A kind of preparation method of molybdenum sulfide/graphene-graphene nanoribbon airgel composite material

A graphene nanoribbon, composite material technology, applied in the direction of molybdenum sulfide, nanotechnology, nanotechnology, etc., can solve the problems of inhibiting catalytic properties and energy storage properties, and the electrochemical active sites cannot be fully exposed, so as to shorten the transfer time. Route, ease of mass production, good synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

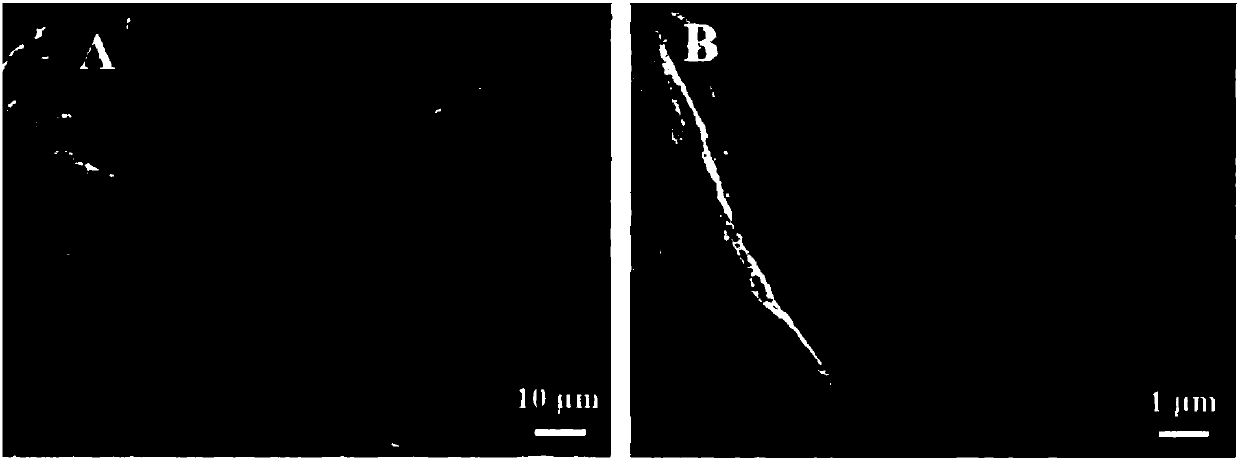

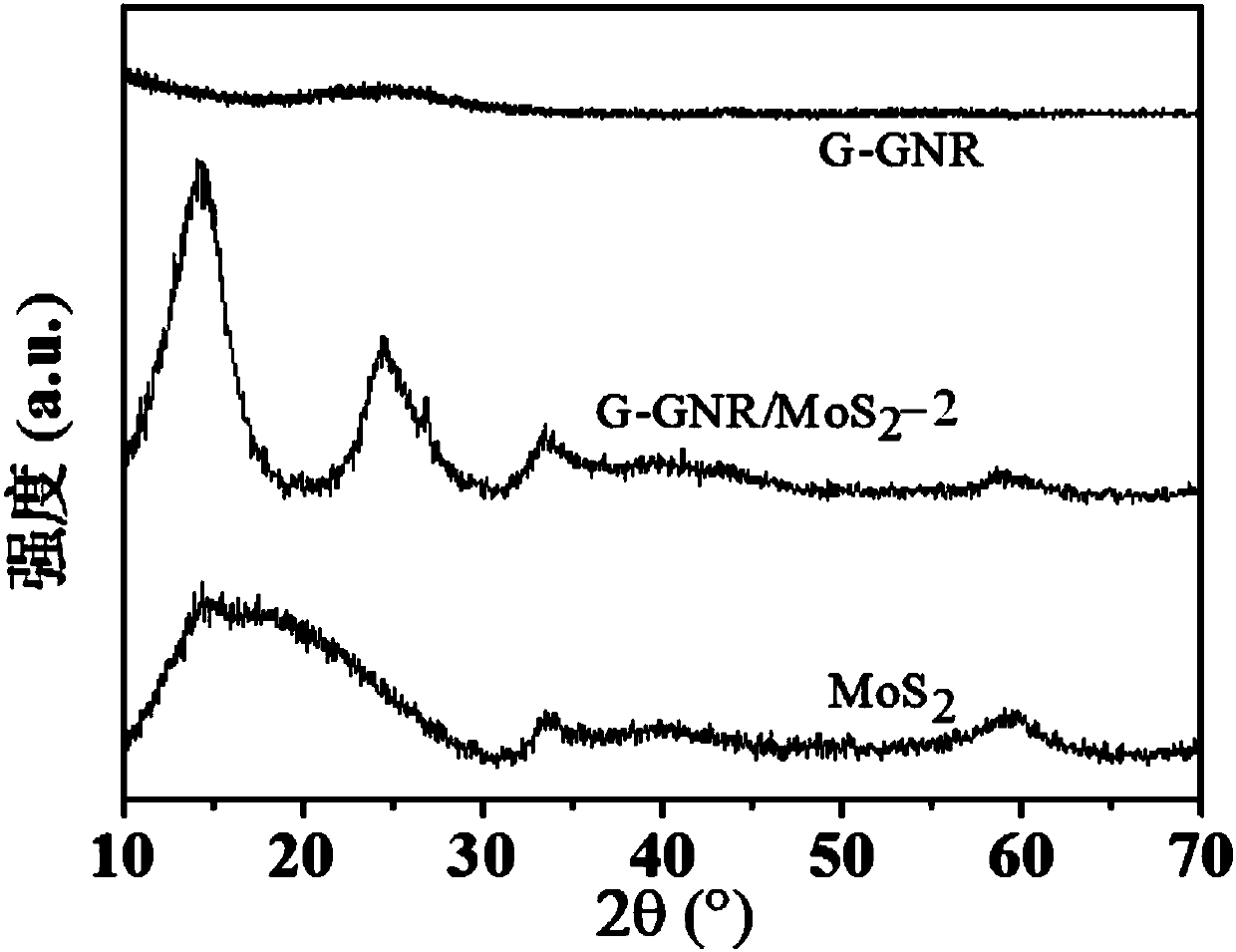

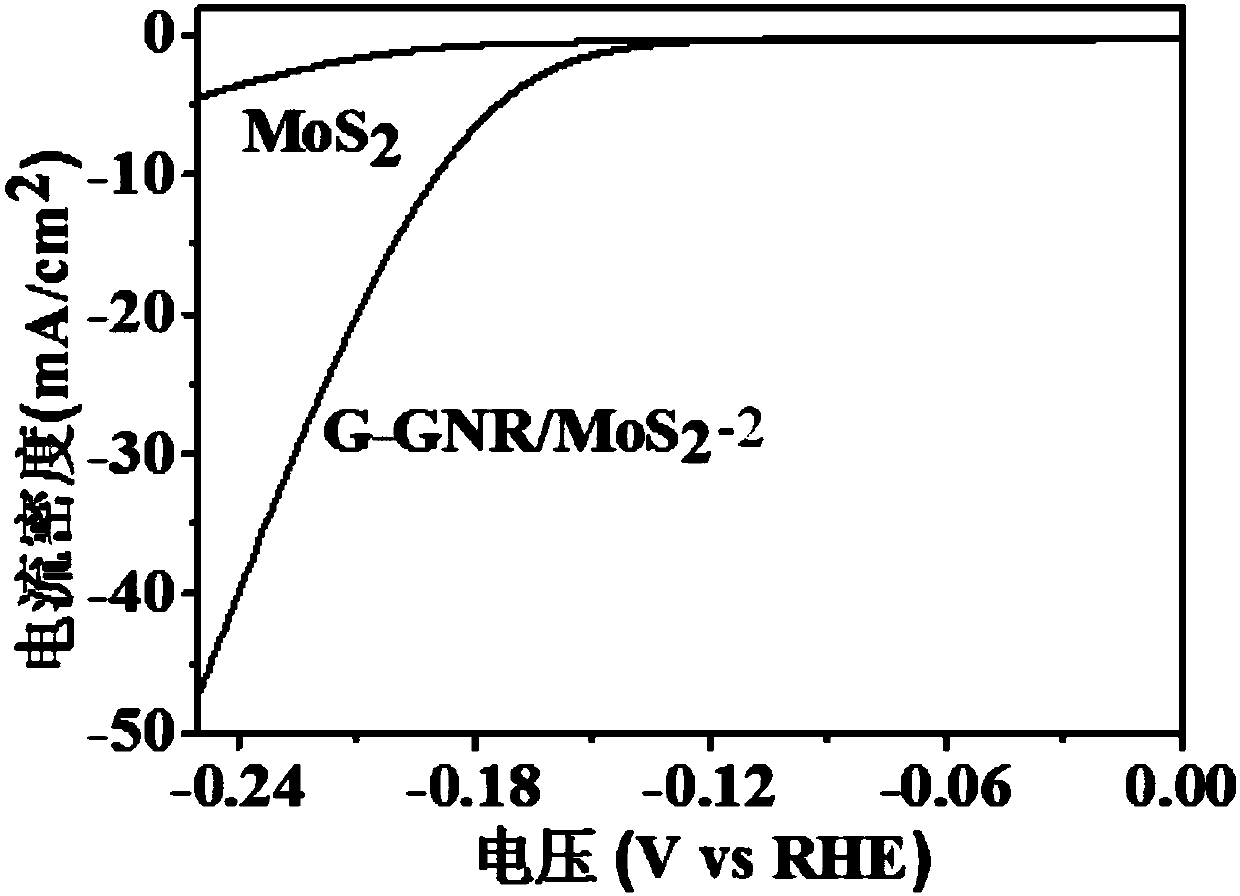

Image

Examples

Embodiment 1

[0038] (1) Disperse 200 mg of graphene oxide in 100 ml of deionized water, and obtain a stable graphene oxide dispersion with a concentration of 2 mg / ml by ultrasound;

[0039] (2) Drop 3ml of graphene oxide nanoribbon aqueous dispersion with a concentration of 2mg / ml into 3ml of the graphene oxide solution in step (1), and stir for 3min to form a homogeneous mixture;

[0040] (3) Freeze the obtained mixed solution into a solid in liquid nitrogen, and then freeze-dry it in a freeze dryer for 48 hours to obtain a precursor of the graphene-graphene nanoribbon gel;

