Carbon black-graphene/aqueous polyurethane coating composite conductive thin film based seawater power generation apparatus, and preparation method and application therefor

A water-based polyurethane, composite conductive technology, applied in new material technology and new energy fields, can solve problems such as restricting development, and achieve excellent conductive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

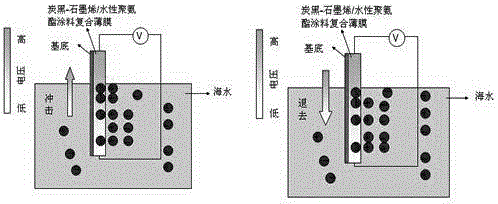

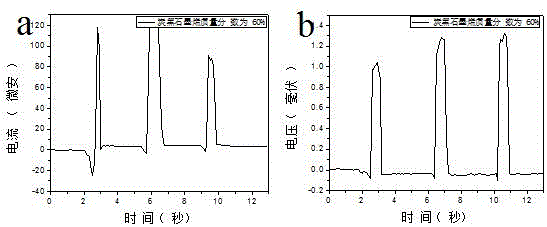

[0025] The seawater power generation device based on the composite conductive film of carbon black graphene / water-based polyurethane coating provided by the invention, its preparation method comprises the following steps:

[0026] (1) Disperse a certain mass of water-based polyurethane coating into distilled water, and prepare a dispersion of water-based polyurethane coating with a mass-volume ratio of 0.001-0.023g / mL.

[0027] (2) Dispersing the mixed powder of graphene and carbon black into the dispersion liquid of the water-based polyurethane coating in step (1), the mass of the mixed powder of graphene and carbon black accounts for the total matter dispersed in the dispersion liquid The mass fraction of the carbon black is 40%, and it is dispersed by ultrasonic to form a stable dispersion; wherein the mass ratio of graphene and carbon black is 2:1.

[0028] (3) Apply the stable dispersion obtained in step (2) to the substrate, and dry naturally in the air to form a composi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com