High-viscosity low-melting-point metal conductive paste and preparation method thereof

A low-melting point metal and conductive paste technology, applied in the direction of metal/alloy conductors, cable/conductor manufacturing, circuits, etc., can solve the problems of limited conductivity, large air gap, metal overflow failure, etc., to achieve adjustable conductivity, Improvement of electrical conductivity, the effect of high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 shows a typical application of a high-viscosity low-melting-point metal conductive paste of the present invention.

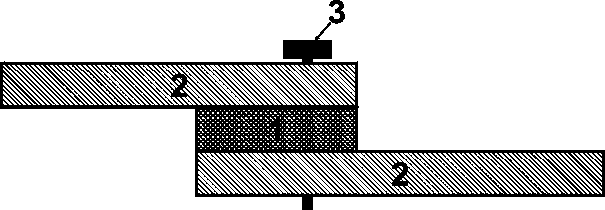

[0028] figure 1 It is a structural schematic diagram of a high-conductivity low-melting-point metal conductive paste applied to electronic components in Example 1. Among them: 1 is conductive paste, 2 is electronic components, and 3 is fastening screws.

[0029] In the high-viscosity low-melting-point metal conductive paste of this embodiment, the low-melting-point metal is gallium-indium-tin-zinc alloy (alloy mass fraction: Ga 61%, In 25%, Sn 13%, Zn 1%), and the melting point is 8°C. The metal powder is copper powder, the mass fraction accounts for 50% of the mass of the conductive paste, and the particle size is 1 μm.

[0030] When using, first apply the high-viscosity low-melting-point metal conductive paste evenly between the electronic components; then fix it tightly with screws. The conductivity and viscosity of the high-viscosity and ...

Embodiment 2

[0033] figure 1 It is a structural schematic diagram of a high-conductivity low-melting-point metal conductive paste applied to electronic components in Example 1. Among them: 1 is conductive paste, 2 is electronic components, and 3 is fastening screws.

[0034] In the high-viscosity low-melting-point metal conductive paste of this embodiment, the low-melting-point metal is gallium-indium-tin-zinc alloy (alloy mass fraction: Ga 61%, In 25%, Sn 13%, Zn 1%), and the melting point is 8°C. The metal powder is copper powder, the mass fraction accounts for 0.01% of the mass of the conductive paste, and the particle size is 1mm. When using, first apply the high-viscosity low-melting-point metal conductive paste evenly between the electronic components; then fix it tightly with screws. The conductivity and viscosity of the high-viscosity and low-melting-point metal conductive paste of the present invention can be adjusted according to different application occasions, that is, it has...

Embodiment 3

[0037] figure 1 It is a structural schematic diagram of a high-conductivity low-melting-point metal conductive paste applied to electronic components in Example 1. Among them: 1 is conductive paste, 2 is electronic components, and 3 is fastening screws.

[0038] In the high-viscosity low-melting-point metal conductive paste of this embodiment, the low-melting-point metal is gallium-indium-tin-zinc alloy (alloy mass fraction: Ga 61%, In 25%, Sn 13%, Zn 1%), and the melting point is 8°C. The metal powder is copper powder, the mass fraction accounts for 20% of the mass of the conductive paste, and the particle size is 4 μm.

[0039] When using, first apply the high-viscosity low-melting-point metal conductive paste evenly between the electronic components; then fix it tightly with screws. The conductivity and viscosity of the high-viscosity and low-melting-point metal conductive paste of the present invention can be adjusted according to different application occasions, that is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com