Patents

Literature

39results about How to "Small application restrictions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

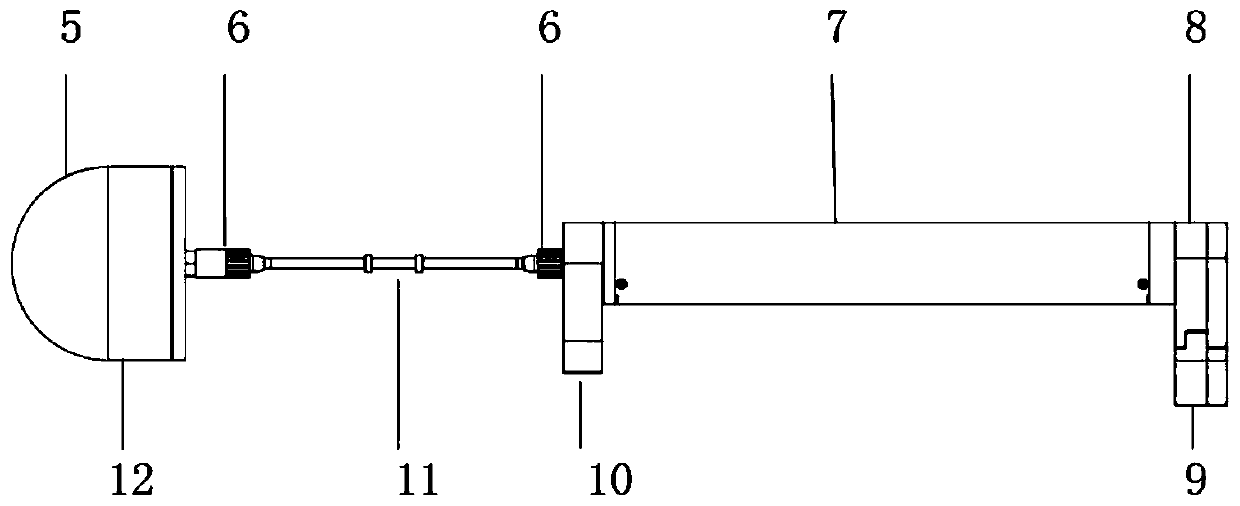

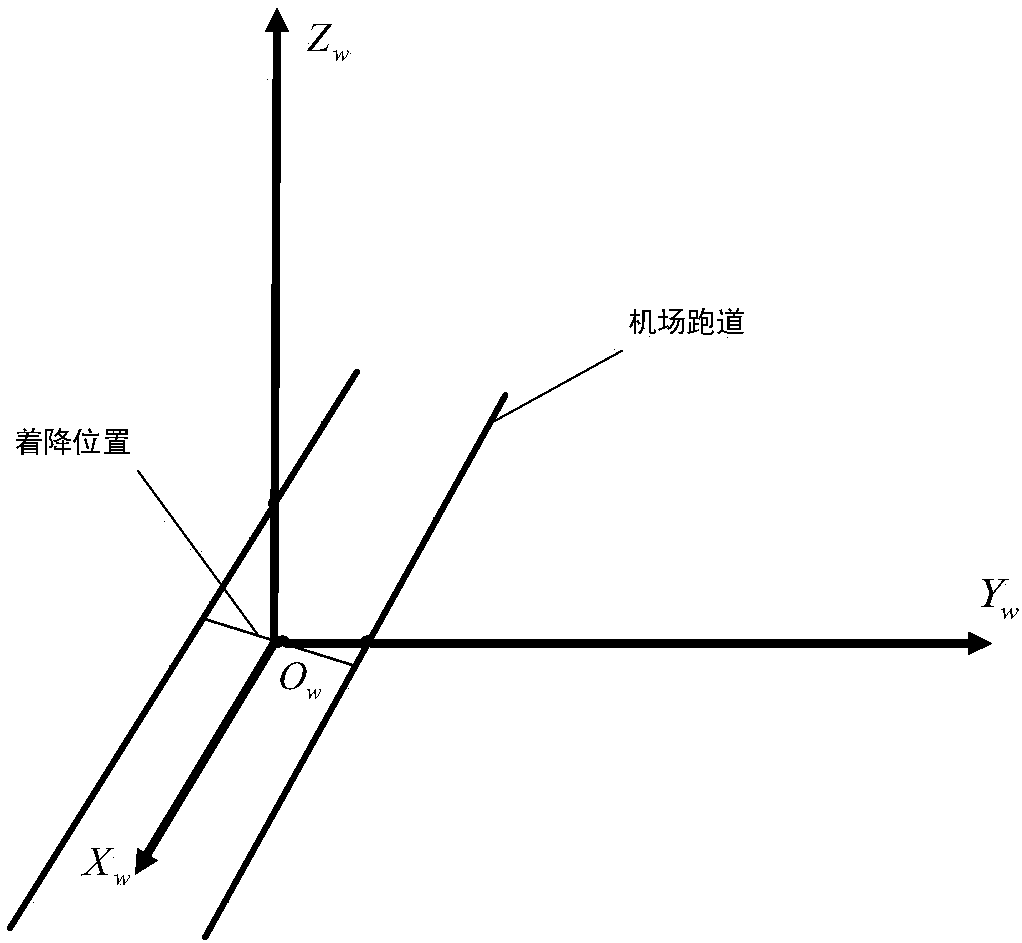

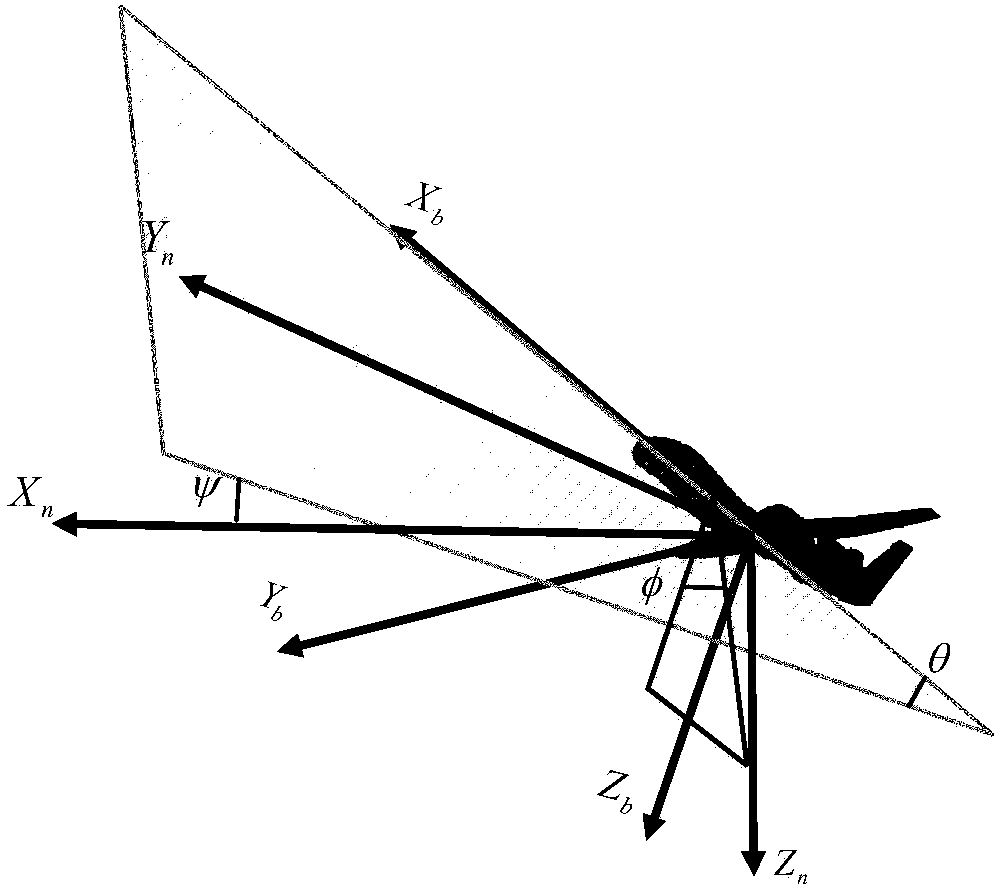

Beacon arranging and image processing method based on UAN (unmanned aerial vehicle) pose calculation

ActiveCN107202982AReduce configuration requirementsSimple methodImage analysisPicture interpretationMachine visionImaging processing

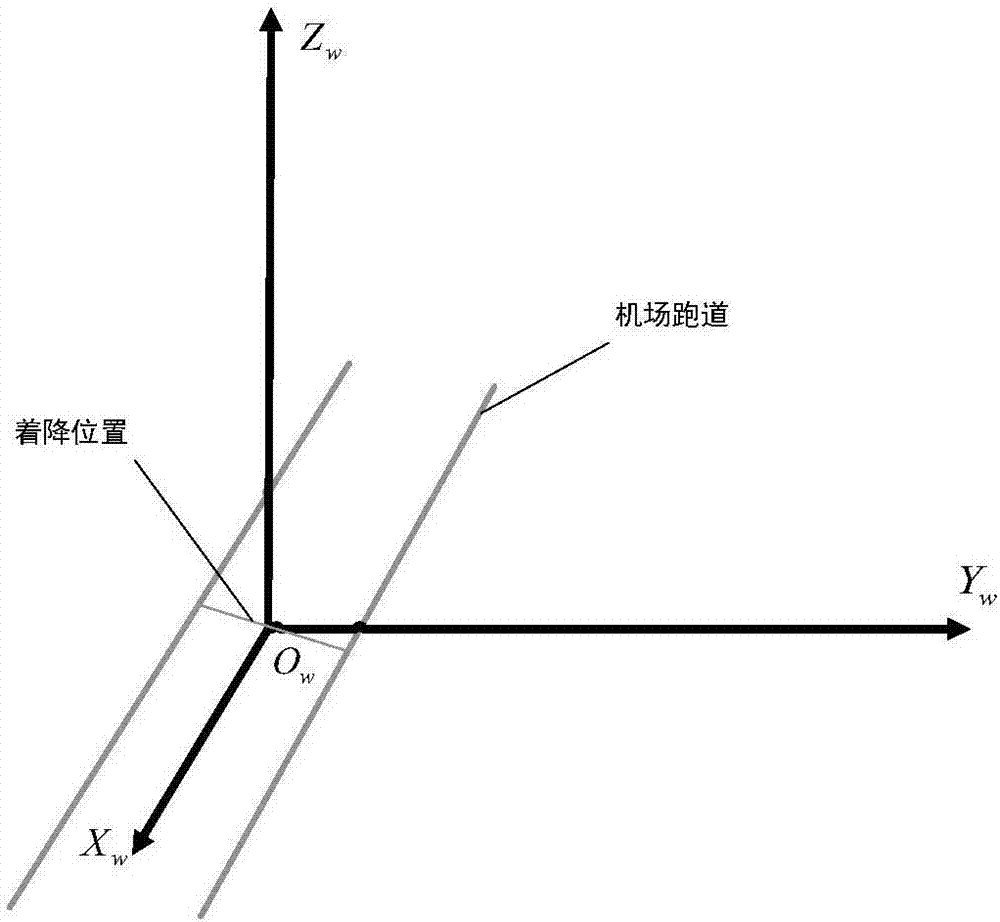

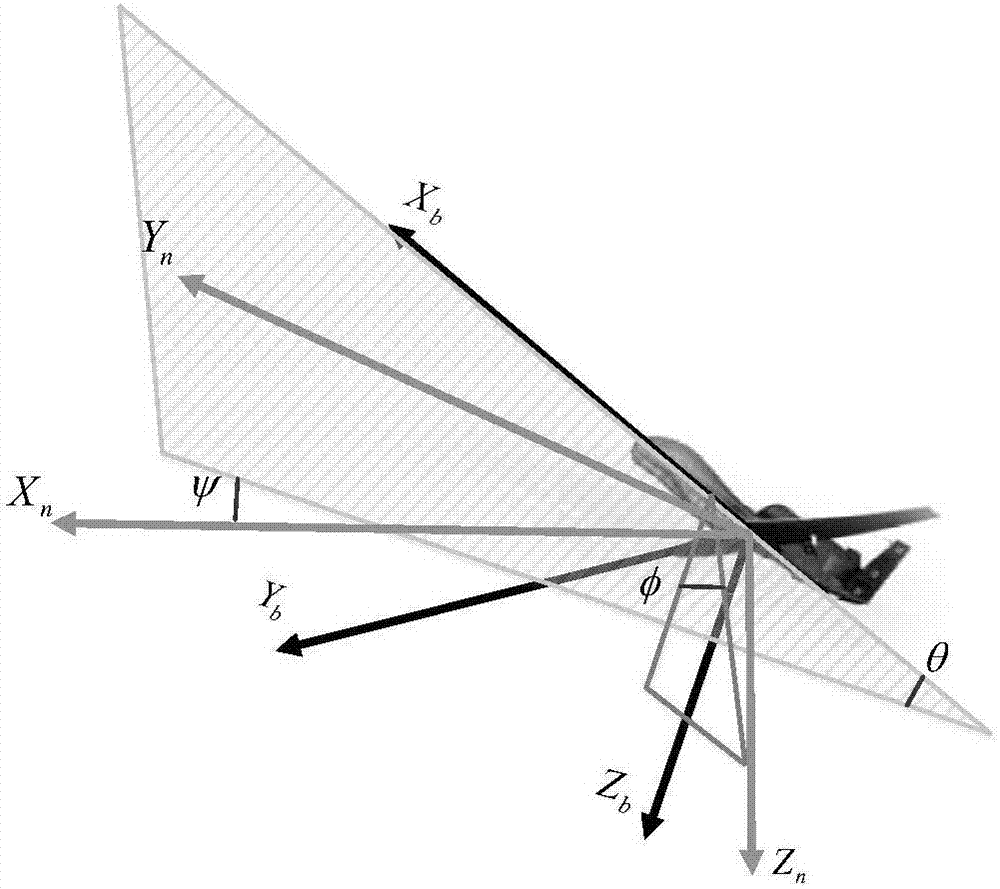

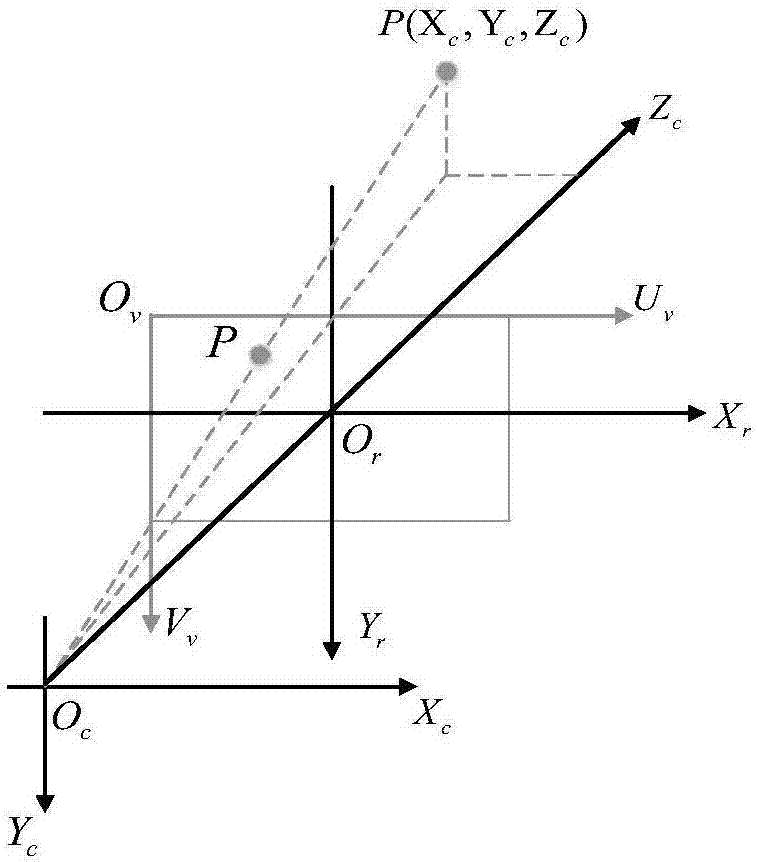

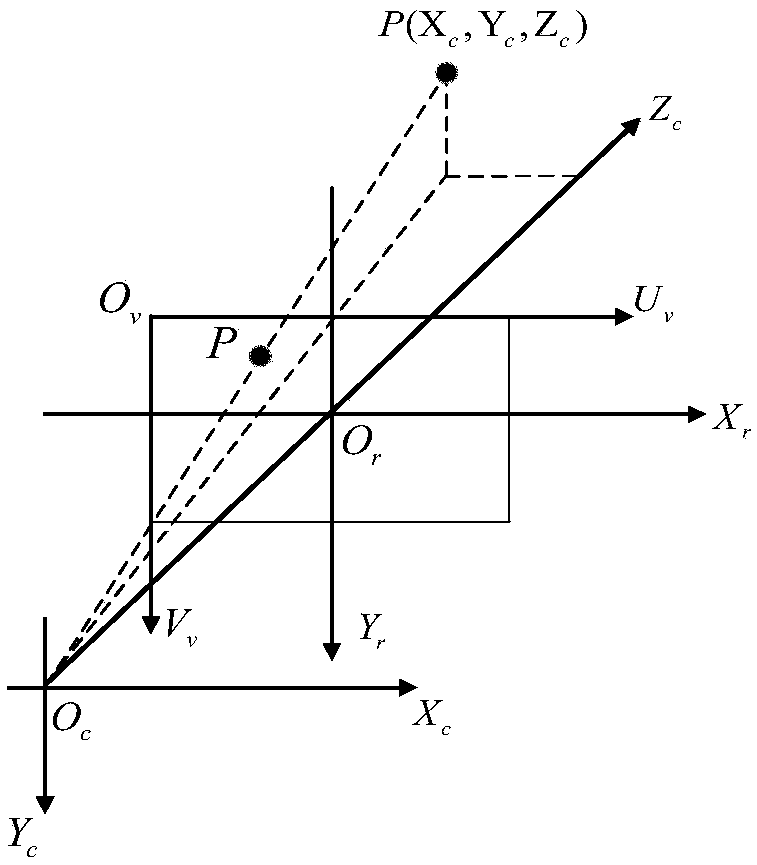

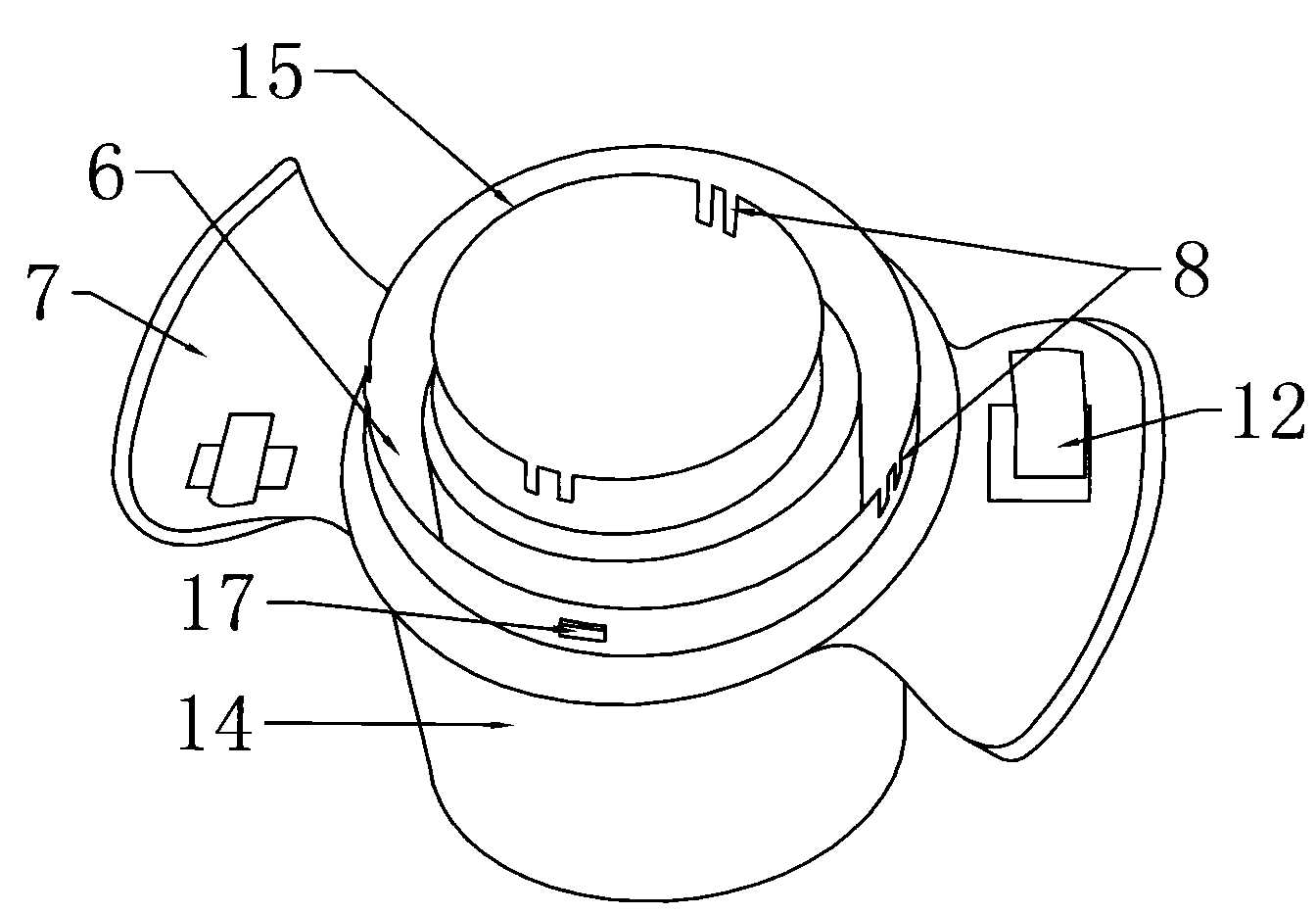

A beacon arranging and image processing method based on UAN (unmanned aerial vehicle) pose calculation comprises the steps as follows: firstly, machine vision guiding landing of an UAN is designed, under the conditions of guarantee of the image sensitivity and analysis of the field distortion, a beacon structure and arranging method required by vision guiding landing is designed according to a built vision imaging system in combination with poses possibly occurring in the landing process, then, three indexes for measuring algorithm applicability are proposed to evaluate and screen pose solution algorithms for different cooperation beacon configurations according to a designed visual guiding system, and finally, adopted ground cooperation beacons are infrared LEDs which have more stable imaging effect, longer imaging distance and higher imaging precision. The method is simple and feasible and has the low landing field configuration requirement, features can be extracted from near infrared images more conveniently and quickly, the application range of the visual system is enlarged, and all-day and all-weather detection and recognition can be realized; the UAN pose information can be solved precisely.