[0041] (4) Add 44 mg of ammonium thiomolybdate to 10 ml of N,N-dimethylformamide solvent, and ultrasonicate for 5 minutes to obtain a uniform red-brown solution;

[0042] (5) Take 10 mg of the obtained graphene-graphene nanoribbon gel precursor and put it into the N,N-dimethylformamide solution of ammonium thiomolybdate in step (4), and let it stand for 8 hours. The molybdenum sulfide / graphene-graphene nanobelt aerogel compo...

Embodiment 2

[0044] (1) Disperse 200 mg of graphene oxide in 100 ml of deionized water, and obtain a stable graphene oxide dispersion with a concentration of 2 mg / ml by ultrasound;

[0045] (2) Drop 4ml of graphene oxide nanoribbons aqueous dispersion with a concentration of 2mg / ml into 2ml of the graphene oxide solution in step (1) and stir for 3min to form a homogeneous mixture;

[0046] (3) Freeze the obtained mixed solution into a solid in liquid nitrogen, and then freeze-dry it in a freeze dryer for 48 hours to obtain a precursor of the graphene-graphene nanoribbon gel;

[0047] (4) Add 44 mg of ammonium thiomolybdate to 10 ml of N,N-dimethylformamide solvent, and ultrasonicate for 5 minutes to obtain a uniform red-brown solution;

