Ammonia gas sensor loaded with platinum particles and preparation method thereof

A technology of ammonia sensor and particles, which is applied in the direction of chemical instruments and methods, instruments, scientific instruments, etc., can solve the problems of too many researches on the gas-sensing performance of ammonia gas, and achieve the improvement of responsiveness and reaction speed, and excellent gas-sensing performance , the effect of changing the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 1. A method for preparing an ammonia gas-sensitive material loaded with platinum particles, comprising the steps of:

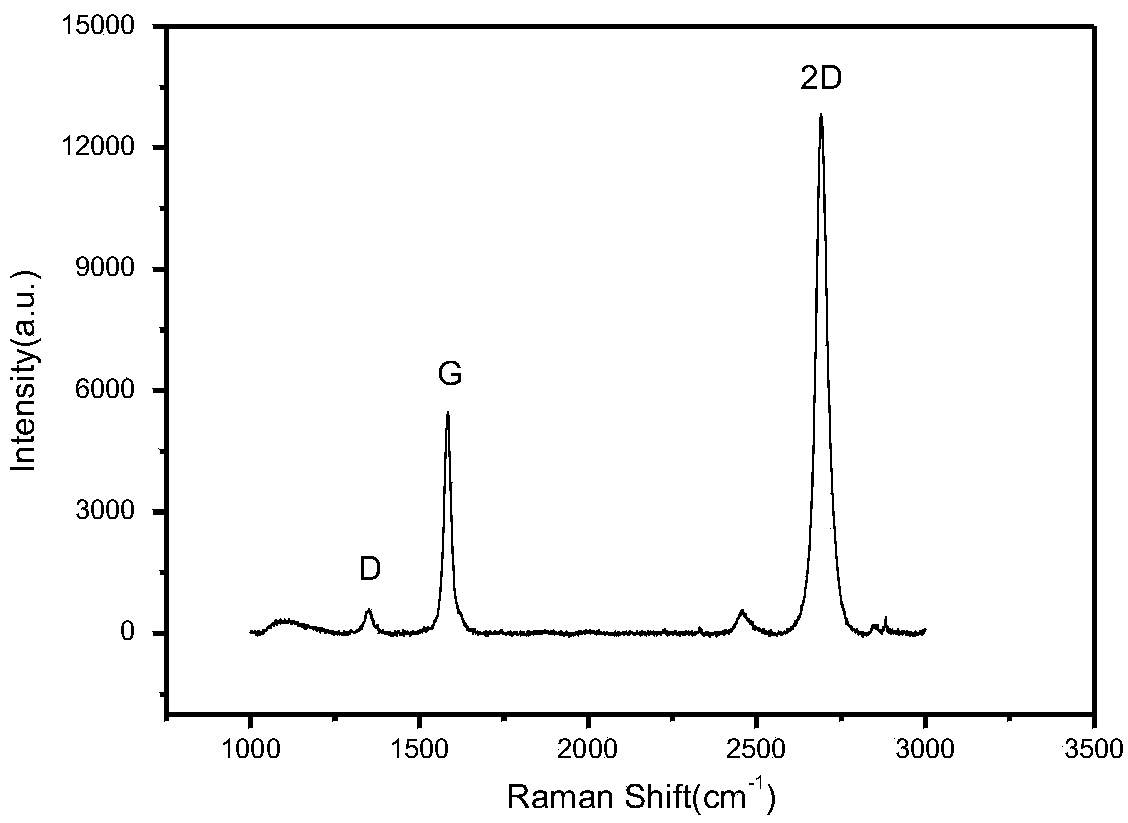

[0057] (1) Preparation of graphene film: select 25 μm thick copper foil as the growth substrate, use acetone, absolute ethanol, and deionized water to clean the copper foil in sequence, and put the copper foil into chemical vapor deposition equipment after drying. Introduce 400sccm argon and 20sccm hydrogen as the gas source for copper foil treatment, and perform annealing treatment on the copper foil at 1000°C for 2 hours. After the end, it enters the natural cooling process, and 400 sccm argon is introduced as a protective gas source. After cooling down, take out the copper foil with graphene, and then press the graphene / copper foil and PET / silica gel with a hot press at 60°C, and put the PET / graphene / copper foil in a concentration of 2.5M Soak in ferric chloride solution for 4 hours to completely dissolve the copper foil, wash it in deionized water ...

Embodiment 2

[0062] 1. A method for preparing an ammonia gas-sensitive material loaded with platinum particles, the same as in Example 1, the difference is that steps (2) and (3) are not included, that is, the ammonia gas-sensitive material of the present embodiment has not passed through ultraviolet ozone modified, and there is no graphene film loaded with platinum particles on the surface.

[0063] 2. A method for preparing an ammonia sensor, which is the same as that in Embodiment 1, except that the gas-sensitive material for the sensor is prepared in this embodiment.

Embodiment 3

[0065] 1. A method for preparing an ammonia gas-sensitive material loaded with platinum particles, the same as in Example 1, except that step (3) is not included, that is, the ammonia gas-sensitive material of the present embodiment has only been modified by ultraviolet ozone, But there is no graphene film loaded with platinum particles on the surface.

[0066] 2. A method for preparing an ammonia sensor, which is the same as that in Embodiment 1, except that the gas-sensitive material for the sensor is prepared in this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com