Novel method for preparing polyaniline composite conductive fabric

A composite conductive and polyaniline technology, applied in physical treatment, textile and papermaking, fiber treatment, etc., can solve problems such as uneven distribution of PANI deposition, uneven conductivity of fabrics, and unsatisfactory durability, so as to improve unevenness And conductive stability, reduce surface resistance, uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below according to the drawings and specific embodiments, so as to better illustrate the technical features and product characteristics of the present invention.

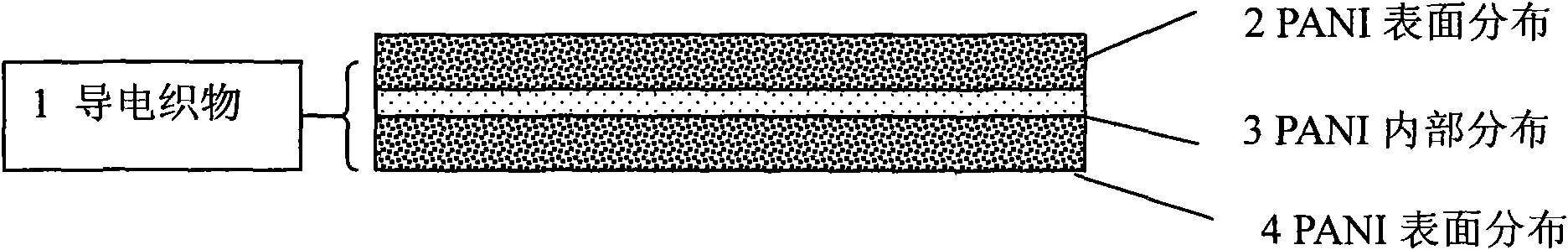

[0022] The present invention adopts in-situ polymerization to prepare polyaniline composite conductive fabric, wherein the structural schematic diagram of conductive fabric is as follows figure 1 shown.

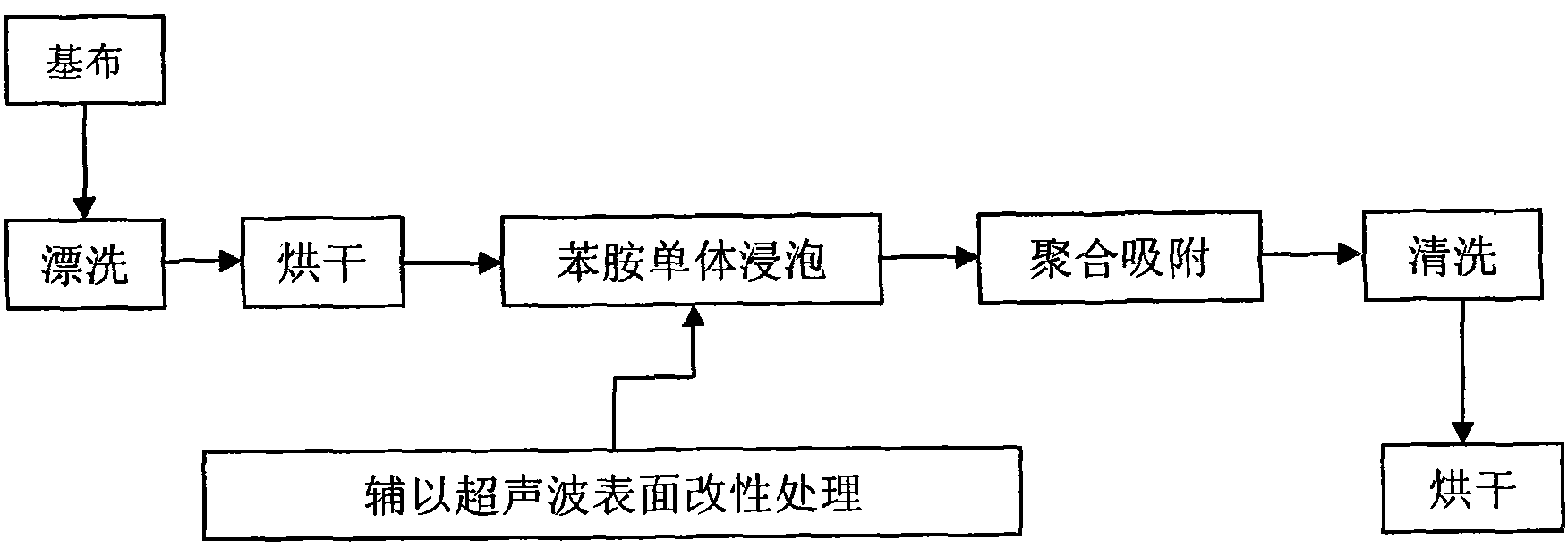

[0023] Its processing steps are as follows:

[0024] (1), choose the base fabric, for example, the weight is 196g / m 2 nylon / spandex warp knitted fabric.

[0025] (2) Immerse the fabric in a concentration of 1-2g·L -1 , liquor ratio 1:50, water bath temperature of 65 ℃ in S16 neutral refining agent pretreatment for 1 hour, take it out, wash with water several times, put it in an oven at 80 ℃ for 1 hour, and dry it for later use.

[0026] (3) Immerse the fabric in the aniline (An) monomer solution, with a bath ratio of 1:30, supplemented by ultrasonic impregn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com