Owner:徐泽宇 +1

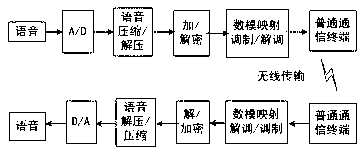

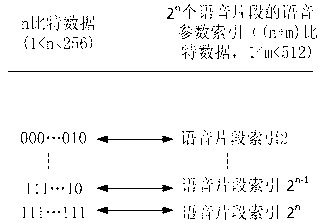

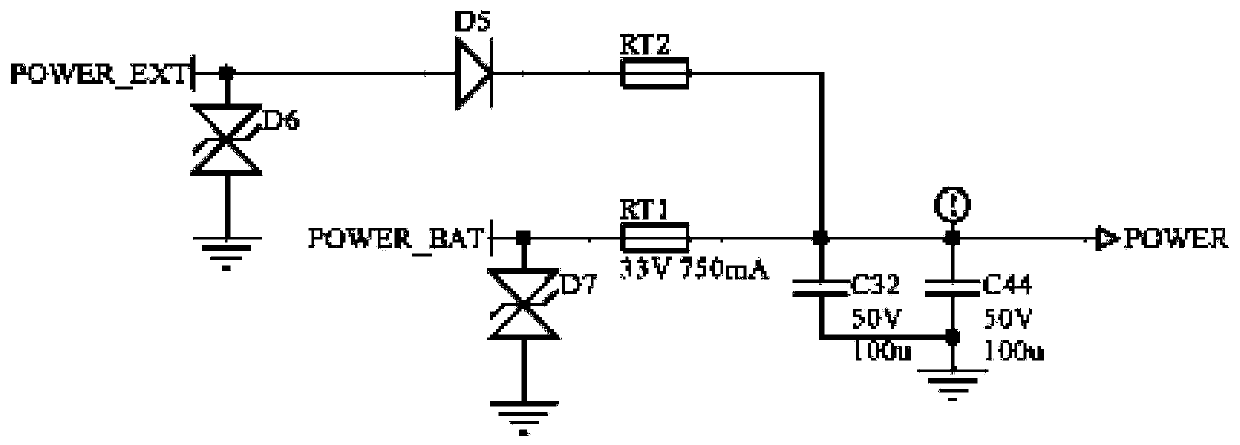

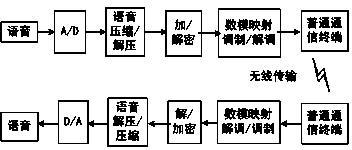

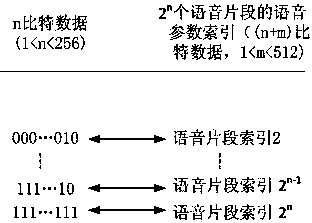

System and implement method thereof for secret communications based on public communication network voice channel

InactiveCN103000181AEncryption is validMeets requirementsSpeech analysisSecuring communicationComputer hardwareVoice communication

The invention discloses a system and an implement method thereof for secret communications based on a public communication network voice channel. The system and the implement method thereof for the secret communications based on the public communication network voice channel mainly solve the problem in an existing technology that a voice encryption method of a public communication network is low in reliability, difficult in technique and not convenient to implement. The system for the secret communications based on the public communication network voice channel comprises a power source, and further comprises a processor connected with the power source, and a storage, a digital / analog conversion module, a voice compression / decompression module, an encryption / decryption module, and a digital analogy mapping modulation / demodulation module all connected with the processor. By adopting the scheme, the system and the implement method thereof for the secret communications based on the public communication network voice channel achieve a purpose of conveniently and reliably keeping voice communications confidential, and have high practical value and promotional value.

Owner:CHENGDU LINGGUANG QUANTUM TECH

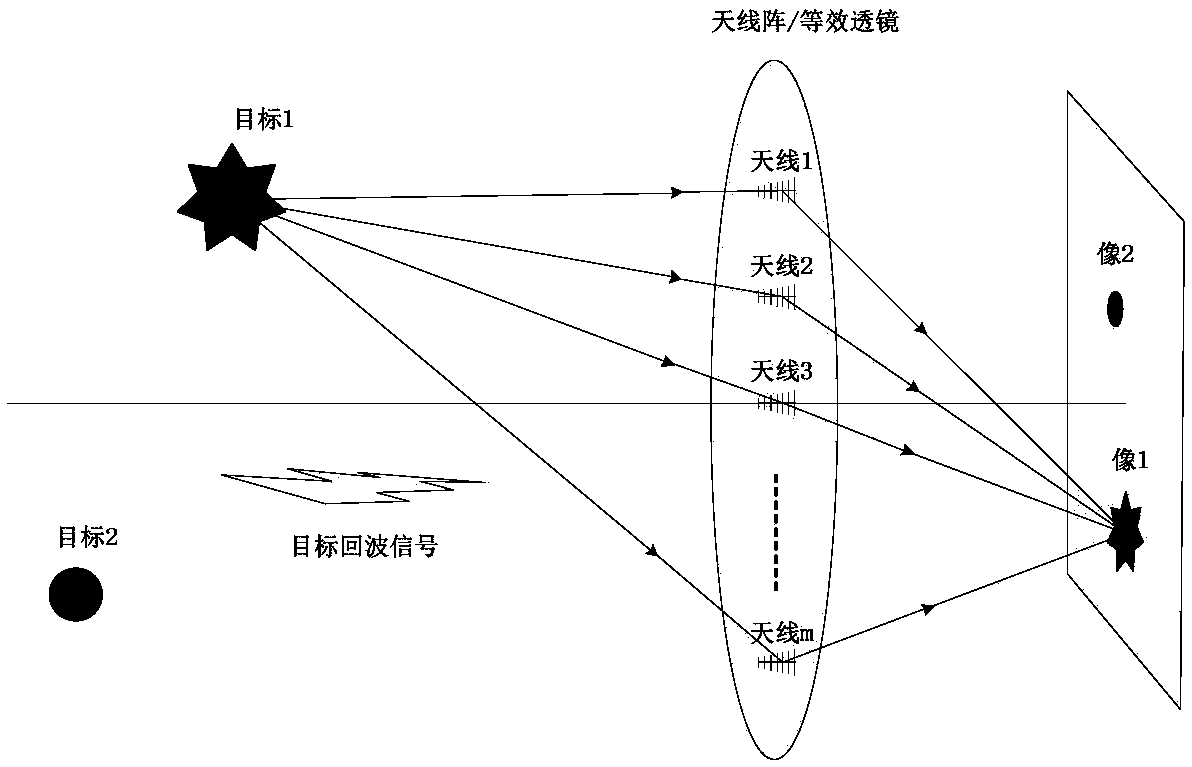

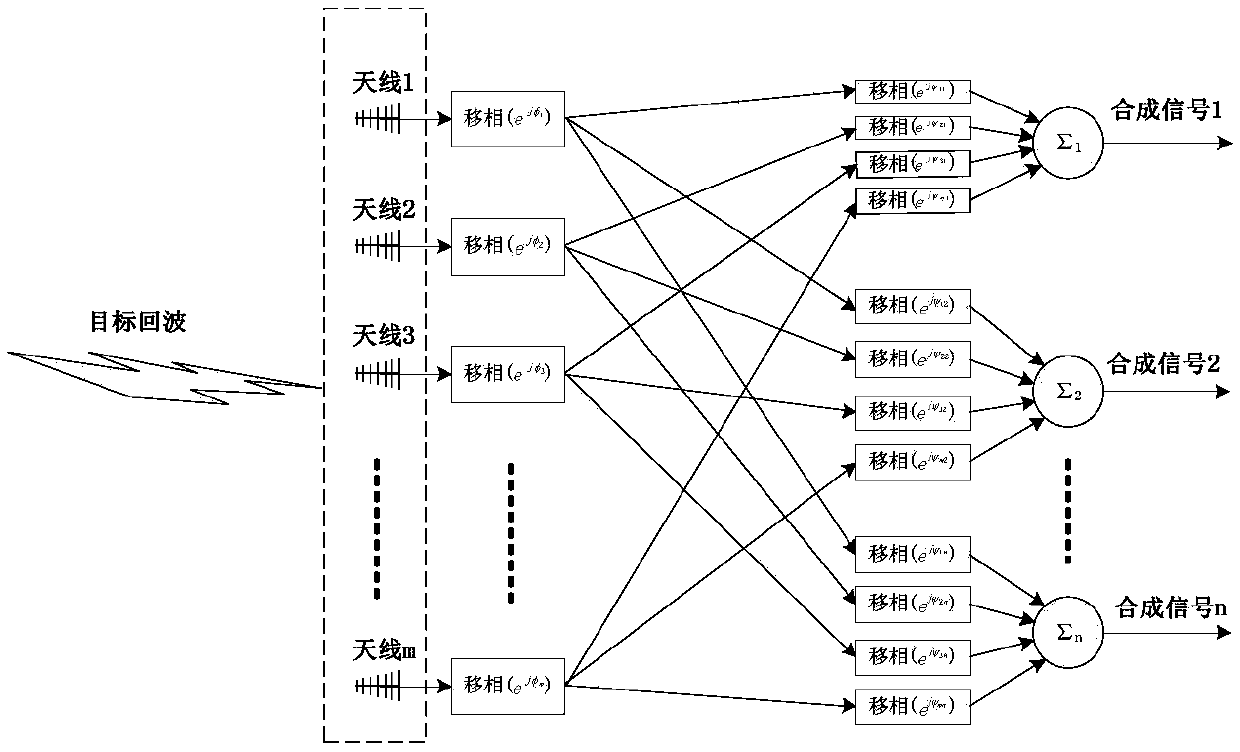

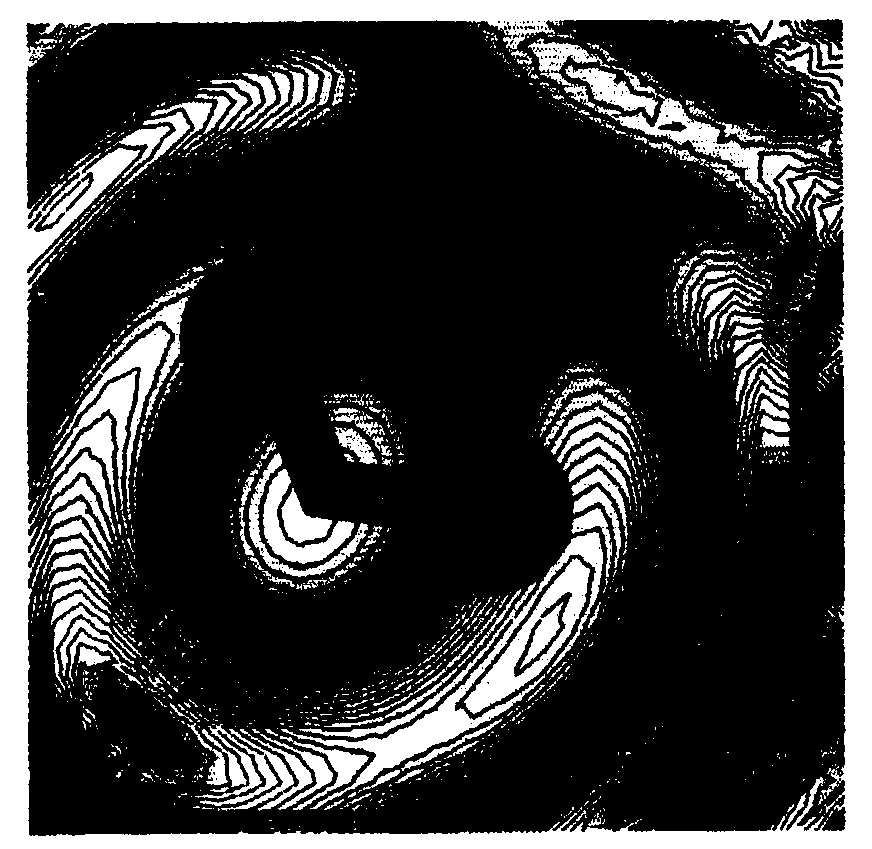

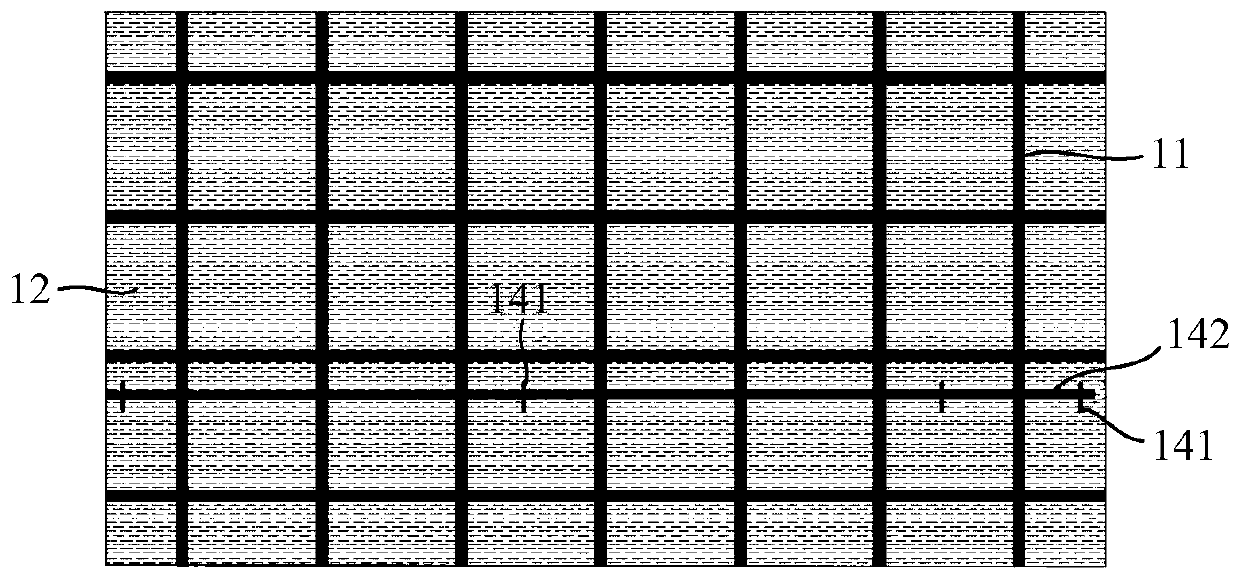

Phased array close-distance digital imaging method

ActiveCN109061638ARealize target detectionHigh precision target imagingRadio wave reradiation/reflectionPhase shiftedDigital imaging

The invention discloses a phased array close-distance digital imaging method. The method comprises the following steps of: Step 1, determining detection airspace; Step 2, determining spatial coordinates of each antenna unit; Step 3, processing and detecting signals received by each antenna unit; Step 4, determining a detection area of rough imaging detection; Step 5, splitting the detection area,and calculating the coordinates of each grid node; Step 6, determining phase shift amounts of each antenna unit; Step 7, determining radio propagation weighting coefficients from each antenna unit toa detection area splitting grid node; Step 8, calculating an image field of the detection area; Step 9, detecting a target according to a field value distribution condition of an imaging area; and Step 10, measuring the coordinates of the target. The phased array close-distance digital imaging method provided by the invention provides an integrated solution for the close-distance phased array detection and imaging, provides high-precision target imaging while achieving the target detection, and fully utilizes limited hardware conditions to realize high performance integrated target detection and imaging identification.