[0048] (5) Take 10 mg of the obtained graphene-graphene nanoribbon gel precursor and put it into the N,N-dimethylformamide solution of ammonium thiomolybdate in step (4), and let it stand for 8 hours. By solvothermal reaction (reaction at 200°C for 8 hours), molyb...

Embodiment 3

[0054] (1) Disperse 200 mg of graphene oxide in 100 ml of deionized water, and obtain a stable graphene oxide dispersion with a concentration of 2 mg / ml by ultrasound;

[0055] (2) Drop 3ml of graphene oxide nanoribbons aqueous dispersion with a concentration of 2mg / ml into 3ml of the graphene oxide solution in step (1), and stir for 3min to form a homogeneous mixture;

[0056] (3) Freeze the obtained mixed solution into a solid in liquid nitrogen, and then freeze-dry it in a freeze dryer for 48 hours to obtain a precursor of the graphene-graphene nanoribbon gel;

[0057] (4) Add 22 mg of ammonium thiomolybdate to 10 ml of N,N-dimethylformamide solvent, and ultrasonicate for 5 minutes to obtain a uniform red-brown solution;

[0058] (5) Take 10 mg of the obtained graphene-graphene nanoribbon gel precursor and put it into the N,N-dimethylformamide solution of ammonium thiomolybdate in step (4), and let it stand for 8 hours. By solvothermal reaction (reaction at 200°C for 8 hours), moly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com