Operation and maintenance device for photovoltaic power station

A photovoltaic power station and maintenance device technology, applied in the field of photovoltaic power stations, can solve the problems of excessive dust accumulation, accumulation, affecting the photoelectric conversion efficiency of photovoltaic panel areas, etc., to avoid accumulation, ensure the cleaning effect, and quickly repair the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

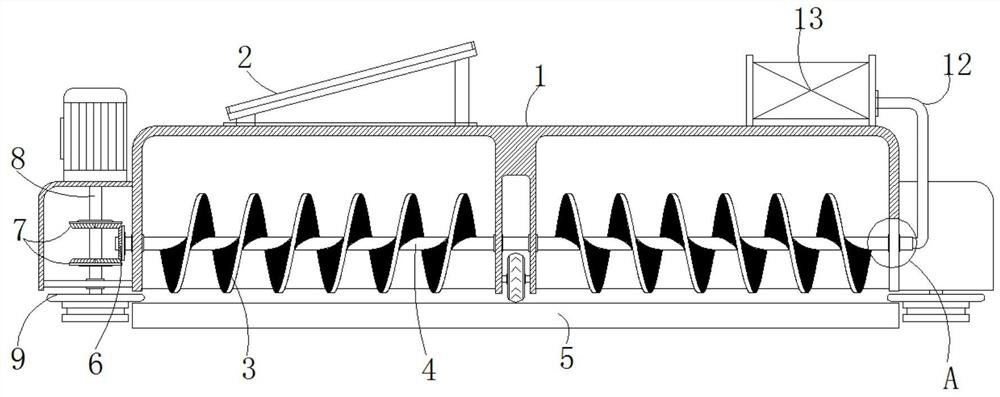

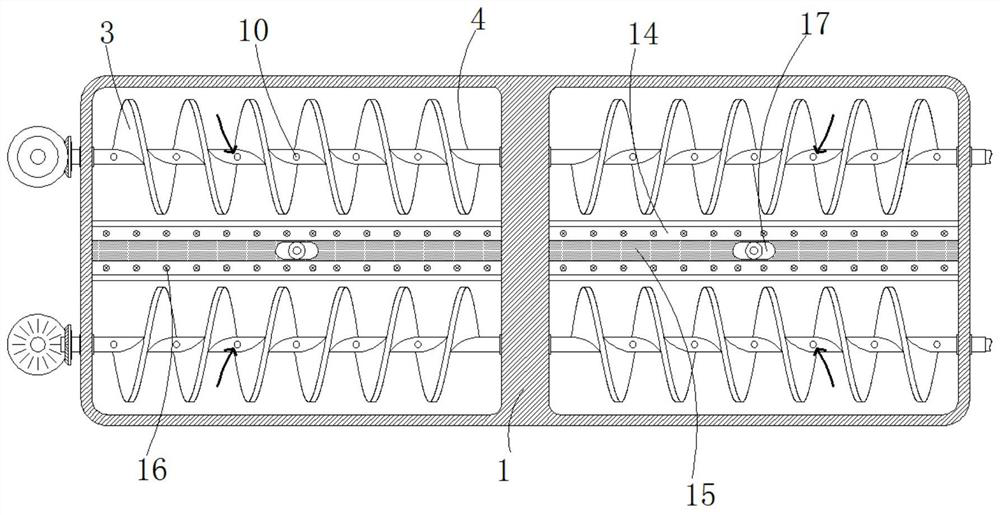

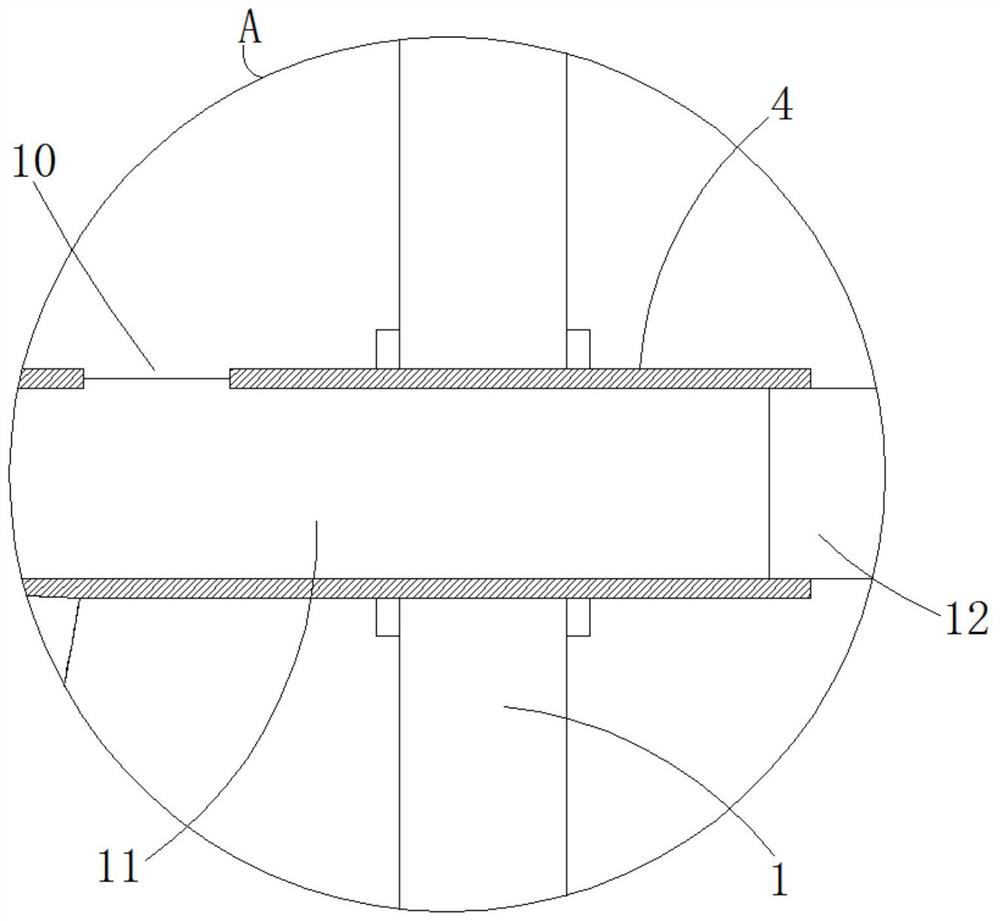

[0036] In this embodiment, in order to solve the problem of low dust cleaning efficiency in the prior art, such as figure 1As shown, the operation and maintenance device includes a casing 1 and a cleaning brush 3. A solar module 2 is installed on the top of the casing 1. The cleaning brush 3 is installed on the horizontally distributed horizontal axis 4. The bottom end of the cleaning brush 3 and the upper end of the photovoltaic panel 5 The surfaces are in contact with each other, and the left end of the horizontal shaft 4 is connected to the vertical shaft 8 through the mutually meshing first bevel teeth 6 and the second bevel teeth 7, and the top end of the vertical shaft 8 is connected to the motor installed on the housing 1, and the vertical shaft is connected. The bottom end of 8 is connected to the roller 9 attached to the edge of the frame of the photovoltaic panel 5, and also includes a one-way bearing. Two second bevel teeth 7 are arranged symmetrically up and down, a...

Embodiment 2

[0041] In order to reduce the overall weight of the maintenance device and reduce the pressure on the photovoltaic panel 5 caused by unnecessary equipment, the difference between this embodiment and the first embodiment is that, such as Image 6 The shown suction device includes a fan blade 23. The fan blade 23 is rotated and installed on the side wall of the casing 1 through the fan shaft 22. The small diameter gear 21 installed on the fan shaft 22 meshes with the large diameter gear 21 on the right end of the horizontal shaft 4. , and the inner space where the fan blade 23 is located is communicated with the top end of the trachea 12. When the horizontal shaft 4 is in a rotating state, the horizontal shaft 4 will drive the fan shaft 22 and the fan blade 23 through two mutually meshing gears 21 to be able to synchronize relative to each other. The high-speed rotation causes the space on the right side of the fan blade 23 to generate a negative pressure effect, and the dust acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com