Owner:SUZHOU WEIMO ELECTRONIC INFORMATION TECH CO LTD

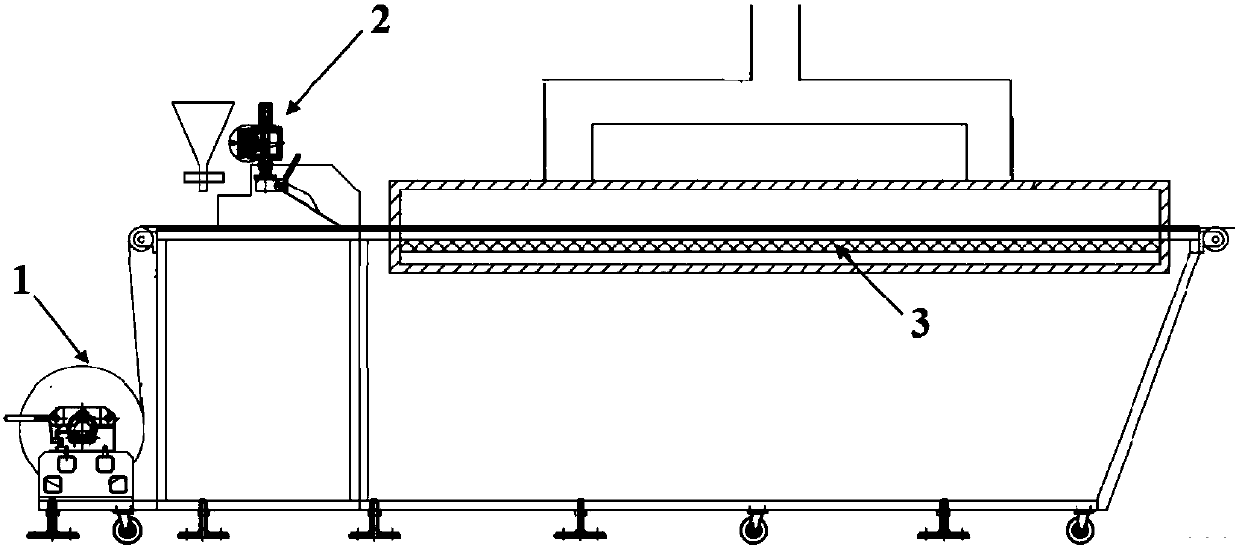

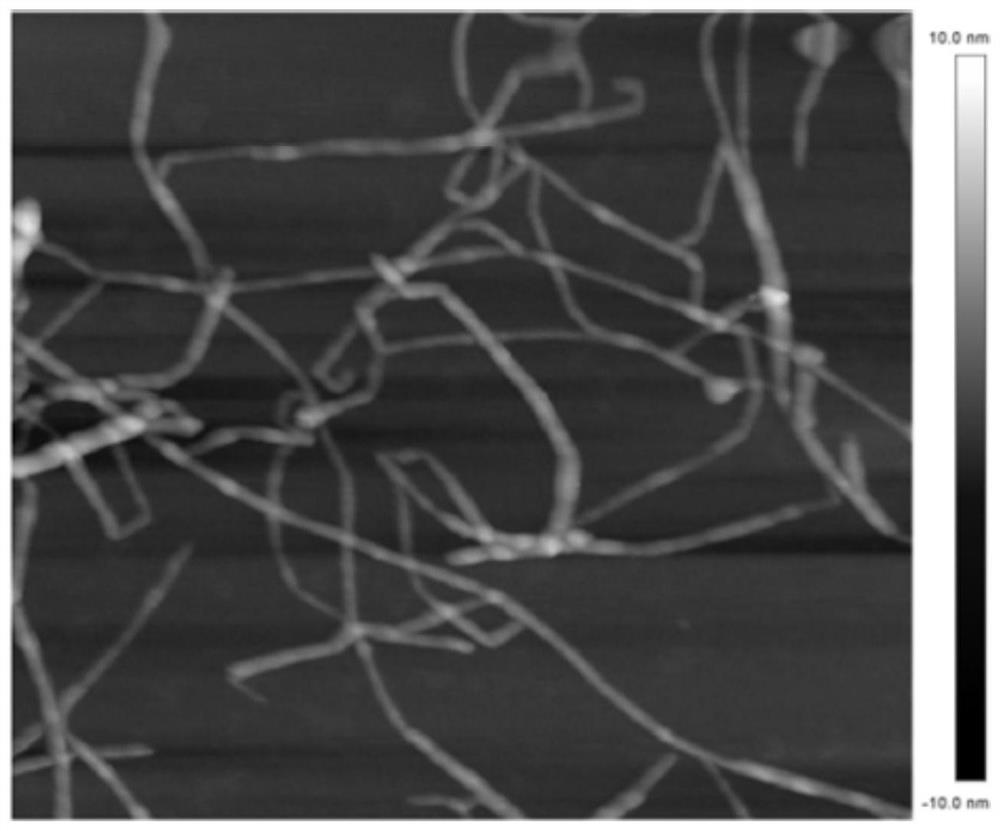

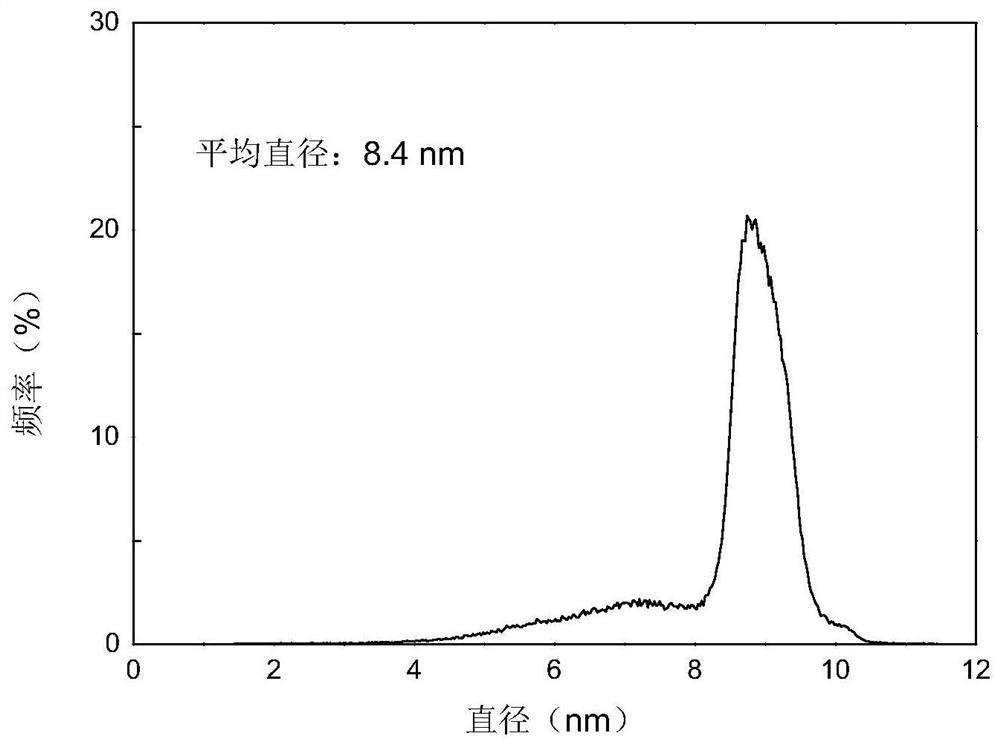

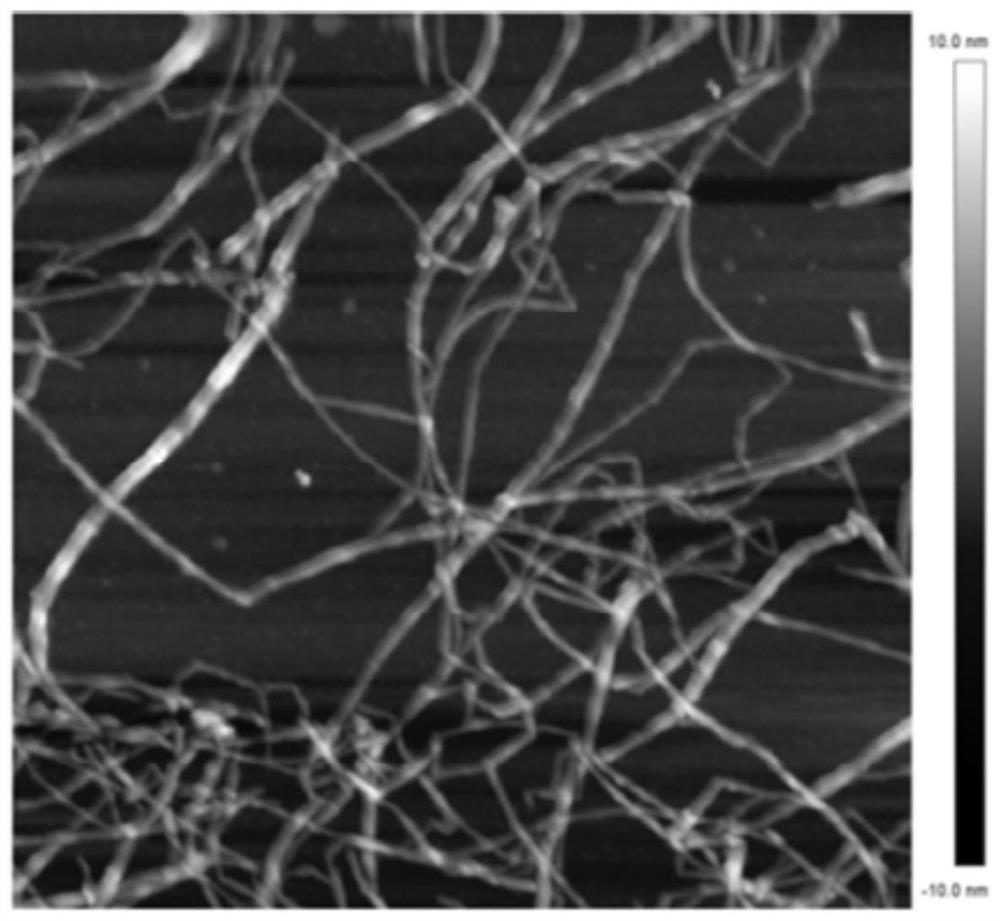

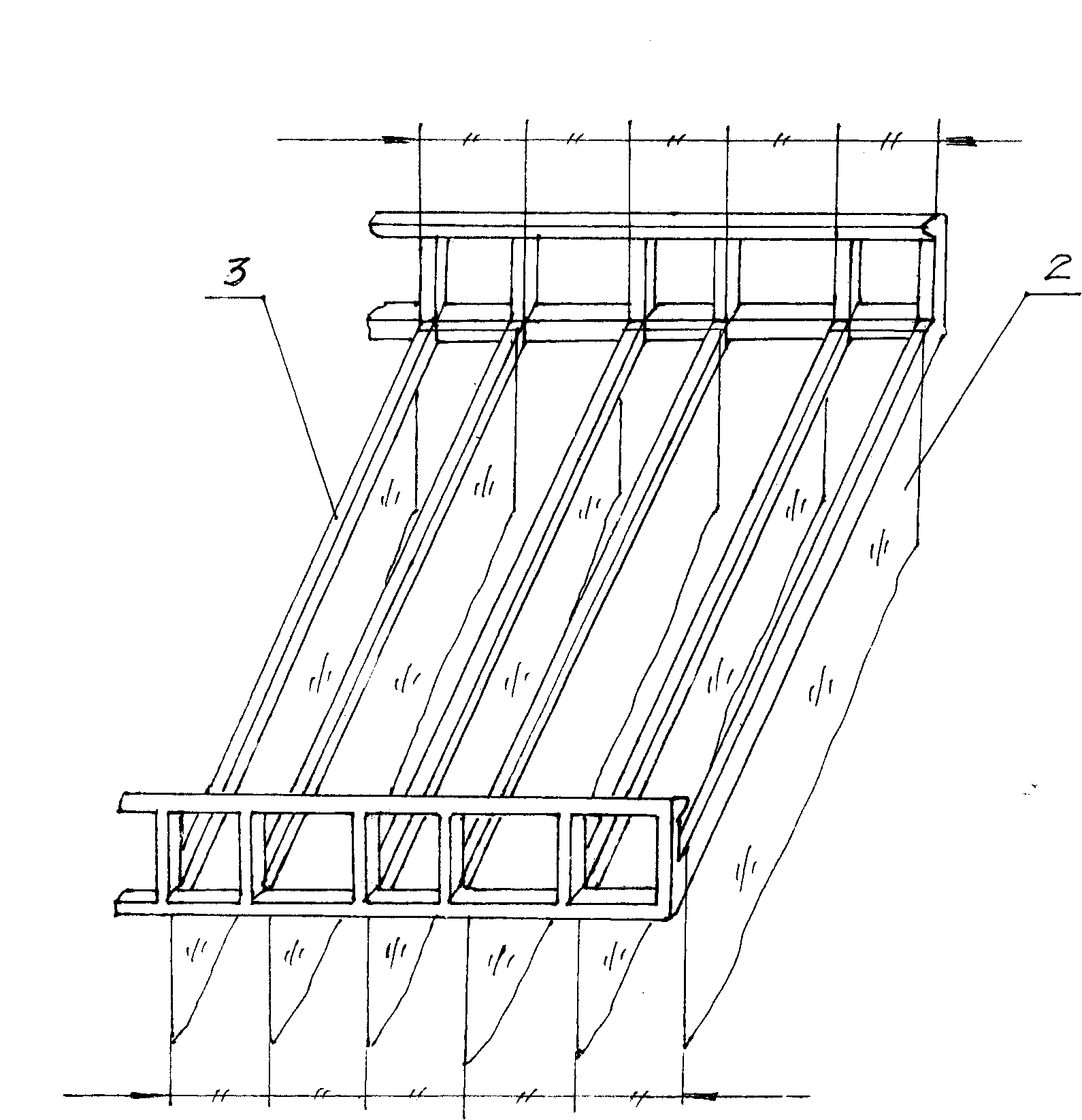

Continuous preparation method of graphene film prereg

The invention relates to a continuous preparation method of a graphene film prereg, and belongs to the technical field of functional materials. The graphene film prereg takes a resin adhesive film anda graphene film as the raw materials and is prepared through the hot melting process, the resin adhesive film is coated with a resin at the breadth of 100-1400 mm at the surface density of 10-100 g / m<2> on release paper, the resin is one of epoxy resin, phenolic resin, unsaturated polyester, polyurethane, bismaleimide resin and polyimide resin; the graphene film is a film having a three-dimensional network structure or a porous structure and is prepared by taking graphene as the main material, and the material composition of the graphene film is determined according to the use function of thegraphene film prereg. The continuous preparation of the method leads to the advantage of high yield of the graphene film prereg, and the heavy demand of the practical application is well met. The most crucial point of the method is the continuous preparation of the graphene film.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

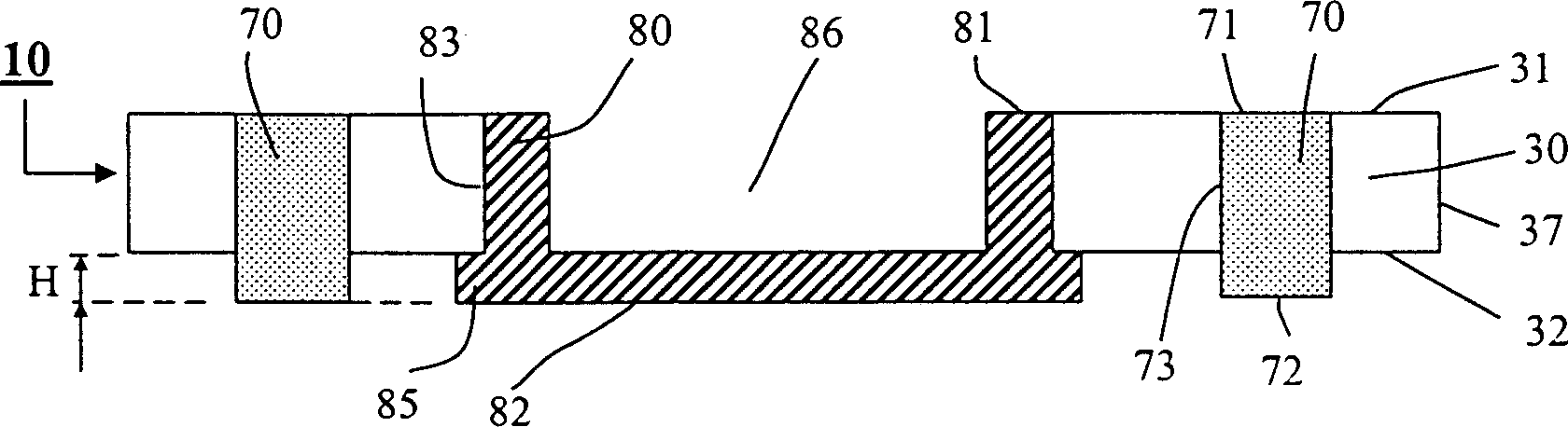

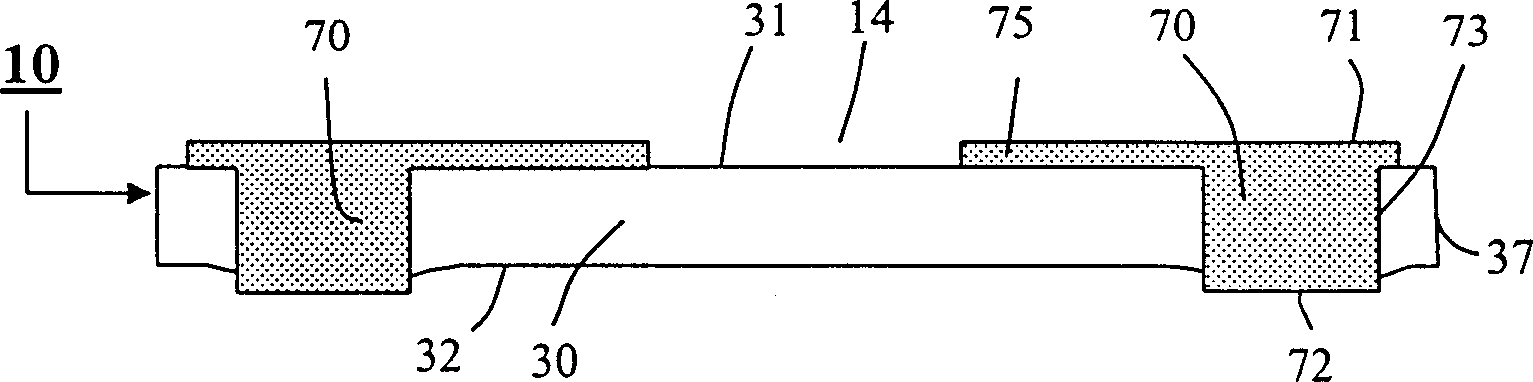

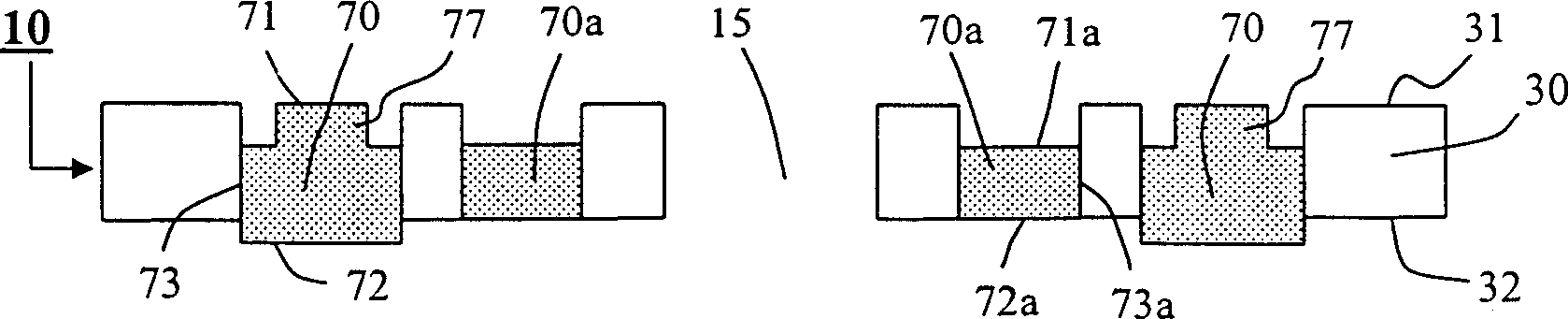

Circuit board of electronic device and mfg method thereof

InactiveCN1835211ANot prone to crackingReduce manufacturing costPrinted circuit assemblingPrinted circuit detailsConductive paste

Structure of the disclosed circuit board includes an insulator and a first conductor. The insulator possesses a first up surface, a first low surface and a broadside. The first conductor possesses a first up surface, a first low surface and a broadside. The insulator clothes the first conductor so that at least part of first broadside of the first conductor is built in the insulator; at least part of first up surface of the first conductor is protruded and exposed out of the first up surface of the insulator; and at least part of first low surface of the first conductor is exposed out of the first low surface of the insulator. The first conductor is not prepared from conductive paste, using characteristic of solid conductor, the invention prevents rimose phenomena happened in conductive path on general circuit board. The invention increases reliability and saves materials.

Owner:王忠诚

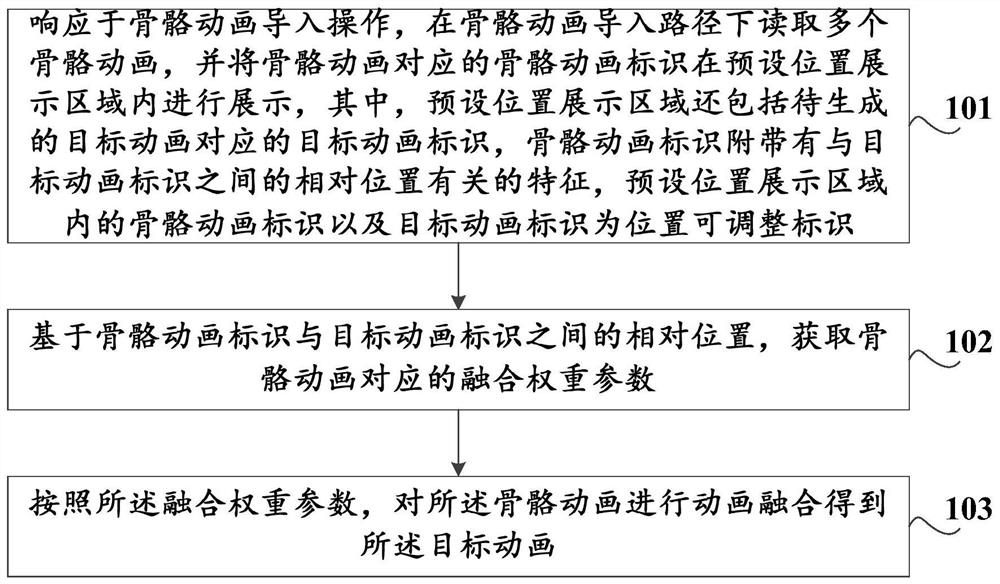

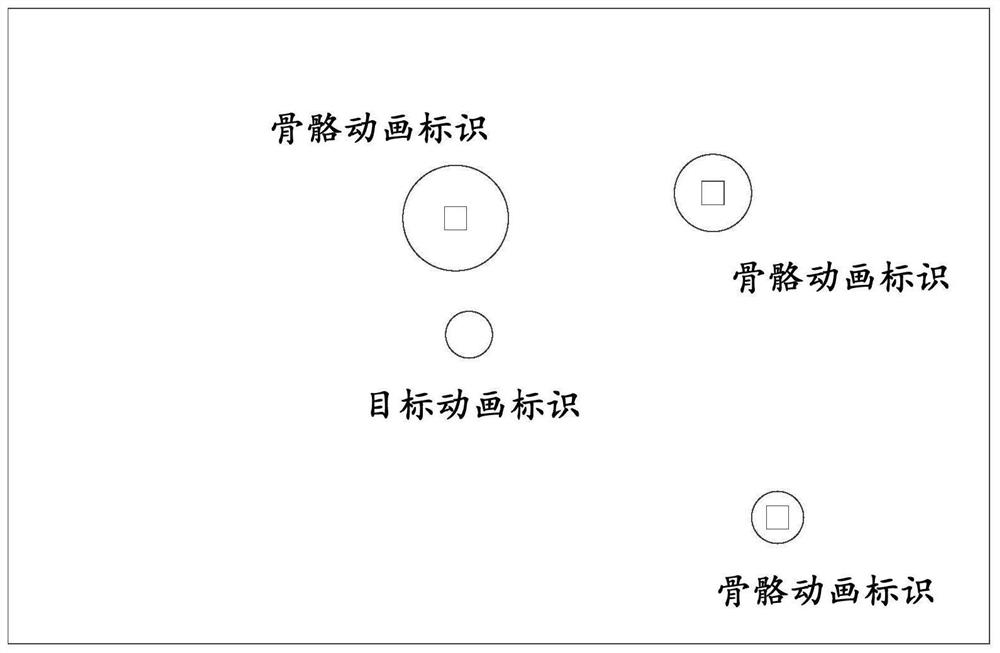

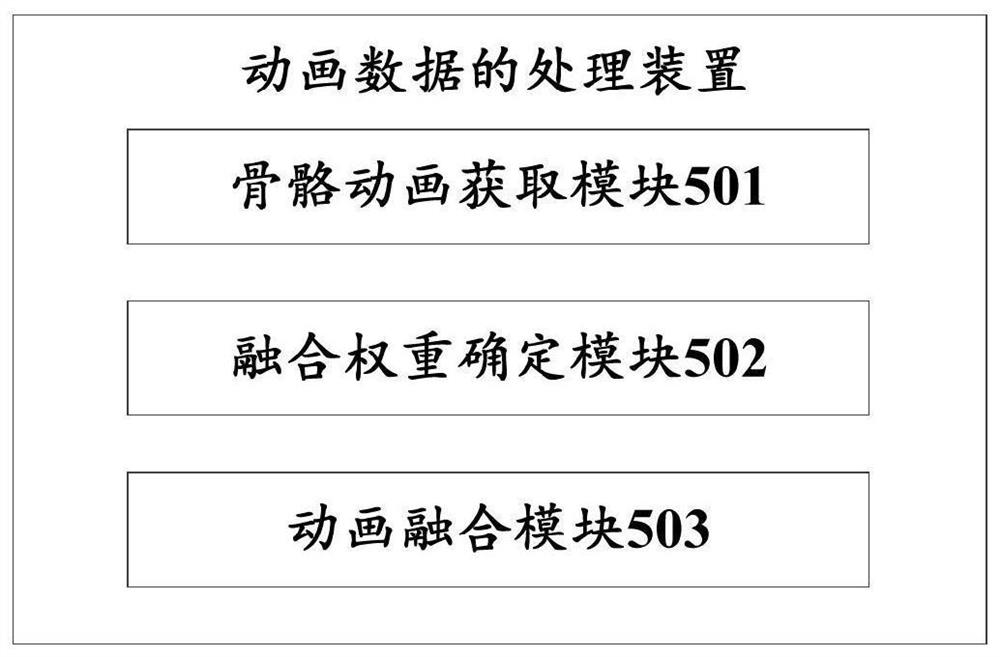

Animation data processing method and device, storage medium and computer equipment

PendingCN112669414AReduce the amount of animation productionFunction increaseAnimationComputational scienceAnimation

The invention discloses an animation data processing method and device, a storage medium and computer equipment, and the method comprises the steps: responding to a skeletal animation importing operation, reading a plurality of skeletal animations under a skeletal animation importing path, and enabling skeletal animation identifiers corresponding to the skeletal animations to be displayed in a preset position display region, wherein the preset position display area further comprises a target animation identifier corresponding to a to-be-generated target animation, the skeletal animation identifier carries a feature related to a relative position between the target animation identifiers, and the skeletal animation identifier in the preset position display area is a position-adjustable identifier; obtaining a fusion weight parameter corresponding to the skeletal animation based on the relative position between the skeletal animation identifier and the target animation identifier; and according to the fusion weight parameter, performing animation fusion on the skeletal animation to obtain the target animation.

Owner:BEIJING PERFECT WORLD SOFTWARE TECH DEV CO LTD

Method for extracting lithium from brine

InactiveCN112063857AEliminate emulsificationEase of industrial applicationProcess efficiency improvementPhysical chemistryPhosphoric acid

The invention discloses a method for extracting lithium from brine. According to the method, tributyl phosphate, an amide compound and a diluent are used as extraction agents and ferric salt as a co-extraction agent to extract the brine. The method comprises the following steps of: (1) preparing the co-extraction agent into a solution to obtain a co-extraction agent solution; carrying out mixed extraction on the co-extraction agent solution, the tributyl phosphate and the diluent, and separating to obtain a first organic phase; (2) adding the amide compound, the tributyl phosphate and the diluent into the first organic phase to obtain a second organic phase; and (3) mixing the second organic phase with the brine, extracting, and separating to obtain a lithium-containing extracting solution. According to the method for extracting the lithium from the brine, an emulsification phenomenon easily occurring during extraction of the tributyl phosphate and the amide compound can be eliminated,smooth operation of an extraction process is ensured, application limitation of an amide extraction agent is reduced, corrosion condition of extraction equipment during extraction can be reduced, andthe industrial application of the tributyl phosphate and the amide compound as the extraction agent is facilitated.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

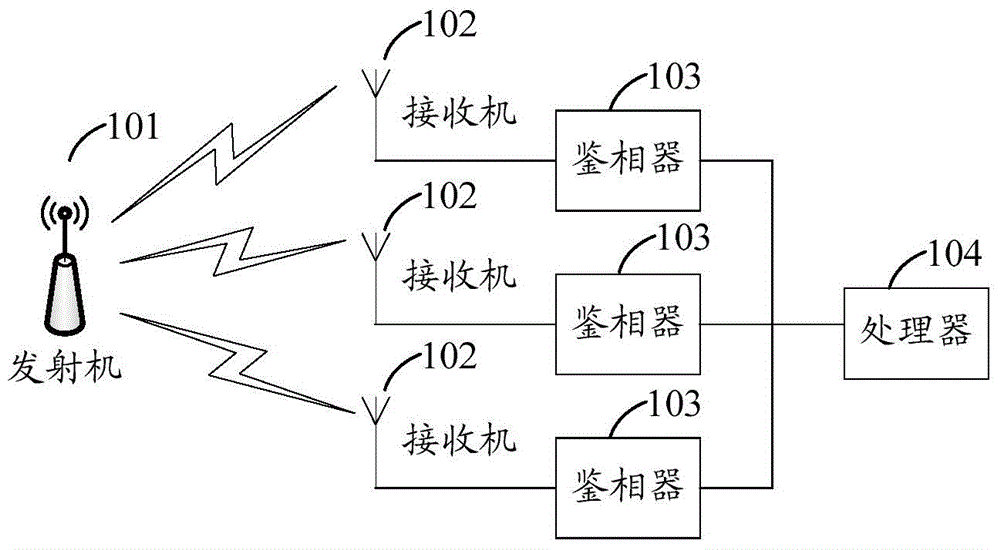

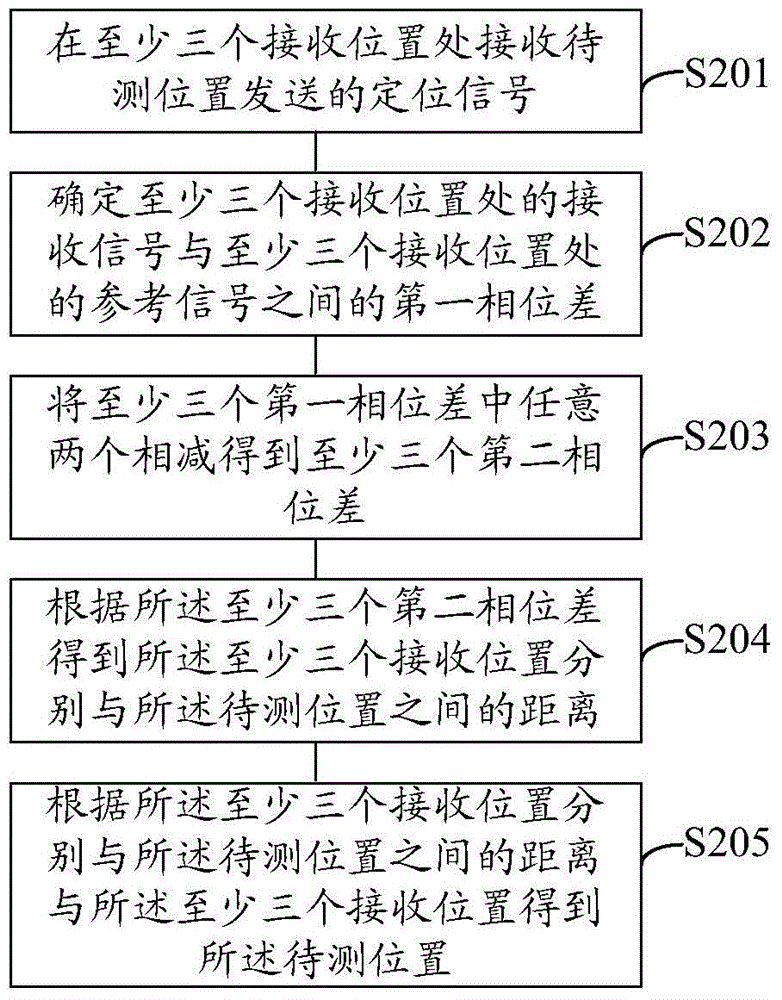

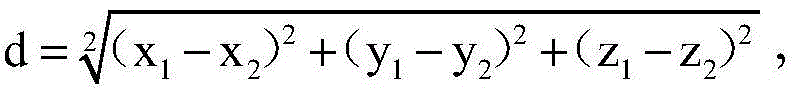

Positioning method and device

InactiveCN105182289AHigh positioning accuracySmall application restrictionsPosition fixationPhase differenceEnvironmental geology

Owner:ZTE CORP

Low-melting point metal-matrix aramid fiber composite material and preparation method thereof

InactiveCN103255360AEnhancement effect is goodImprove the bonding strength of the interfaceFiber-reinforced compositeMetal matrix composite

The invention relates to a low-melting point metal-matrix aramid fiber composite material and a preparation method thereof, belonging to the field of low-melting point soft metal-matrix fiber reinforced composite materials. The structure of the composite material is as follows: aramid fiber is embedded into a low-melting point metal matrix, and the volume ratio of the low-melting point metal to the aramid fiber is (95-97):(5-3). High-strength aramid fiber is used as a reinforcement of lead and lead alloy, and the molten lead and lead alloy permeate into the aramid fiber after surface metallization to prepare a lead and lead alloy-matrix aramid fiber composite material. A composite material taking a low-melting point soft metal as a matrix is reinforced by fiber in great difference from the strength of the matrix metal material; by adopting a liquid permeation method, a composite material with an obvious reinforcement effect can be effectively prepared only by use of low fiber volume percent; and the tensile strength of the low-melting point metal-matrix composite material provided by the invention can reach 150MPa, and the elongation can reach 20%.

