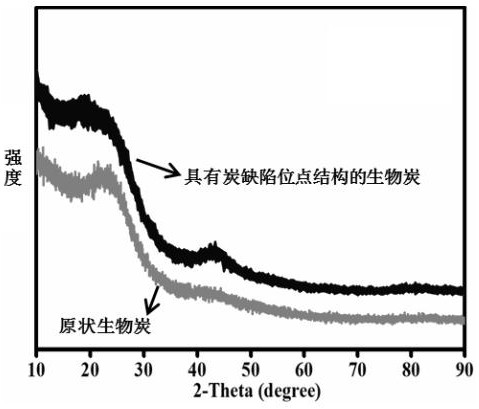

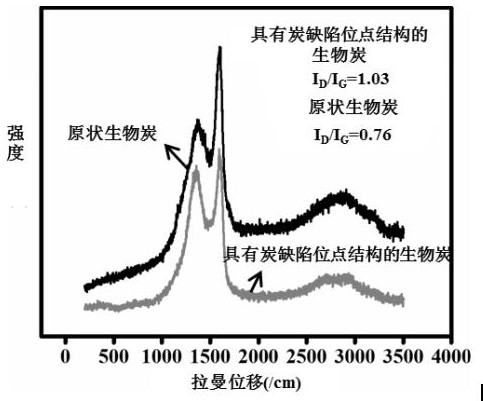

Biochar adsorbent with carbon defect site structure, and preparation method and application of biochar adsorbent

A biochar and adsorbent technology, applied in chemical instruments and methods, adsorption of water/sewage treatment, water pollutants, etc., can solve the problems of non-selective adsorption, etc., reduce environmental burden, low cost, improve disorder degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Carbon adsorbent having a biological preparation and its application position carbon defect structure, comprising the steps of:

[0025] (1) Granulation: The washed, dried bamboo shell crushed through a 60 mesh sieve;

[0026] (2) pre-: Apply sifted bamboo shell, placed in a muffle furnace at 500 ° C preform 4 h, cooled to room temperature, taken out, washed to neutrality, dried, to obtain biocoke bamboo shell;

[0027] (3) Transformation: Take 0.2 g Hock biochar and 0.6 g CH 3 COOK in the mortar, mixed homogeneously ground, placed in a tube furnace temperature program, into N 2 A flow rate of 60 mL / min, conversion 2 h at 700 ° C. ;

[0028] After the conversion of biochar beaker 20mL beaker was added to a concentration of 2moL / L HCl, the beaker was placed in a water bath oscillator at a temperature of 25 ° C, shaking speed of 120rpm shaking 20min under conditions: (4) was purified removed by filtration, and washed with deionized water until the filtrate is neutral.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com