Preparation method of mullite oxidation resistant coating

A technology of anti-oxidation coating and mullite, which is applied in the field of preparation of mullite anti-oxidation coating, can solve the problems such as difficulty in meeting the thickness requirements of anti-oxidation coating, low upper limit of coating thickness, easy cracking and peeling of coating, etc. , to avoid the phenomenon of coating peeling, improve the bonding interface, and eliminate the effect of coating cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

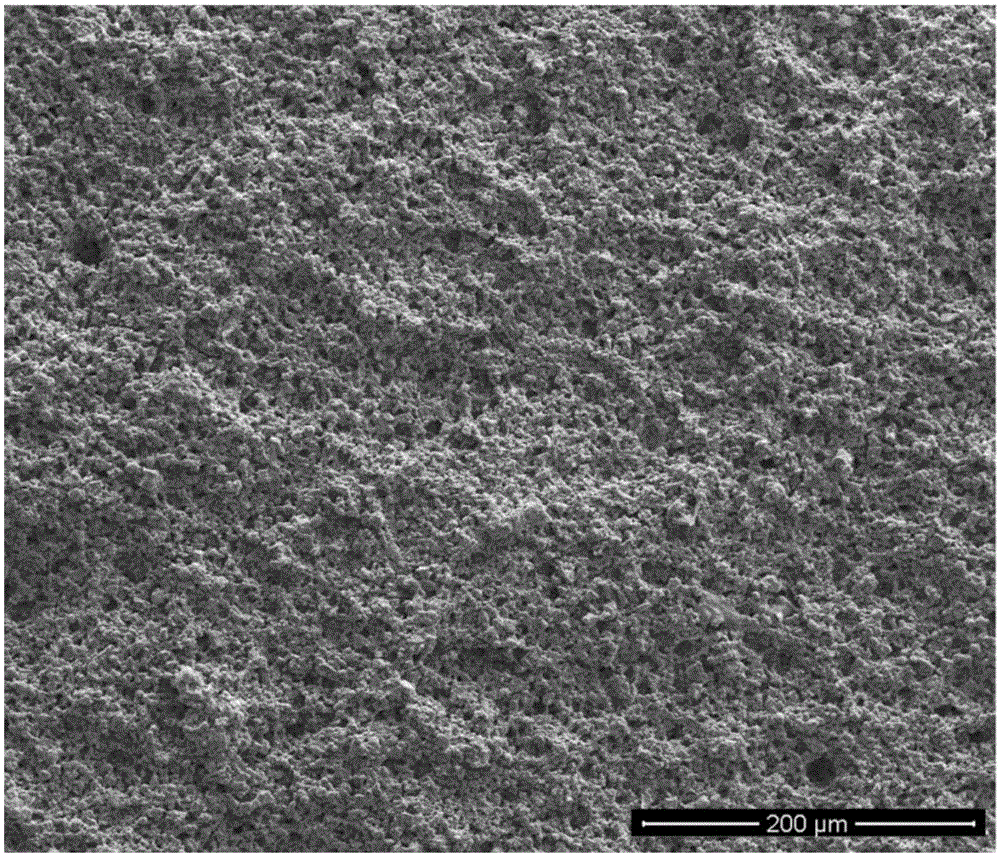

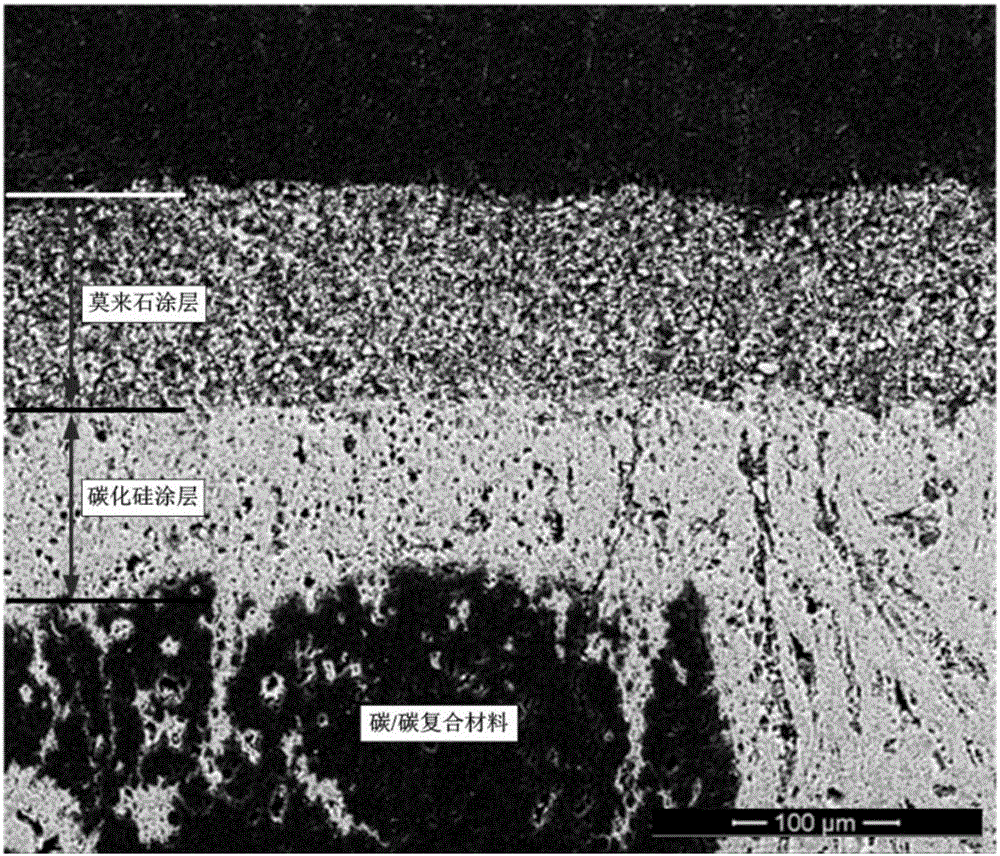

[0063] Preparation of SiC coating by embedding method: first, 180g Si powder, 90g SiC powder, 15g carbon powder, 15g Al 2 o 3 Put it in a ball mill jar and wet grind it at a speed of 200r / min for 24 hours, take it out, put it in a drying oven at 90°C for 12 hours, and then sieve it with a 60-mesh sieve to obtain the embedding powder.

[0064] Put the embedding powder into a graphite jar and embed the C / C matrix sample in the embedding powder, heat it to 1750°C in an argon atmosphere in a vacuum sintering furnace, keep it warm for 2 hours, and then cool it slowly to room temperature Take out the sample. The sample was ultrasonically cleaned with absolute ethanol and dried at 90°C for 2 hours to obtain a SiC coating-coated C / C composite sample.