Owner:KUNMING UNIV OF SCI & TECH

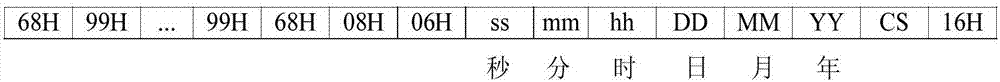

Electric energy meter clock checkout method

PendingCN107991643AHigh schooling efficiencyIncreased schooling efficiencySynchronous motors for clocksElectrical measurementsCorrection methodComputer science

The invention discloses an electric energy meter clock checkout method. A district concentrator issues an encrypted broadcast clock checkout command message to an electric energy meter, a clock checkout command is decrypted after the electric energy meter receives the broadcast clock checkout command message, and the decrypted clock checkout command comprises a clock checkout command serial numberand clock checkout time. After the encrypted broadcast clock checkout mode is adopted, the clock checkout speed and the clock checkout success rate of the electric energy meter can be greatly increased, replay attack caused by illegal interception of the clock checkout message can be effectively prevented, a clock of the electric energy meter is prevented from being illegally adjusted, and safetyof the clock is ensured.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +2

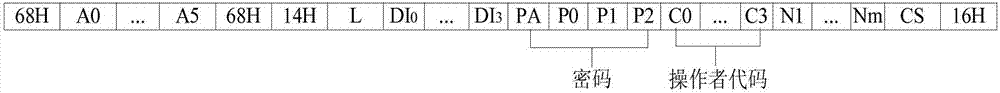

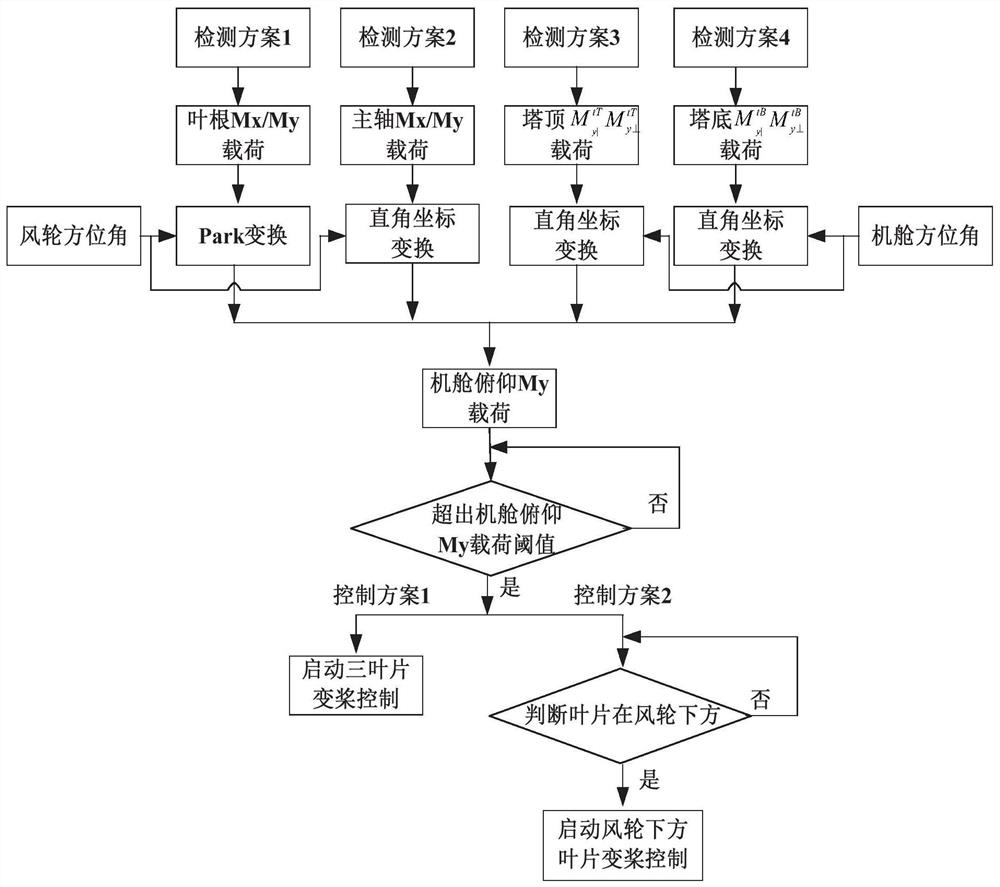

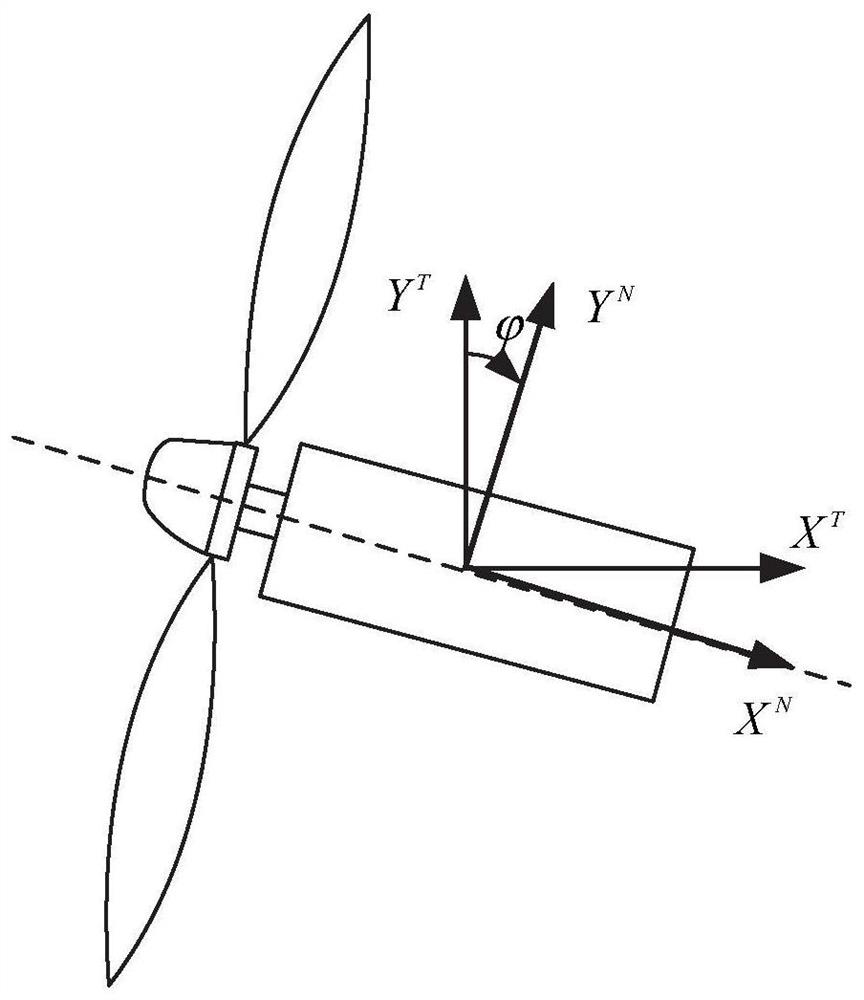

Wind turbine generator blade clearance control method based on load detection

ActiveCN112610412AIncrease headroomImprove securityWind motor controlMachines/enginesNacelleMarine engineering

The invention provides a wind turbine generator blade clearance control method based on load detection, and relates to the field of wind turbine generator regulation and control. The wind turbine generator blade clearance control method comprises the steps that detection points of key parts of a wind turbine generator structure are selected, and load detection is carried out on the key parts; the load of the detected key parts is converted into the load in the pitching direction of a cabin under a static hub coordinate system according to the acquired yawing azimuth angles of a wind wheel and the cabin; a cabin pitching load negative threshold value is obtained through wind turbine generator simulation software according to design specifications, and a variable pitch protection angle is determined; and loads of the key parts such as a blade root, a main shaft, a tower top and a tower bottom of a wind turbine generator are used for identifying a negative pitching load borne by the wind wheel, and the purpose of increasing blade clearance is achieved along with the specific operating condition characteristics of negative wind shearing in combination with a targeted pitch angle control method.

Owner:CRRC WIND POWER(SHANDONG) CO LTD

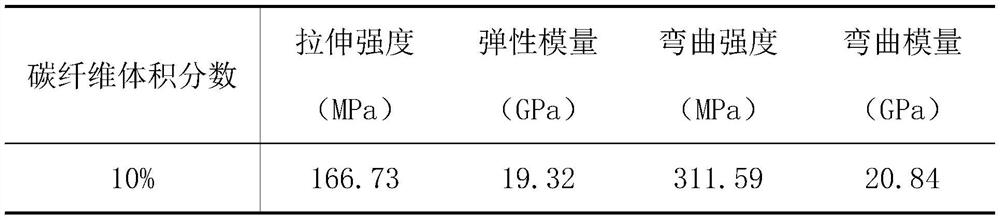

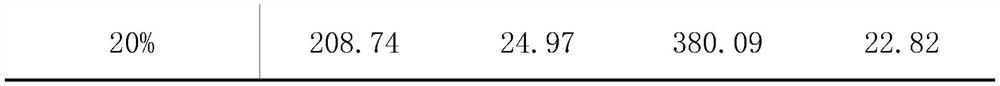

Carbon fiber reinforced thermosetting resin-based composite material and preparation method thereof

The invention discloses a carbon fiber reinforced thermosetting resin-based composite material and a preparation method thereof, and belongs to the technical field of advanced composite materials. The preparation method comprises the following steps: sampling matrix resin, a low-shrinkage agent, a curing agent, a polymerization inhibitor, an internal release agent, a thickening agent and a dispersing aid according to the mass ratio, and conducting stirring and uniform mixing to prepare resin paste; preparing flaky carbon fiber prepreg from the resin paste and the carbon fiber non-woven fabric through a flaky molding compound process; flatly laying and overlaying the sheet-shaped carbon fiber prepreg, and conducting vacuum hot pressing and die assembly molding; and after the vacuum hot pressing die pressing is finished, and conducting cooling and demolding to obtain the carbon fiber reinforced thermosetting resin-based composite material. The preparation method has the characteristics of simple process, short production period, low energy consumption, designable strength and modulus, easiness in large-area forming, capability of meeting the forming requirements of products with complex shapes and structures and the like; and the prepared composite material has the excellent performances of high strength, high modulus, light weight, isotropy and the like.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method of mild and green lignin-containing nanocellulose fibrils and product

PendingCN113502675AReduce energy consumptionReduce environmental loadMonocomponent cellulose artificial filamentPulping with inorganic basesFiberUltraviolet lights

The invention discloses a preparation method of mild and green lignin-containing nanocellulose fibrils and a product. The method comprises the steps that straw raw materials are added with water and then placed in a cooking system, sodium hydroxide and magnesium sulfate are added, then oxygen is introduced, and raw material fibers are obtained through washing with deionized water after cooking treatment; and deionized water is added, and treaded by using a wall breaking machine, and then treated by using a cell crusher to obtain a lignin-containing nanocellulose fibril suspension. The bagasse, rice and wheat straw and other straws are used as raw materials, and the method has the characteristics of waste utilization, economy, environmental protection and easy application to industrial production; the film material is preliminarily prepared by utilizing the obtained LCNF, the film material has relatively high transmission in a visible light region, the transmissivity in an ultraviolet light region is close to 0, and due to the characteristic, the material has relatively good application potential in the fields of food packaging materials, electronic products and the like. The method of combining oxygen-alkali chemical pretreatment with mechanical treatment is adopted, and the preparation process has the advantages of environmental friendliness and low energy consumption.

Owner:SOUTH CHINA UNIV OF TECH

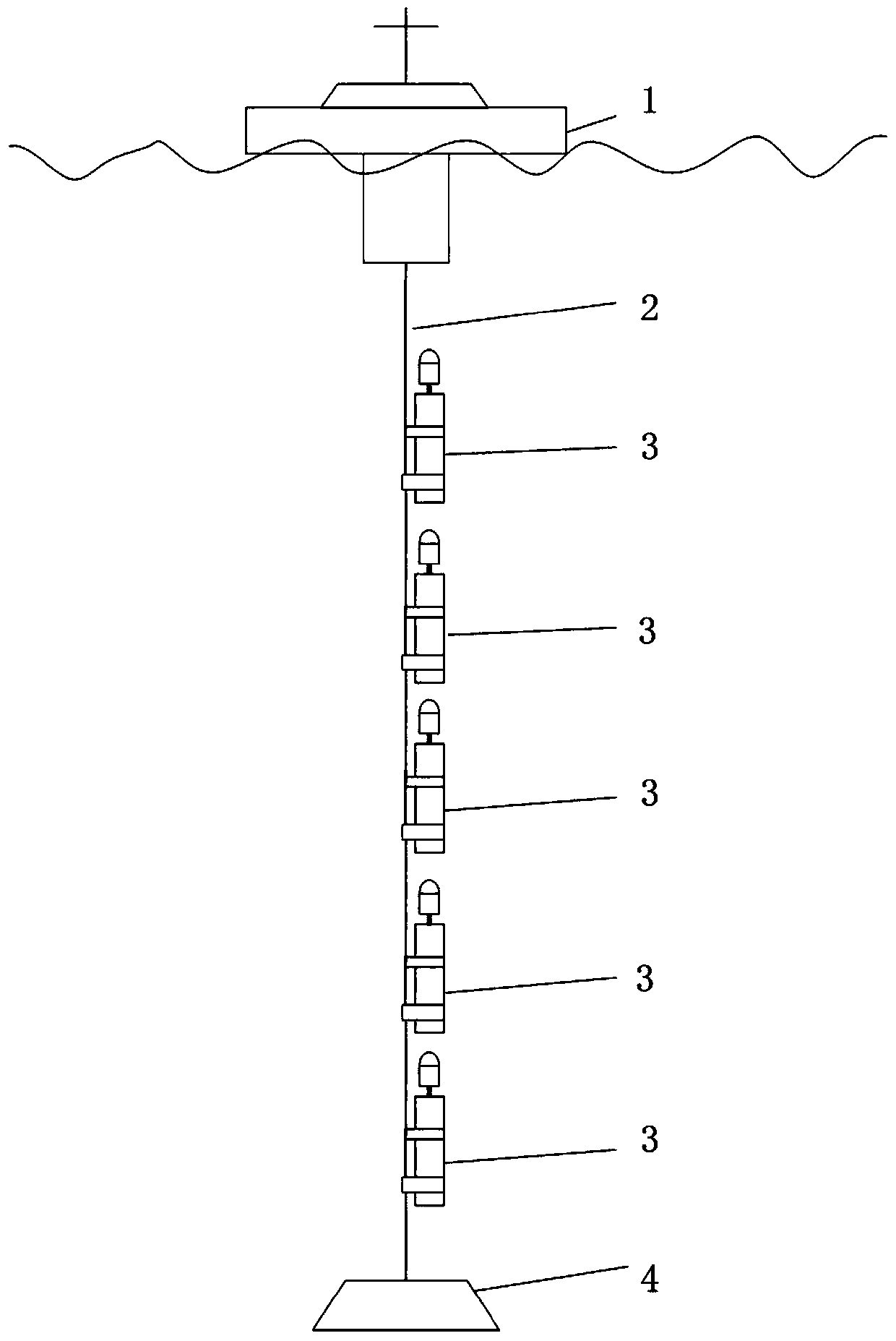

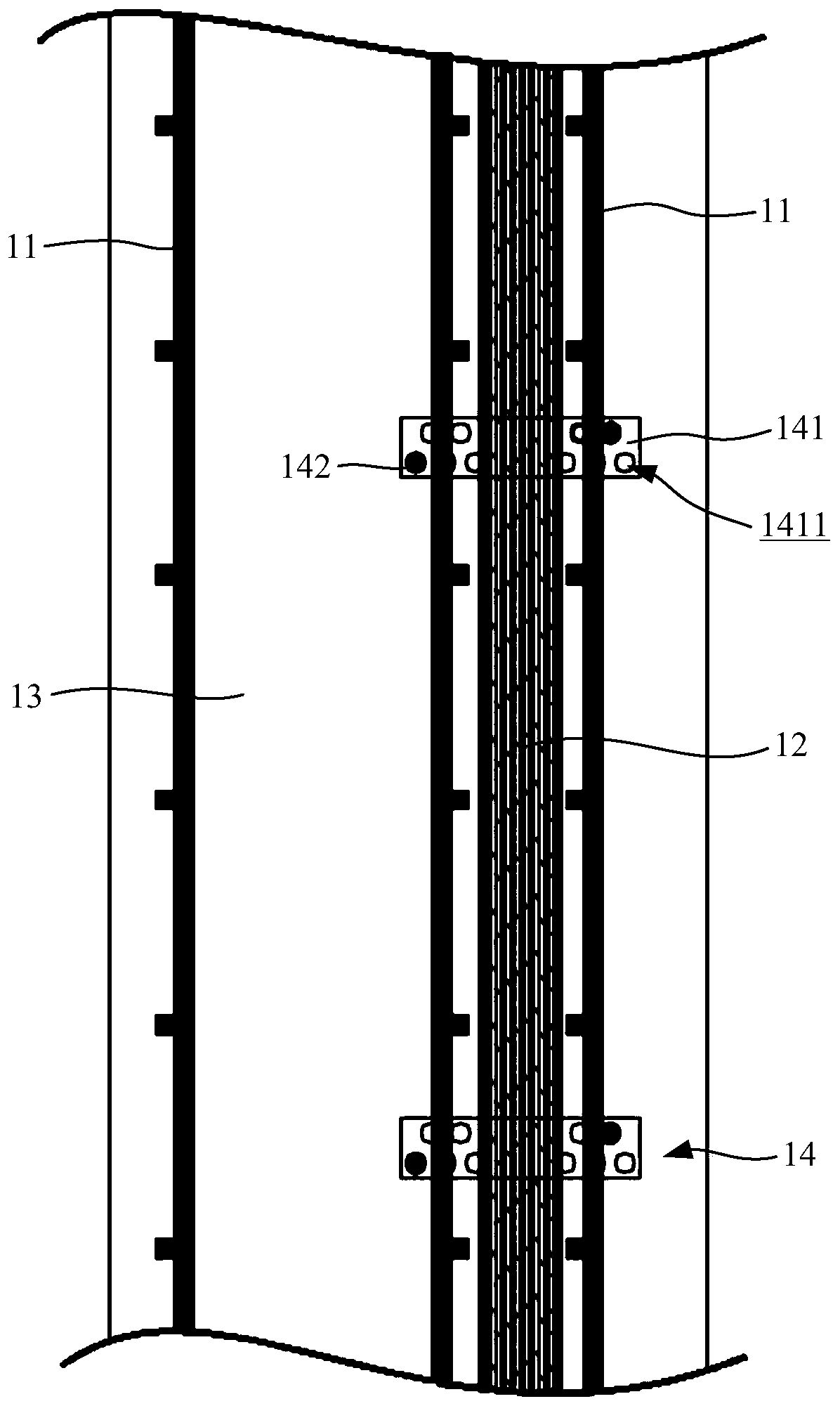

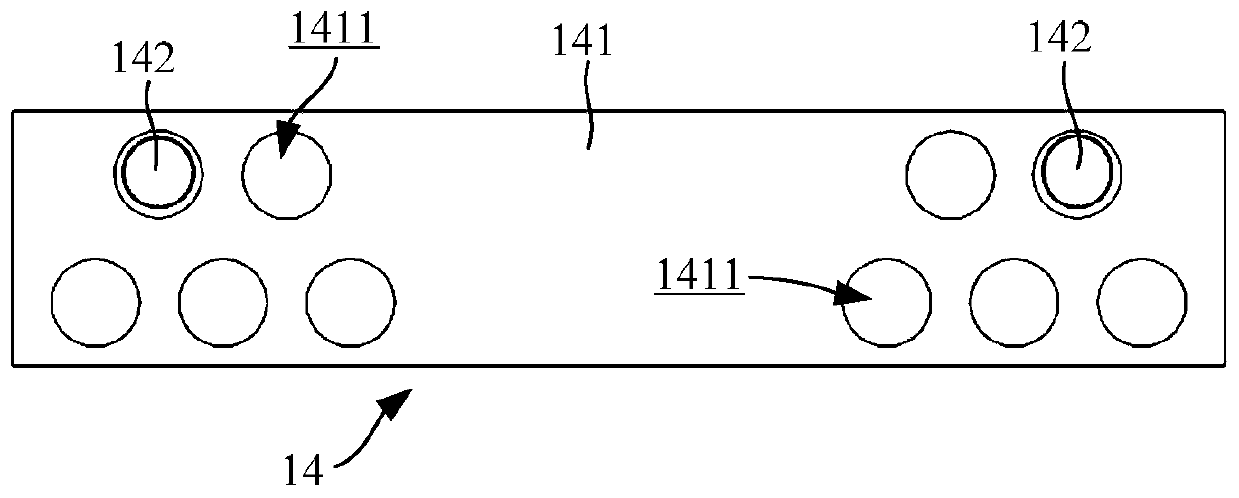

Deep sea current meter with induction transmission communication mode and measurement method thereof

PendingCN111323611ASmall application restrictionsImprove timelinessWaterborne vesselsBuoysCurrent meterOcean observations

The invention relates to the technical field of sea current meters and discloses a deep sea current meter with an induction transmission communication mode. The sea current meter comprises an anchoring object and a buoy body, and is characterized in that the anchoring object and the buoy body are connected through a communication steel cable; and an induction transmission modem is arranged on thebuoy body, and a plurality of induction transmission sea current meters are arranged on the communication steel cable at intervals. The sea current meter can be deployed in a buoy anchor system and asubsurface buoy anchor system, or is integrated in a comprehensive sea observation platform; platform application limitation of a traditional sea current meter is basically removed, data can be uploaded to the platform in real time through the induction transmission module, timeliness and an application value of the data are greatly improved, and problems existing in data storage and access in anapplication of the traditional deep sea current meter are solved. The invention further discloses a measuring method of the deep sea current meter with the induction transmission communication mode.

Owner:杭州浅海科技有限责任公司

A beacon layout and image processing method based on UAV pose calculation

ActiveCN107202982BReduce configuration requirementsSimple methodImage analysisPicture interpretationMachine visionImaging processing

A beacon layout and image processing method based on UAV pose calculation. Firstly, the machine vision-guided landing of UAV is designed. According to the built visual imaging system, the image sensitivity is ensured and the field of view distortion is analyzed. Under certain conditions, combined with the possible poses during the landing process, design the beacon structure and layout method required for the vision-guided landing. Then, according to the designed vision-guided system, for different cooperative beacon configurations, three measures are proposed. The index of algorithm applicability is used to evaluate and screen the pose calculation algorithm. Finally, the ground cooperation beacon used is infrared LED. The imaging effect of infrared LED is more stable, the imaging distance is longer, and the imaging accuracy is higher. This method is simple and easy to implement, has low requirements on the configuration of the landing site, is more convenient and faster to extract features from near-infrared images, expands the scope of application of the vision system, and can detect and identify all-weather and all-weather; Machine attitude information.

