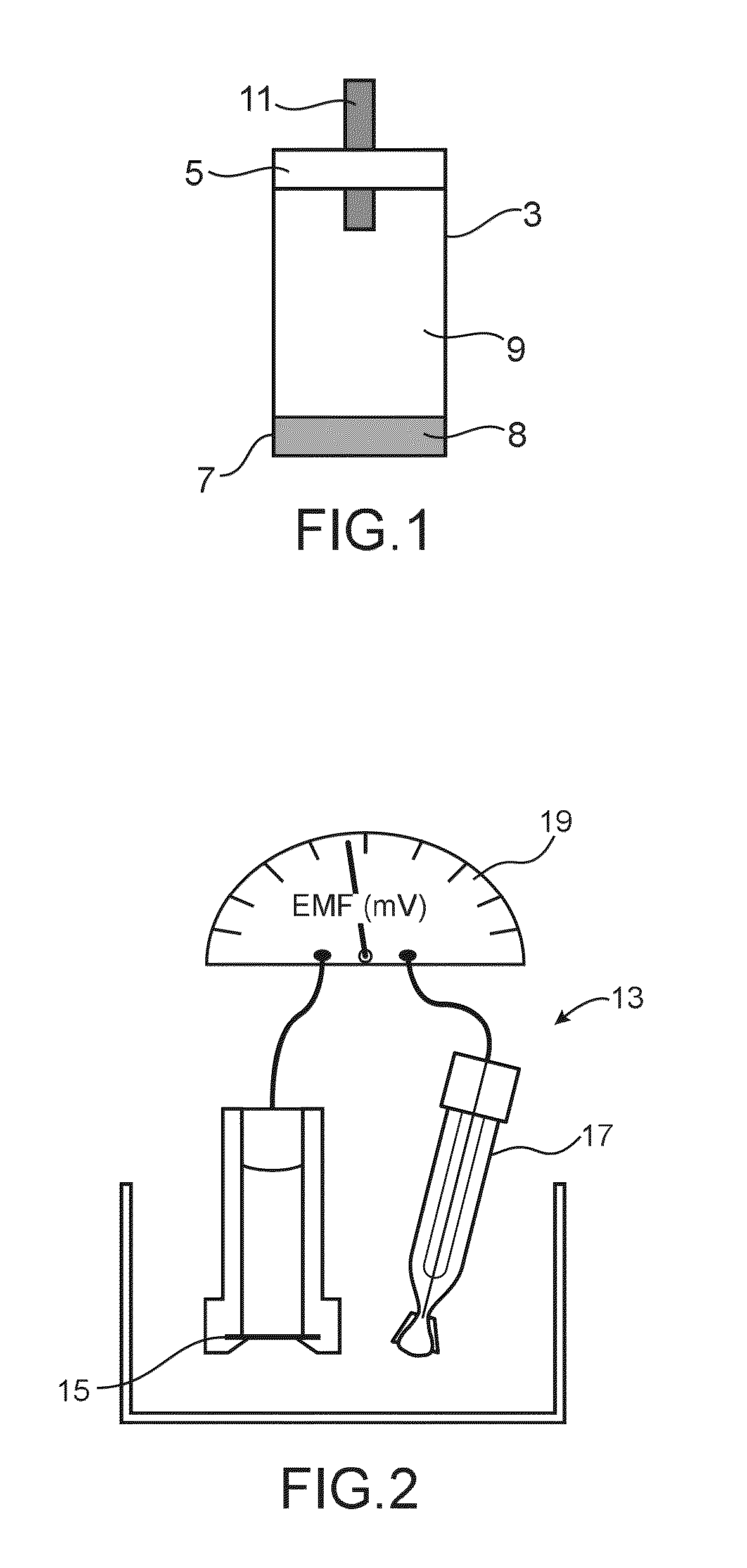

Method for producing a polymer membrane of a polymer membrane electrode for the potentiometric detection of at least one analyte present in a solution

InactiveUS20160257035A1Soften them.Lower glass transition temperatureMaterial analysis by electric/magnetic meansTesting waterAnalytePotentiometric titration

A method for developing a polymer membrane of a polymer membrane electrode intended for the potentiometric detection of at least one analyte present in a solution to be analysed, the method including: depositing a solution, in the liquid phase, including the constituents of the polymer membrane at the surface of an internal electrolyte solution, the latter being in the liquid phase and occupying the internal cavity of an electrode body; drying the solution including the constituents of the polymer membrane, resulting in the polymer membrane at the surface of the internal electrolyte solution.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

