Card spacer type convection blocker

A barrier and spacer technology, which is applied in the field of double-glass cassette spacer type convective barrier, can solve the problems of inconvenient processing and installation, increased width and size, and large labor input, and achieves increased drying and dehumidification functions and heat insulation. The effect of improving thermal insulation performance and shortening cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

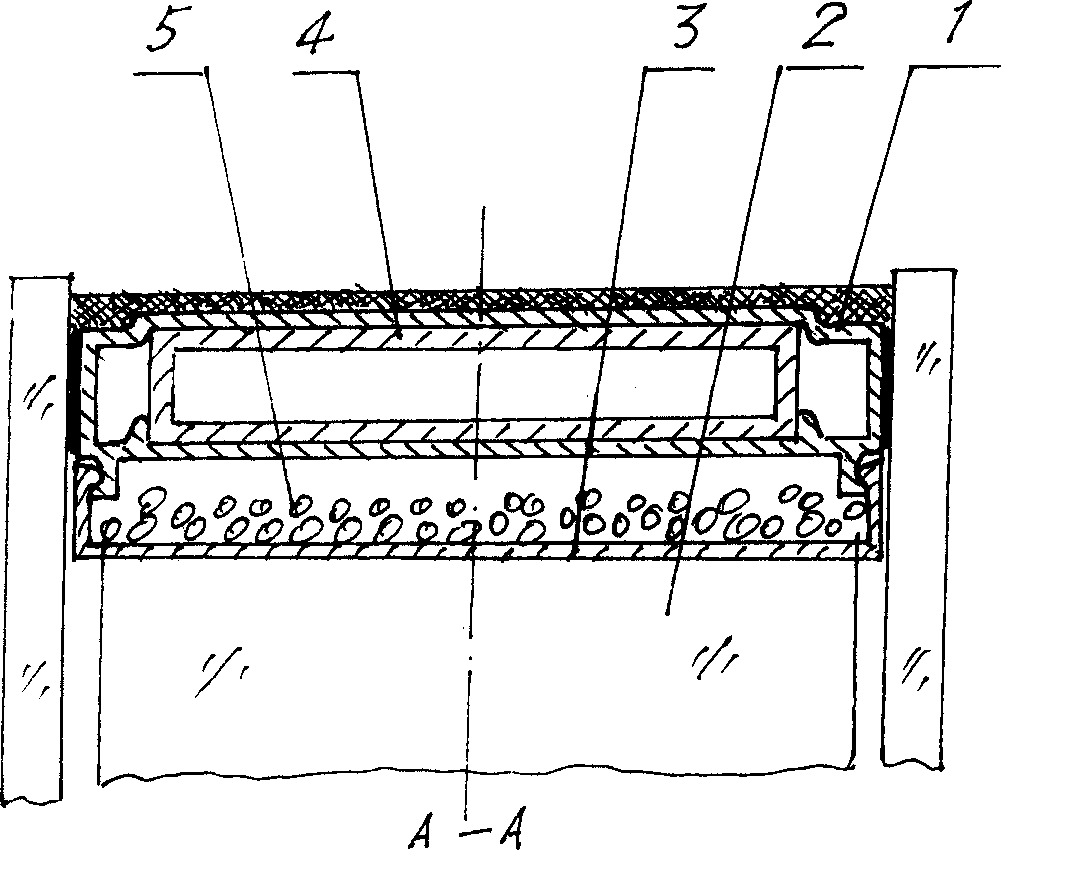

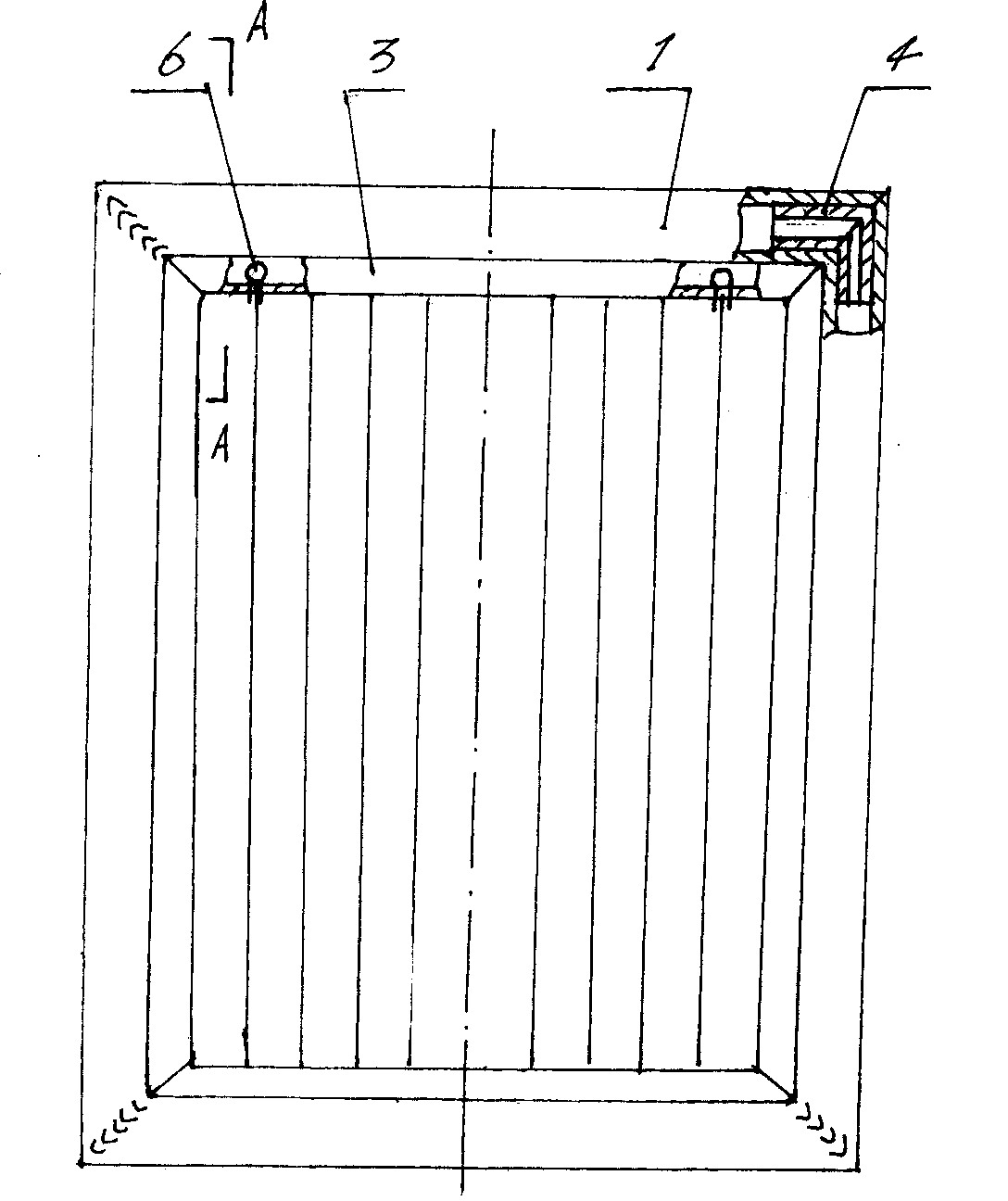