Owner:徐泽宇 +1

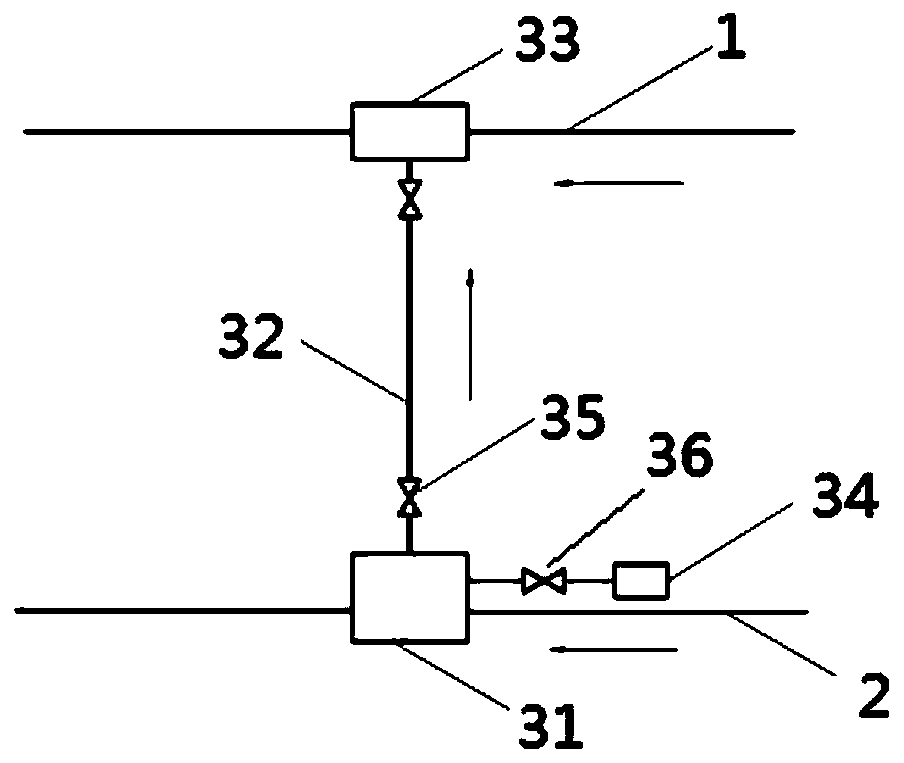

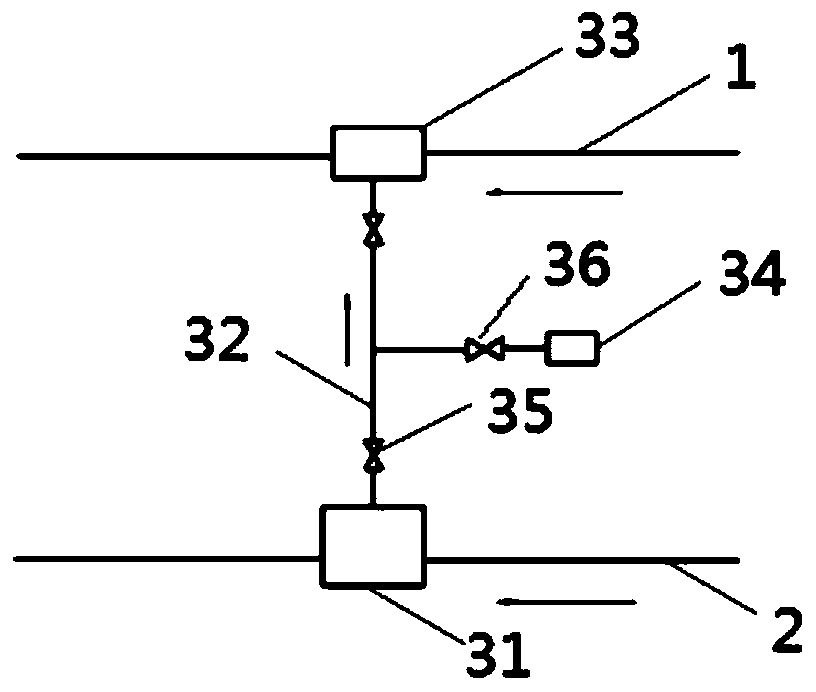

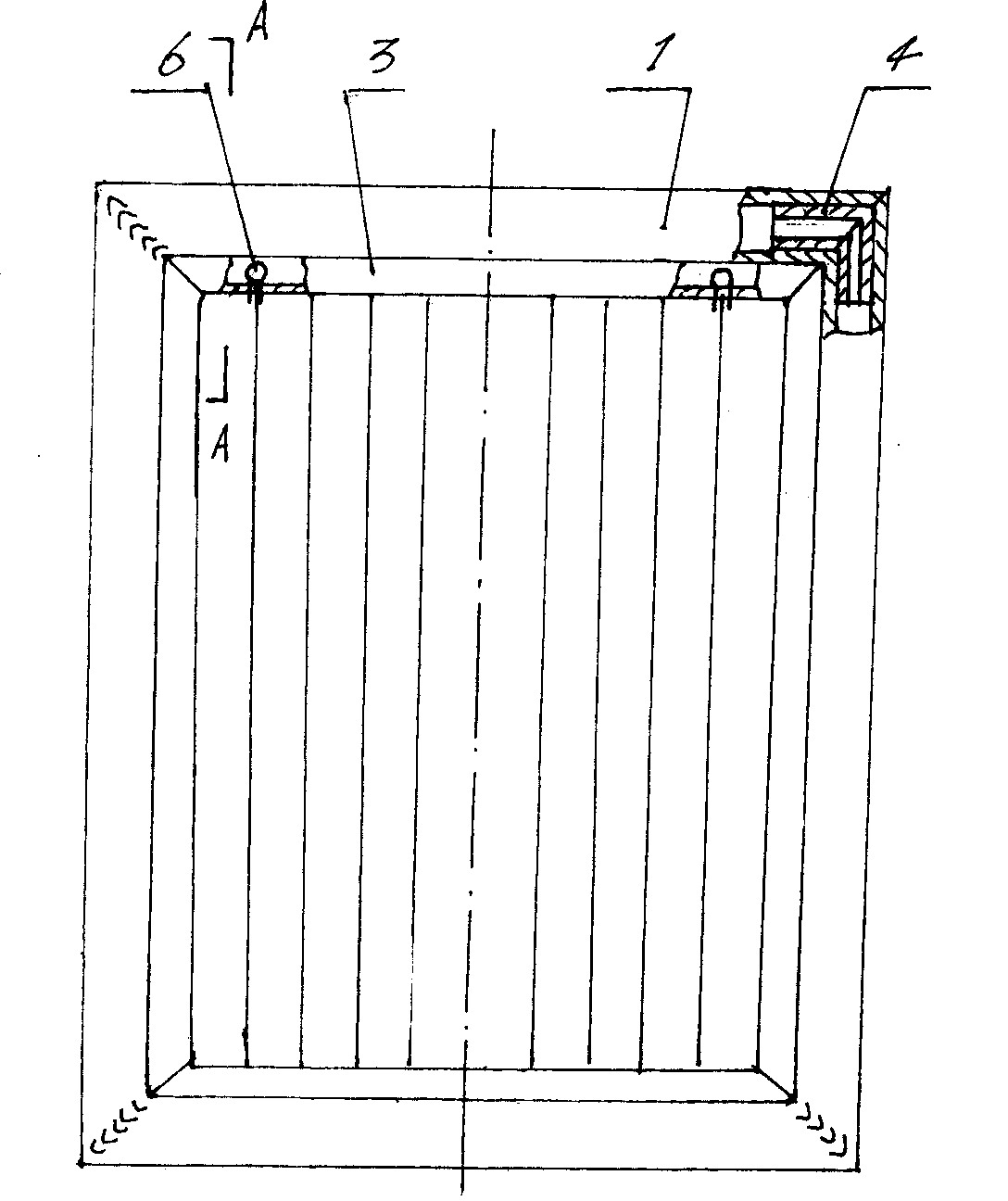

Boiler system

PendingCN110332524AHigh coal input powerSmall application restrictionsFuel feeding arrangementsSolid fuel pretreatmentEngineeringCoal

The invention relates to the technical field of boilers, in particular to a boiler system. The boiler system comprises a first boiler provided with a first primary air pipe, a second boiler provided with a second primary air pipe and a between-boiler pulverized coal conveying device. The between-boiler pulverized coal conveying device is connected with the first primary air pipe and the second primary air pipe, and conveys pulverized coal in the second primary air pipe to the first primary air pipe. On the basis, the application limitation caused by the high coal feeding power of a coal pulverizing system to a fuel-prudent ignition technology in beginning of the boilers can be reduced.

Owner:YANTAI LONGYUAN POWER TECH

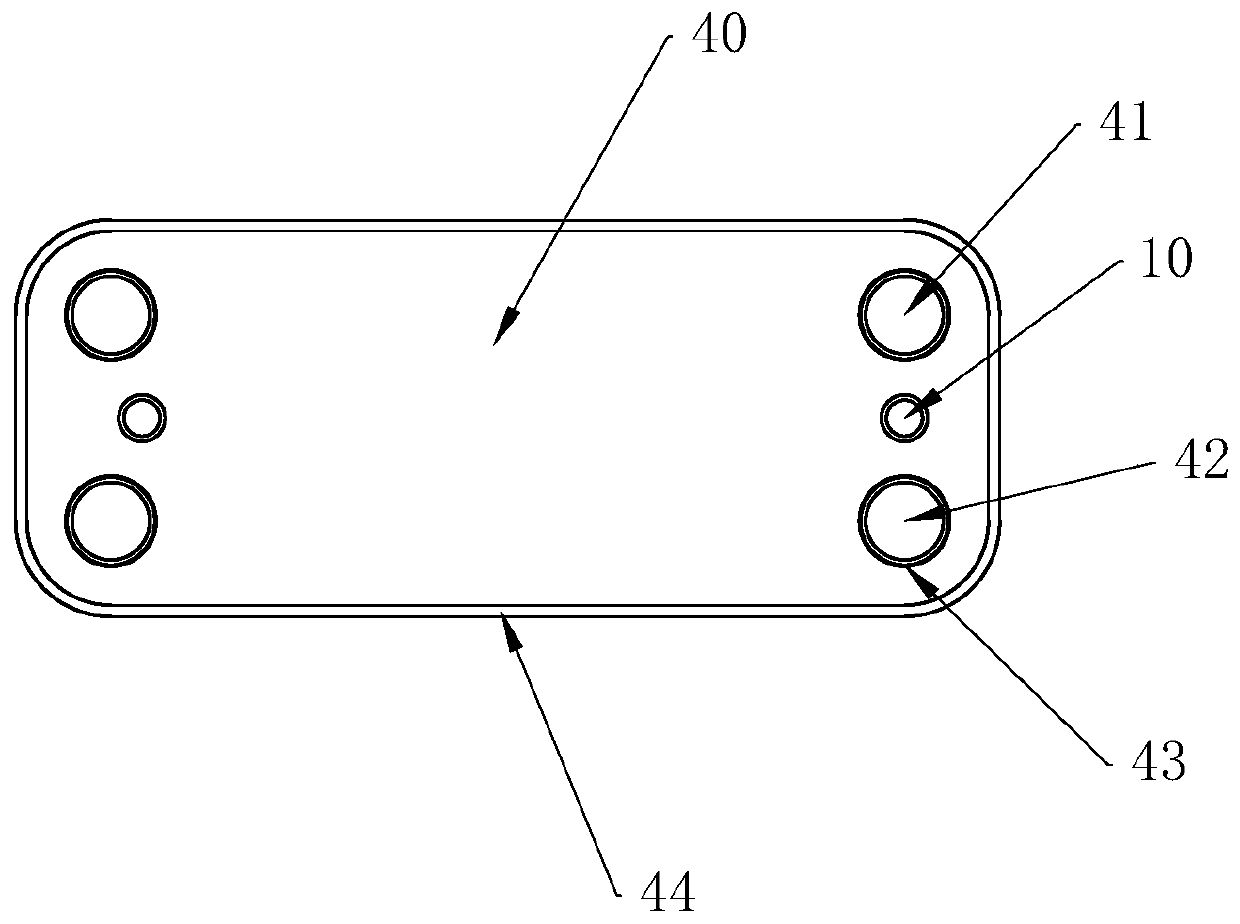

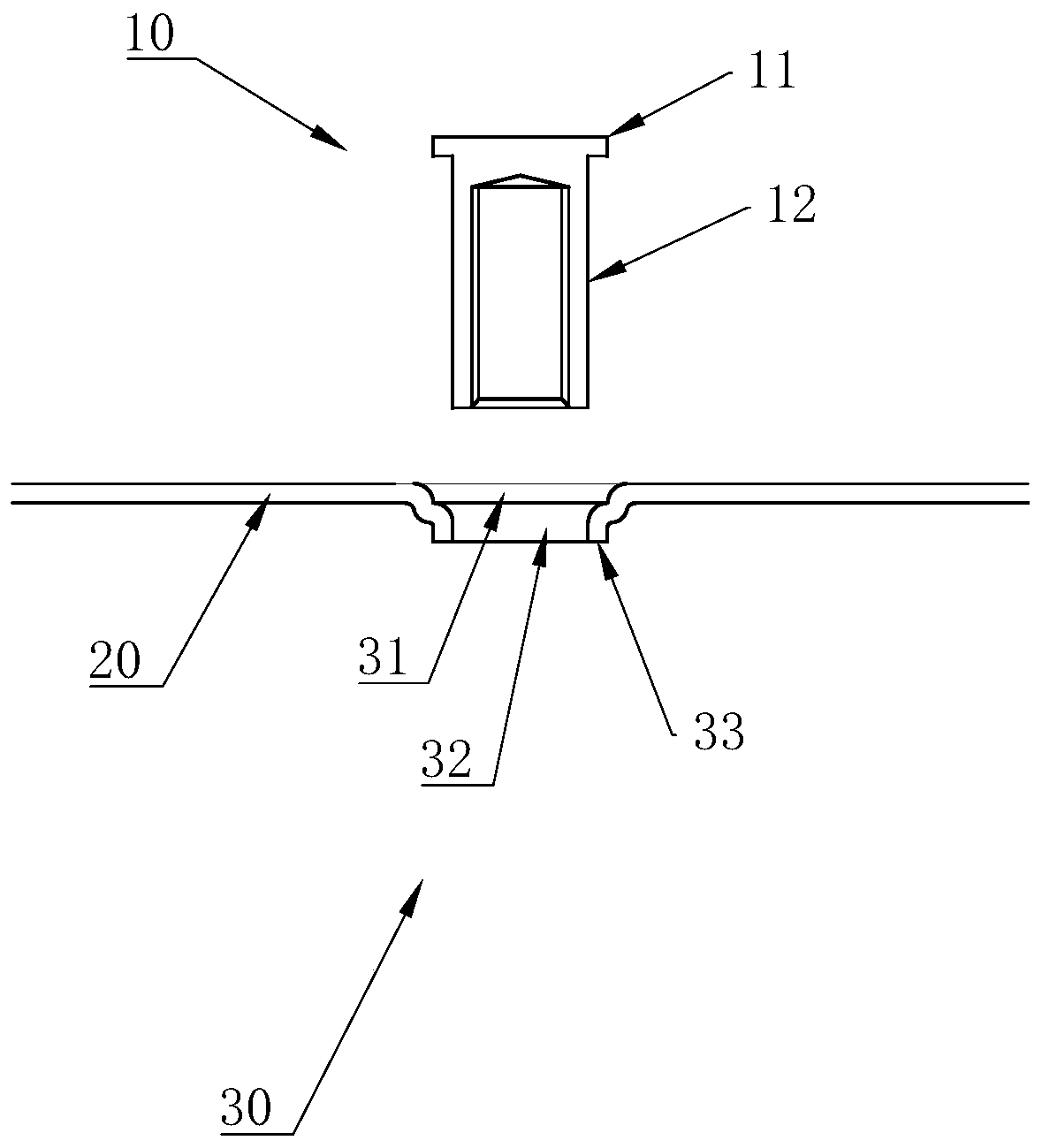

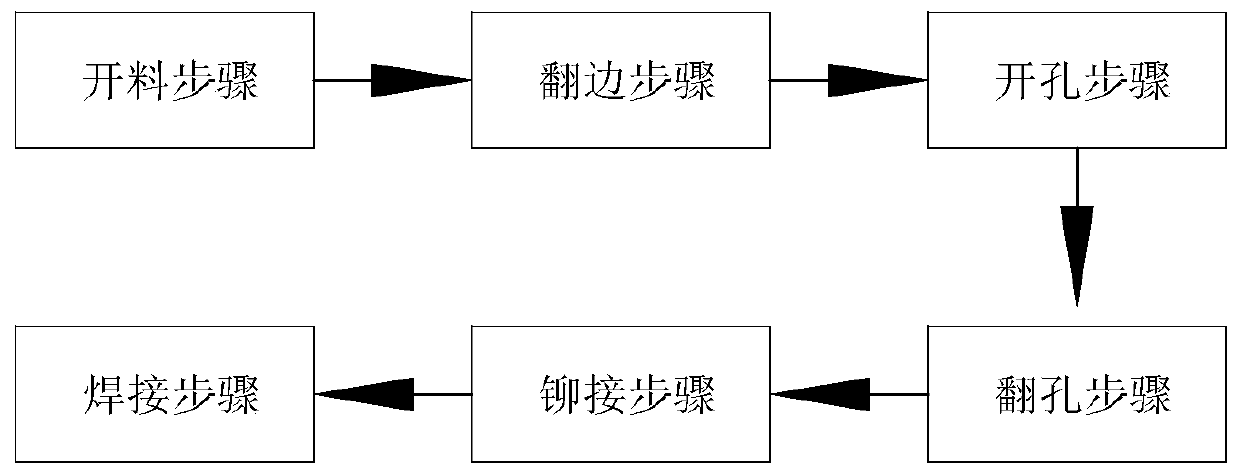

Rivet mounting method, rivet mounting structure and brazing type heat exchanger for wall-hanging furnace

PendingCN110017720APositional Accuracy Improvement and AssuranceImprove verticalityHeat exchanger casingsHeat exchanger fasteningPlate heat exchangerEngineering

The invention discloses a rivet mounting method. The rivet mounting method comprises the following steps that a hole opening step is carried out, specifically, a mounting hole of a rivet is formed ina thin wall; a hole turning step is carried out, specifically, the mounting hole is stretched, so that a positioning flange is generated on one side of the thin wall; and the riveting step is carriedout, specifically, the rivet is arranged in the mounting hole, the positioning flange is compressed, and the rivet is fixed to the thin wall. According to the rivet mounting method, the rivet mountingstructure and the brazing type heat exchanger for the wall-hanging furnace, the position precision and perpendicularity of the rivet are improved.

Owner:江门市东联热工设备有限公司

Energy-saving lamp with air insulating cavity

InactiveCN102011961AExtend delivery timeRemove app restrictionsElectric circuit arrangementsLighting heating/cooling arrangementsEngineeringThermal resistance

The invention provides an energy-saving lamp with an air insulating cavity. The energy-saving lamp comprises a lamp tube, a lamp housing and an electronic ballast, wherein the electronic ballast is arranged in the lamp housing; the lamp tube surrounds the lamp housing which is outside the electronic ballast; the lamp housing is composed of an upper housing and a lower housing which are fastened to each other; the fastened upper housing and lower housing have an inner side wall and an outer side wall; and a closed insulating cavity filled with air is formed between the inner side wall and the outer side wall. The scheme provided by the invention utilizes the heat insulation principle of air cleverly as follows: when the heat generated by the lamp tube is transferred to the inside of the lamp housing, the heat firstly passes through the outer wall of the lamp housing and heats air in the air insulating cavity, and secondly passes through the inner sleeve of the electronic ballast to affect the electronic ballast. As air has higher thermal resistance, the time that the heat of the lamp tube is transferred to the electronic ballast can be greatly prolonged, the electronic ballast can not be affected by high external temperature in long-term operation and the application of the energy-saving lamp can not be limited.

Owner:FOSHAN METROPOLIS LIGHTING

System and implement method thereof for secret communications based on public communication network voice channel

InactiveCN103000181BEncryption is validMeets requirementsSpeech analysisSecuring communicationVoice communicationComputer module

The invention discloses a system and an implement method thereof for secret communications based on a public communication network voice channel. The system and the implement method thereof for the secret communications based on the public communication network voice channel mainly solve the problem in an existing technology that a voice encryption method of a public communication network is low in reliability, difficult in technique and not convenient to implement. The system for the secret communications based on the public communication network voice channel comprises a power source, and further comprises a processor connected with the power source, and a storage, a digital / analog conversion module, a voice compression / decompression module, an encryption / decryption module, and a digital analogy mapping modulation / demodulation module all connected with the processor. By adopting the scheme, the system and the implement method thereof for the secret communications based on the public communication network voice channel achieve a purpose of conveniently and reliably keeping voice communications confidential, and have high practical value and promotional value.

Owner:CHENGDU LINGGUANG QUANTUM TECH

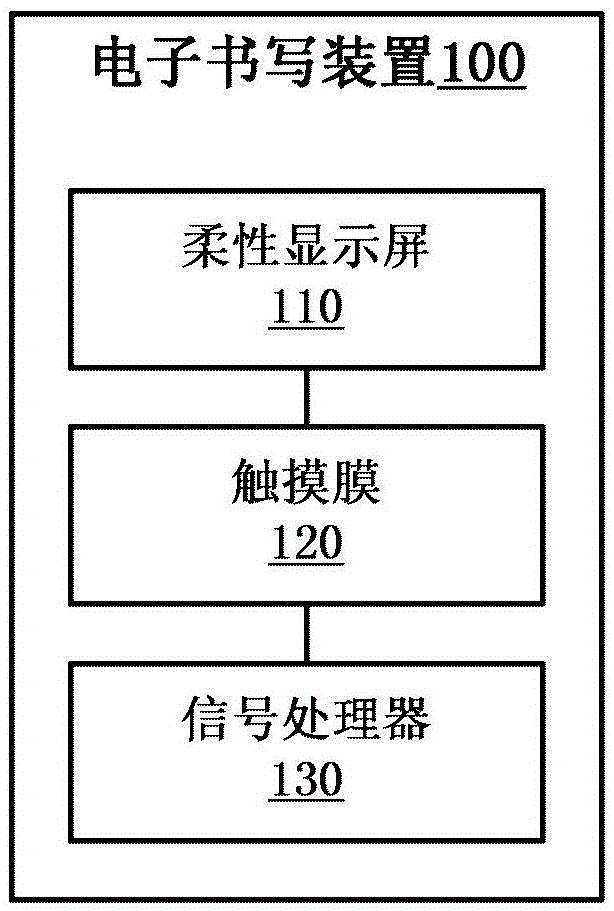

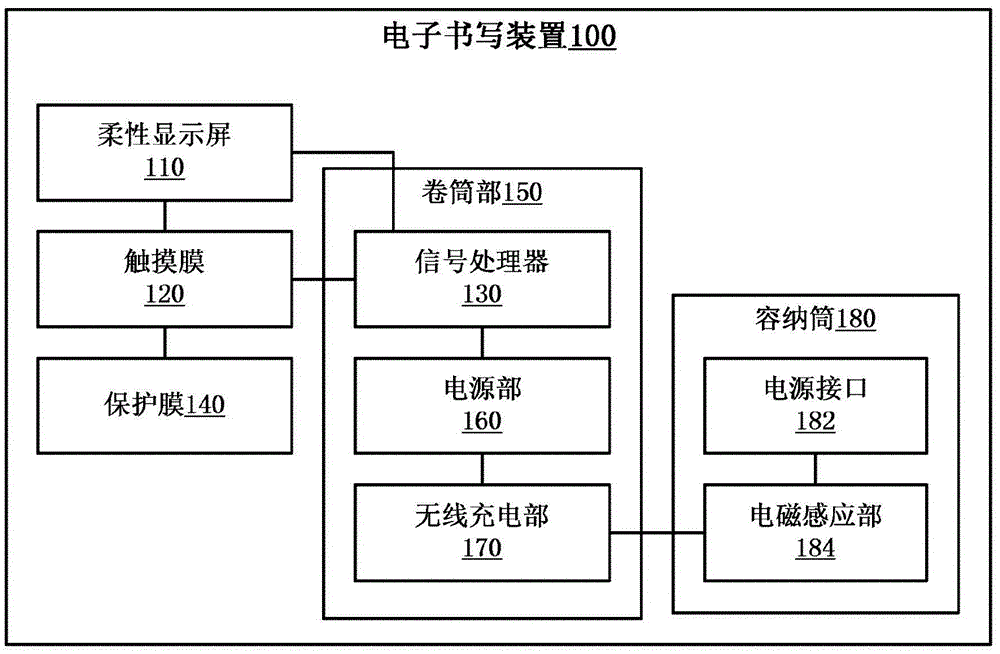

Electronic writing apparatus

InactiveCN106708774AEasy to storeEasy to carryDigital computer detailsElectric digital data processingElectricityFlexible display

The invention provides an electronic writing apparatus. The electronic writing apparatus comprises a flexible display screen, a touch film covering the surface of the flexible display screen and used for converting touch operation on the touch film from outside into corresponding induction data, and a signal processor electrically connected with the flexible display screen and the touch film and configured to obtain the induction data and drive the flexible display screen to output a corresponding track according to the induction data so as to form handwriting. By use of the electronic writing apparatus, on one hand, the electronic writing apparatus is convenient to carry by utilizing a characteristic that the flexible display screen is convenient to store; and on the other hand, by utilizing the electronic apparatus, good writing experience is obtained, multiple functions of appreciation and analysis, copybook reading, modeling, copying and the like are realized, and various writing demands of users are met.