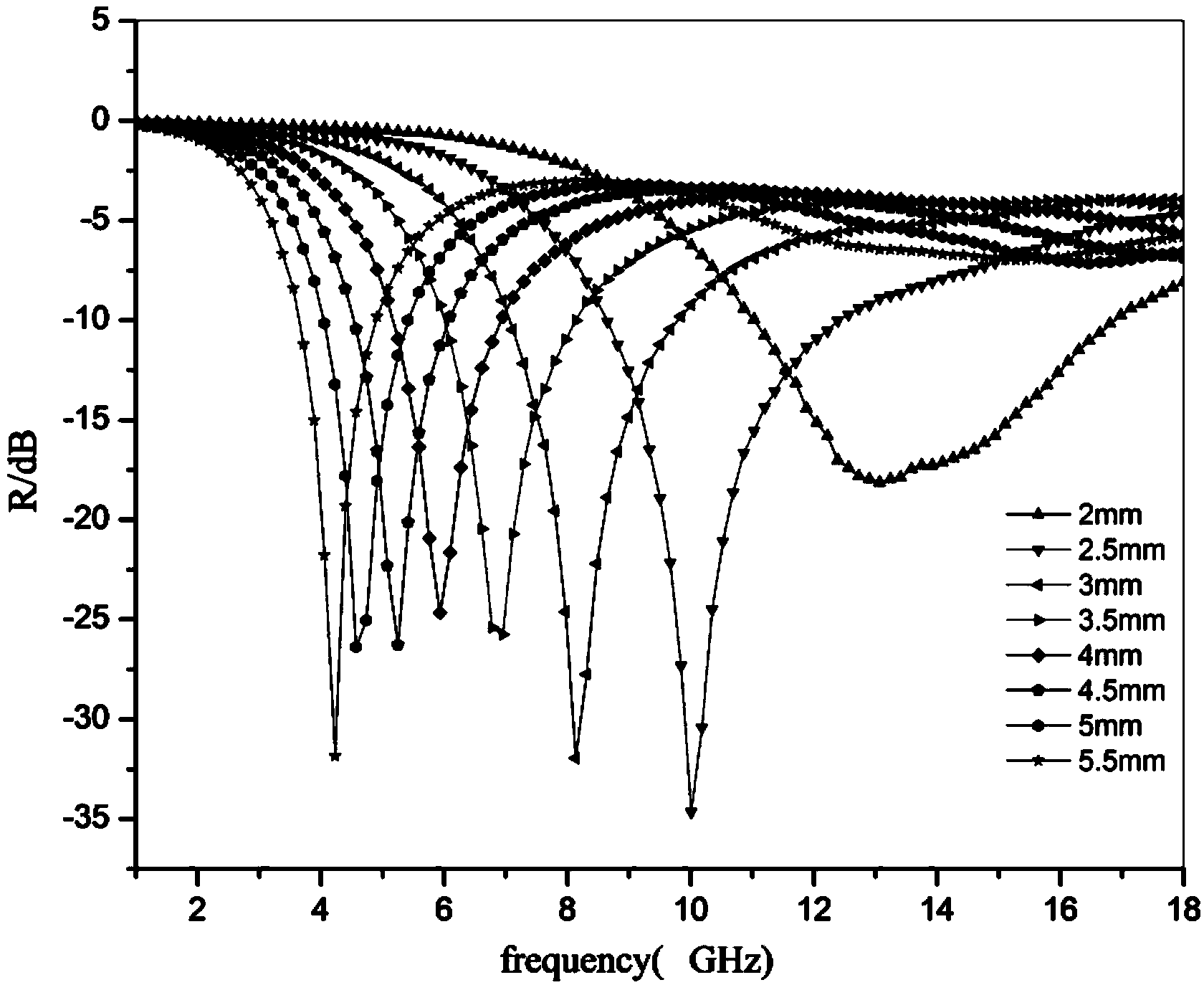

Polypyrrole-polyaniline/Fe3O4 compound and preparation method thereof

The invention relates to a polypyrrole-polyaniline / Fe3O4 compound with the characteristic of microwave absorption and a preparation method of the polypyrrole-polyaniline / Fe3O4 compound. The preparation method includes the steps of preparing white emulsion, adding ferrous chloride, adding ferric chloride, carrying out washing and drying, and the like. The absorption frequency band of the compound prepared according to the method can be adjusted by changing the thickness of the compound, the microwave absorption frequency band is obviously broadened, and good wave absorption performance is achieved. In the preparation process, electromagnetic parameters can be adjusted by changing temperature and the use number of oxidizing agents, and the method is of great significance in broadening the microwave absorption frequency band of the compound and preparing novel wave absorption materials.

Owner:OCEAN UNIV OF CHINA

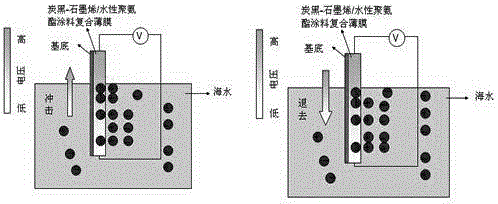

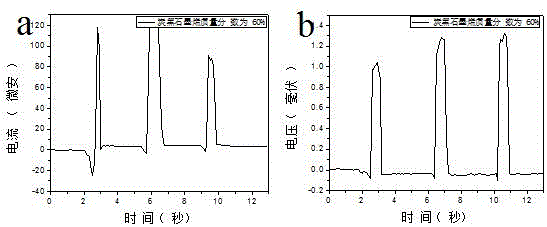

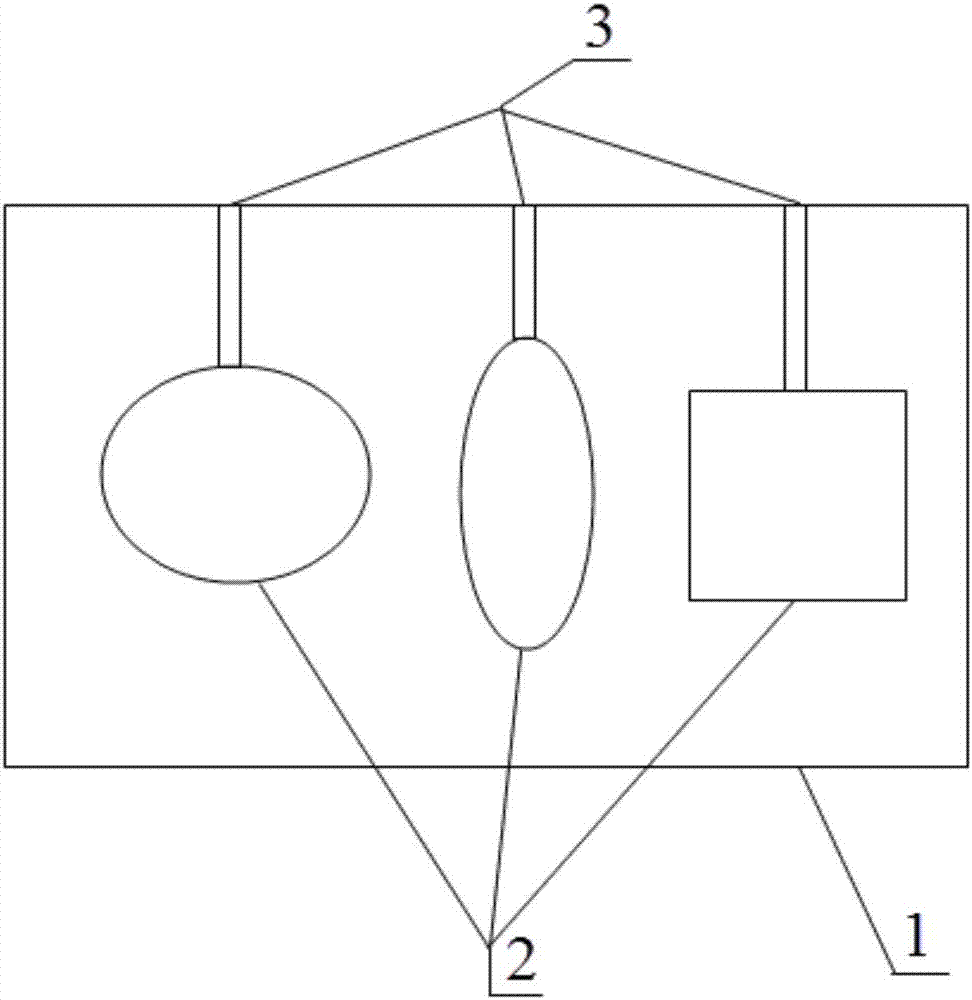

Carbon black-graphene/aqueous polyurethane coating composite conductive thin film based seawater power generation apparatus, and preparation method and application therefor

InactiveCN106025174AImprove conductivityImprove thermal conductivityPrimary cell manufacturePrimary cell electrodesCvd graphenePolyurethane coating

The invention discloses a carbon black-graphene / aqueous polyurethane coating composite conductive thin film based seawater power generation apparatus, and a preparation method and an application therefor. The seawater power generation apparatus is prepared by the steps of dispersing the aqueous polyurethane coating into a dispersion liquid firstly; then enabling the dispersion liquid, graphene and carbon black to be mixed and dispersed; next, coating a substrate with the mixed dispersion liquid, and drying the substrate naturally to obtain the carbon black-graphene / aqueous polyurethane coating loaded composite conductive thin film; and then further assembling the seawater power generation apparatus. By making full use of the interface charge transmission generated when the composite conductive thin film is washed by sea water, the output of the current and voltage signals is realized; when the thin film is washed by seawater, the seawater power generation apparatus is formed; the seawater power generation apparatus has simple preparation method and low cost; the large-area preparation of the seawater power generation apparatus can be realized; and meanwhile, the seawater power generation apparatus is excellent in performance, and can be applied in power generation on coastlines, rocks, ships, sea islands and the like, so that the utilization of the inherent source of the sea is improved.

Owner:OCEAN UNIV OF CHINA

Preparation method of polyacrylonitrile/ionic liquid/polyaniline conducting composite material

The invention discloses a preparation method of a polyacrylonitrile / ionic liquid / polyaniline conducting composite material, which comprises the following steps: (1) adding aniline into 1-butyl-3-methylimidazolyl hexafluorophosphate, and stirring uniformly to obtain a mixed liquid; (2) putting polyacrylonitrile powder into a high-speed mixer, slowly adding the mixed liquid in the step (1), and stirring for 1-3 hours to obtain a mixture; (3) putting the mixture in the step (2) into a mold, and carrying out hot pressing in a flat vulcanizing bed for 10-30 minutes to obtain a polyaniline-monomer-containing polyacrylonitrile sheet; and (4) immersing the sheet in the step (3) into an acid-doped water solution, reacting for 2-10 hours, cleaning the material with water after the reaction finishes, and drying to obtain the polyacrylonitrile / ionic liquid / polyaniline composite conducting material. According to the method, the aniline and ionic liquid plasticizer 1-butyl-3-methylimidazolyl hexafluorophosphate are blended to synergically plasticize the polyacrylonitrile, and then, melting is performed to prepare the product.

