Method and device for recycling edible mushroom residues

A treatment device and resource utilization technology, which is applied in the fields of energy and wastewater treatment, biochemical cleaning devices, biochemical equipment and methods, etc., and can solve the problems of difficult discharge, easy crusting, and difficult feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Resource utilization method of Flammulina velutipes mushroom residue with corn cob as main raw material-method and device for producing biogas by anaerobic fermentation.

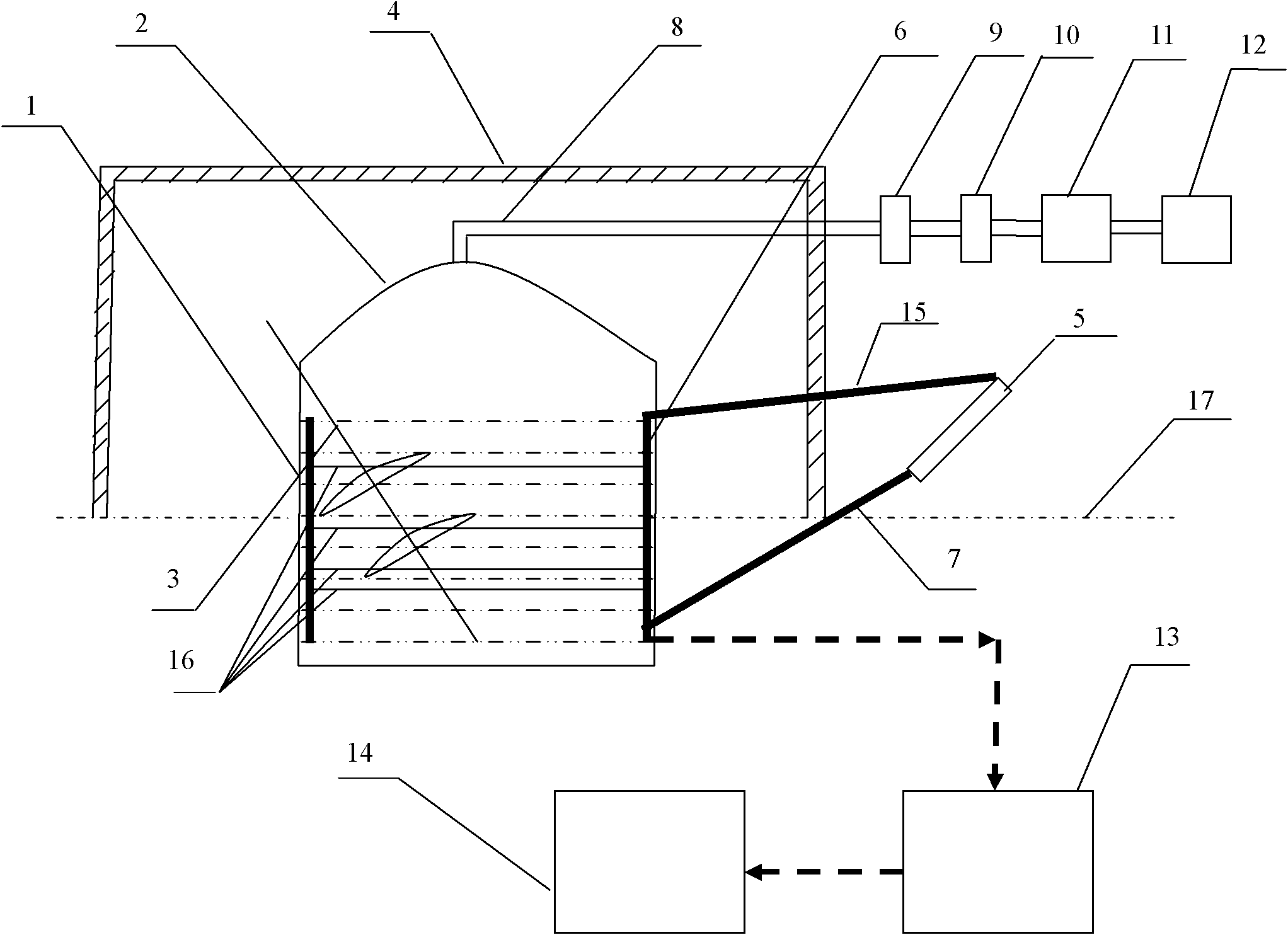

[0070] Anaerobic reactor device for edible fungus residue treatment method, such as figure 1 As shown, including anaerobic reactor device, biogas dehydrator, biogas desulfurizer, gas storage device and biogas utilization device, it is characterized in that, described anaerobic reactor device includes anaerobic reactor 1, greenhouse 4, solar energy Heat collecting device 5; the top of the anaerobic reactor is covered with a red mud plastic top cover 2, and the inside of the anaerobic reactor is provided with an oblique agitator 3 and an internal heat pipe 6 of the anaerobic reactor, and the internal heat pipe 6 of the anaerobic reactor is connected to several The annular tube of the pool wall is covered with the pool wall of the anaerobic reactor; a greenhouse 4 is built outside the anaerobic reactor 1...