Owner:BEIJING QIHOO TECH CO LTD +1

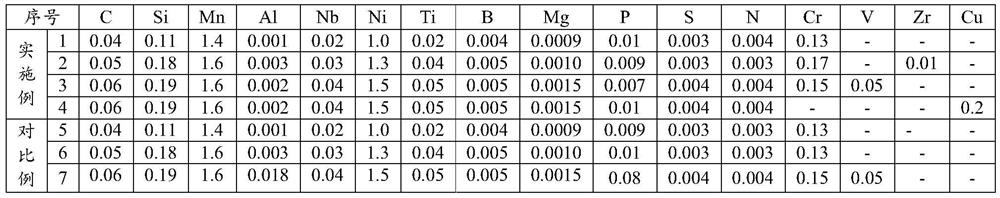

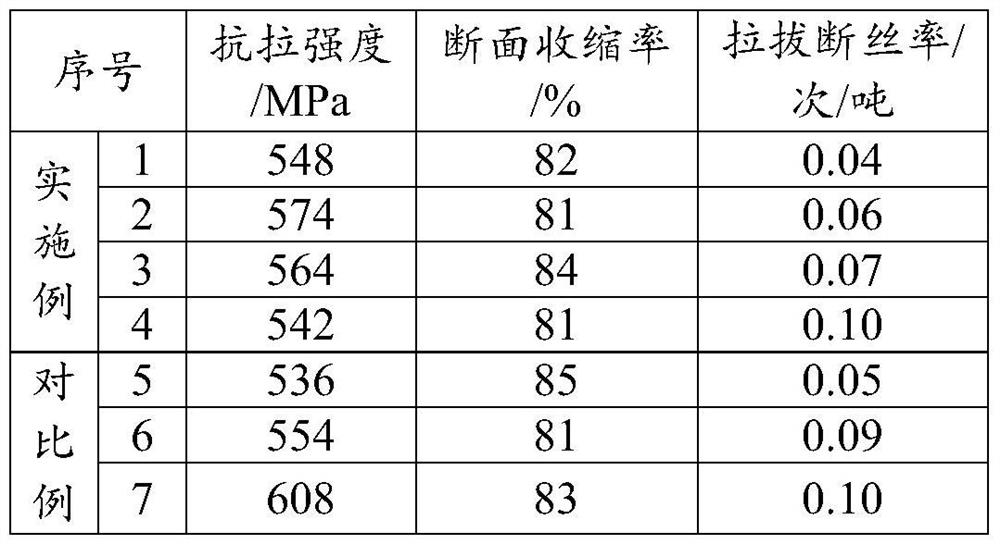

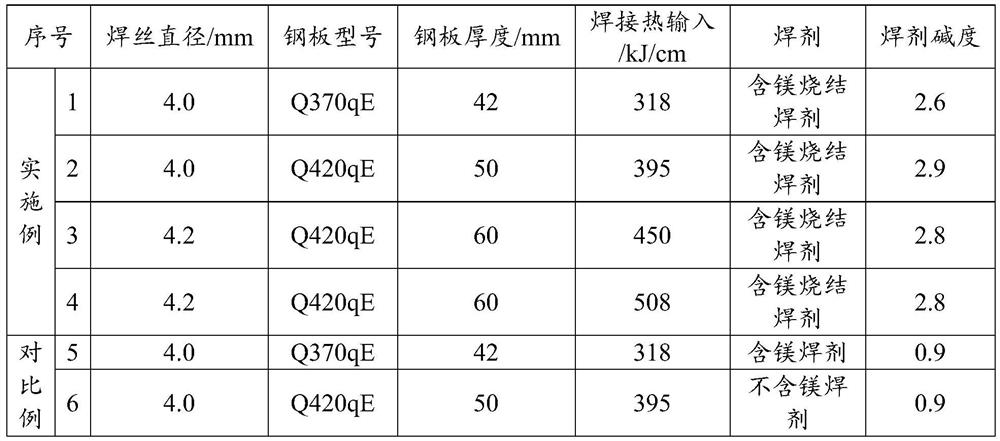

High-heat-input submerged-arc welding wire steel wire rod, preparation method thereof, high-heat-input submerged-arc welding wire and high-heat-input welding method

ActiveCN114378480ALow carbon equivalentImprove low temperature toughnessArc welding apparatusWelding/cutting media/materialsWire rodAlloy

The invention discloses a high-heat-input submerged-arc welding wire steel wire rod and a preparation method thereof, a high-heat-input submerged-arc welding wire and a high-heat-input welding method. The high-heat-input submerged-arc welding wire steel wire rod comprises the following chemical components in percentage by mass: 0.04 to 0.06 percent of C, 0.1 to 0.2 percent of Si, 1.4 to 1.6 percent of Mn, 1.0 to 1.5 percent of Ni, 0.02 to 0.04 percent of Nb, 0.02 to 0.05 percent of Ti, 0.0040 to 0.0055 percent of B and the balance of Al, the alloy comprises the following components in percentage by weight: 0.004% of Mg, 0.0005-0.0020% of P, less than or equal to 0.005% of S, less than or equal to 0.005% of N and the balance of Fe and inevitable impurities. Through reasonable design of the chemical components and the content, the high-heat-input submerged-arc welding wire steel wire rod has low carbon equivalent in the welding wire preparation process, the low-temperature toughness of weld metal can be improved, generation of brittle phases is reduced, the yield ratio of the weld metal is reduced, and the prepared high-heat-input submerged-arc welding wire has good application prospects. The allowable welding heat input is greater than or equal to 300kJ / cm, and a steel plate with the thickness of more than 40mm can be thoroughly welded in a single pass.

Owner:ZHANGJIAGANG RONGSHENG SPECIAL STEEL CO LTD +1

Energy-saving lamp with air insulating cavity

InactiveCN102011961BExtension of timeSmall application restrictionsElectric circuit arrangementsLighting heating/cooling arrangementsEngineeringHot Temperature

The invention provides an energy-saving lamp with an air insulating cavity. The energy-saving lamp comprises a lamp tube, a lamp housing and an electronic ballast, wherein the electronic ballast is arranged in the lamp housing; the lamp tube surrounds the lamp housing which is outside the electronic ballast; the lamp housing is composed of an upper housing and a lower housing which are fastened to each other; the fastened upper housing and lower housing have an inner side wall and an outer side wall; and a closed insulating cavity filled with air is formed between the inner side wall and the outer side wall. The scheme provided by the invention utilizes the heat insulation principle of air cleverly as follows: when the heat generated by the lamp tube is transferred to the inside of the lamp housing, the heat firstly passes through the outer wall of the lamp housing and heats air in the air insulating cavity, and secondly passes through the inner sleeve of the electronic ballast to affect the electronic ballast. As air has higher thermal resistance, the time that the heat of the lamp tube is transferred to the electronic ballast can be greatly prolonged, the electronic ballast can not be affected by high external temperature in long-term operation and the application of the energy-saving lamp can not be limited.

Owner:FOSHAN METROPOLIS LIGHTING

Low-melting point metal-matrix aramid fiber composite material and preparation method thereof

InactiveCN103255360BEnhancement effect is goodImprove the bonding strength of the interfaceFiber-reinforced compositeMetal matrix composite

The invention relates to a low-melting point metal-matrix aramid fiber composite material and a preparation method thereof, belonging to the field of low-melting point soft metal-matrix fiber reinforced composite materials. The structure of the composite material is as follows: aramid fiber is embedded into a low-melting point metal matrix, and the volume ratio of the low-melting point metal to the aramid fiber is (95-97):(5-3). High-strength aramid fiber is used as a reinforcement of lead and lead alloy, and the molten lead and lead alloy permeate into the aramid fiber after surface metallization to prepare a lead and lead alloy-matrix aramid fiber composite material. A composite material taking a low-melting point soft metal as a matrix is reinforced by fiber in great difference from the strength of the matrix metal material; by adopting a liquid permeation method, a composite material with an obvious reinforcement effect can be effectively prepared only by use of low fiber volume percent; and the tensile strength of the low-melting point metal-matrix composite material provided by the invention can reach 150MPa, and the elongation can reach 20%.