Owner:ZHONGYUAN ENGINEERING COLLEGE

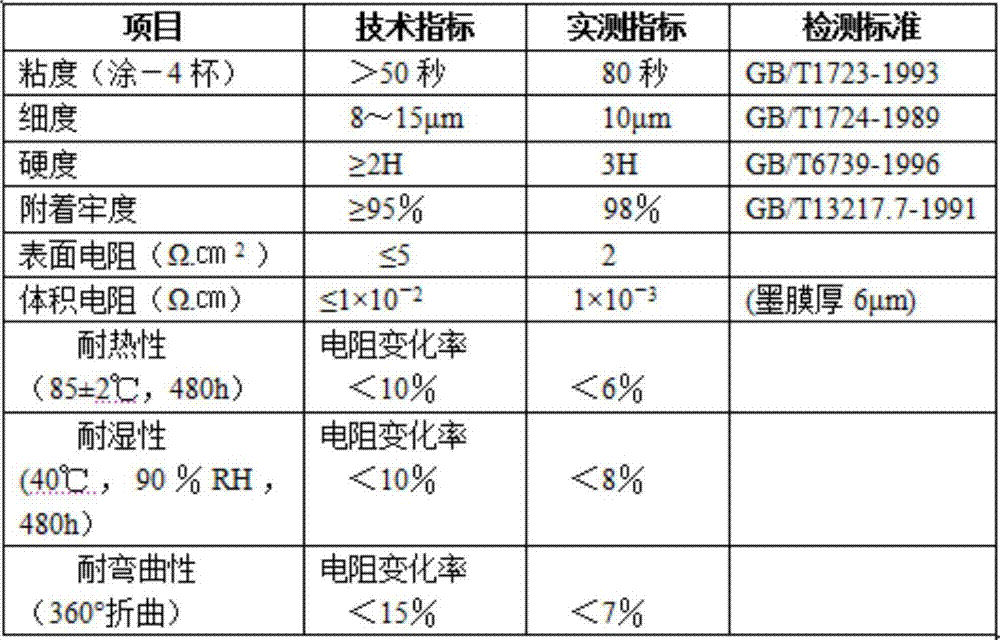

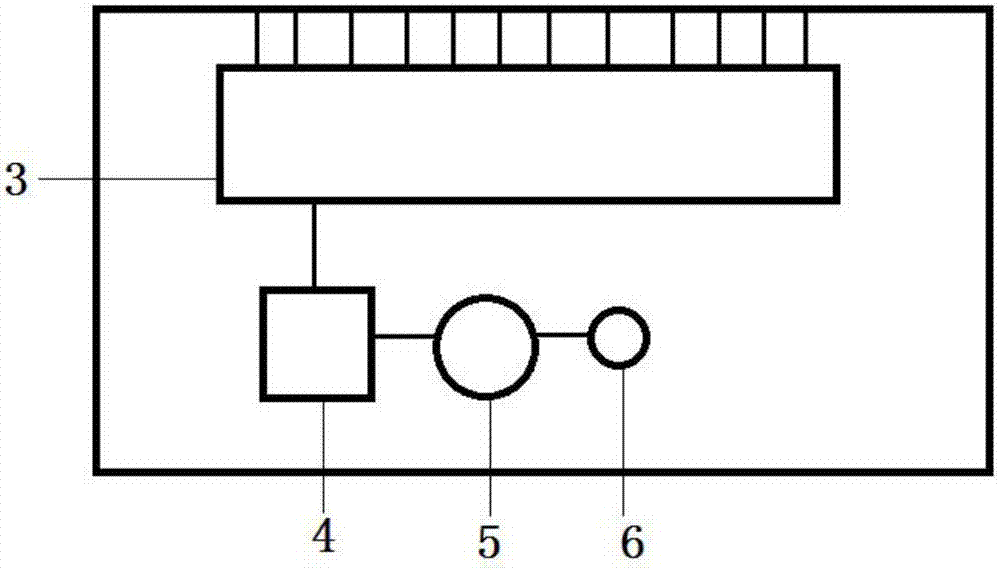

Inductive percussion instrument based on wood grain style printing and conductive ink

InactiveCN107221315ASimple processLow costElectrophonic musical instrumentsInksCapacitanceManufacturing technology

The invention provides an inductive percussion instrument based on wood grain style printing and color conductive ink. The inductive percussion instrument comprises a percussion panel. Conductive color ink blocks are coated on the upper surface of the percussion panel. Sound generating speakers powered by a power supply module are arranged on the lower surface of the percussion panel. The sound generating speakers are connected with the conductive color ink blocks on the upper surface of the percussion panel through conductive color ink lines. According to the inductive percussion instrument based on wood grain style printing and the color conductive ink, vibration and sound generation of the conventional percussion instrument depend on physical percussion, the multipart mode of the capacitive touch percussion instrument is eliminated, and on / off of the sound generating device is realized by using the capacitive induced conductivity of the color conductive ink so that the manufacturing technology is simple, parts are less and the percussion instrument is safe and stable and suitable for children in comparison with the conventional capacitive touch percussion instrument.

Owner:武汉鸥易光电科技有限公司

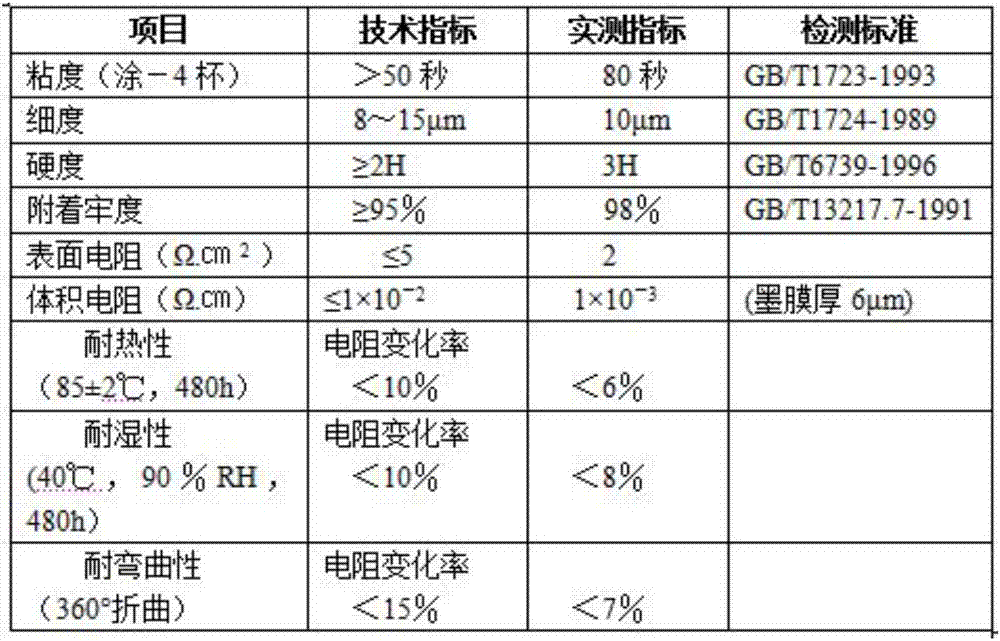

High-viscosity low-melting-point metal conductive paste and preparation method thereof

ActiveCN104992742BSolution to short lifeWon't failMetal/alloy conductorsCable/conductor manufactureContact resistanceElectron

The invention relates to a high-viscosity low-melting-point metal conductive paste and its preparation method and application, which is characterized in that it is obtained by uniformly mixing low-melting-point metal and metal powder in a certain ratio and method. The metal powder can increase the viscosity and electrical conductivity of the low melting point metal. The high-viscosity and low-melting-point metal conductive paste of the invention can significantly reduce the contact resistance between electronic components, thereby reducing the contact surface temperature of the electronic components and prolonging the working life of the electronic components as much as possible. The high-viscosity and low-melting-point metal conductive paste of the invention has high conductivity, remarkable conductive effect and long service life, and can be widely used in the technical fields of electric power and energy.

