Device and method for pretreating steel slag through air quenching of CO2-containing tail gas

A technology for pretreatment and steel slag, applied in the field of steel slag recycling, can solve the problems of restricting the large-scale resource utilization of steel slag, obtaining stability requirements, and the inability of one-time steel slag pretreatment process to improve the utilization rate of subsequent resource utilization, The effect of improving the utilization rate of heat energy and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

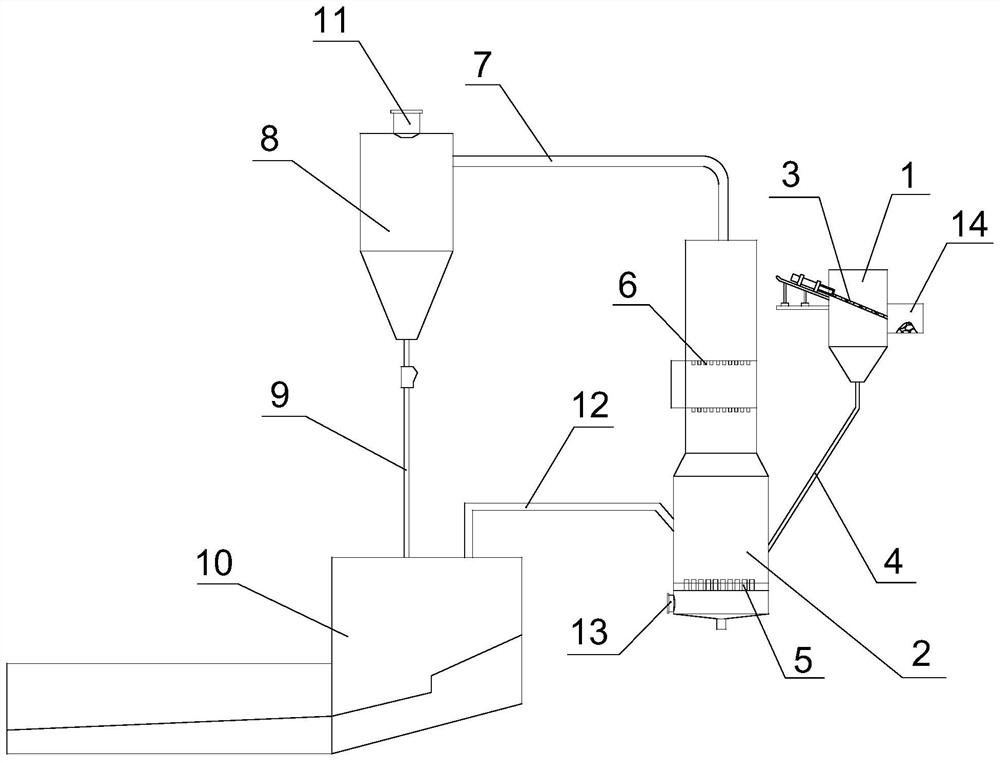

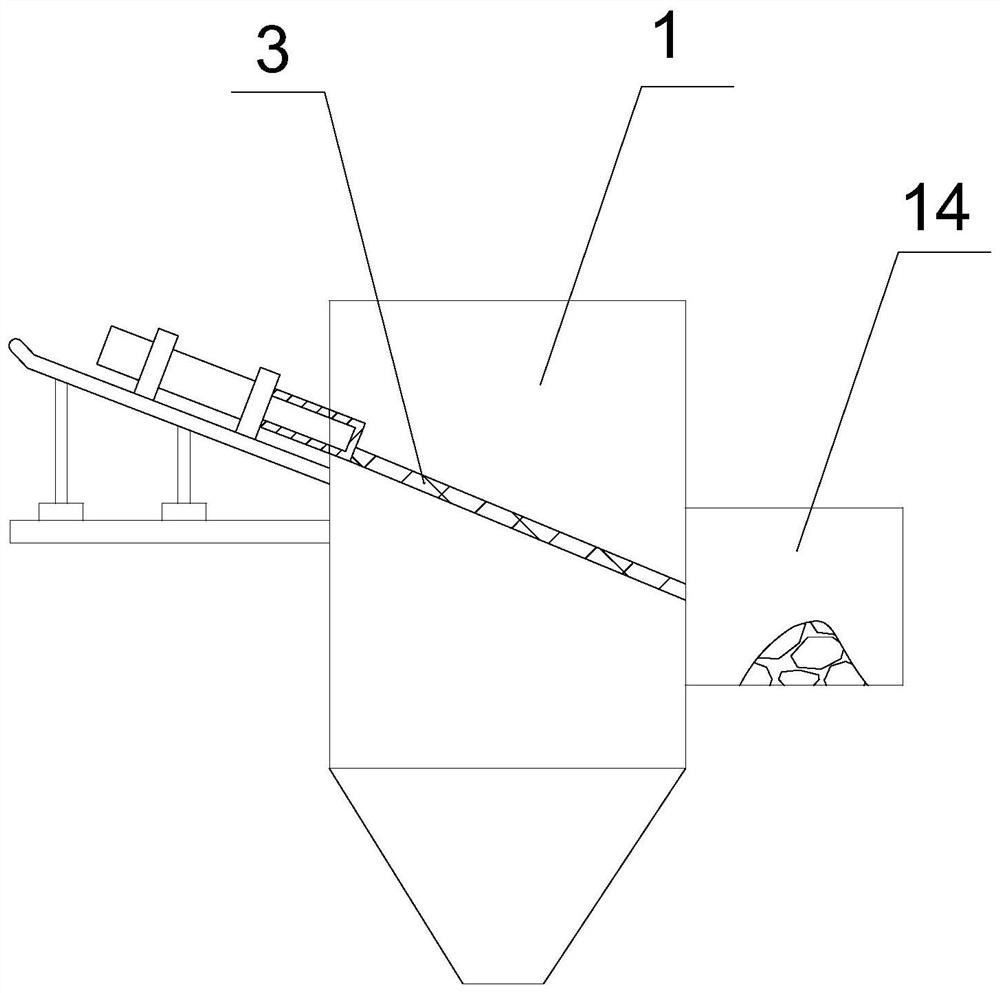

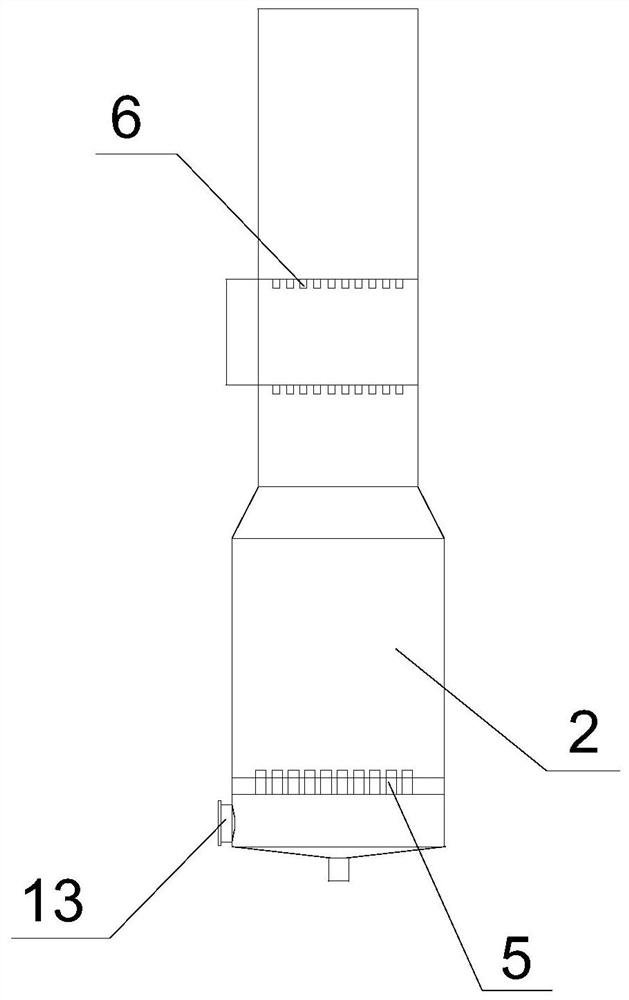

[0029] see Figure 1-3 , the present embodiment provides a device and method for pretreating steel slag by air quenching with CO2-containing tail gas, including a steel slag tank 1 and an air quencher 2, the steel slag tank 1 is a square tank, and the inner middle of the steel slag tank 1 is provided with a grid plate 3 The middle part of the side wall of the steel slag tank 1 away from the wind quencher 2 is fixedly connected with a waste slag chamber 14, and the liquid steel slag is poured into the steel slag tank 1 with a large-inclination grid plate 3 and rolled down to the waste slag chamber 14, the bottom of the steel slag tank 1 The end outlet is fixedly connected with the delivery pipe 4, the lower end of the delivery pipe 4 is fixedly connected with the middle part of one side of the air quencher 2, and the lower surface of the side of the air quencher 2 away from the delivery pipe 4 is provided with an air inlet 13, and the steel slag can pass through The conveying p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com