Sodium ion battery negative electrode material based on carbon material and pitch and preparation method and application thereof

A technology of sodium ion battery and negative electrode material, applied in the field of materials, can solve problems such as restricting the practical application of sodium ion battery, and achieve the effects of adjustable disorder degree, high working voltage and energy density, and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

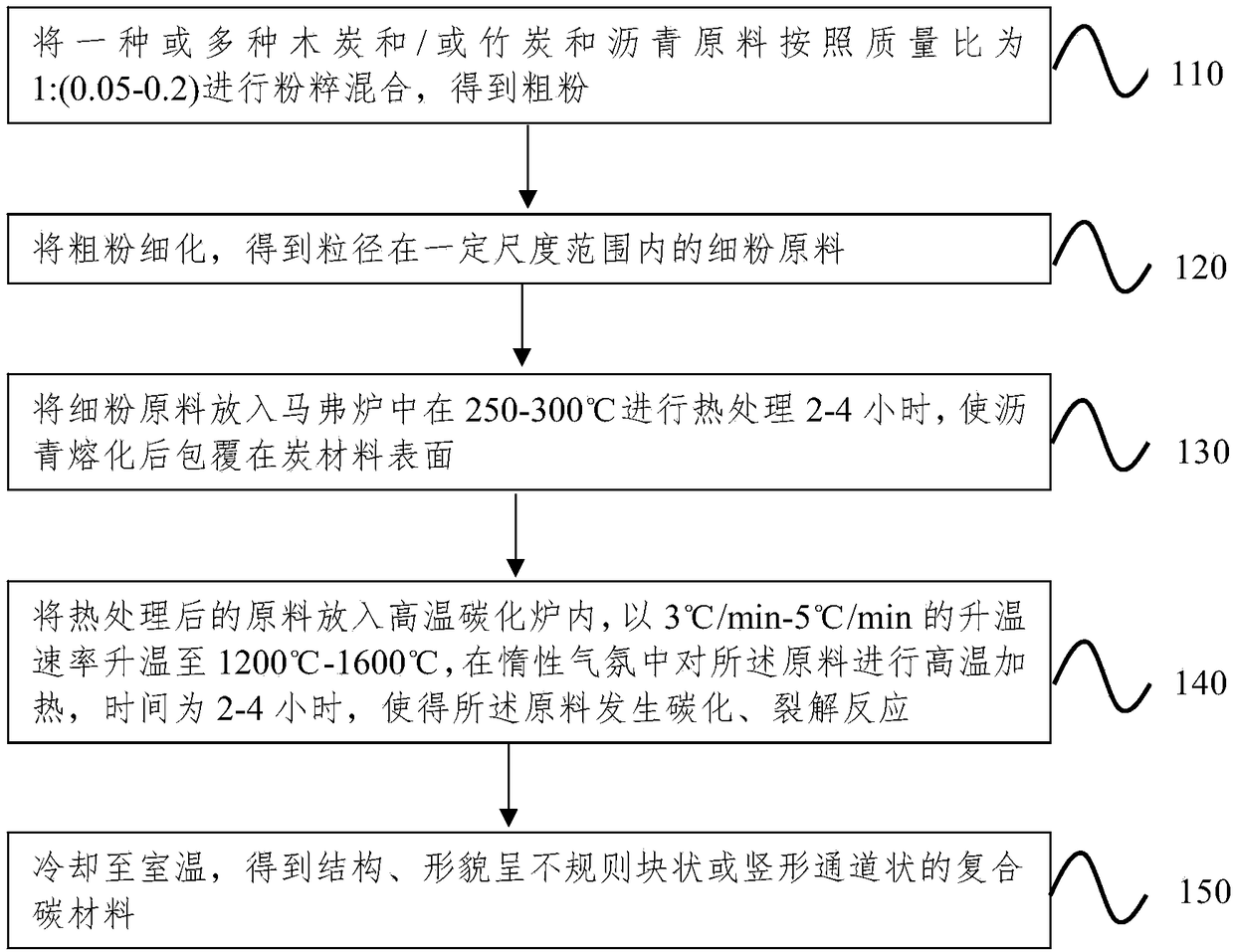

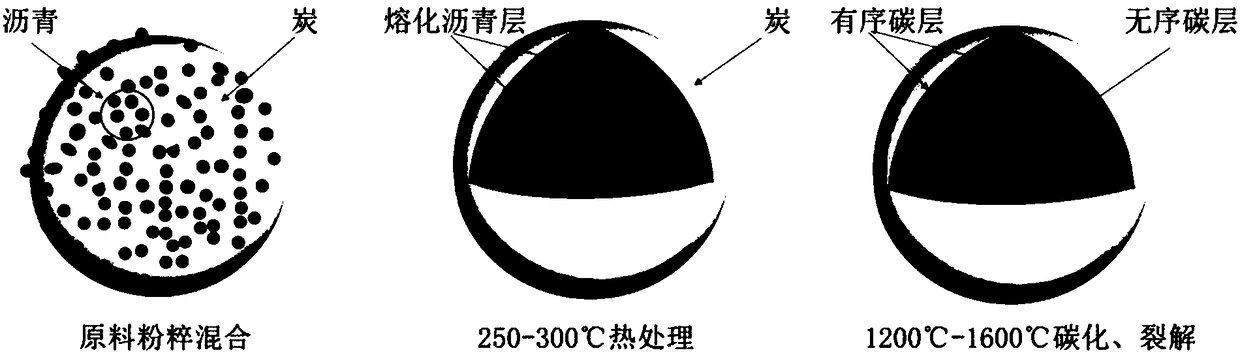

[0047] figure 1 The preparation method of the sodium ion battery negative electrode material based on carbon material and pitch provided for the embodiment of the present invention, its steps are as follows figure 1 shown, including:

[0048]Step 110, pulverizing and mixing one or more charcoal and / or bamboo charcoal and asphalt raw materials according to a mass ratio of 1:(0.05-0.2) to obtain coarse powder;

[0049] Specifically, the pulverization and mixing method is preferably mechanical mixing, including mechanical pulverization, ball milling, stirring, sieving and ultrasonic dispersion, and any combination of the above-mentioned methods. The time of mechanical mixing can be determined according to the selected precursor and the size of the required pulverized particle size.

[0050] Among them, charcoal includes one or more mixtures of white carbon, black carbon, activated carbon and machine-made carbon, bamboo charcoal includes one or more mixtures of carbonized materi...

Embodiment 2

[0061] This example provides the negative electrode material for a sodium ion battery prepared in Example 1 above.