Owner:BEIJING EMIKON TECH DEV

A kind of preparation method of molybdenum sulfide/graphene-graphene nanoribbon airgel composite material

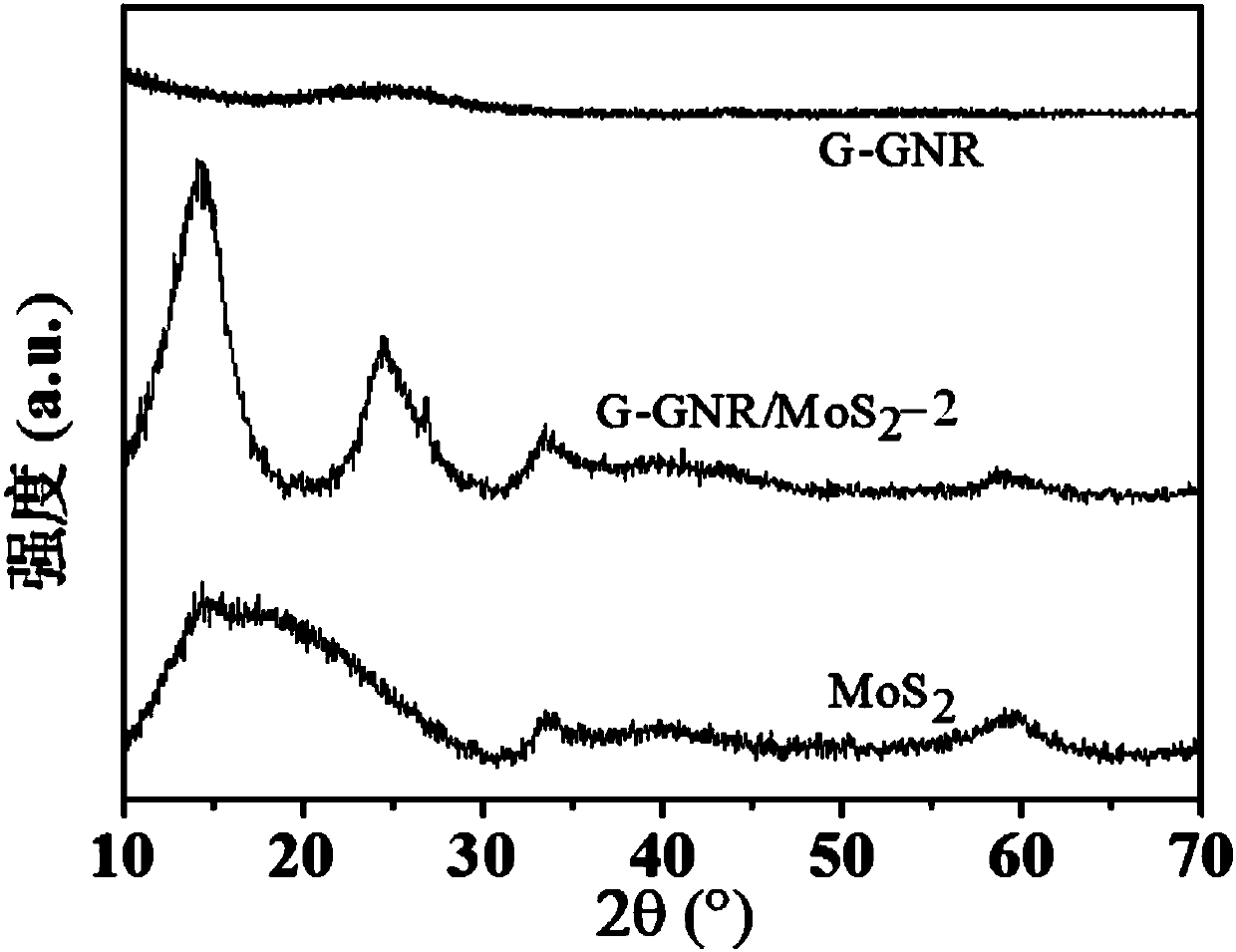

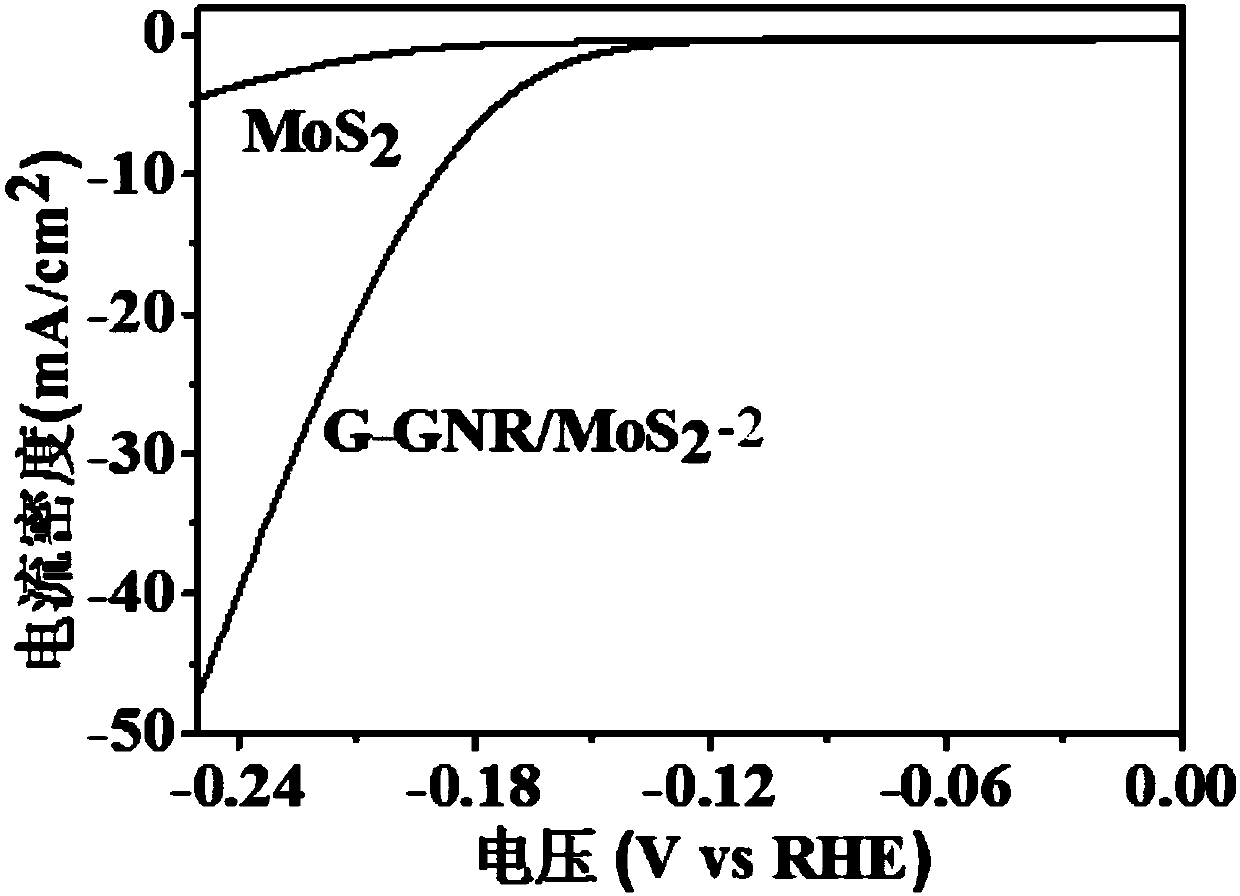

InactiveCN106082341BInhibition of agglomerationExposed active edgeMaterial nanotechnologyCell electrodesPorous carbonFreeze-drying

