Carbon fiber reinforced thermosetting resin-based composite material and preparation method thereof

A composite material and carbon fiber technology, applied in the field of carbon fiber reinforced thermosetting resin-based composite materials and their preparation, can solve the problems of limited application scope, complicated operation, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

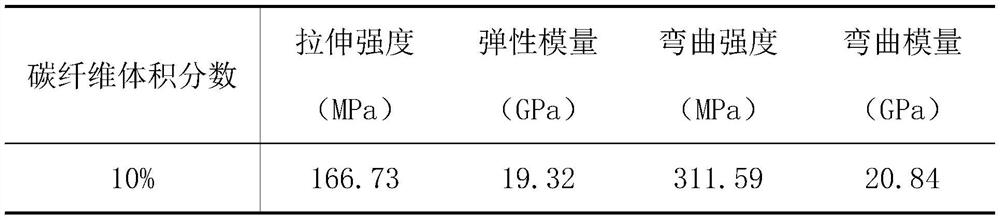

Embodiment 1

[0038] Step 1. Combine thermosetting styrene-butadiene resin, PVAC (40% styrene solution), TBPB, PBA, zinc stearate, magnesium hydroxide (25% matrix resin dispersion), BYK9076 in a mass ratio of 60:40:1 : 0.2: 3: 1.5: 0.3 Take the material and mix it evenly to get a resin paste; the prepared surface density is 20g / m 2 The high modulus carbon fiber non-woven fabric is cut to the size suitable for the mold cavity section used.

[0039] Step 2. Prepare the above-mentioned resin paste and carbon fiber non-woven fabric into a sheet carbon fiber prepreg through an automatic sheet molding compound production line device. Each carbon fiber prepreg is composed of 7 layers of carbon fiber non-woven fabric, which needs to be fully impregnated and compacted evenly everywhere.

[0040] Step 3. Clean the flat mold and spray an appropriate amount of release agent after the assembly is completed. Cut the above-mentioned sheet-like carbon fiber prepreg into a size suitable for the mold cavity...

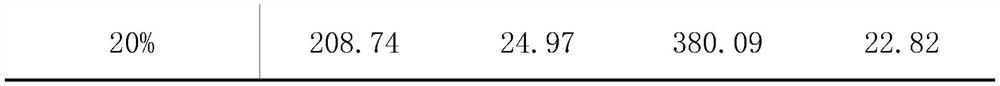

Embodiment 2

[0048] Step 1. Combine thermosetting styrene-butadiene resin, PVAC (40% styrene solution), TBPB, BHT, zinc stearate, magnesium oxide (25% vinyl resin dispersion), BYK9076 in a mass ratio of 65:35:1.5 : 0.8: 4: 1.8: 1 Take the material and mix it evenly to get a resin paste; the prepared area density is 30g / m 2 The high modulus carbon fiber non-woven fabric is cut to the size suitable for the mold cavity section used.

[0049] Step 2. Prepare the above-mentioned resin paste and carbon fiber non-woven fabric into a sheet carbon fiber prepreg through an automatic sheet molding compound production line device. Each prepreg is composed of 6 layers of carbon fiber non-woven fabric, which needs to be fully impregnated and compacted evenly everywhere.

[0050] Step 3. Clean the flat mold and spray an appropriate amount of release agent after the assembly is completed. Cut the above-mentioned sheet-like carbon fiber prepreg into a size suitable for the mold cavity used, and lay and su...

Embodiment 3

[0059] Step 1, furan resin modified by phenolic resin, PVAC (40% styrene solution), BPO, BHT, stearic acid, calcium oxide (25% matrix resin dispersion), BYK972 according to the mass ratio of 60:40:1.5 : 1:5:2:1 Take the material and mix it evenly to get a resin paste; the prepared area density is 30g / m 2 The high modulus carbon fiber non-woven fabric is cut to the size suitable for the mold cavity section used.

[0060] Step 2. Prepare the above-mentioned resin paste and carbon fiber non-woven fabric into a sheet carbon fiber prepreg through an automatic sheet molding compound production line device. Each prepreg is composed of 8 layers of carbon fiber non-woven fabric, which needs to be fully impregnated and compacted evenly everywhere.

[0061] Step 3. Clean the flat mold and spray an appropriate amount of release agent after the assembly is completed. Cut the above-mentioned sheet-like carbon fiber prepreg into a size suitable for the mold cavity used, and lay and superimp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com