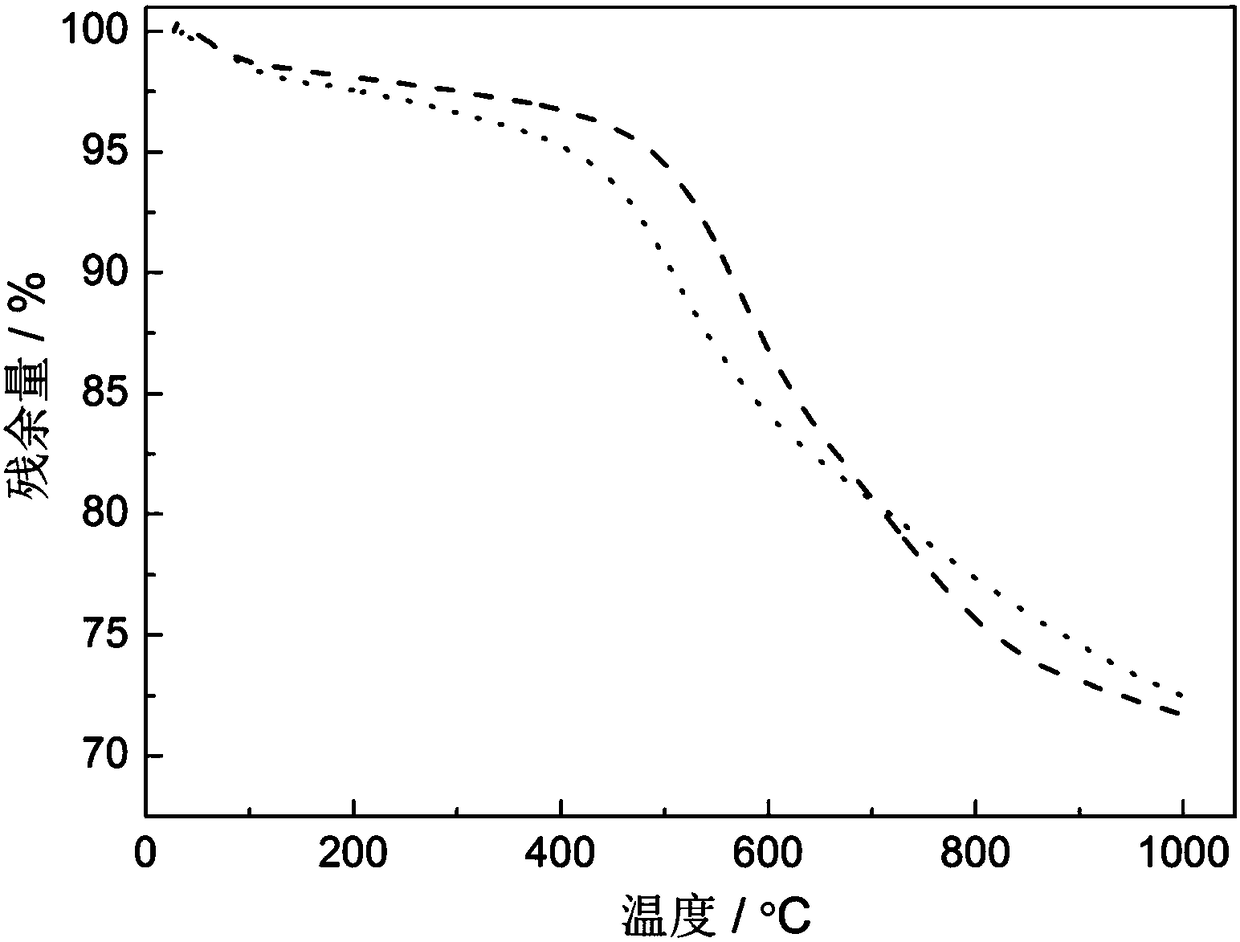

[0062] According to the selected carbon material raw materials and the ratio of compounding with asphalt, the prepared negative electrode material has an orderly surface structure, disordered interior, and irregular block or vertical channel shape. Irregular massive carbon materials prepared by compounding charcoal and pitch, with a size between 2-10 microns, d 002 The value is between 0.37-0.40nm, the Lc value is between 1-4nm, and the La value is between 3-5nm; the vertical channel-shaped carbon material prepared by compounding charcoal and pitch, the length is between 5-30 microns, Pipe pore size between 2-3 microns, d 002 The value is between 0.36-0.38nm, the Lc value is between 1-4nm, and the La value is between 3-5nm; the irregular block carbon material prepared by compounding bamboo charcoal and pitch, the size is between 2-15 microns, d 002 The value ...

Embodiment 3

[0066] Weigh 2g of iron charcoal, mechanically grind 0.1g of petroleum asphalt, mix them evenly, and put them into a magnetic boat. First put it into a muffle furnace, raise the temperature to 260°C at a rate of 3°C / min, and keep it warm for 3 hours to obtain a heat-treated pitch-coated carbon material. Then put the heat-treated powder into a tube furnace with argon as a protective gas, raise the temperature to 1400°C at a rate of 3°C / min, and keep it warm for 2 hours; then naturally cool to room temperature, take out the material, and obtain the final compound The carbon material is the negative electrode material of the sodium ion secondary battery.

[0067] Its XRD pattern sees Figure 4 . The d of the carbon material can be obtained from the XRD pattern 002 = 0.392nm, L c = 2.15nm. Its Raman spectrum see Figure 5 , the L of the carbon material can be obtained from the Raman spectrum a = 3.18nm. Image 6 The SEM image of the carbon material prepared in this example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com