Highly-efficient air energy water source heat pump integrated unit

A high-efficiency air and water source heat pump technology, applied in refrigerators, compressors, refrigeration components, etc., can solve the problems of increasing the tube wall, increasing the air flow resistance, troublesome management and maintenance, etc., to achieve low surface vapor pressure, efficient operation and use , the effect of stable solution properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

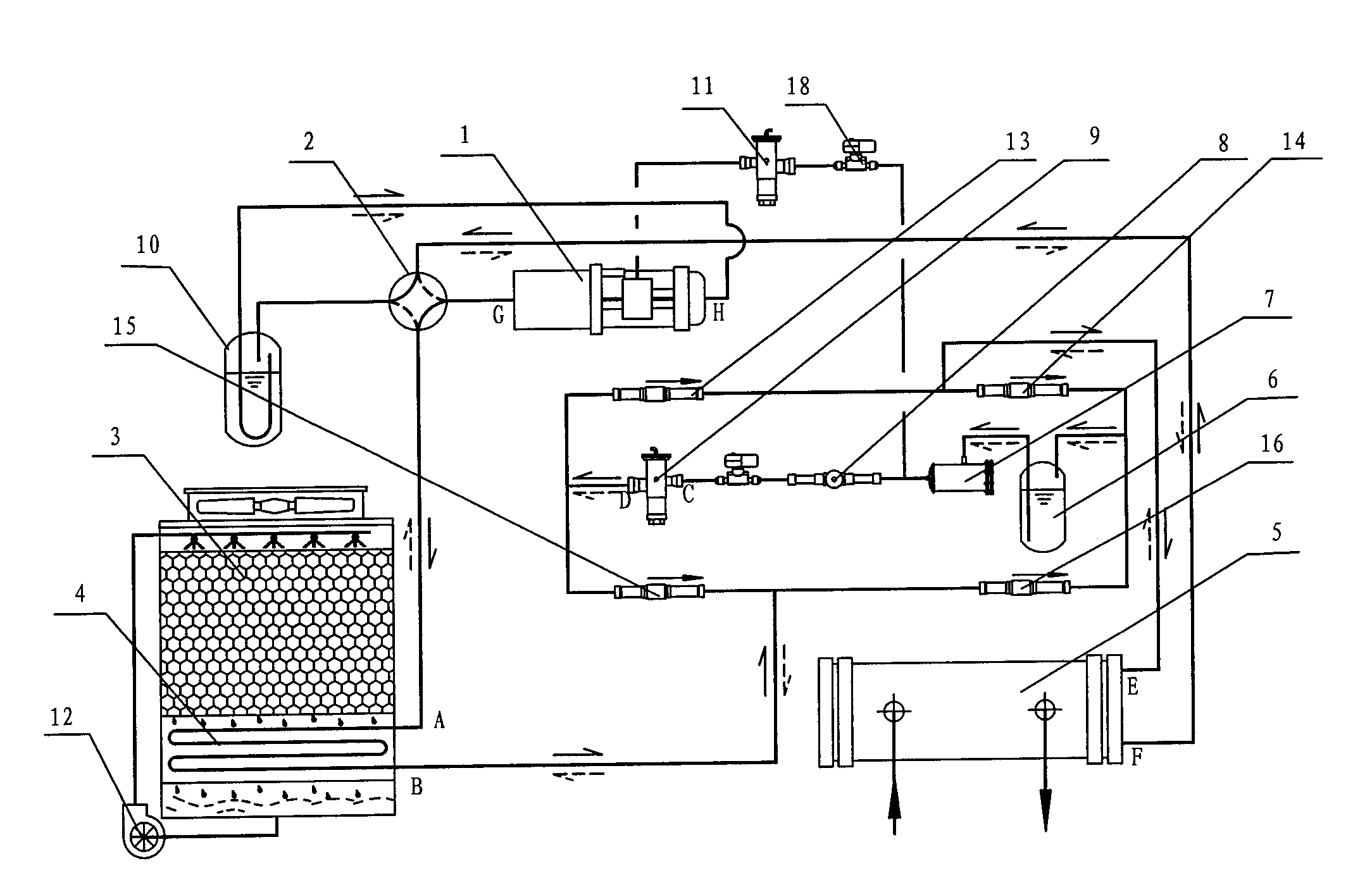

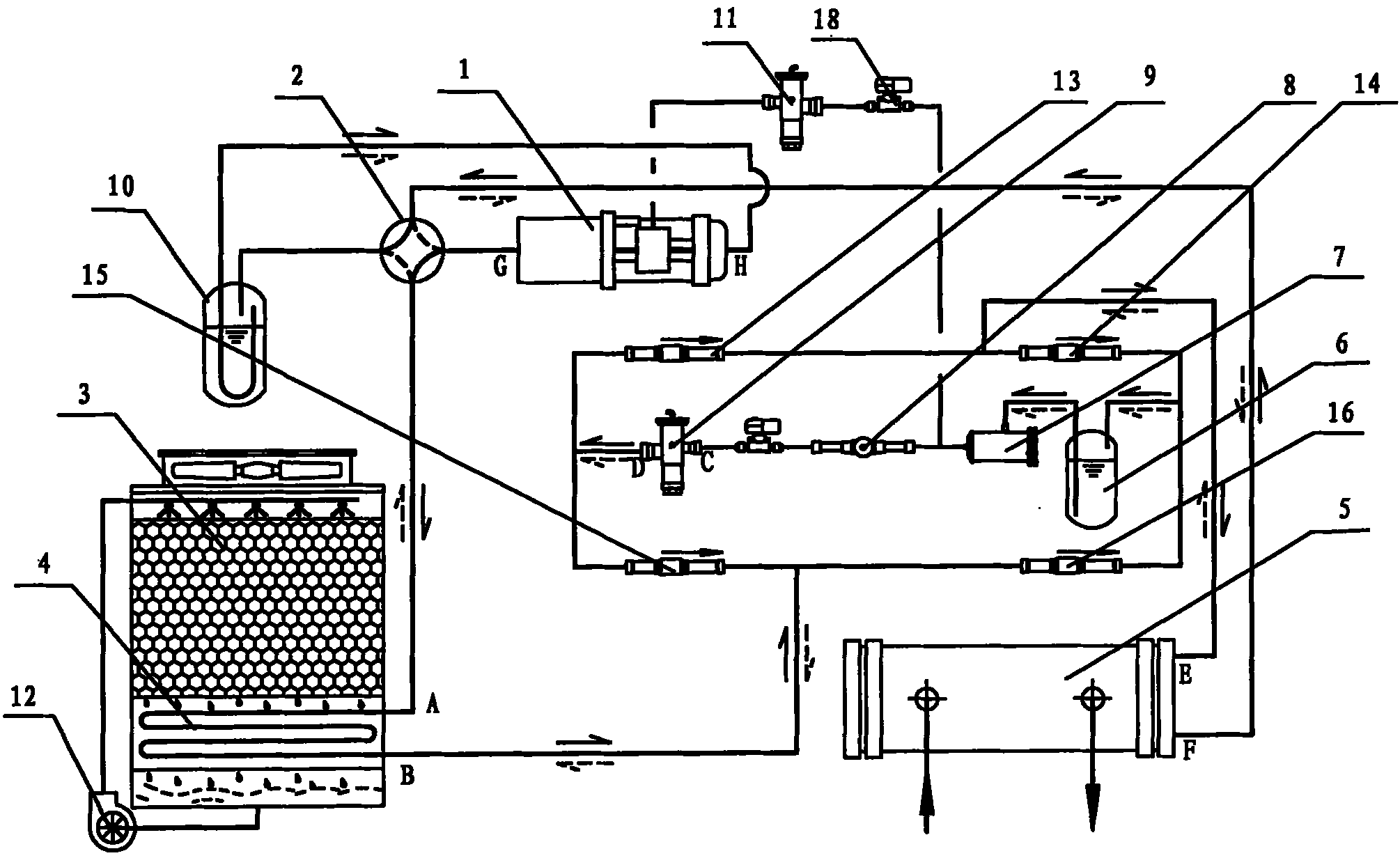

[0034] Embodiment 1: see attached figure 1 , Embodiment 1 of the present invention consists of a compressor 1, a four-way reversing valve 2, a heat exchange tower 3, a first heat exchanger 4, a second heat exchanger 5, a liquid reservoir 6, a dry filter 7, and a sight glass 8. An expansion valve 9, a gas-liquid separator 10, a liquid injection expansion valve 11, a water pump 12, check valves 13, 14, 15, 16, and a solenoid valve 18 form.

[0035]The first heat exchanger 4 is installed in the heat exchange tower 3; the outlet G of the compressor 1 is connected to the inlet A of the first heat exchanger 4 through the four-way reversing valve 2, so The outlet B of the first heat exchanger 4 is divided into two paths, one path is connected with the inlet C of the expansion valve 9 through the check valve 16, and the other path is connected with the outlet D of the expansion valve 9 through the check valve 15; The outlet D of the expansion valve 9 is connected to the inlet E of th...

