Preparation methods of carbon-carbon composite material and carbon-ceramic composite material with inner holes

A carbon-carbon composite material and carbon-ceramic composite material technology, which is applied in the field of preparation of carbon-carbon composite materials and carbon-ceramic composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

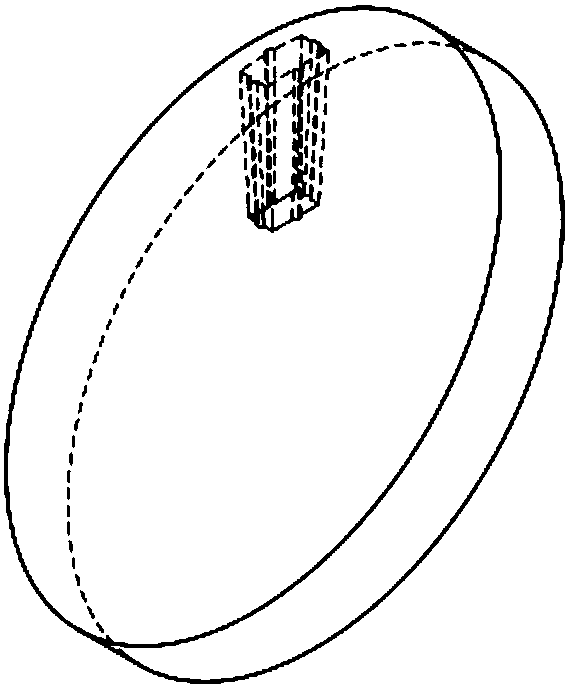

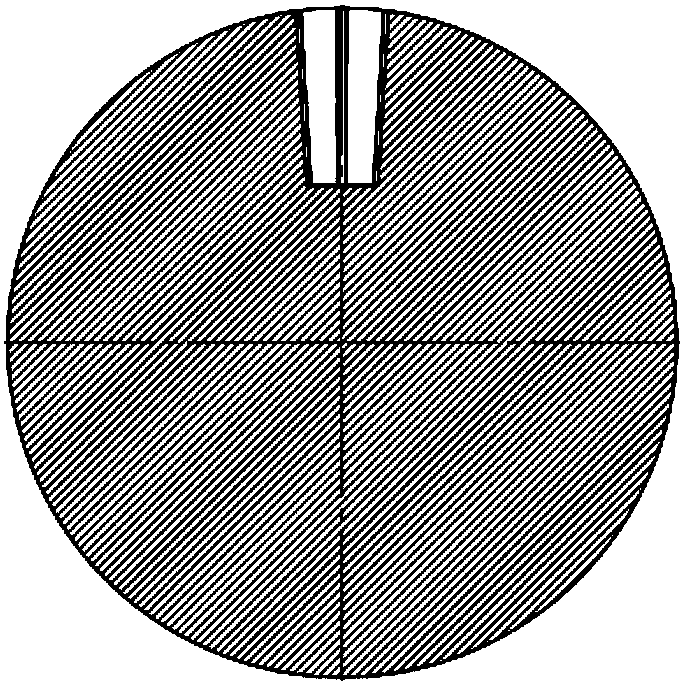

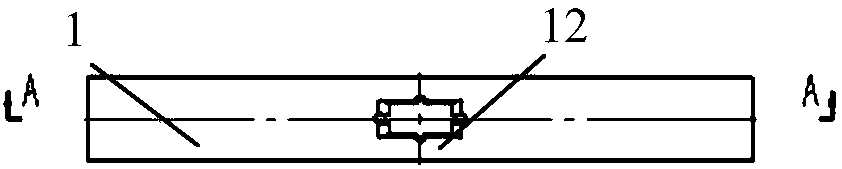

[0078] see Figure 1a-1c , the carbon-ceramic composite material part 1 with a trapezoidal inner hole 12 in the illustration is a preferred solution of the present invention, and the carbon-ceramic composite material part 1 is a circular disc with a density of 2.0 g / cm 3 ~2.4g / cm 3 , its specific preparation method is:

[0079] Cover the trapezoidal graphite mold with a layer of carbon fiber paper with air guide grooves (the thickness of the carbon fiber paper with air guide grooves is 20mm) (one end is large and the other end is small) to obtain a spare mold; according to the number and distribution of inner holes set Fix the spare mould, and then use carbon fiber as raw material to weave according to the size of the carbon-ceramic composite material to obtain a density of 0.6g / cm 3 the prefabricated body;

[0080] The preform is placed in an argon protective gas atmosphere at 1800°C for degumming treatment, and then CVI’s C densification treatment is performed in a vapor de...

Embodiment 2

[0083] see Figure 2a-2c , the carbon-carbon composite material part 2 with a special-shaped inner hole 22 in the illustration is a preferred solution of the present invention, and the carbon-carbon composite material part 2 is an annular disc body with a density of 1.8-1.9 g / cm 3 , its specific preparation method is:

[0084] Coat the special-shaped plastic material mold with a layer of graphite paper (the thickness of the graphite paper is 0.15mm, and the fixed carbon content in the graphite paper is not less than 99wt%) to obtain a spare mold; according to the number and distribution of the set inner holes Fix the spare mold, and then use carbon fiber as raw material to weave according to the size of the carbon-carbon composite material to obtain a density of 0.6g / cm 3 the prefabricated body;

[0085] Place the preform in a nitrogen protective gas atmosphere at 1800°C for degumming and removal of the plastic mold, and then perform CVI densification treatment in a vapor de...

Embodiment 3

[0087] The density of carbon ceramic composite material is 2.2~2.4g / cm 3 , its specific preparation method is:

[0088] Cover the plastic material mold with graphite paper that has been thermally sprayed with SiC to obtain a spare mold; fix the spare mold according to the number and distribution of the set inner holes, and then use carbon fiber as the raw material according to the size of the carbon-ceramic composite material. Woven to obtain a density of 0.7g / cm 3 the prefabricated body;

[0089] Place the preform in a nitrogen protective gas atmosphere at 1800 ° C for degumming of carbon fibers and removal of plastic molds, and SiC graphite paper is adhered to the inner hole, and then CVI C densification treatment is carried out in a vapor deposition furnace, during which the process lasts Introduce carbon source gas propylene and diluent gas nitrogen, the volume ratio of carbon source gas and diluent gas is 1, and control the pressure in the furnace to 2000Pa, carry out c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com