Multifunctional intelligent fiber or fabric

A multi-functional and intelligent technology, applied in the field of materials, can solve problems such as single function, achieve the effect of process safety, wide application range and good product uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

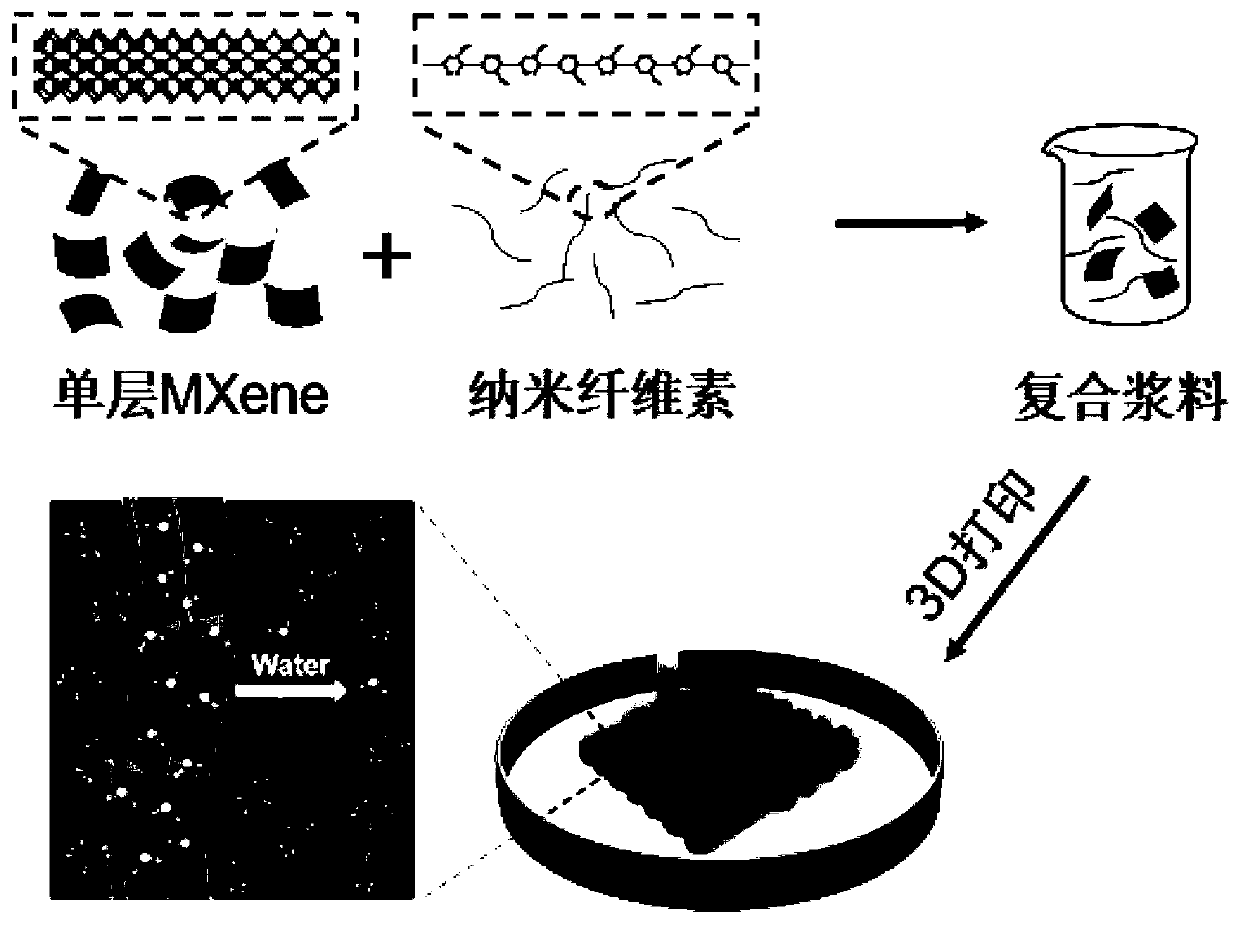

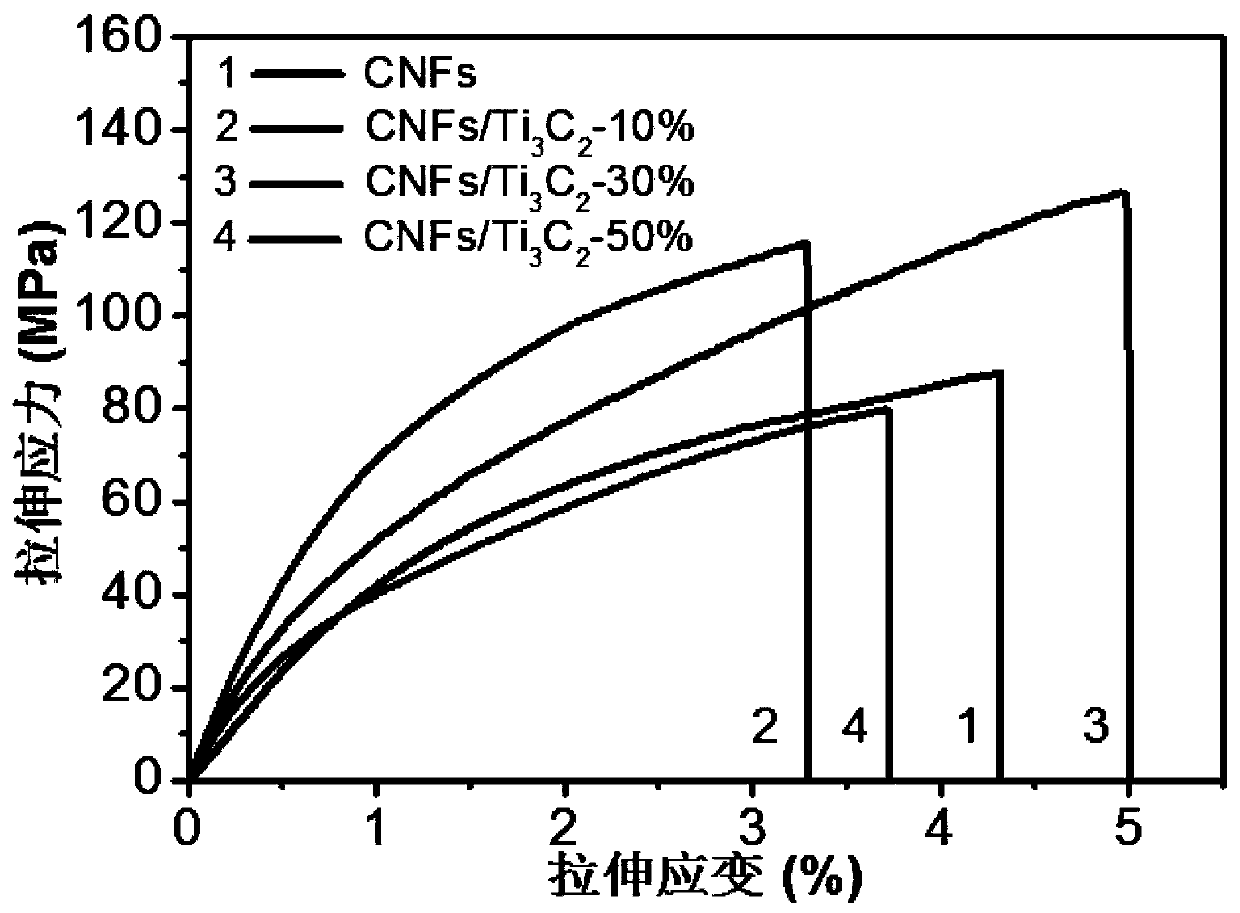

[0034] The preparation method of the invention is simple and convenient, has wide application range, safe process and good uniformity of the obtained product, and is an efficient, quick and environment-friendly method for preparing intelligent fibers and fabrics. Moreover, TOCNFs / MXene fibers in the resulting multifunctional smart fibers and fabrics not only have high mechanical properties and electrical conductivity, but also have photothermal, electrothermal and mechanical sensing properties, which can be used in wearable fabric products, such as wearable health monitoring fabrics. and other fields have good application potential. The preparation method of smart fiber and smart fiber fabric is exemplarily described below, such as figure 1 shown.

[0035] Set the mass ratio of raw materials as required, stir and mix the MXene material aqueous dispersion and the TOCNFs aqueous dispersion according to different weight ratios (9:1 to 3:7) of TOCNFs and MXene (for example, stirr...