The present invention relates to a molybdenum sulfide / graphene-graphene nano-belts aerogel composite material preparation method, which comprises: dispersing oxidized graphene in deionized water, and carrying out an ultrasonic treatment to obtain an oxidized graphene dispersing liquid; adding an oxidized graphene nano-belt dispersing liquid into the oxidized graphene dispersing liquid in a dropwise manner, stirring to obtain a mixed liquid, freezing with liquid nitrogen to obtain a solid, and carrying out freeze-drying to obtain the precursor of a graphene-graphene nano-belt gel; adding ammonium thiomolybdate to a solvent, and carrying out an ultrasonic treatment to obtain an ammonium thiomolybdate solution; and adding the precursor of the graphene-graphene nano-belt gel to the solution, standing, and carrying out a solvothermal reaction to obtain the molybdenum sulfide / graphene-graphene nano-belts aerogel composite material. According to the present invention, the method has characteristics of simple operation, easy control, low cost, no pollution, and easy large-scale production; and the prepared porous carbon nanometer aerogel has advantages of large specific surface area, stable chemical property, good conductivity, adjustable pore size, and the like.

Owner:DONGHUA UNIV

Negative electrode material for sodium ion battery, preparation method and application thereof

ActiveCN109148838BWork lessIncrease energy densityCell electrodesSecondary cellsElectrical batteryCarbonization

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI +1

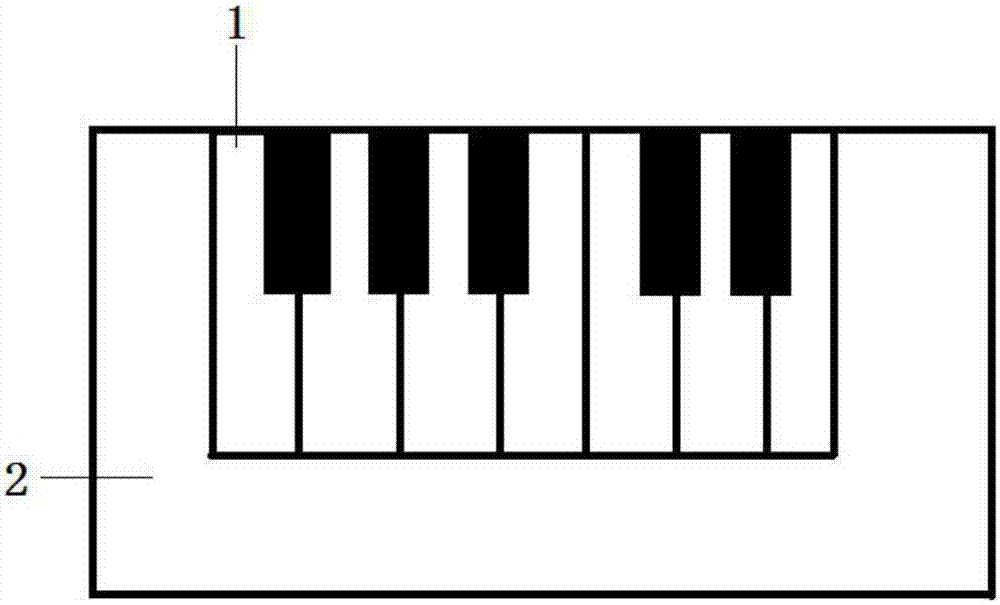

Touch electronic piano

InactiveCN107221314AEasy to carryReduce manufacturing costElectrophonic musical instrumentsInksElectricityPiano

The invention discloses a touch electronic piano which at least comprises an electric touch control chip, a sound generating chip and a sound generating device which are electrically connected and a keyboard equipped with key modules and a power supply which supplies power to the circuit. The keyboard is arranged on the upper surface of a hardboard. The conductive parts of the key modules are the keys covered by conductive ink. The key modules and the electric touch control chip are electrically connected through the conductive ink. The body of the electronic piano is only manufactured by the hardboard without using plastics to manufacture the keys or the body so that the manufacturing cost can be reduced, the size is small, the weight is low and the electronic piano can be easily carried by the user to enjoy the fun of music anytime and anywhere; the number of the keys can be increased or decreased according to the actual requirement, and the color of the keys can also be manufactured by black and white or color conductive ink according to the requirement so that the interestingness of the electronic piano can be increased; and the conductive ink of the keys on the key modules can be manufactured through printing and can also be manufactured through coating by the user so that the operability of the electronic piano can be increased.