Embodiment 2

[0099] Example 2: Resource utilization method of fungus slag planted with oyster mushroom as raw material of cottonseed hulls - method and device for anaerobic fermentation to produce biogas The device used is the same as that in embodiment 1.

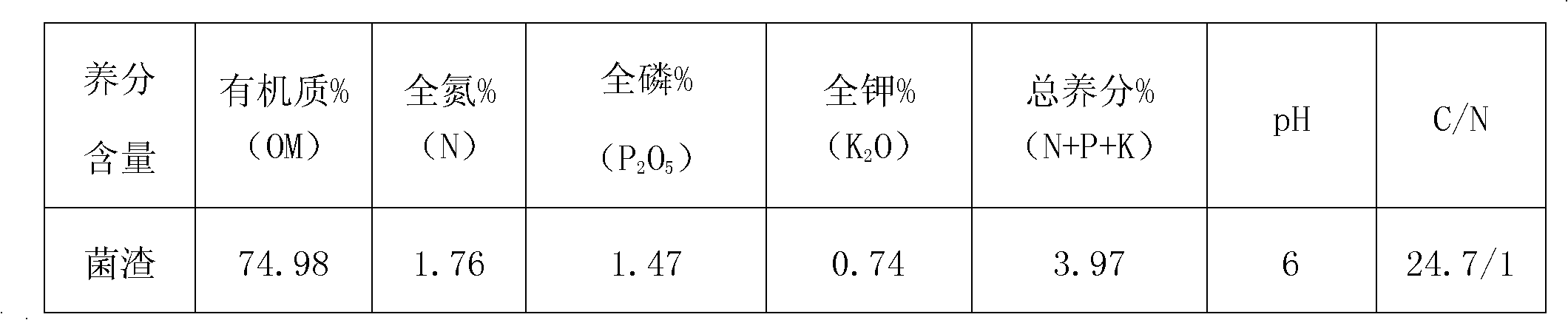

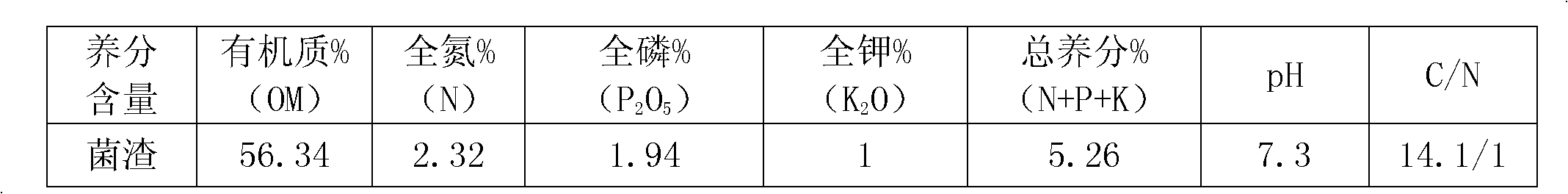

[0100] The raw material of edible fungus slag is the slag of oyster mushroom planted by cottonseed shell raw material, and the main nutritional components are (both in mass percentage):

[0101]

[0102] Cottonseed husk raw materials from nearby dairy farms have a daily output of 0.5t oyster mushroom enterprises, which can produce 200t of discarded fungus residues per year. According to the fermentation cycle of fungal residues, each batch of feed liquid is fermented for 3 months, and the feed is fermented 4 times a year. For 50 tons of fungus residue raw material, 8 tons of dry corn stalks need to be added to adjust the carbon-to-nitrogen ratio. The material for each fermentation is 180 tons. Try not to change the material in winter...

Embodiment 3

[0114] Embodiment 3: the device that the bacterium residue anaerobic fermentation of cottonseed shell raw material planting oyster mushroom produces biogas

[0115] There is an oyster mushroom enterprise with a daily output of 0.5t of cottonseed shell raw materials in dairy farms. Each time the fungus slag raw material is 50t, 25t of fresh cow manure needs to be added to adjust the carbon-nitrogen ratio. The fermentation material is 180t each time. The device is the same as in Example 1. The steps of the method are the same as in Example 2, except that the operation of step (2) is as follows: take fresh cow feces and edible fungus residues and mix them with water, and stir evenly while adding water, so that the final moisture content is 70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com