Continuous preparation method of graphene film prereg

A graphene film and prepreg technology, applied in the field of functional materials, can solve problems such as the inability to realize continuous preparation of graphene prepregs, and achieve the effects of high output and wide use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

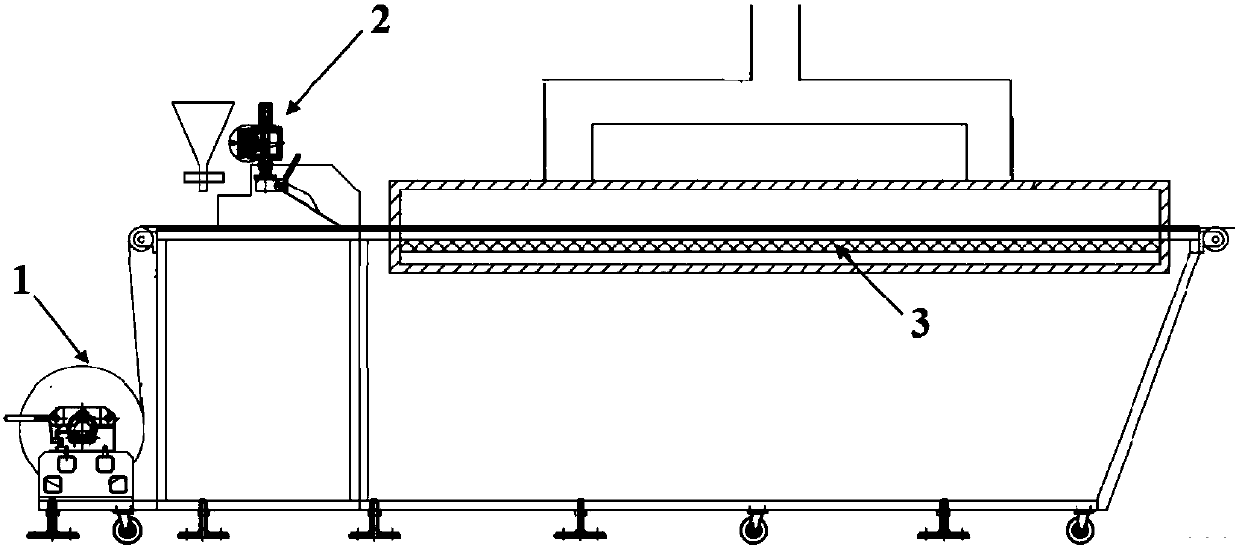

Image

Examples

Embodiment 1

[0033] Embodiment one (conduction):

[0034] Step 1, continuous preparation of graphene film:

[0035] Slurry preparation: Weigh 22.5g of graphene nanosheets, 2.5g of epoxy resin and 500ml of ethanol, after ultrasonication for 20min and stirring for 20min, mix evenly to make a graphene slurry with a concentration of 50mg / ml;

[0036] Coating film: Store the evenly mixed graphene slurry in the storage tank, place the storage tank above the release paper of the conductive film machine, and adjust the discharge switch to make the evenly mixed graphene slurry flow to the release paper superior. Turn on the transmission switch, the transmission speed is 0.1m / min, use the scraper and the baffle to scrape the graphene slurry on the release paper into a film with a thickness of 1mm and a width of 300mm. The scraper is inclined at an angle of 30o to the platform;

[0037] Film formation: The scraped graphene slurry film is forwarded to the heating zone through the release paper, and...

Embodiment 2

[0040] Embodiment two (heat conduction):

[0041] Step 1, continuous preparation of graphene film:

[0042] Slurry preparation: Weigh 18g of graphene nanosheets, 4.5g of tetrapod zinc oxide whiskers, 2g of graphene oxide, 0.5g of sodium hydroxide and 500ml of deionized water, and mix them evenly after ultrasonication for 20min and stirring for 20min to prepare Concentration is the graphene slurry of 50mg / ml;

[0043] Coating film: Store the evenly mixed graphene slurry in the storage tank, place the storage tank above the release paper of the conductive film machine, and adjust the discharge switch to make the evenly mixed graphene slurry flow to the release paper superior. Turn on the transmission switch, the transmission speed is 0.1m / min, use the scraper and the baffle to scrape the graphene slurry on the release paper into a film with a thickness of 1mm and a width of 300mm. The scraper is inclined at an angle of 30o to the platform;

[0044] Film formation: the scrape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com