Owner:武汉鸥易光电科技有限公司

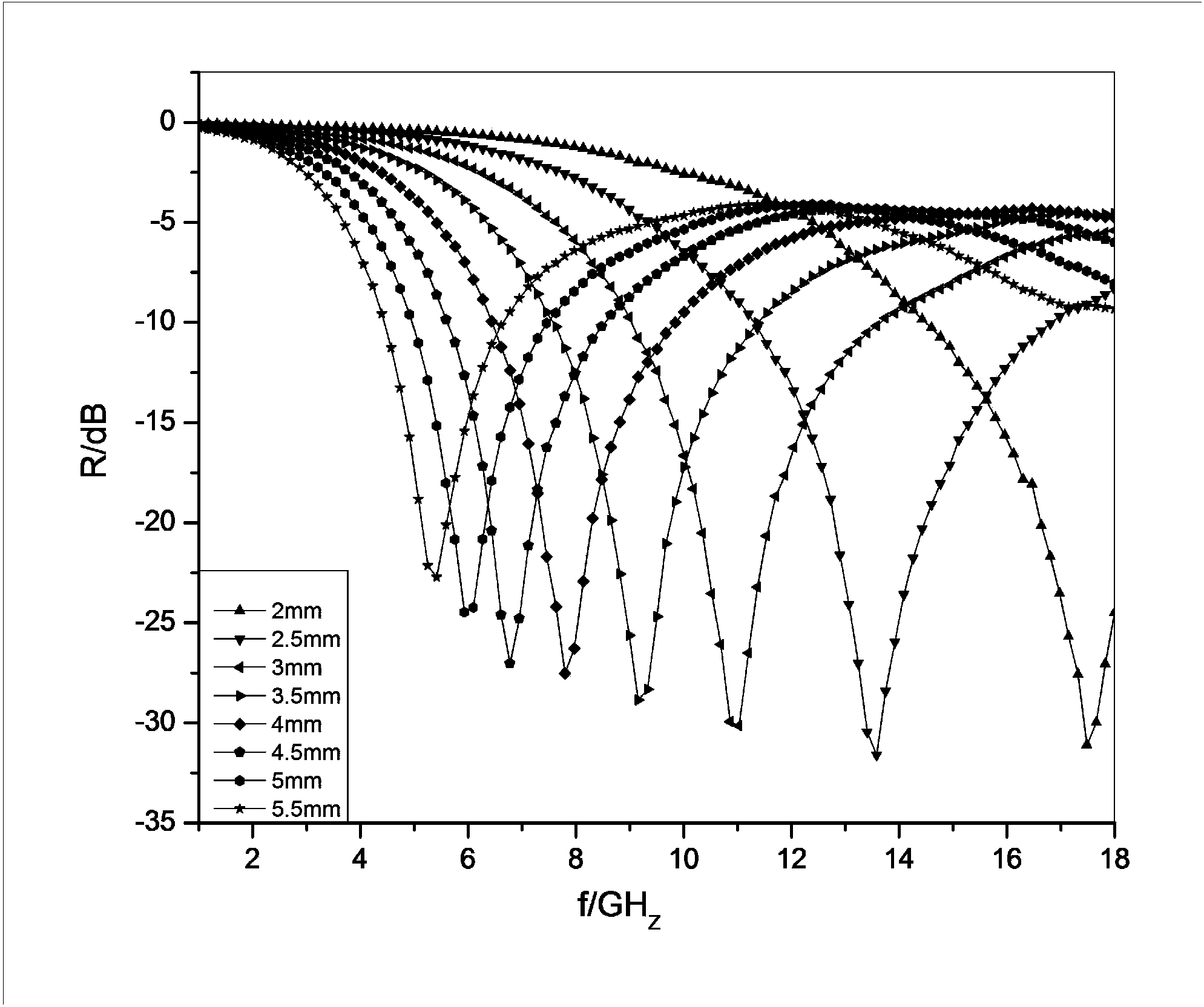

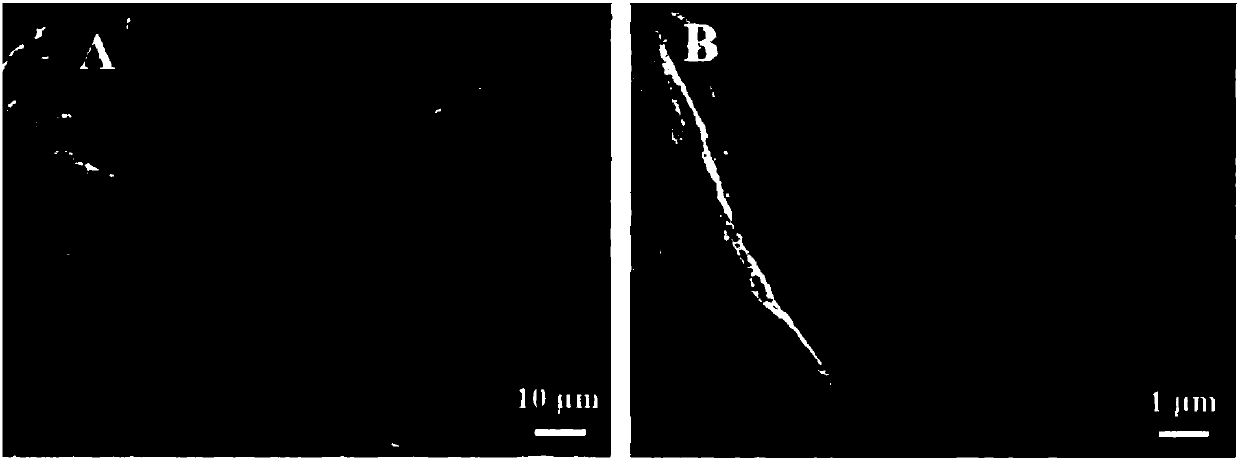

Preparation method of nitrogen-doped carbon nanotube wave-absorbing agent

PendingCN114314562AConductivity adjustableEfficient electromagnetic wave absorption performanceMagnetic/electric field screeningCarbon nanotubesPolypyrrolePyrrole

The invention discloses a preparation method of an aza carbon nanotube wave-absorbing agent. The method comprises the following steps: dissolving pyrrole in methanol, adding an induction reagent and an oxidant ferric chloride solution, rapidly stirring and reacting to obtain a polypyrrole nanotube, and carbonizing the polypyrrole nanotube at 500-700 DEG C to obtain the nitrogen-doped carbon nanotube. And the material has efficient electromagnetic wave absorption performance. The invention further discloses a preparation method of the nitrogen-doped carbon nanotube wave-absorbing agent, the method is simple in process, complex synthesis equipment is not needed, large-scale production is easy, the prepared nitrogen-doped carbon nanotube wave-absorbing agent has efficient electromagnetic wave absorbing performance, the conductivity is 10 <-2 >-10 < 2 > S / cm, and the electromagnetic wave absorbing frequency is 2-18 GHz.

