Preparation method of mild and green lignin-containing nanocellulose fibrils and product

A technology of nanocellulose and lignin, which is applied to pulping of cellulose raw materials, single-component cellulose rayon, and rayon manufacturing, etc., can solve the problems of unfavorable LCNF preparation, low pulp whiteness, cumbersome process, etc. Achieve the effect of good application potential, reduced process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Accurately weigh 40.0g bagasse raw material to add water at a solid-to-liquid ratio of 1:10, and 23w% (mass ratio of bagasse raw material, the same below) NaOH, 0.5w% MgSO 4 well mixed;

[0037] (2) Put the above-mentioned raw materials mixed with chemicals in the rotary cooking system, then fill with 0.6MPa oxygen, set the heating time to 95°C for 30 minutes, and keep warm for 3 hours; after the chemical treatment, use a large amount of deionized Bagasse fiber can be obtained by washing with water several times;

[0038] (3) Disperse the bagasse fiber obtained in step (2) in a certain volume of aqueous solution to make its solid content 2%, then treat it with a wall breaker for 15 minutes and then use a 600W cell breaker for ultrasonication for 30 minutes;

[0039] (4) Store the obtained lignin-containing nanocellulose fibril solution in a refrigerator at 4° C. to prevent the cellulose solution from overheating and agglomerating.

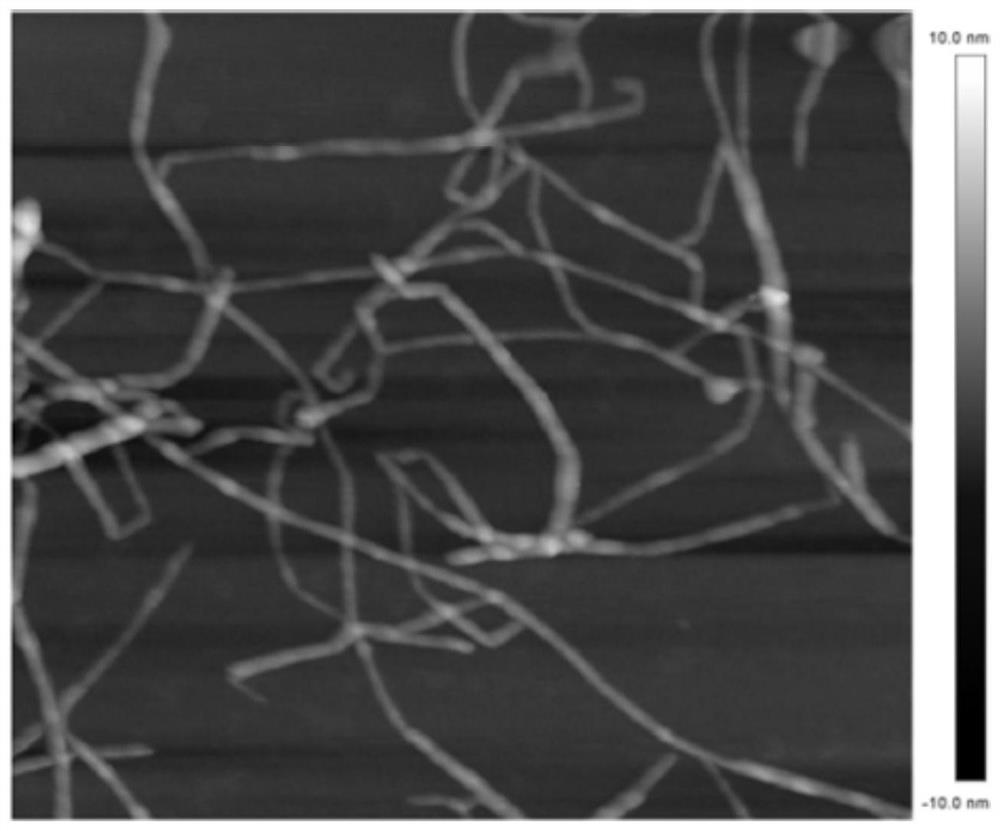

[0040] The resulting AFM pictur...

Embodiment 2

[0042] (1) Accurately weigh 40.0g bagasse raw material to add water at a solid-to-liquid ratio of 1:10, and 18w% (mass ratio of bagasse raw material, the same below) NaOH, 0.5w% MgSO 4 well mixed;

[0043] (2) Put the above-mentioned raw materials mixed with chemicals in the rotary cooking system, then fill with 0.6MPa oxygen, set the heating time to 95°C for 30 minutes, and keep warm for 3 hours; after the chemical treatment, use a large amount of deionized Bagasse fiber can be obtained by washing with water several times;

[0044] (3) Disperse the bagasse fiber obtained in step (2) in a certain volume of aqueous solution to make its solid content 0.8%, then use a cell breaker to treat it for 15 minutes and then use a 600W cell breaker for ultrasonication for 30 minutes;

[0045] (4) Store the obtained lignin-containing nanocellulose fibril solution in a refrigerator at 4° C. to prevent the cellulose solution from overheating and agglomerating.