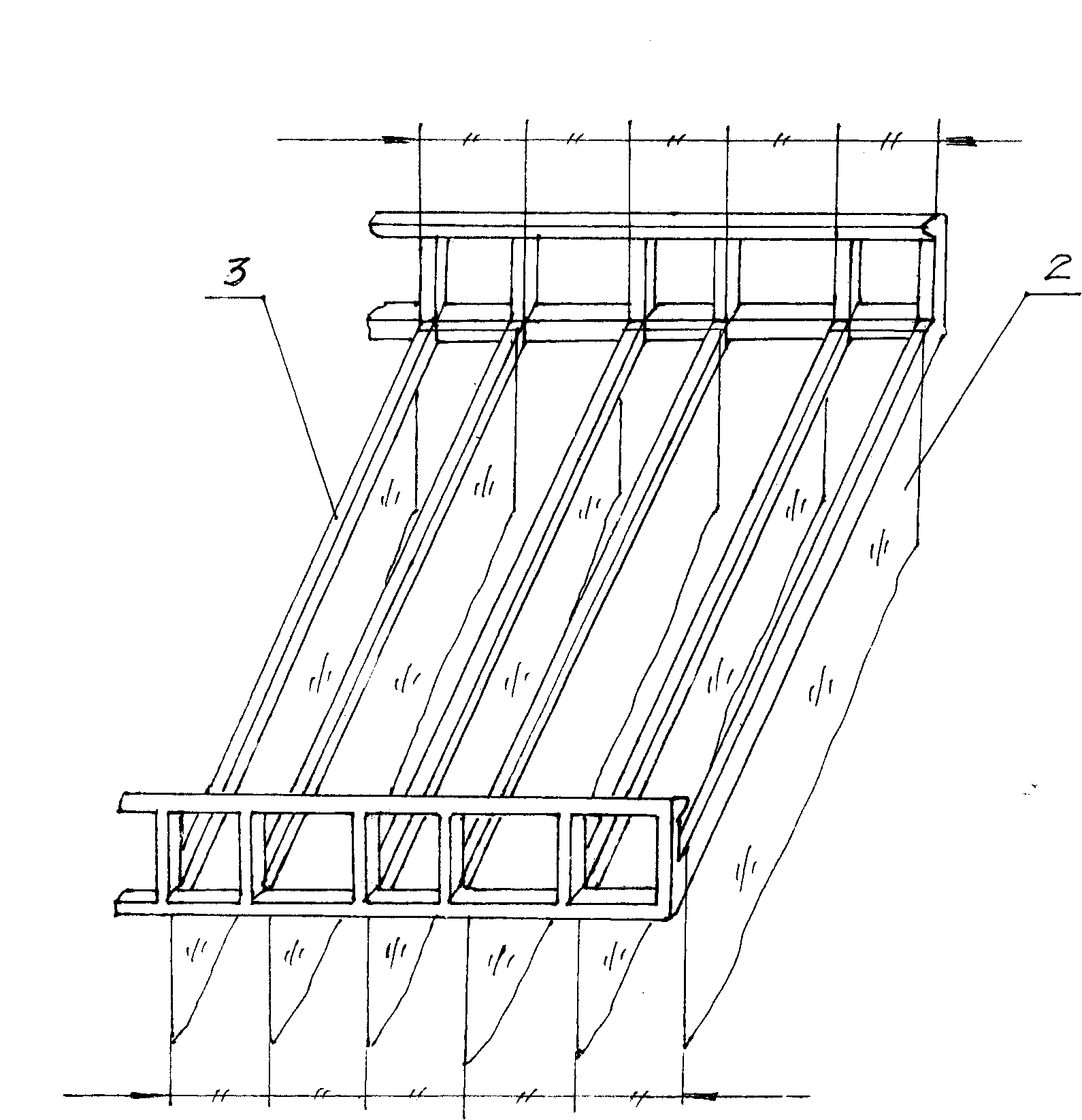

[0011] according to figure 1 , figure 2 As shown, one embodiment of the card-type spacer-type convection barrier of the present invention is composed of a spacer 1, a transparent fin 2, a fin installation bar 3, a reinforced corner lining 4, a desiccant 5, and a fin connector 6. , and are all arranged between two or more transparent panels forming a sandwich of double-layered transparent panels, wherein the fin connector 6 includes a fixed bar 61 and a transparent elastic film 62 . A rectangular side frame is formed by the spacer 1 and the reinforced corner lining 4, which is sealed and connected to the periphery of the light-transmitting plate. The inner cavity of the spacer forming the rectangular side frame has ribs for the installation and positioning of the reinforced corner lining 4, and the reinforced corner lining Installed in the inner cavity of the spacer to strengthen the strength and rigidity of the joint corners, and the joint corners of the spacer can be welded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com