Embodiment 1

[0044] Aqueous dispersion of cellulose TOCNFs oxidized by 2,2,6,6-tetramethylpiperidine-1-oxydione (TEMPO) and the composition as Ti 3 C 2 After the MXene nanosheets are mixed and stirred evenly in a ratio of 9:1 by solid content weight ratio, they are stirred at room temperature for 24h to obtain a mixed slurry (concentration is 12mg / ml);

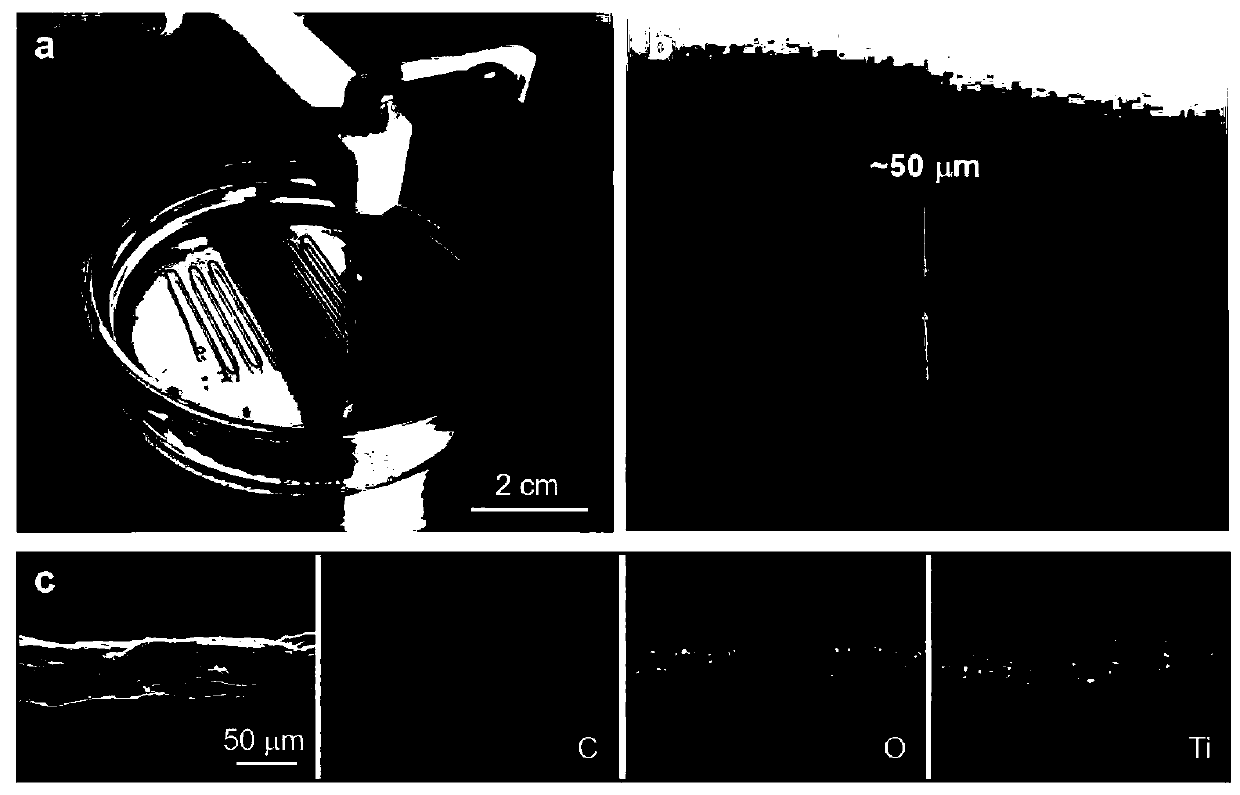

[0045] The resulting mixed slurry was placed in a vacuum bottle for 30 min to remove air bubbles. Subsequently, the mixed slurry was printed into ethanol by 3D printing method, and after taking out and drying, composite fibers and fabrics with a weight ratio of TOCNFs and MXene of 9:1 were obtained. In the above-mentioned process of preparing smart fibers or preparing smart fiber fabrics, the diameter of the needle used for extrusion molding may be 0.60 mm. The injection rate of the mixed slurry can be 0.67ml / min. The speed of movement of the needle may be 4.2 mm / sec. Such as figure 2 As shown, the composite slurry is printed into et...

Embodiment 2

[0047] Except that the TOCNFs dispersion and the MXene material are at a solid content ratio of 7:3, other parameters and steps refer to Example 1 to prepare a composite fiber and fabric with a weight ratio of TOCNFs and MXene of 7:3. In the above-mentioned process of preparing smart fibers or preparing smart fiber fabrics, the diameter of the needle used for extrusion molding may be 0.60 mm. The injection rate of the mixed slurry can be 0.67ml / minute. The speed of movement of the needle may be 4.2 mm / sec. The diameter of the dried smart fibers (or fibers in the fabric) is about 0.05 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com