Owner:NANJING UNIV OF SCI & TECH

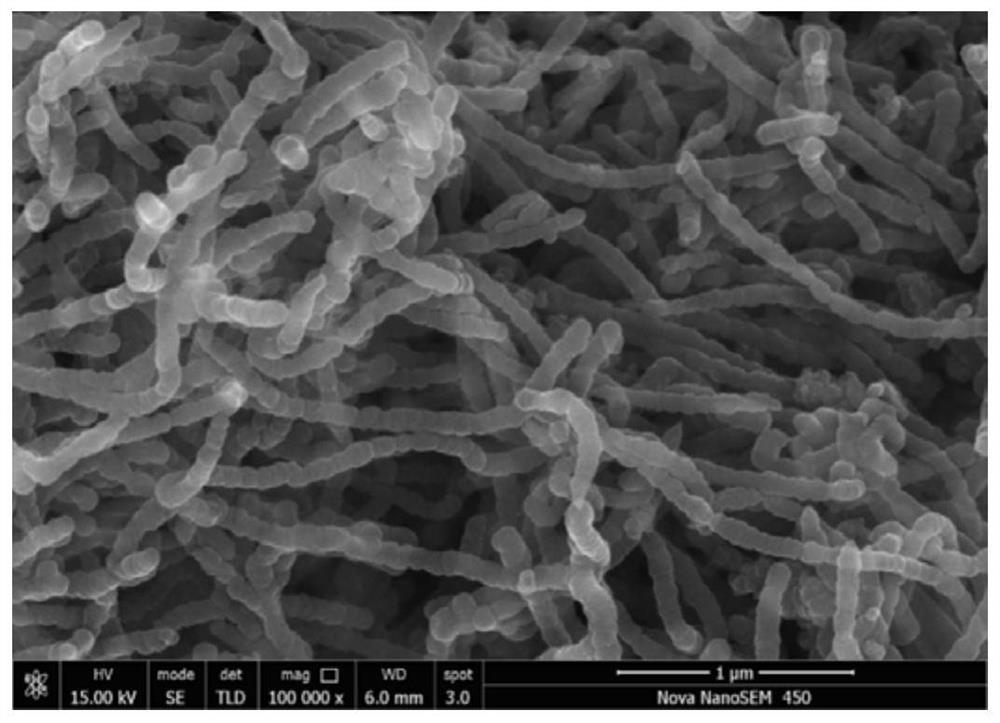

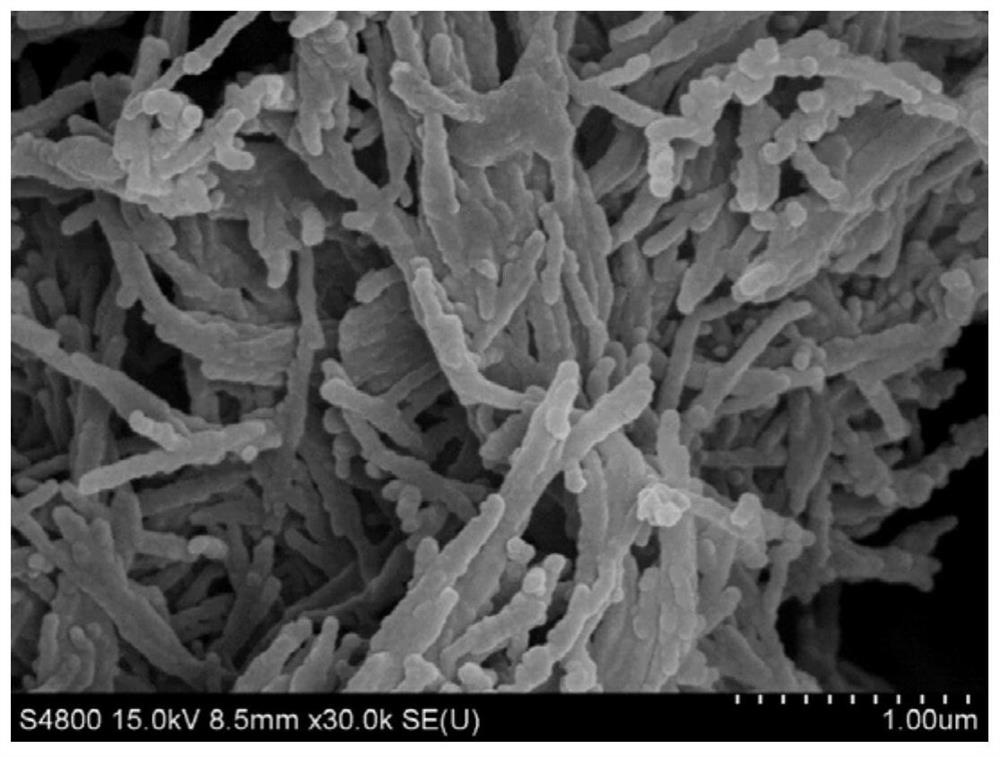

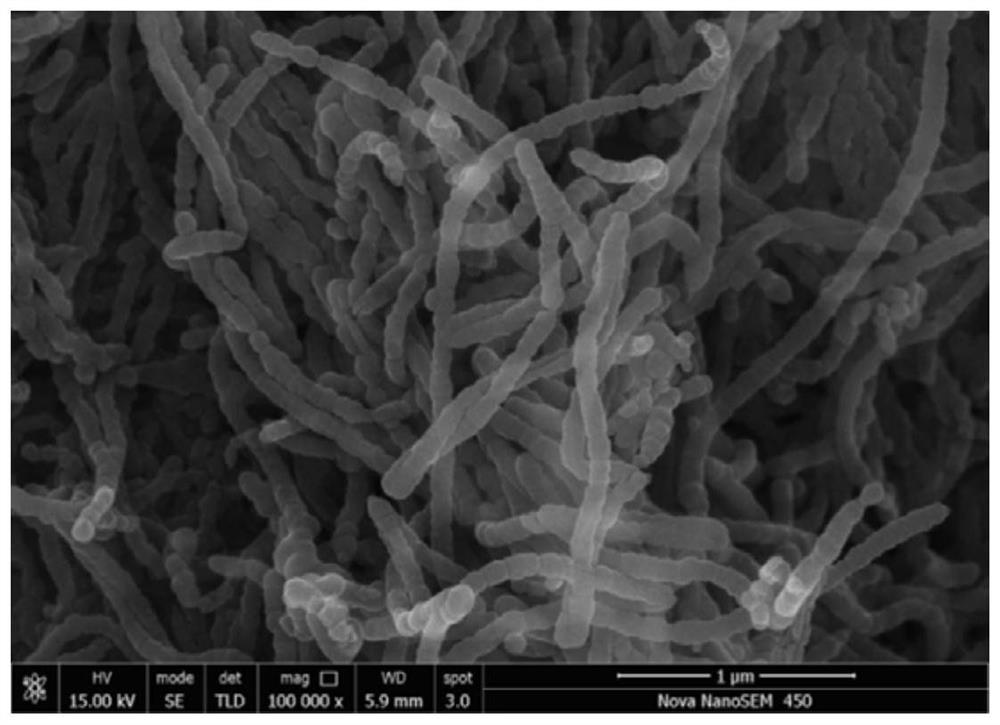

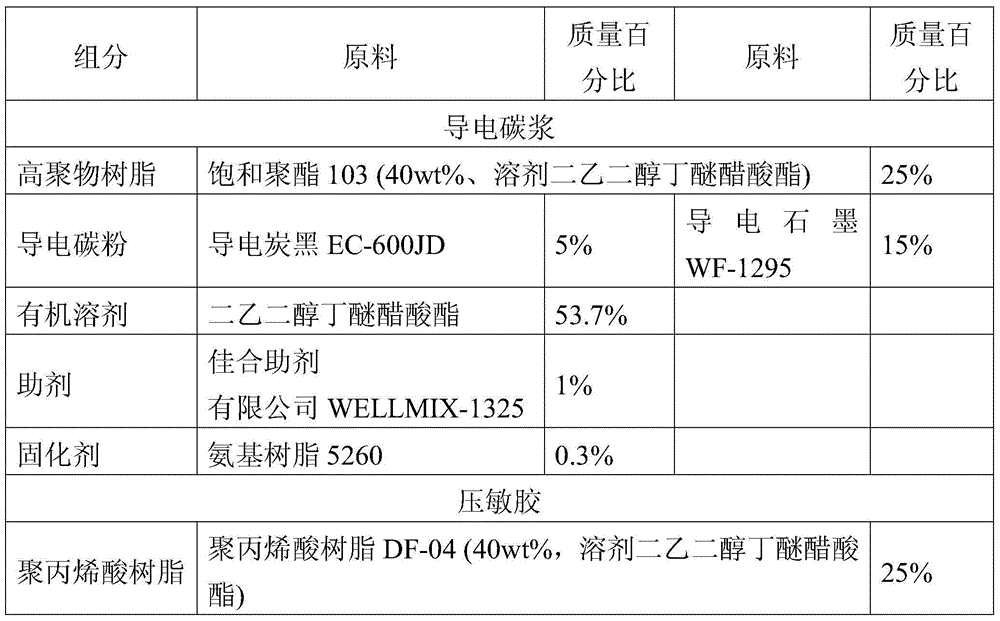

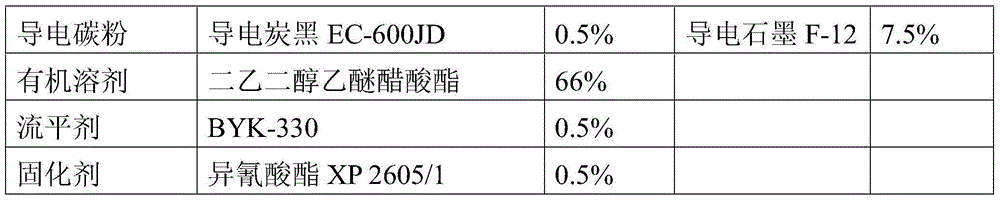

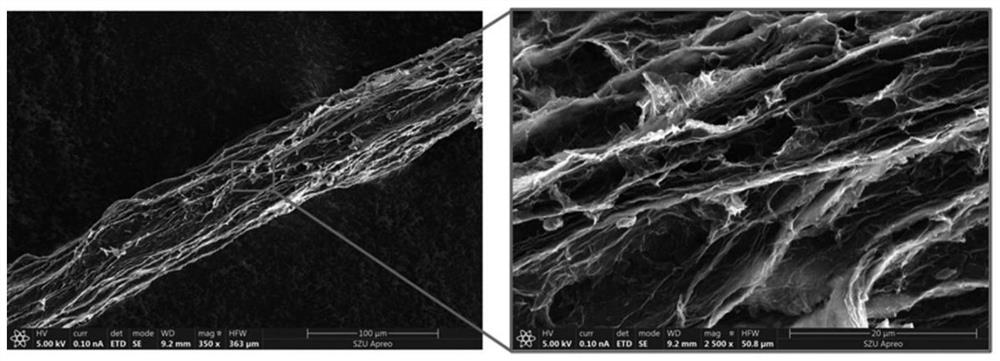

A two-step preparation method of high-performance conductive pressure-sensitive adhesive tape

ActiveCN103865423BReduce distanceImprove conductivityNon-macromolecular adhesive additivesFilm/foil adhesivesSlurryGraphite

The invention relates to a two-step preparation method of a high-property conductive pressure-sensitive adhesive tape. The pressure-sensitive adhesive tape comprises two-layer membrane materials, namely a lower conductive carbon slurry layer and an upper pressure-sensitive adhesive layer. The two-step preparation method particularly comprises the following steps of: (1) uniformly coating conductive carbon slurry on the surface of a substrate to prepare a membrane, and drying; (2) uniformly coating a layer of pressure-sensitive adhesive on the conductive carbon slurry membrane layer to prepare a membrane, and drying. The two-step preparation method disclosed by the invention can meet the requirements for both high conductivity and high adhering property by using low-cost carbon black or graphite as conducting particles.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD

Zeolite-porous carbon-photocatalyst ternary composite material, preparation method thereof and wastewater treatment device

ActiveCN110302828AImprove utilization efficiencyImprove catalytic performanceWater treatment parameter controlMolecular sieve catalystsMicroorganismTreatment effect

The invention provides a zeolite-porous carbon-photocatalyst ternary composite material and a preparation method thereof. The ternary composite material comprises a carrier and photocatalysts, whereinthe carrier comprises composite zeolite and porous carbon, and the photocatalysts are loaded on the inner surface and the outer surface of the carrier. The carrier of the zeolite-porous carbon-photocatalyst ternary composite material comprises the zeolite and the porous carbon, and the wastewater treatment effect of the ternary composite material is improved by the aid of the composite zeolite serving as a carrier. The carrier of the ternary composite material is a porous carrier, so that an adsorption environment is provided for the photocatalysts, the zeolite or the porous carbon functionsin adsorption and filtration, heavy metals are adsorbed, or irons are exchanged, organic matters are intercepted and fixed, microorganisms are adsorbed on the surface of the zeolite or the porous carbon, the intercepted organic matters are degraded and decomposed, photocatalyst nano-particles are prepared into a strong oxidation environment, and all the organic matters in water are decomposed.

Owner:SHANGHAI JIAO TONG UNIV +1

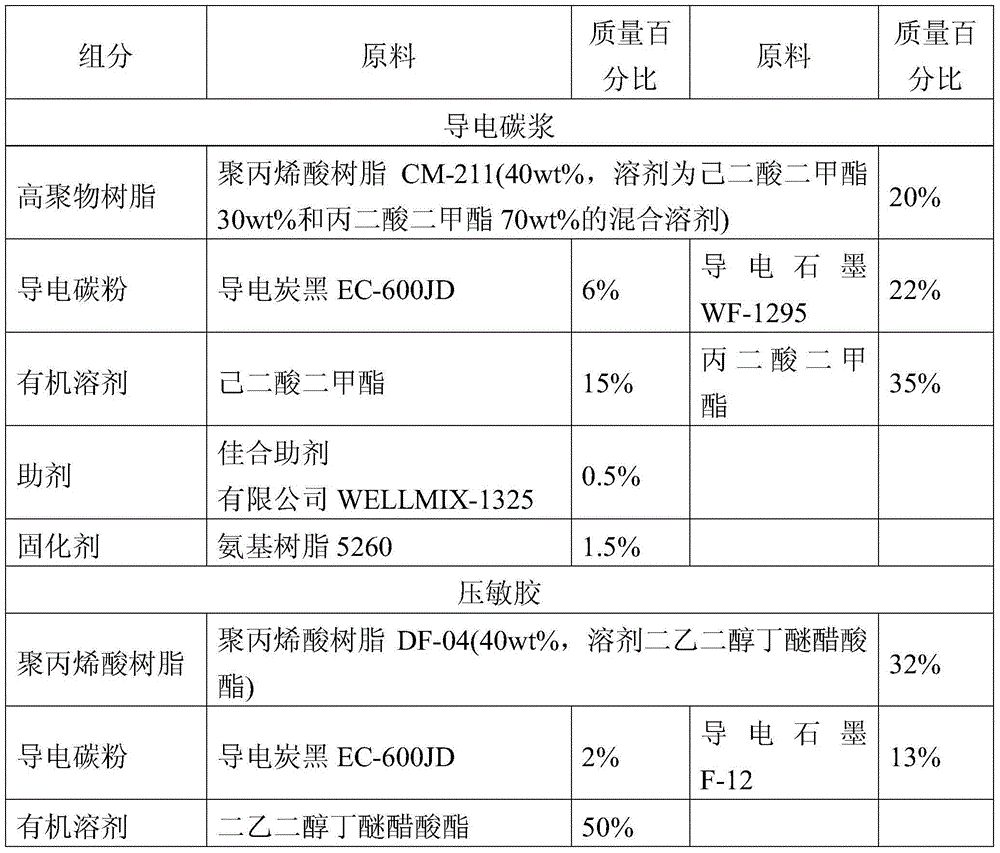

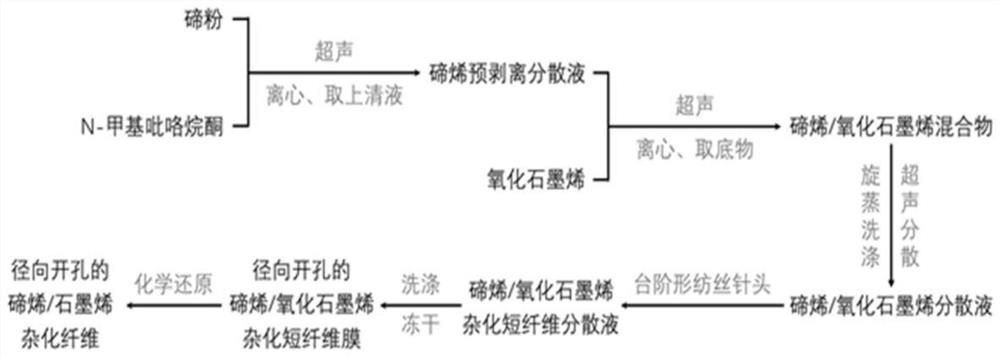

Tellurium terpene/graphene hybridization porous fibers with radial opening holes and preparation method and application thereof

ActiveCN111636119AAchieve homogeneous mixingPrevent subsidenceInorganic material artificial filamentsSolid-state devicesPorous fiberGraphene

The invention provides a preparation method of tellurium terpene / graphene hybridization porous fibers with radial opening holes. The method includes the steps that a mixture of the tellurium terpene and oxidized graphene is prepared, a mixing dispersion solution of the tellurium terpene / oxidized graphene is prepared, and spinning and post-processing are made. According to the preparation method oftellurium terpene / graphene hybridization porous fibers with radial opening holes, the defects that the tellurium terpene is prone to stacking with each other, the dispersity in water is poor, and thetellurium terpene dispersion solution itself has no spinnability is solved through the function of the oxidized graphene to assist dispersion and spinning, and the orientation construction of holes of porous tellurium terpene / oxidized graphene in the process of spinning is achieved. Tellurium terpene / graphene hybridization porous fibers with radial opening holes and an application thereof are provided.

Owner:SHENZHEN UNIV

Preparation method of conductive polypyrrole hollow compound microsphere sensitive to temperature

InactiveCN102198384BThe synthesis method is simpleParticle size controllableMicroballoon preparationMicrocapsule preparationCross-linkPolypyrrole

The invention discloses a preparation method of a conductive polypyrrole hollow compound microsphere which is sensitive to temperature, comprising the steps of: adopting a poly-(N-isopropylamide-styrene) compound microsphere prepared by a soap-free emulsion polymerization method as a core, synthesizing a poly(N-isopropylamide-methacrylic acid) shell with a cross-linked structure by a seed emulsion polymerization method, preparing a polypyrrole compound microsphere by an oxidation polymerization method, and preparing a polypyrrole hollow compound microsphere by adopting the polypyrrole compound microsphere as a template. The preparation method of the conductive polypyrrole hollow compound microsphere which is sensitive to temperature is simple in synthesizing method; the size of the obtained product is easy to control; the microsphere has large specific surface and obvious volume swelling effect; the cavity in the microsphere can contain large amount of guest molecules or macromoleculecarriers; and the cavity size, sensitivity and conductivity of the microsphere are adjustable.

Owner:SHAANXI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com