Owner:KUNMING UNIV OF SCI & TECH

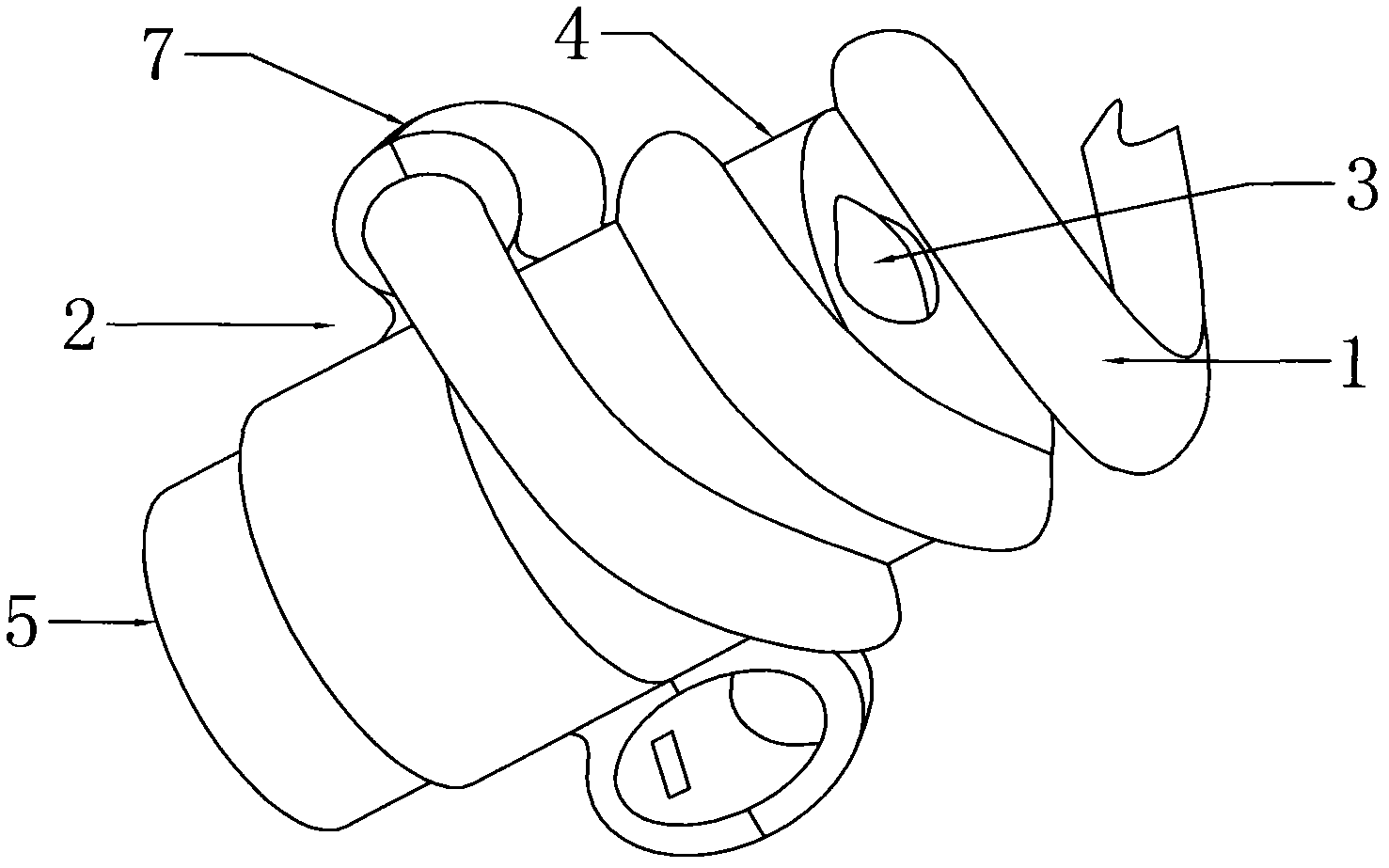

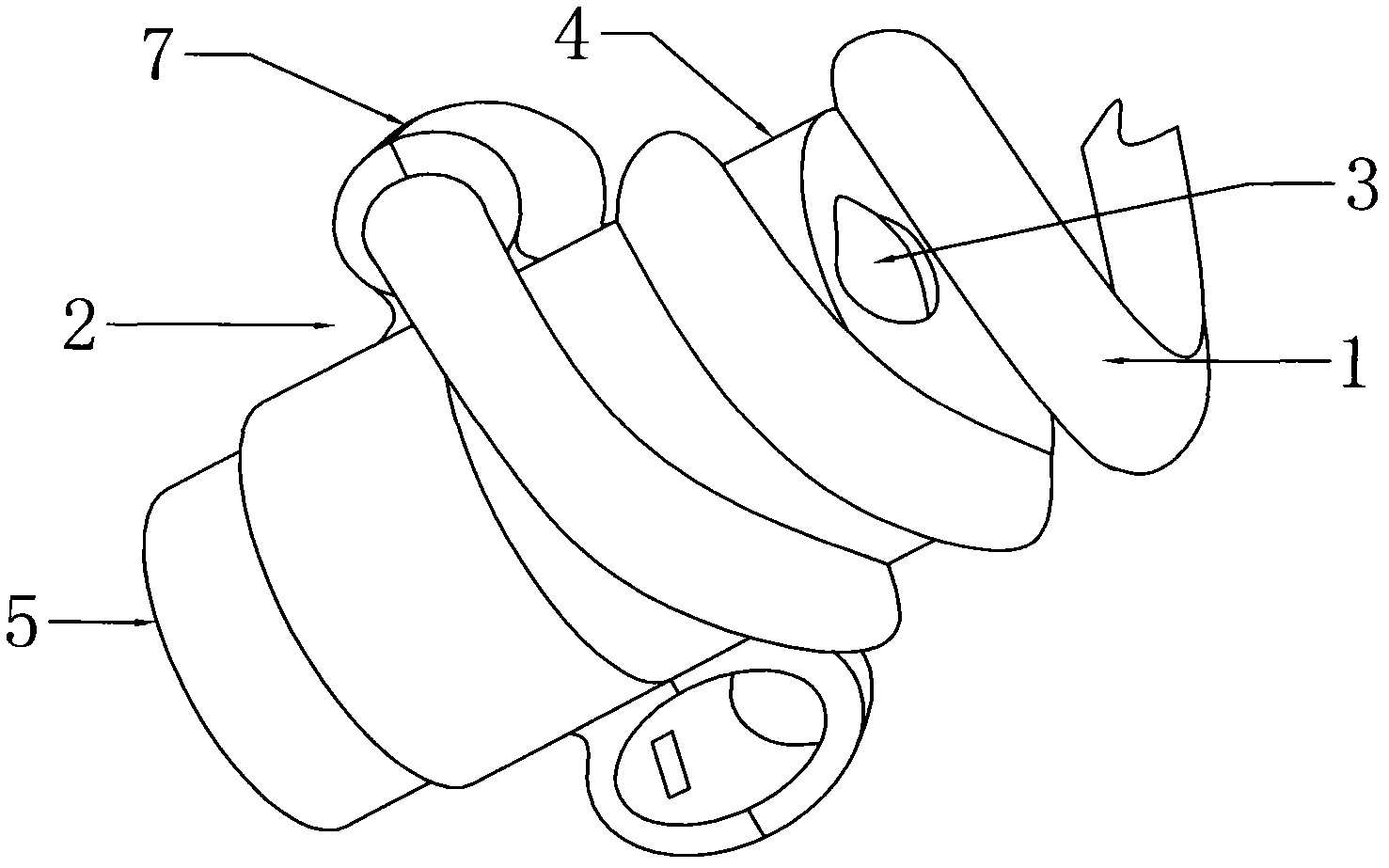

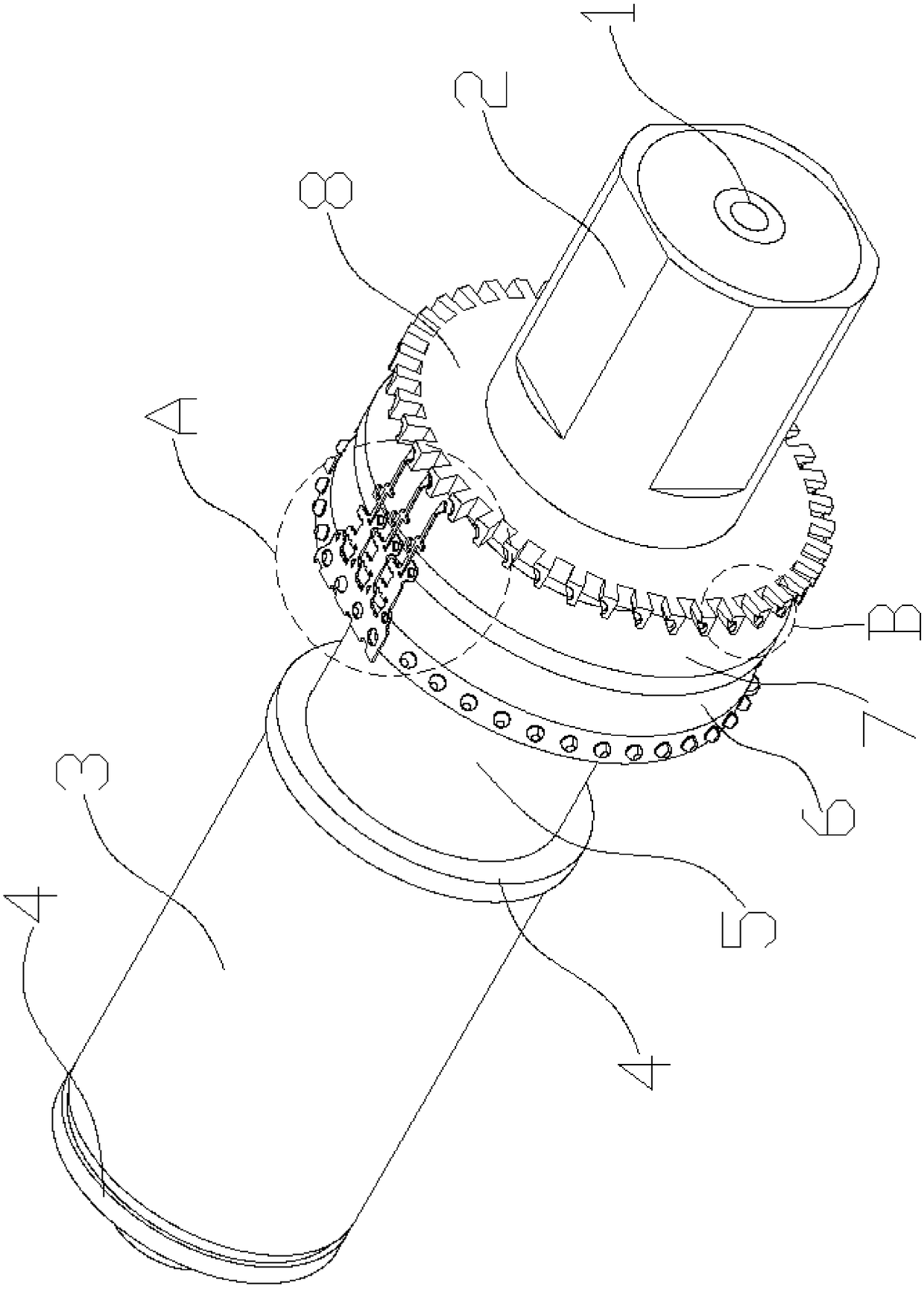

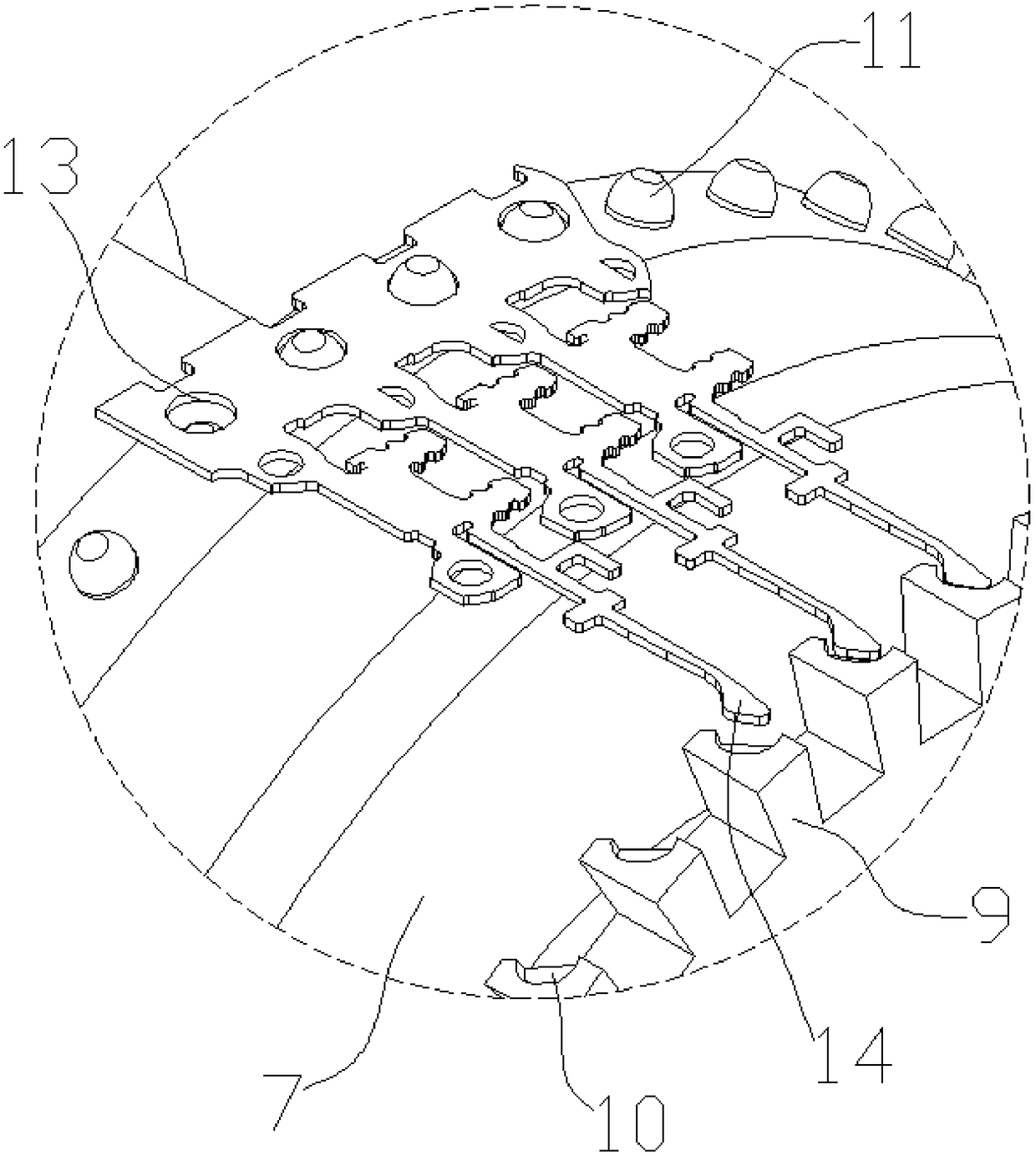

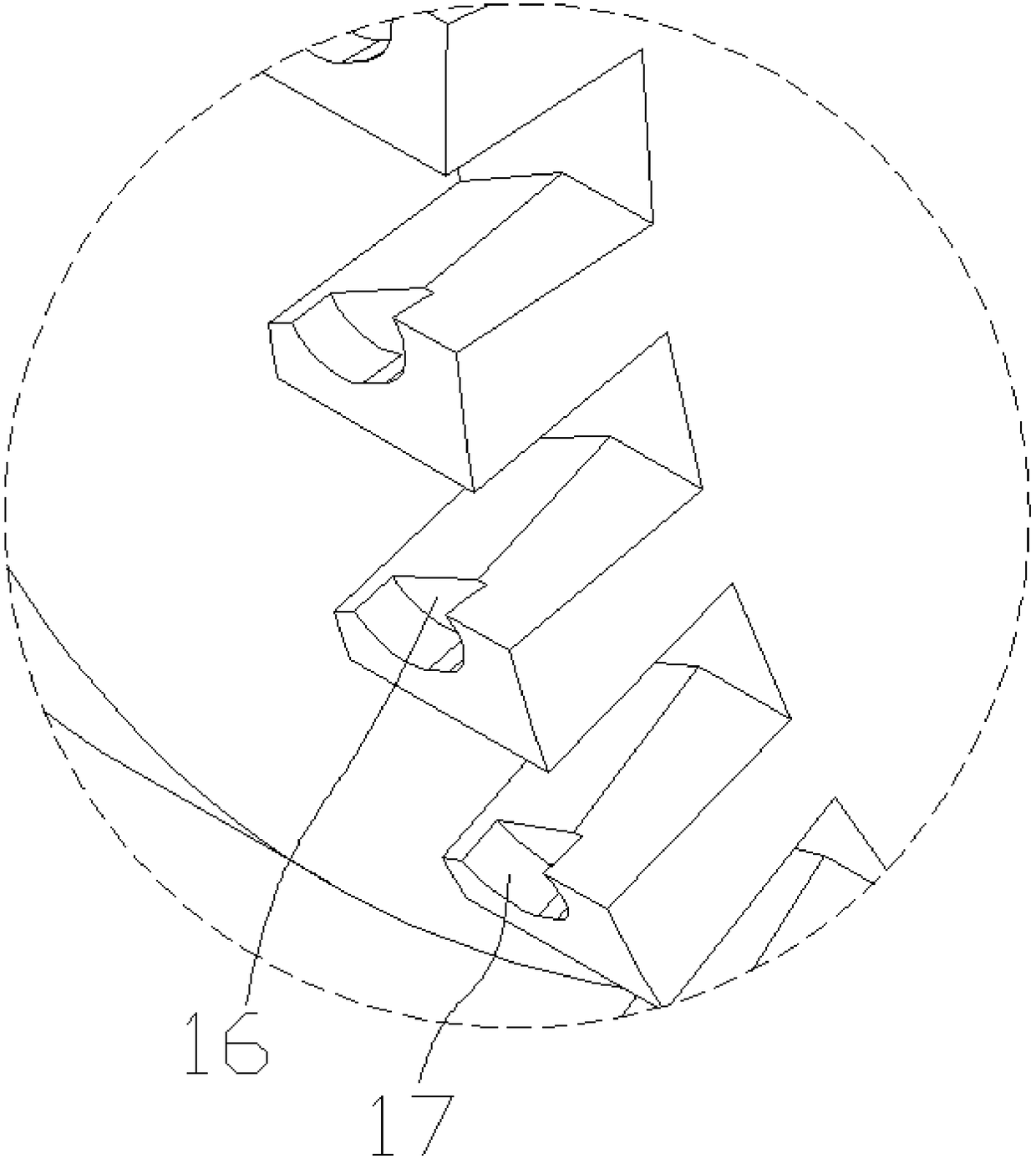

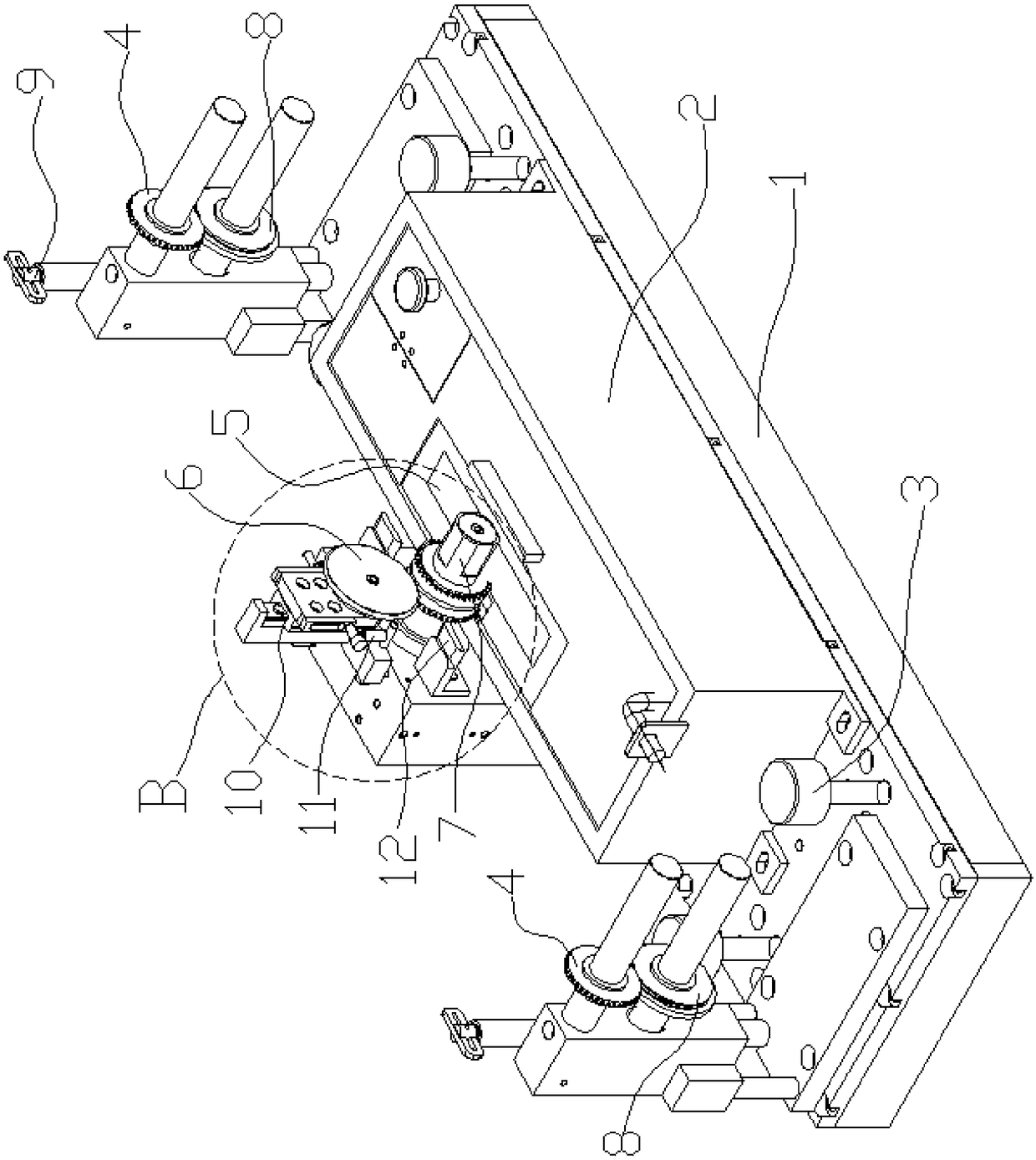

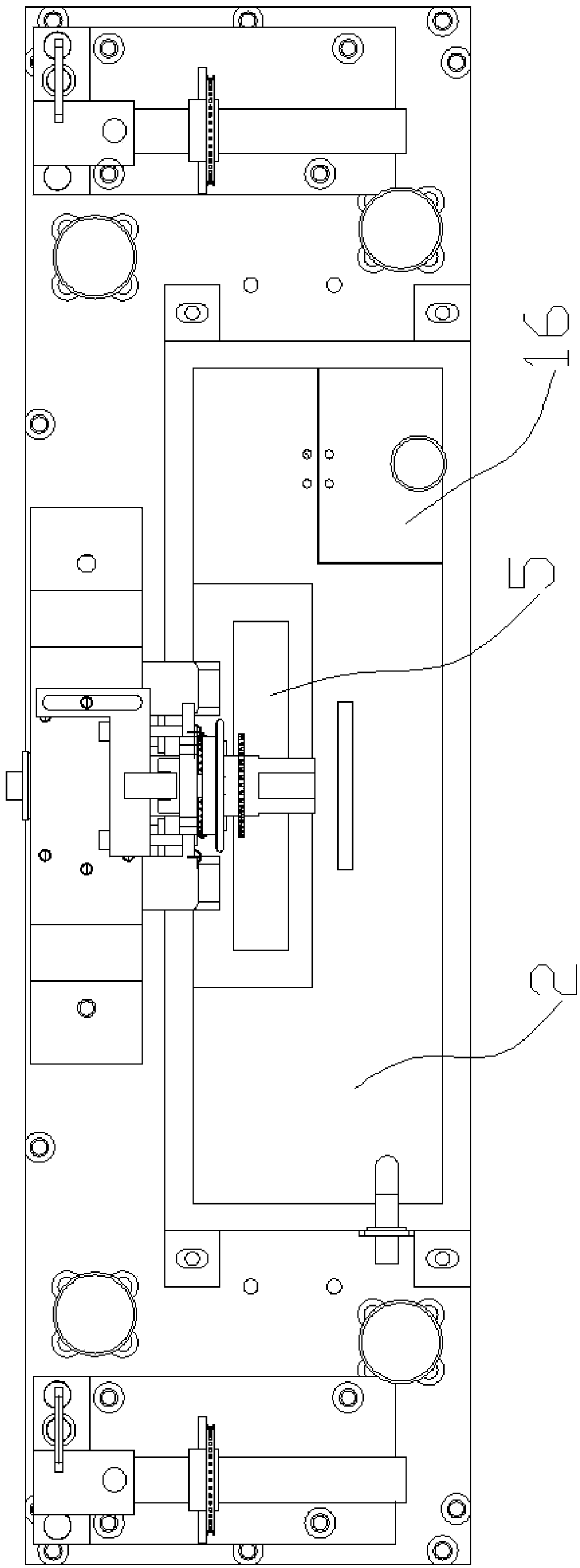

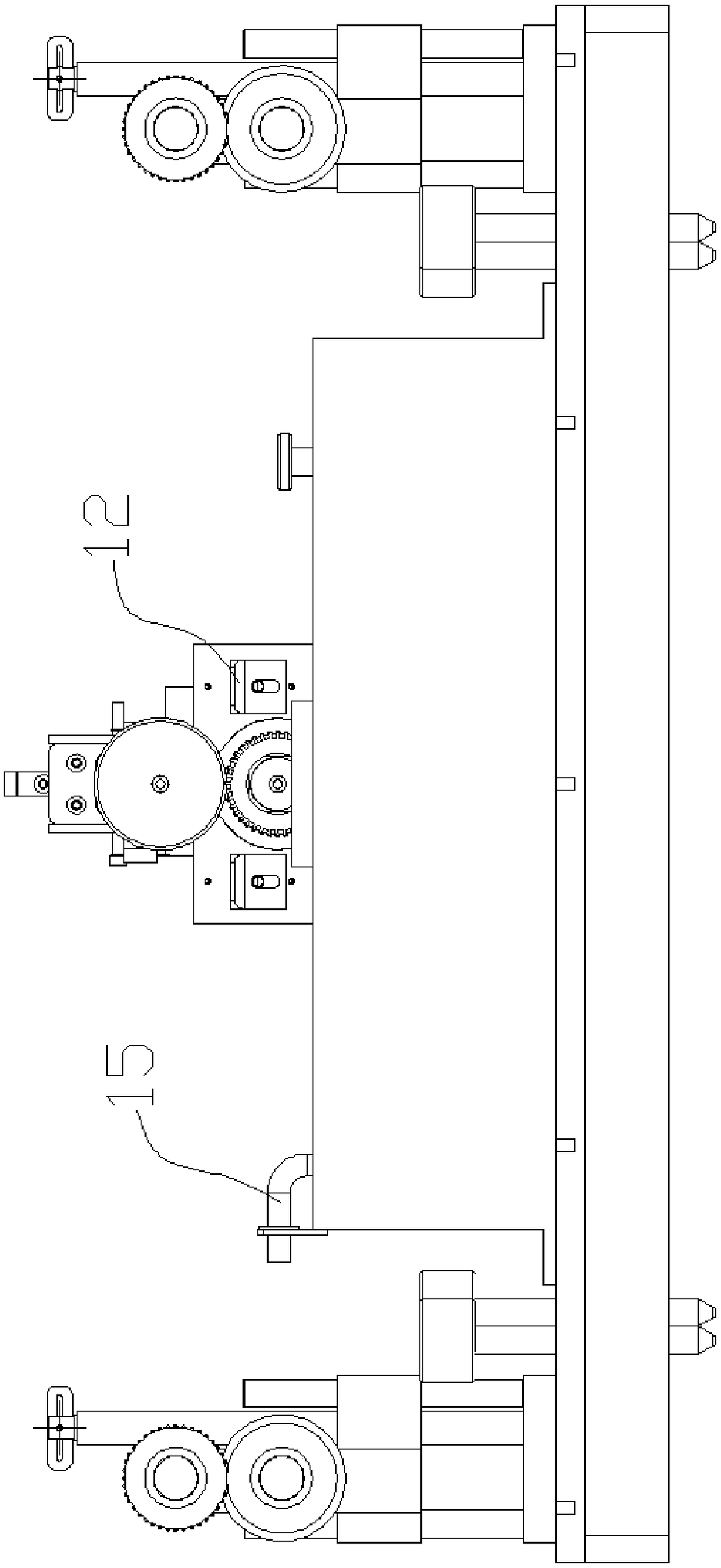

Continuous wax dotting shaft

The invention discloses a continuous wax dotting shaft which comprises a locating wheel, a wax sticking wheel and a heater. The circumference face of the locating wheel is provided with a plurality oflocating protruding points protruding in the radial direction. The locating protruding points are inserted into round holes of a material belt and drive the material belt to be conveyed horizontally.The wax sticking wheel and the locating wheel are arranged in parallel and are connected integrally through a center shaft. The self axis of the wax sticking wheel coincides with that of the locatingwheel. The wax sticking wheel is provided with protruding radial teeth. Each radial tooth is provided with a sunken wax containing groove. Wax liquid adheres to the inner wall of each wax containinggroove. The wax sticking wheel and the locating wheel rotate coaxially to enable the wax liquid to adhere to the material belt. The heater is nested in the center shaft and controls the wax liquid onthe wax sticking wheel within the liquid state temperature. A coaxial bearing wheel is arranged between the locating wheel and the wax sticking wheel and is provided with a circumference face. By theadoption of the continuous wax dotting shaft, a plurality of wheels on one shaft are utilized for precisely conveying the strip-shaped material belt, bearing the material belt and carrying out local wax sealing on the material belt, the structure cost is low, and the wax sealing efficiency is high.

Owner:KUNSHAN SOKAY AUTOMATION TECH CO LTD

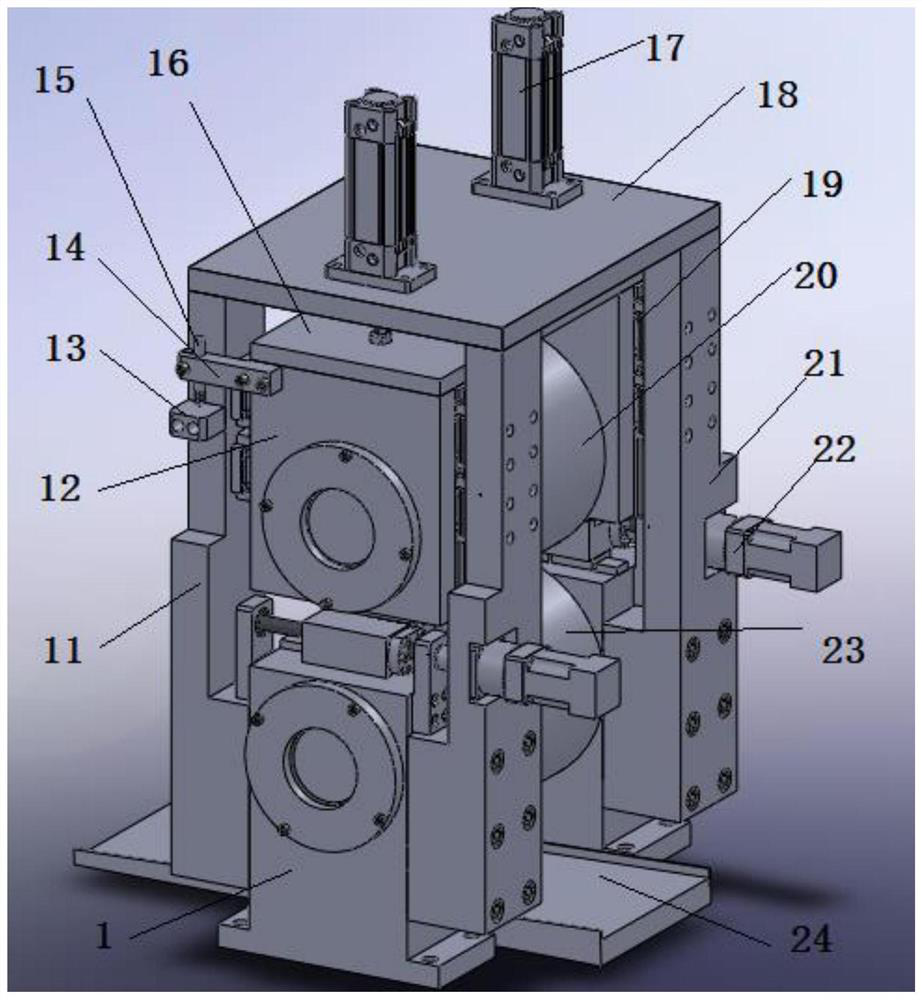

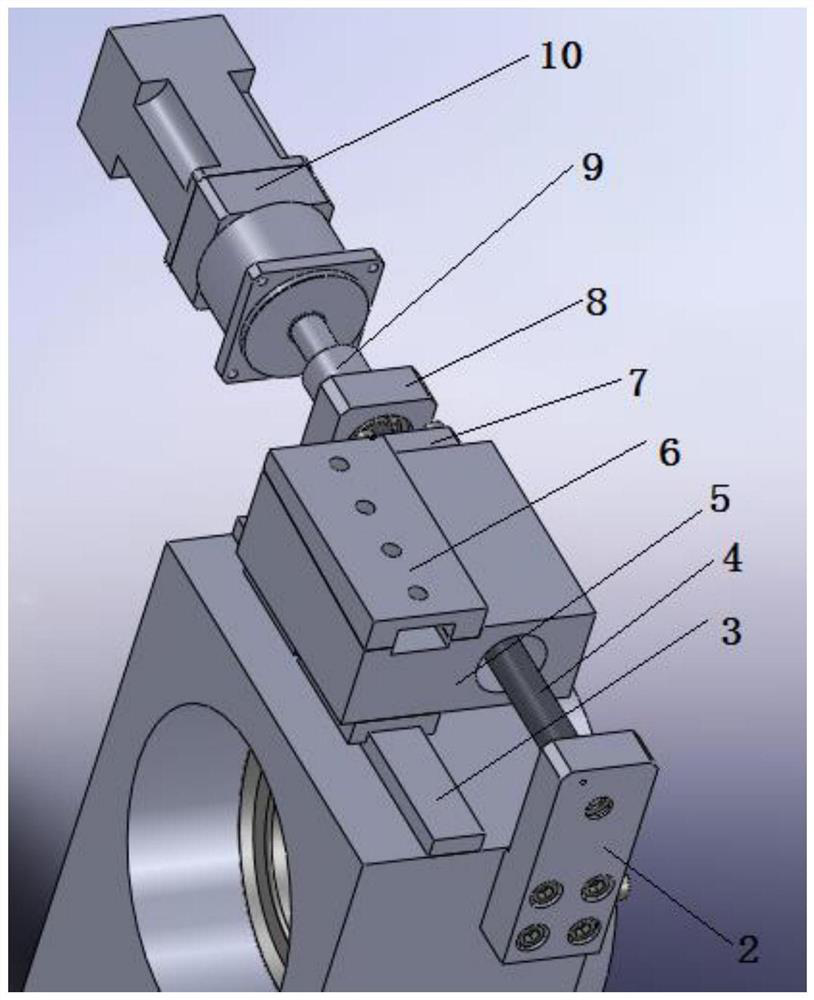

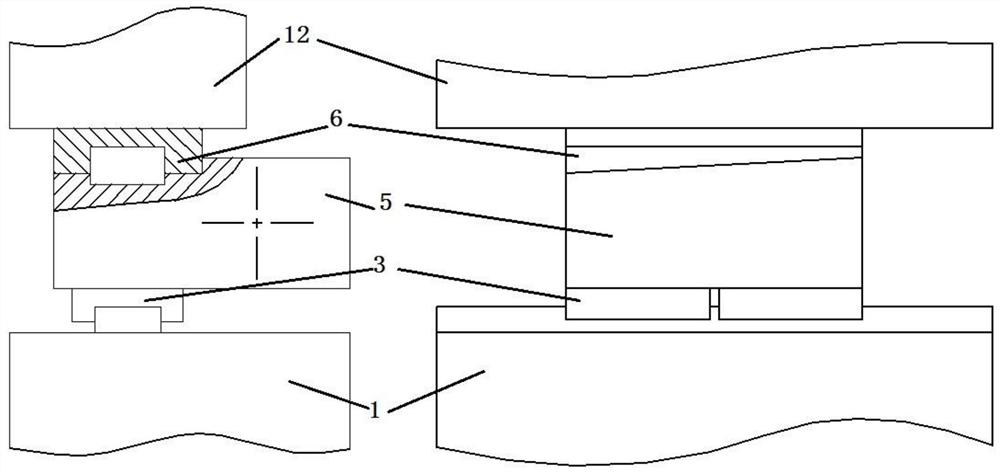

Accurate control device for carbon fiber impregnation amount

PendingCN114311620ASmall application restrictionsThe device works reliablyRettingManufacturing engineering

The invention relates to a device for accurately controlling the impregnation amount of carbon fibers, which can be used for accurately controlling the impregnation amount of the fibers in a carbon fiber wet winding process, and can solve the technical problems that the existing impregnation amount of the carbon fibers is unstable, the impregnation amount cannot be quantified, and defects of wound products are caused by poor infiltration degree of the fibers. The device can be mounted in a gum dipping system of wet winding numerical control equipment for matched use, the device comprises a set of double-roller device, a lower roller is fixed, an upper roller can lift and move along a guide, a gap between the two rollers can be adjusted with the precision of 0.001 mm through a precision adjusting mechanism, the stability of the position of the upper roller when the device works is ensured through a pressing air cylinder, and the working efficiency of the device is improved. Electromagnetic heating devices are arranged in the double rollers, and the viscosity of glue on fibers passing through a gap between the double rollers can be controlled, so that high-quality impregnated fibers with accurate and stable impregnation amount are conveyed before a product is wound.