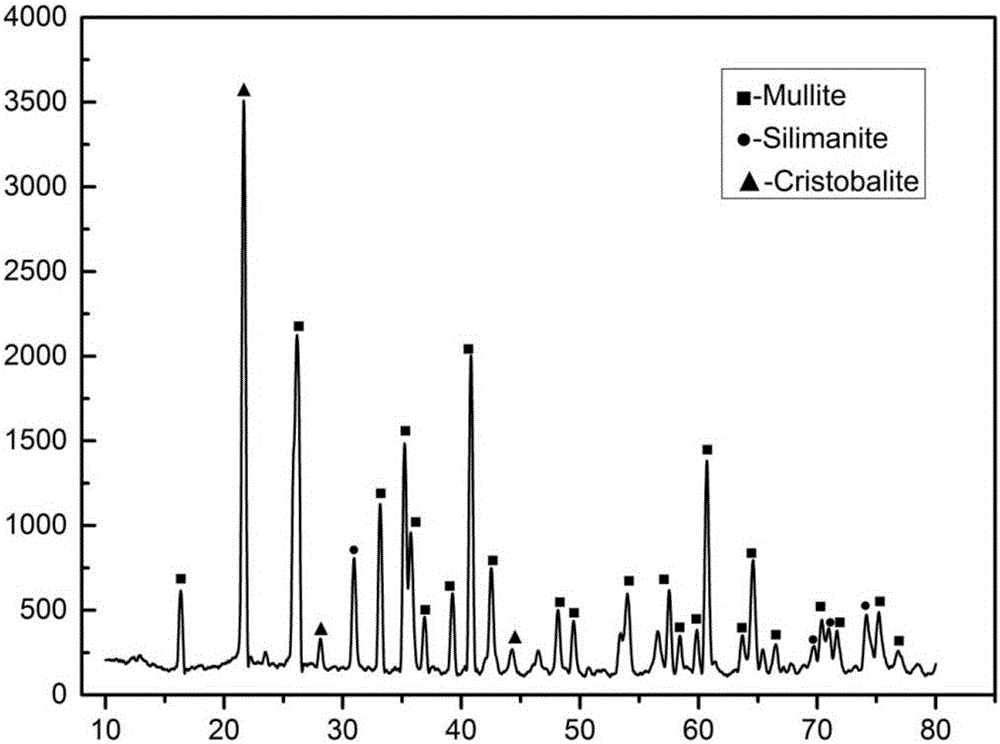

[0065] Preparation of mullite outer coating by sol-gel method:

[0066] 1) 10.4165g ethyl orthosilicate and 56.247g Al(NO 3 ) 3 9H 2 O was dissolved in 14mL of ethanol, added 1.800g of glacial acetic acid, refluxed in a water bath...

Embodiment 2

[0070] Preparation of SiC coating by embedding method: first, 260g Si powder, 96g SiC powder, 40g carbon powder, 4g Al 2 o 3 Put it in a ball mill jar and wet grind it at a speed of 200r / min for 24 hours, take it out, put it in a drying oven at 90°C for 12 hours, and then sieve it with a 60-mesh sieve to obtain the embedding powder.

[0071] Put the embedding powder into a graphite jar and embed the C / C matrix sample in the embedding powder, heat it to 1800°C in an argon atmosphere in a vacuum sintering furnace, keep it warm for 2 hours, and then cool it slowly to room temperature Take out the sample. The sample was ultrasonically cleaned with absolute ethanol and dried at 90°C for 2 hours to obtain a SiC coating-coated C / C composite sample.

[0072] Preparation of mullite outer coating by sol-gel method:

[0073] 1) 41.666g tetraethyl orthosilicate and 224.988g Al(NO 3 ) 3 9H 2 Dissolve O in 200mL of ethanol, add 30g of glacial acetic acid, reflux in a water bath at 60°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com