Component prepared from laser processing diamond material and preparation method of component

A technology of laser processing and components, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problem that the conductivity of the substrate material or the carrier concentration change range is limited, it is difficult to have a high modulation depth of electromagnetic waves, and the modulation is restricted The depth of modulation of the device and other issues can be easily met, and the effects of good thermal conductivity and high precision can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are enumerated hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

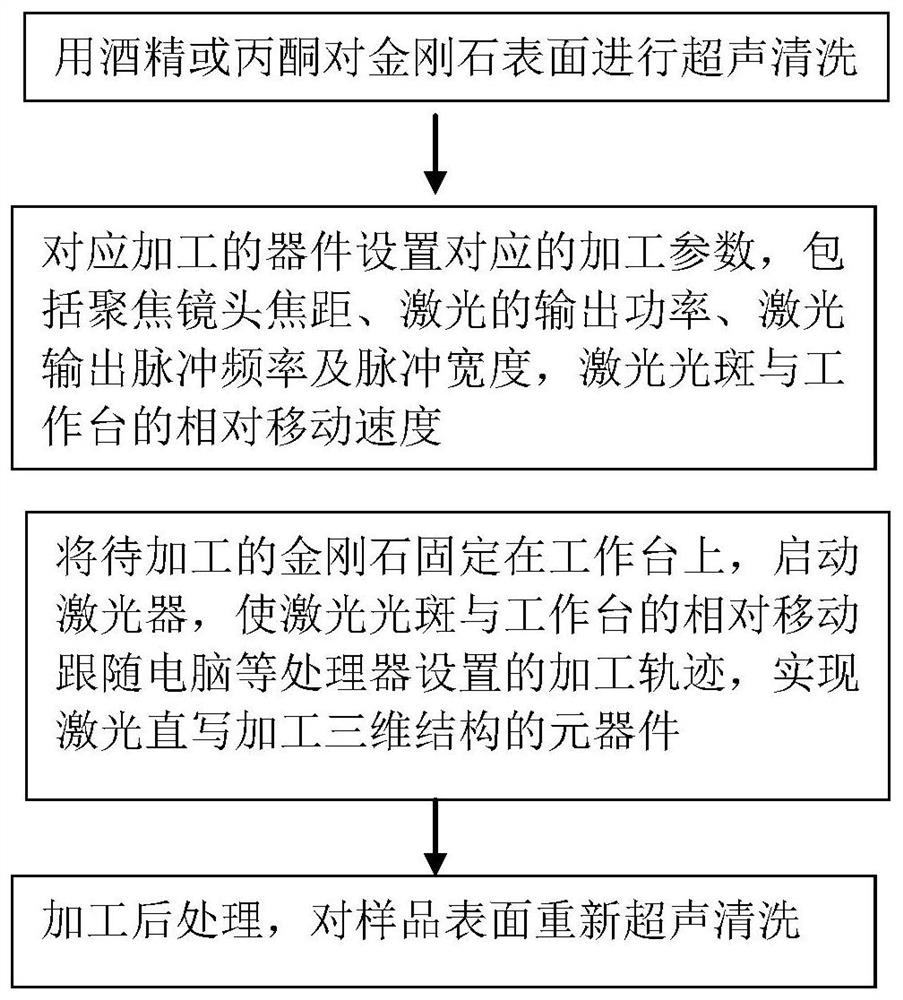

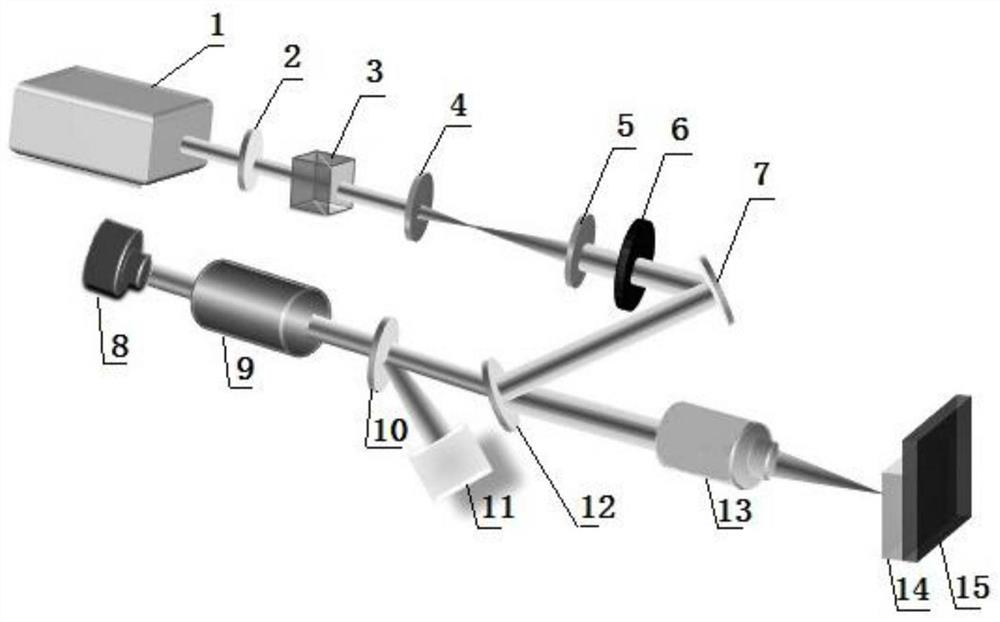

[0022] See Figure 1 to Figure 2 , a kind of method that prepares components and parts with laser processing diamond material, adopt following device: laser device, the beam shutter 6 that is used to control the laser output of laser device, the workbench 15 that places diamond material 14; A focusing lens 13 for focusing is arranged between them; the laser light emitted by the laser passes through the focusing lens 13 and is irradiated on the diamond material 14 on the worktable 15; by controlling the relative movement of the laser spot and the worktable 15, the laser is focused on the diamond surface or inside; by adjusting the optical characteristic parameters of the focusing lens, the output power of the laser, the pulse re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com