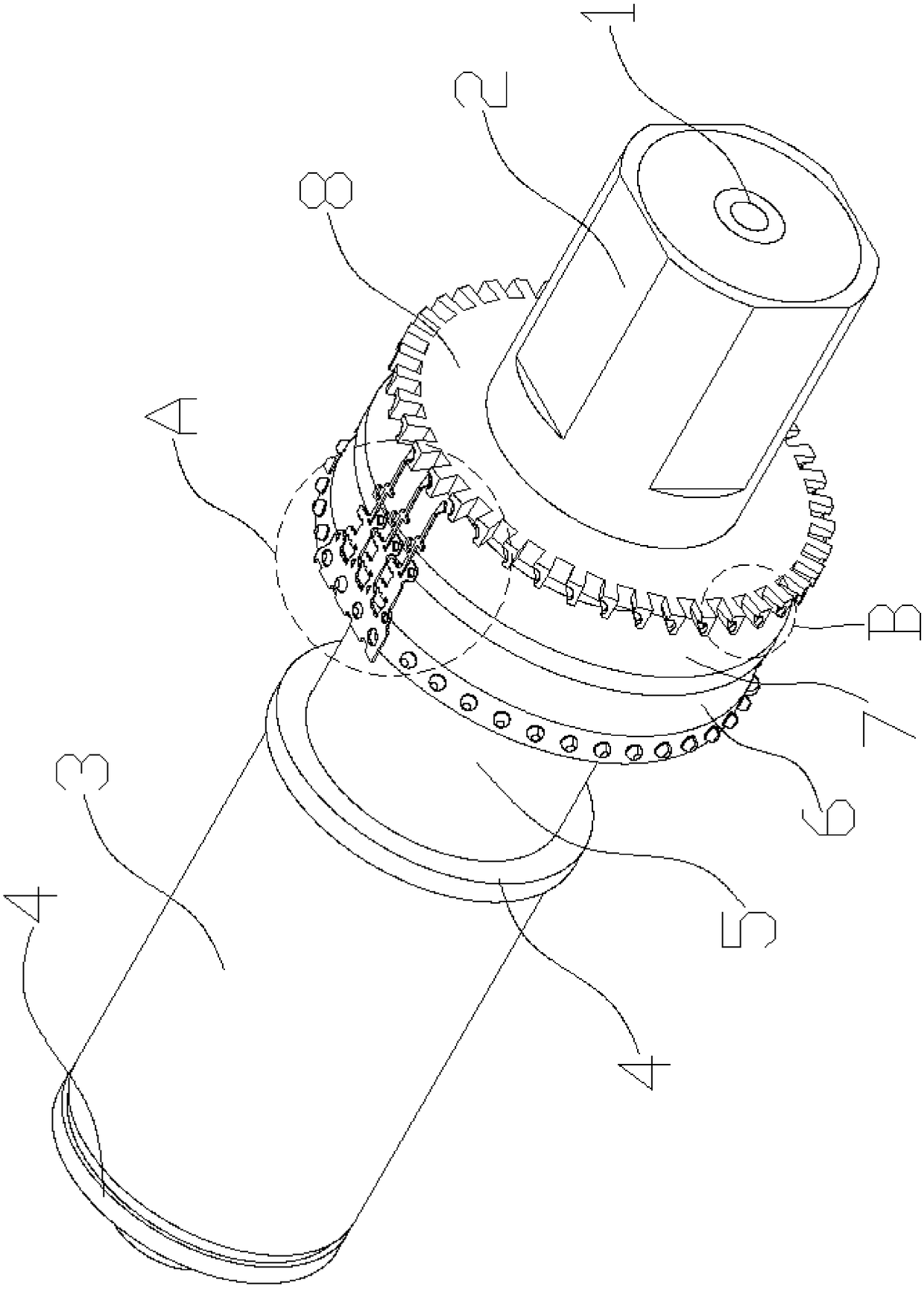

Continuous wax dotting shaft

A technology of spotting wax and wax wheel, which is applied in the direction of electrolytic coating, electrophoretic plating, coating, etc., which can solve the problems of high intensity of wax sealing work, and achieve the effect of compact structure, low failure rate and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