Owner:CHANGCHUN EQUIP TECH RES INST

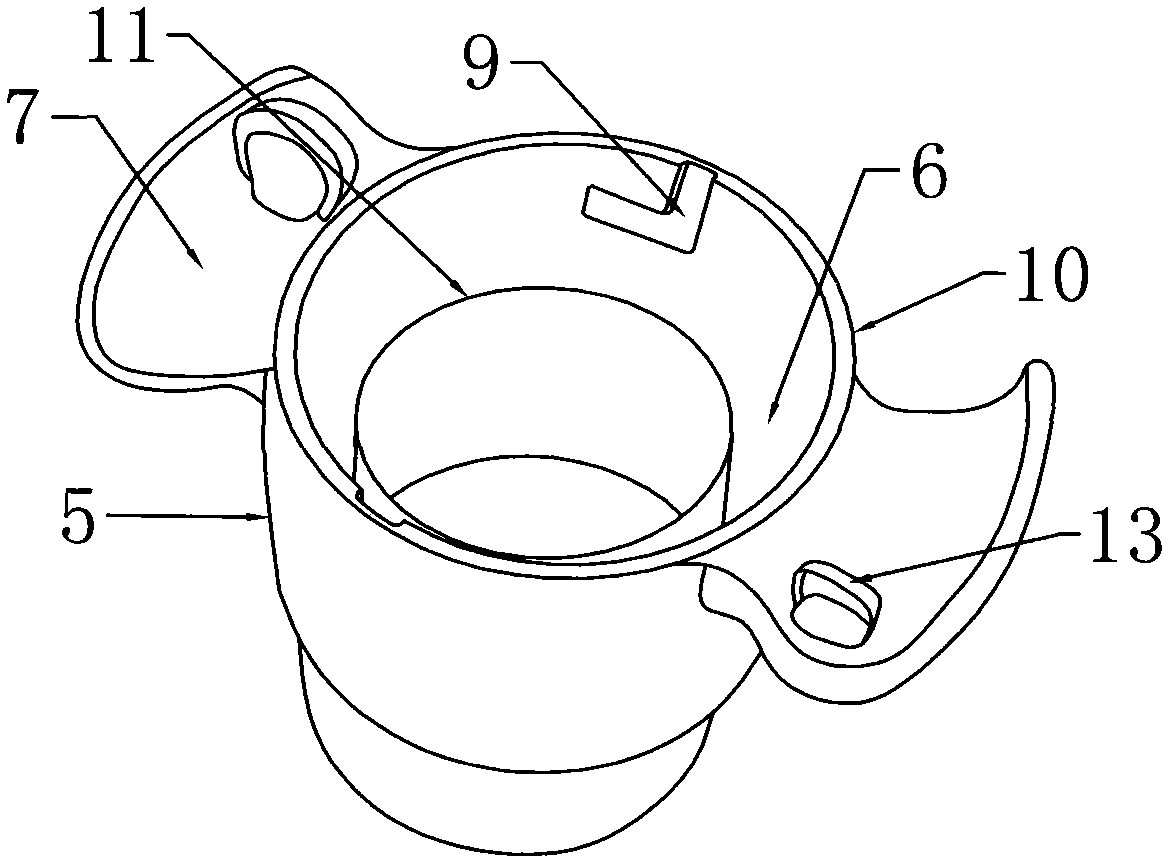

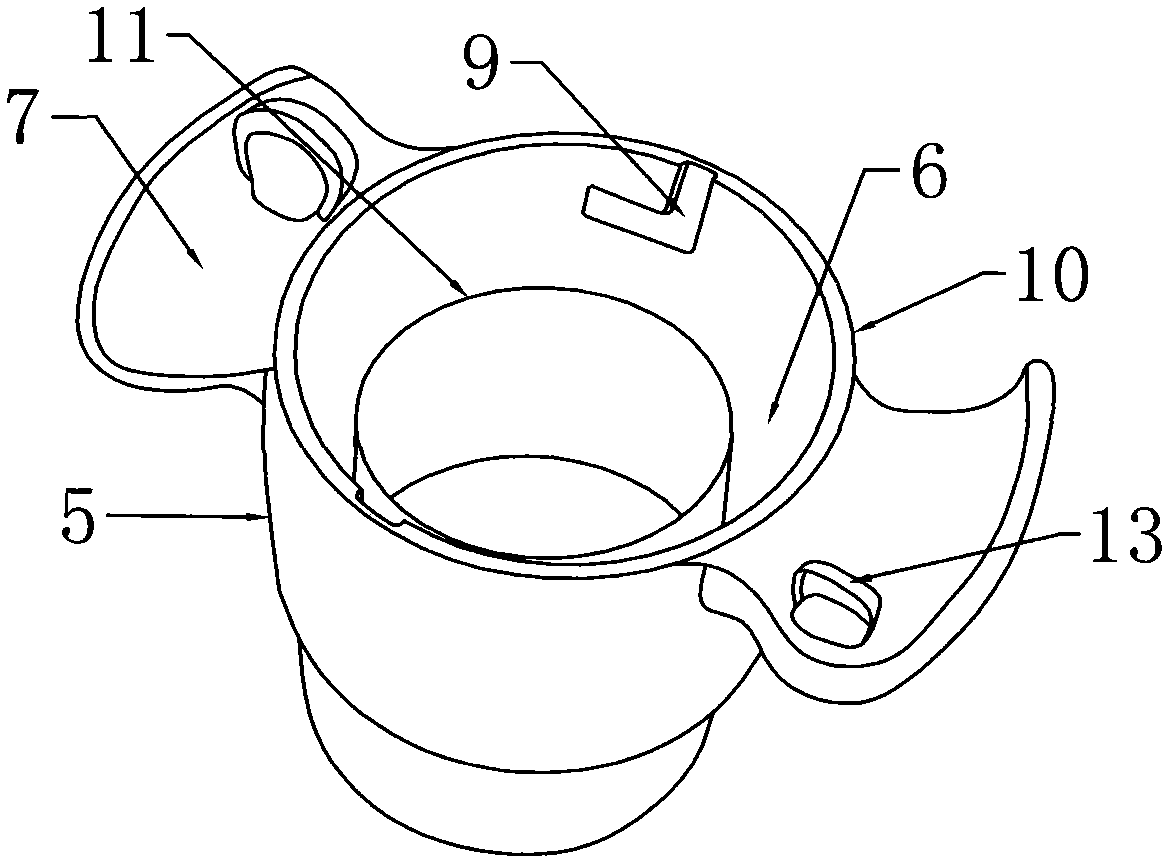

Continuous wax dispersing groove

The invention discloses a continuous wax dispersing groove which comprises a wax storage groove located below a material belt, a wax dispersing shaft and a conveying limiting mechanism. Liquid wax isstored in the wax storage groove, the axial line of the wax dispersing shaft is parallel to the horizontal plane, the wax dispersing shaft makes contact with the lower surface of the material belt, the wax dispersing shaft is provided with wax attaching teeth protruded in the radial direction, and liquid wax in the wax storage groove is attached to the material belt through the wax attaching teethalong with rotation of the wax dispersing shaft. The conveying limiting mechanism is provided with feeding wheels and lower supporting wheels which carry out up-down outer cutting, the axial lines ofthe feeding wheels and the lower supporting wheels are parallel to the axial line of the wax dispersing shaft, the two sides of the wax dispersing shaft are each provided with one feeding wheel and one lower supporting wheel, the connection line between the two feeding wheels is parallel to the conveying direction of the material belt, the feeding wheels are provided with a plurality of convex points extended in the radial direction, the material belt is provided with holes matched with the convex points, and the circumferential faces of the lower supporting wheels are provided with annular grooves. By adopting the continuous wax dispersing groove, wax in the wax storage groove is dispersed to the material belt through circumferential movement of the wax dispersing shaft, local wax sealing of the material belt is achieved, and meanwhile horizontal conveying of the material belt is ensured.

Owner:KUNSHAN SOKAY AUTOMATION TECH CO LTD

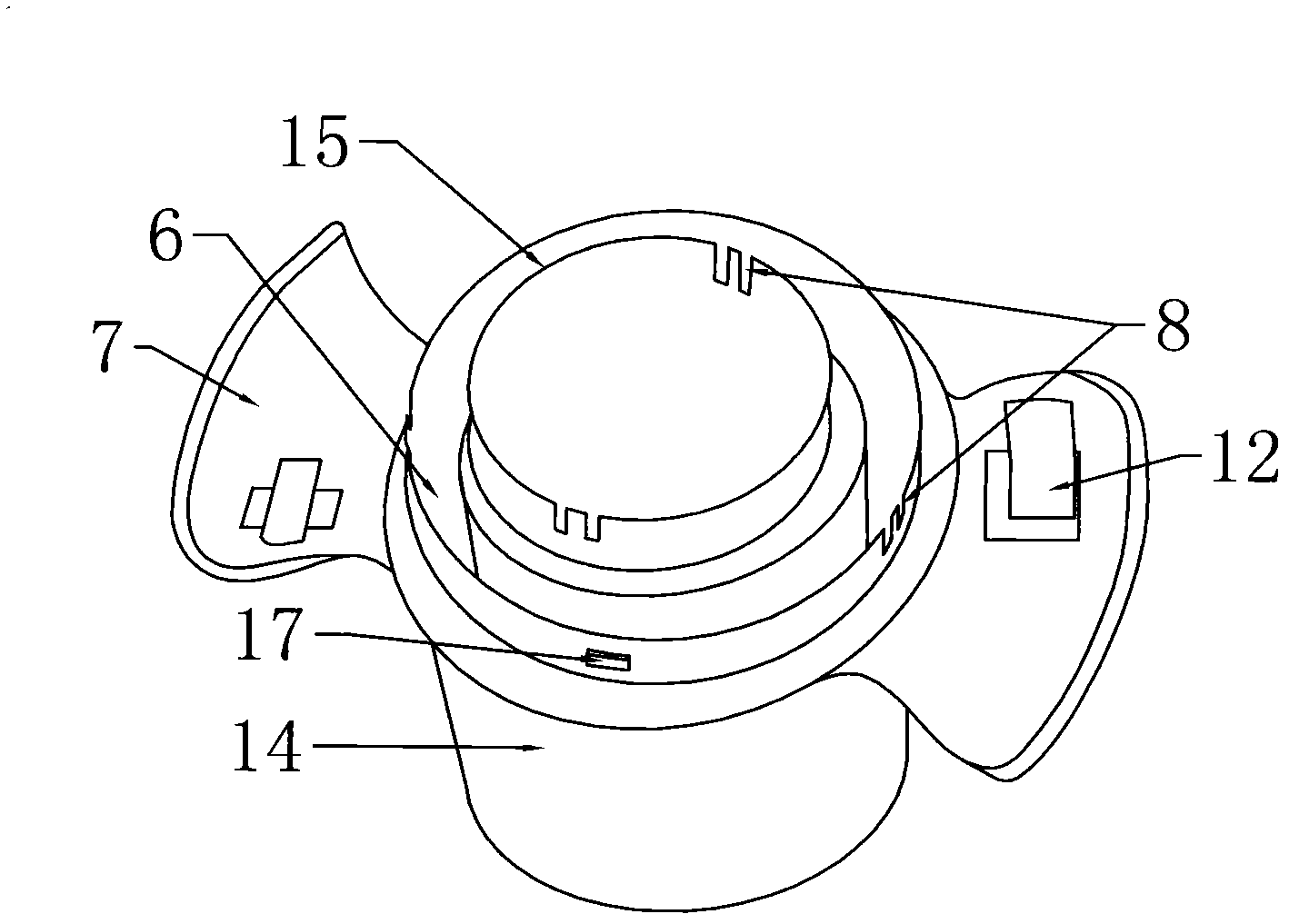

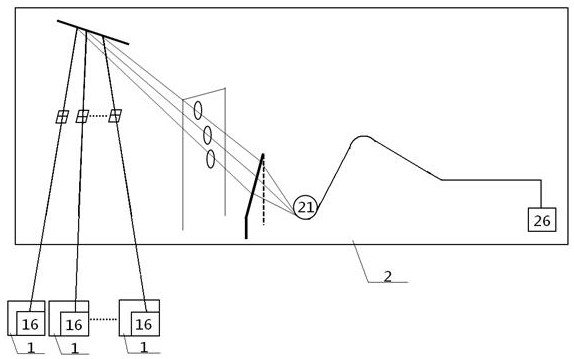

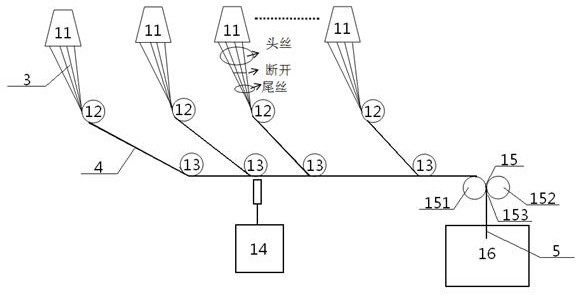

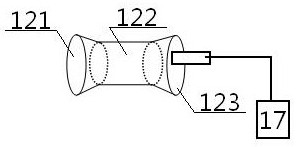

A head and tail yarn automatic isolation system

ActiveCN110219058BEasy to detectSmall application restrictionsSpinnerette packsArtificial thread manufacturing machinesClassical mechanicsGuide wires

An automatic isolation system for head and tail filaments comprises front units and rear units. A single rear unit corresponds to at least two front units, and only one filament barrel is arranged ina single front unit. Each front unit comprises a plurality of raw filament nozzles, a plurality of filament guide wheels, a raw head device, a traction wheel and the filament barrel. The raw filamentnozzles and the filament guide wheels are in one-to-one correspondence. The filament guide wheels are located at downstream positions of the raw filament nozzles. Speed detectors are arranged on the filament guide wheels. The traction wheels are located at downstream positions of the filament guide wheels. The filament barrels are located at downstream positions of the traction wheels. Each rear unit comprises a bundle collection wheel, a first drafting wheel and a packaging device. The filament barrels of the front units are located at upstream positions of the bundle collection wheels, the first drafting wheels are located at downstream positions of the bundle collection wheels, and the packaging devices are located at downstream positions of the first drafting wheels. The automatic isolation system has the advantages of good detection effect on the head and tail filaments, less application limitation and small application range.

Owner:WUHAN TEXTILE UNIV +2

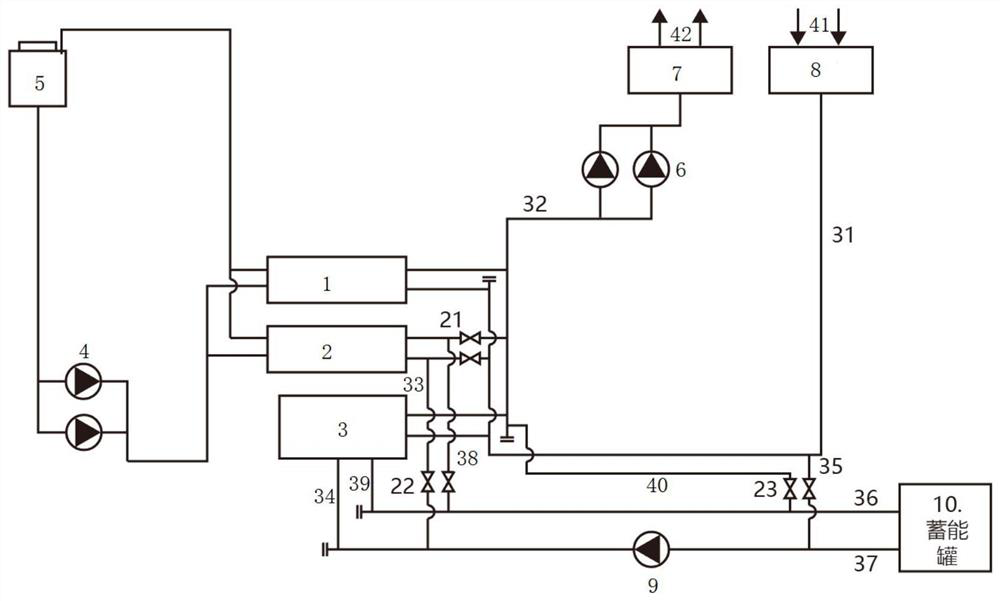

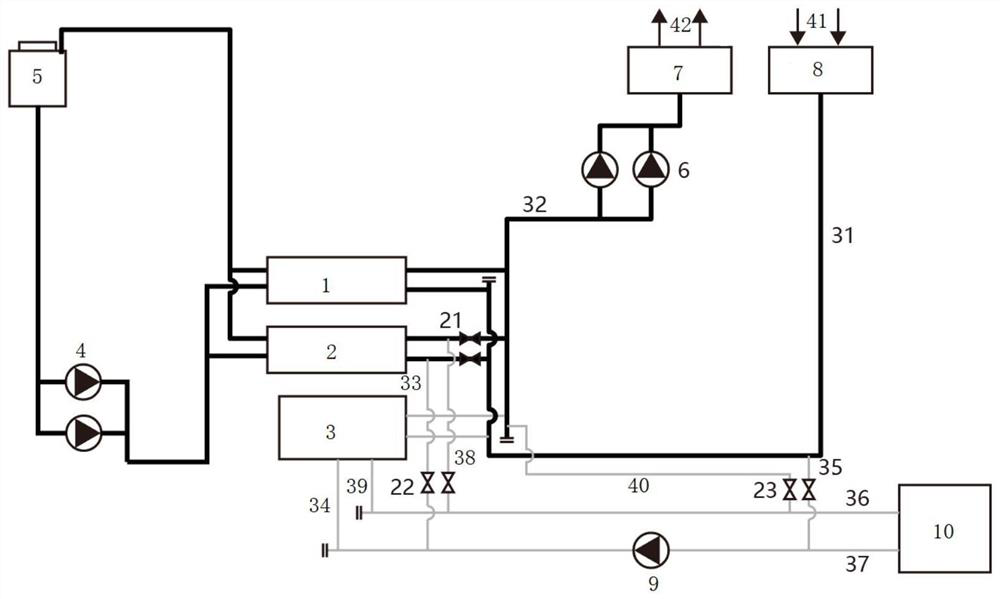

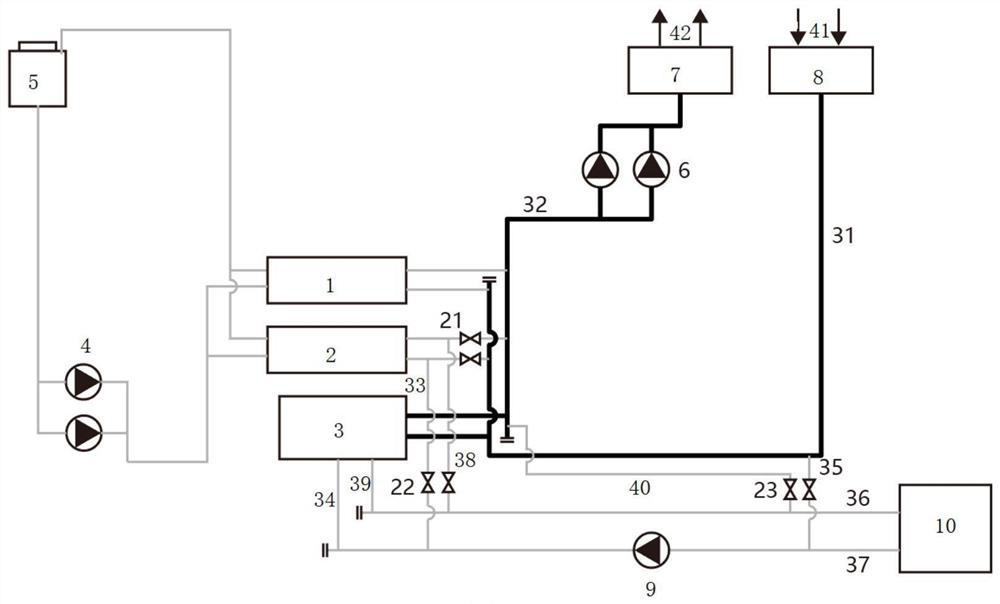

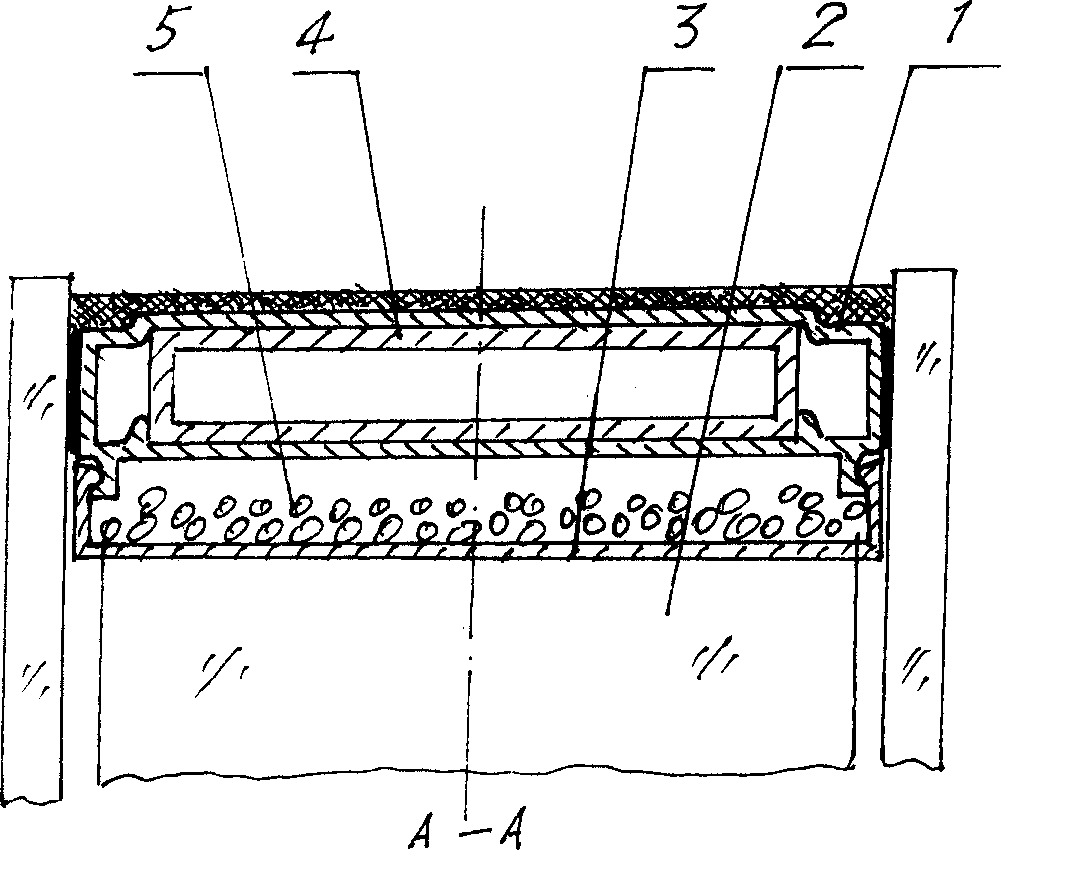

A regional energy station co-built with a substation

ActiveCN111947259BRemove the bondageSave land areaMechanical apparatusTransformer housesCooling towerProcess engineering

The invention discloses a regional energy station jointly built with a substation, including a substation and an energy station, the energy station includes an energy supply system and an energy station room for arranging the energy supply system, and the energy station room is set up in Under the ground of the substation, the energy supply system includes the first centrifugal unit, the second centrifugal unit, electrode boiler, energy storage tank, cooling tower group, cooling pump, cold temperature pump, energy storage pump, energy supply return water main pipe, energy supply water supply Main pipe, cold storage water supply branch pipe, cold storage return water branch pipe, heat storage water supply branch pipe, heat storage return water branch pipe, energy discharge water supply main pipe, energy discharge return water main pipe, energy storage and discharge water supply main pipe, and energy storage and discharge return water main pipe. Through the innovative design of the energy supply system, the invention enables the regional energy station to be co-constructed with the substation, and adopts the co-construction method, which saves land resources and improves system efficiency.

Owner:JIANGSU QUYU ENERGY CO LTD

Card spacer type convection blocker

InactiveCN1696470BSolve visualSolve the barrierUnits with parallel planesThermal insulationEngineering

The present invention adopts a card-type spacer-type convection barrier, which includes two or more light-transmitting plates forming an interlayer. The double-layer light-transmitting plates are sealed and connected to the spacers around the light-transmitting plates, transparent fins, and fin installation barriers. It is characterized in that the spacers form a rectangular side frame, and the fins are installed on the retaining strips and the spacers are buckled through the slots. Molecular sieves or hygroscopic agents can be placed in the cavity formed between the two, and the transparent wings are vertically and parallelly arranged on the upper and lower sides. The lower fins are installed between the retaining bars. Since the above-mentioned spacers are set to form a rectangular side frame, and the fins are installed and fastened with the spacers through the slots, the manufacturing and installation process is simpler and the cost is reduced; at the same time, transparent wings are vertically and parallelly arranged on the upper, The lower fins are installed between the retaining bars, so the downward tension or gravity can be used to hang the fins, which can effectively fix the fins and solve the problem of easy sagging of the middle part of the fins when the width of the light-transmitting sandwich panel is large. It causes visual discomfort, thereby improving the reliability of use and expanding the application range of width. Compared with the existing technology, the vertical and parallel arrangement of the fins can limit the upper and lower convection and front and rear backflow of the heated air. The thermal insulation performance and light transmittance of the light-transmitting plate are improved in the same range.

Owner:潘戈

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com