Embodiment 2

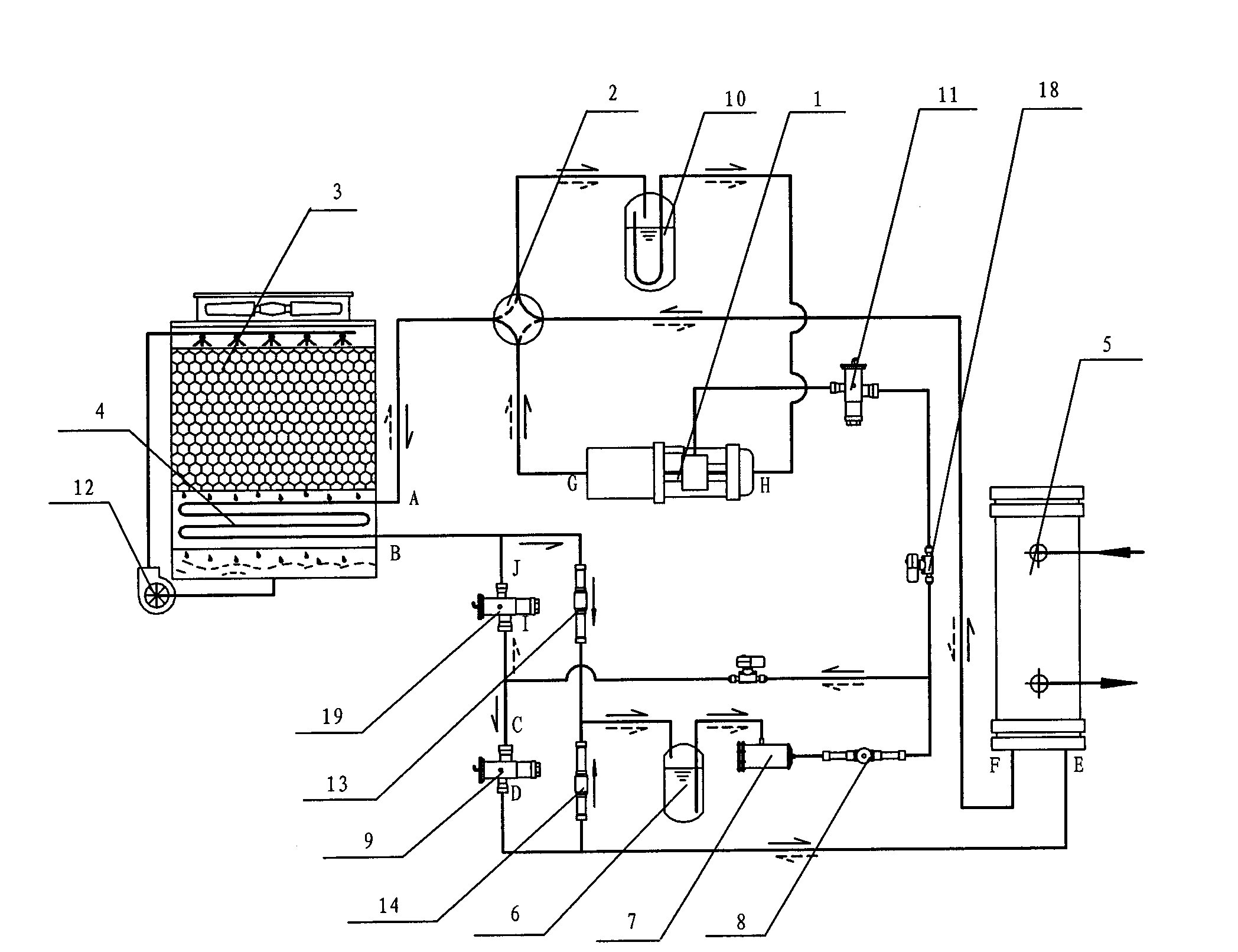

[0042] Embodiment 2: see attached figure 2 , Embodiment 2 of the present invention consists of a compressor 1, a four-way reversing valve 2, a heat exchange tower 3, a first heat exchanger 4, a second heat exchanger 5, a liquid reservoir 6, a dry filter 7, and a sight glass 8. Refrigeration thermal expansion valve 9, heating thermal expansion valve 19, liquid injection expansion valve 11, water pump 12, check valves 13, 14, and solenoid valve 18. Valves 15 and 16 are replaced by expansion valve 19. The outlet B of the first heat exchanger 4 is divided into two paths, and one path is connected to the inlet C of the expansion valve 9 and the inlet I of the expansion valve 19 respectively through the check valve 13. The other way is connected to the outlet J of the expansion valve 19; the outlet D of the expansion valve 9 is connected to the inlet E of the second heat exchanger 5, and the inlet E of the second heat exchanger 5 is also passed through a non-return The valve 14 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com