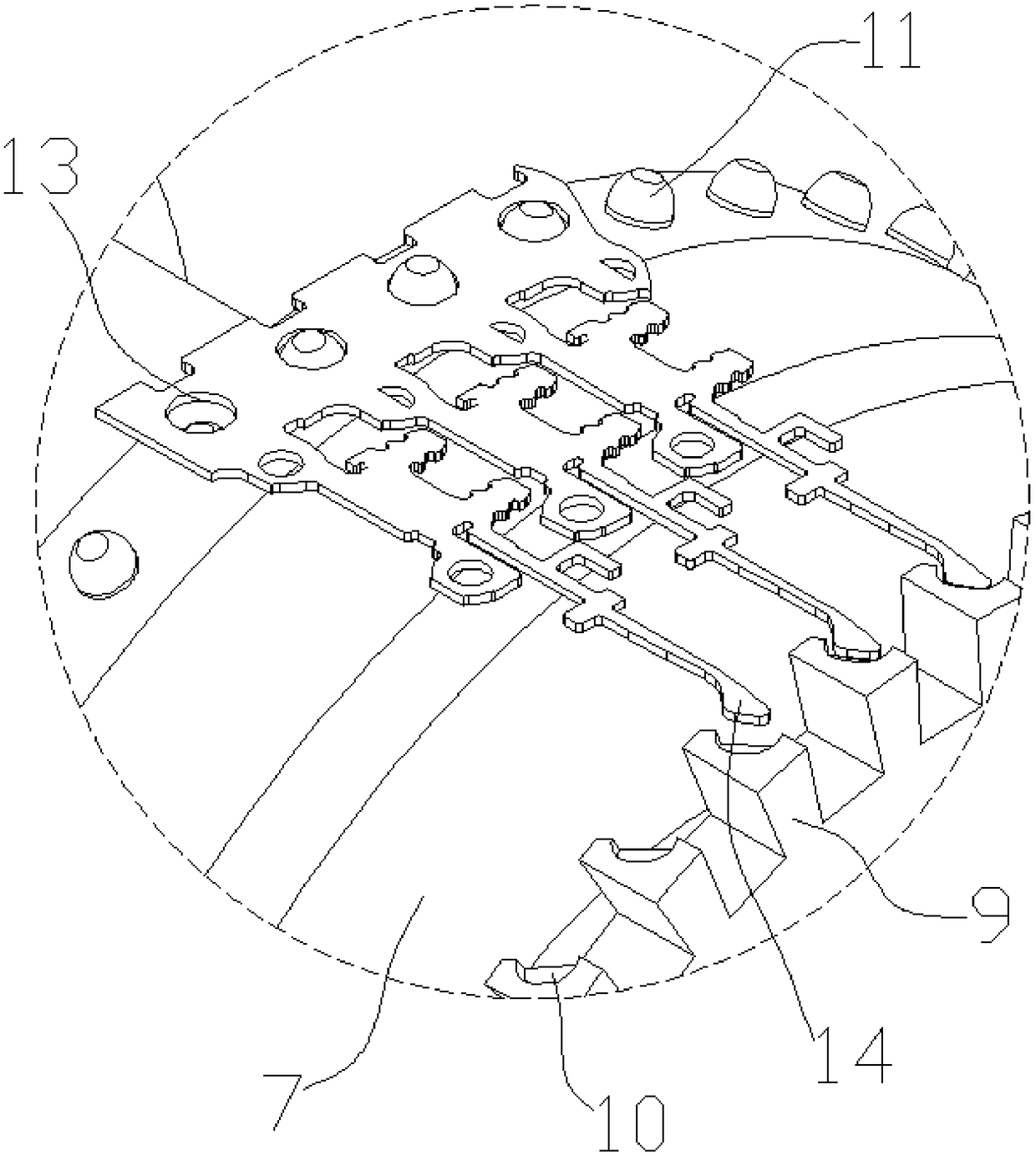

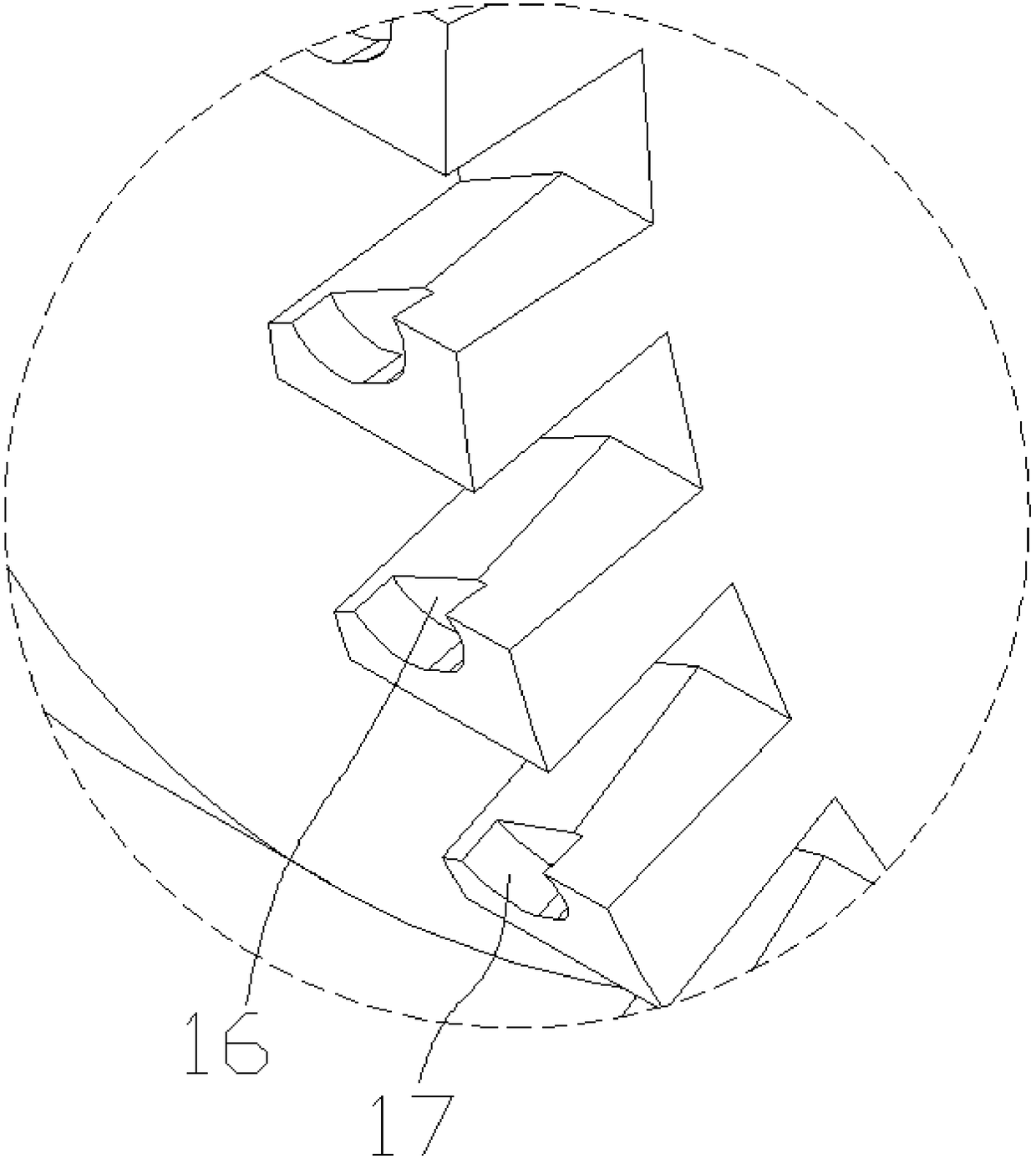

[0032] In order to achieve the purpose of the present invention, a continuous waxing shaft includes: a positioning wheel 6, which has several radially protruding positioning bumps 11 on its circumferential surface, and the positioning bumps 11 are inserted into the circular holes 13 of the material belt 12, The driving material belt 12 is horizontally conveyed; the wax sticking wheel 8 is arranged in parallel with the positioning wheel 6 and is integrally connected by the central shaft. Radial teeth 9, each radial tooth 9 is equipped with a sunken wax holding tank 10, wax liquid 15 is stained on the inner wall of the wax holding tank 10, the sticking wax wheel 8 rotates coaxially with the positioning wheel 6, and the wax liquid 15 sticks Attached to the material belt 12; the heater 1; nested in the central axis, the wax liquid 15 on the sticky wax wheel 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com