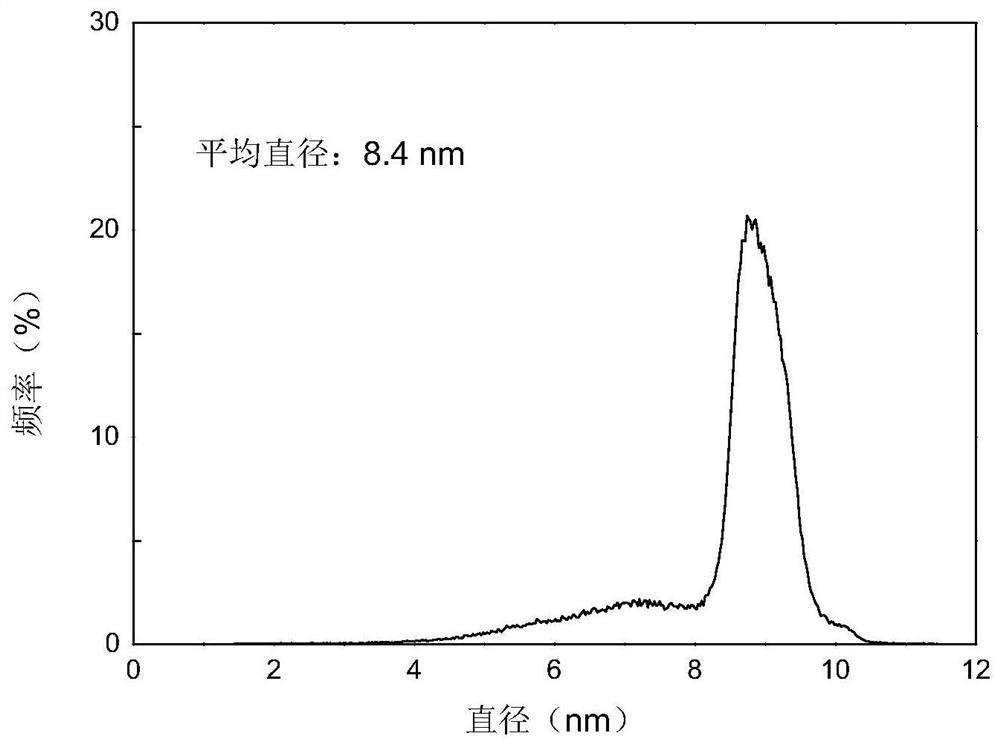

[0046] The resulting AFM pi...

Embodiment 3

[0048] (1) Accurately weigh 40.0g bagasse raw material to add water at a solid-to-liquid ratio of 1:10, and 18w% (mass ratio of bagasse raw material, the same below) NaOH, 0.5w% MgSO 4 well mixed;

[0049] (2) Put the above-mentioned raw materials mixed with chemicals in the rotary cooking system, then fill with 0.6MPa oxygen, set the heating time to 95°C for 30 minutes, and keep warm for 1 hour; after the chemical treatment, use a large amount of deionized Bagasse fiber can be obtained by washing with water several times;

[0050](3) Disperse the bagasse fiber obtained in step (2) in a certain volume of aqueous solution to make its solid content 0.8%, then use a cell breaker to treat it for 15 minutes and then use a 600W cell breaker for ultrasonication for 30 minutes;

[0051] (4) Store the obtained lignin-containing nanocellulose fibril solution in a refrigerator at 4° C. to prevent the cellulose solution from overheating and agglomerating.

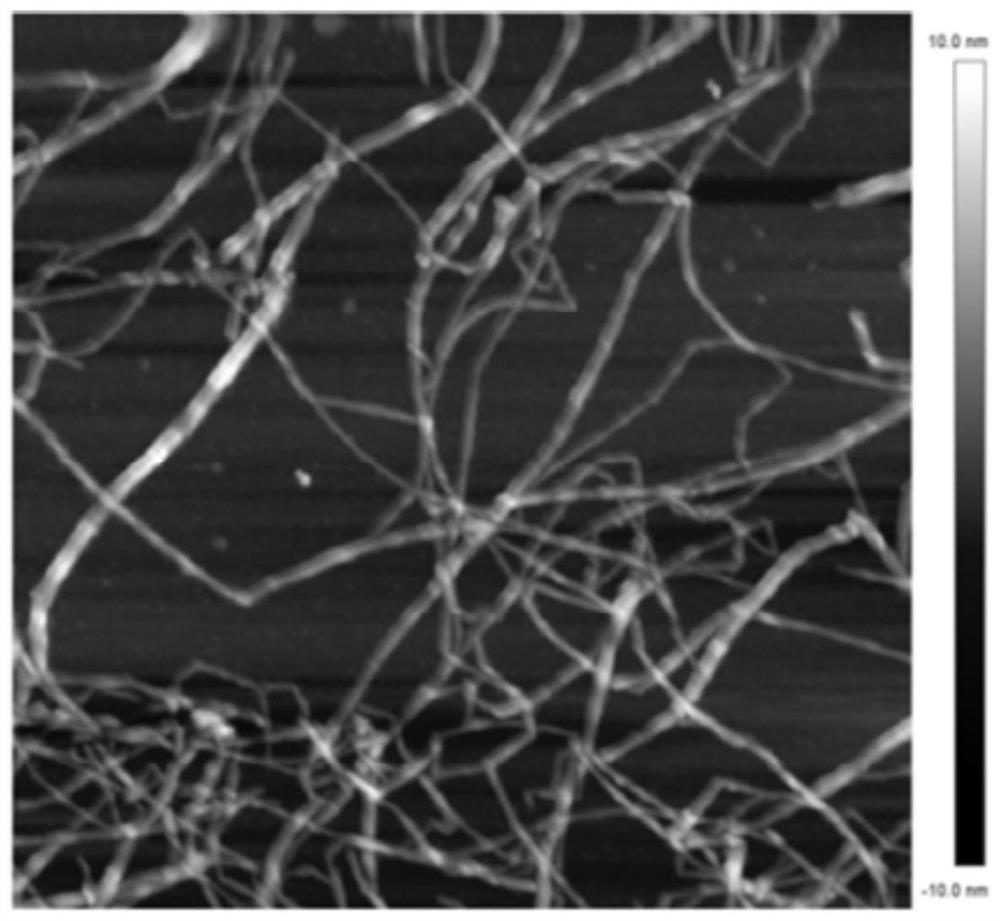

[0052] The resulting AFM pict...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com