High-heat-input submerged-arc welding wire steel wire rod, preparation method thereof, high-heat-input submerged-arc welding wire and high-heat-input welding method

A technology of high heat input welding and high heat input, applied in arc welding equipment, welding equipment, welding medium, etc., can solve the problems of complicated welding process and low welding efficiency, and achieve low wire breakage rate during drawing and not easy to break wires , the effect of reducing the yield ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

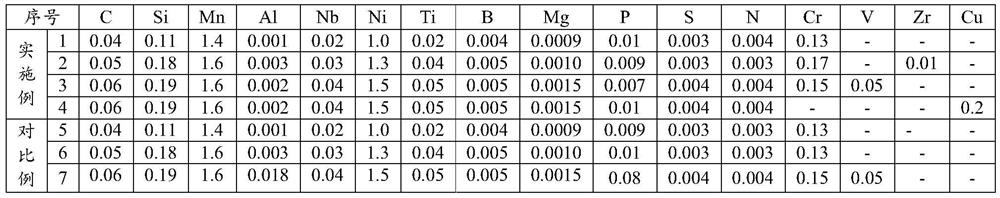

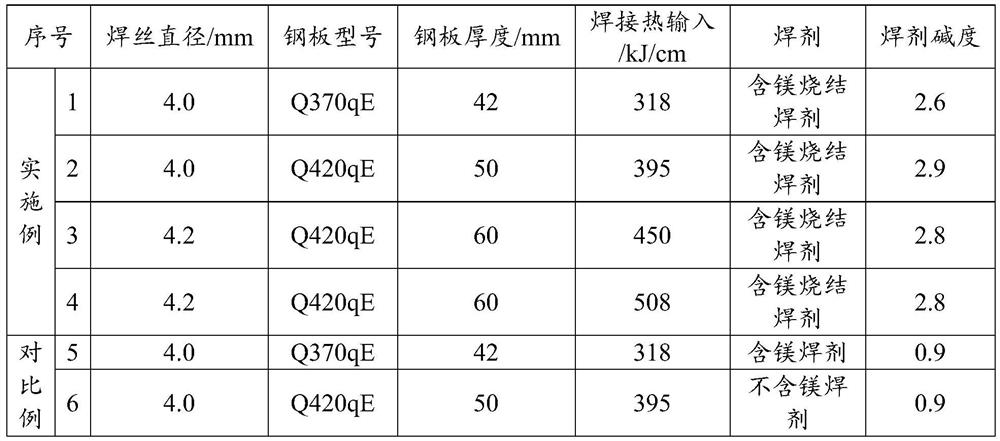

[0035] In one embodiment of the present invention, there is provided a large heat input submerged arc welding wire steel coil, the chemical composition of which comprises: C 0.04 ~ 0.06%, Si 0.1 ~ 0.2%, Mn 1.4 ~ 1.6%, Ni 1.0 ~ 1.5%, Nb0.02 ~ 0.04%, Ti 0.02 ~ 0.05%, B 0.0040 ~ 0.0055%, Al < 0.004%, Mg 0.0005 ~ 0.0020%, P≤0.012%, S≤0.005%, N≤0.005%, the rest is Fe and unavoidable impurities.

[0036] And preferably, the chemical composition of the large heat input submerged arc welding wire steel wire in terms of mass percentage further comprises: Cr 0.05 ~ 0.30%, V 0.01 ~ 0.15%, Zr 0.005 ~ 0.020%, Cu 0.05 ~ 0.30% of one of the four and more.

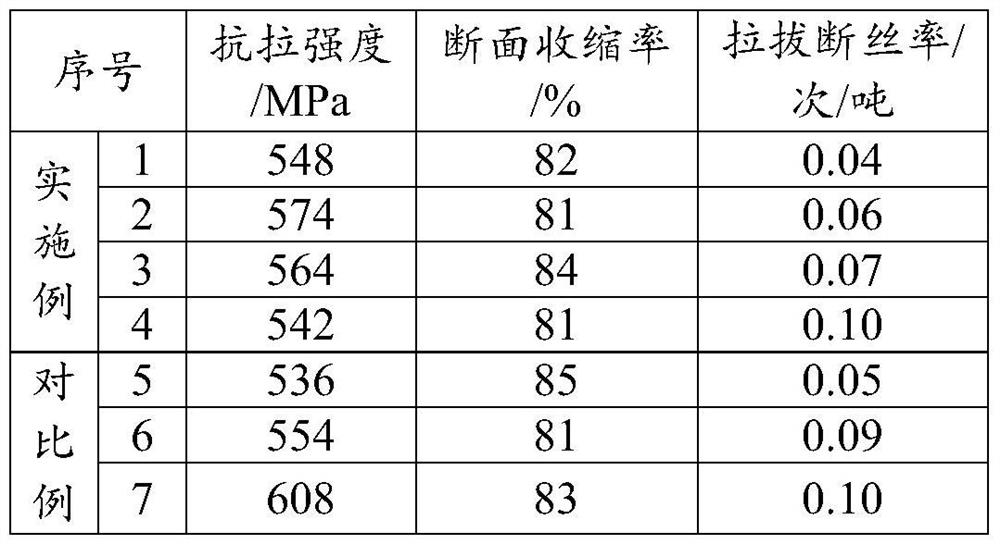

[0037] Preferably, the density of the magnesium inclusions in the steel wire of the large heat input submerged arc welding wire > 200 / mm 2 The tensile strength of the wire rod ≤ 600MPa, and the cross-sectional shrinkage rate ≥ 80%.

[0038] Further, the present embodiment further provides a method for preparing a large heat input submerged...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com