Ultrafine-grained Al-bearing multiple-principal-element high-entropy alloy and preparation method thereof

A high-entropy alloy and multi-principal element technology, applied in the field of metal materials, can solve problems such as insufficient high-temperature oxidation resistance, and achieve the effects of improving high-temperature creep resistance, improving strength, and improving theoretical toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

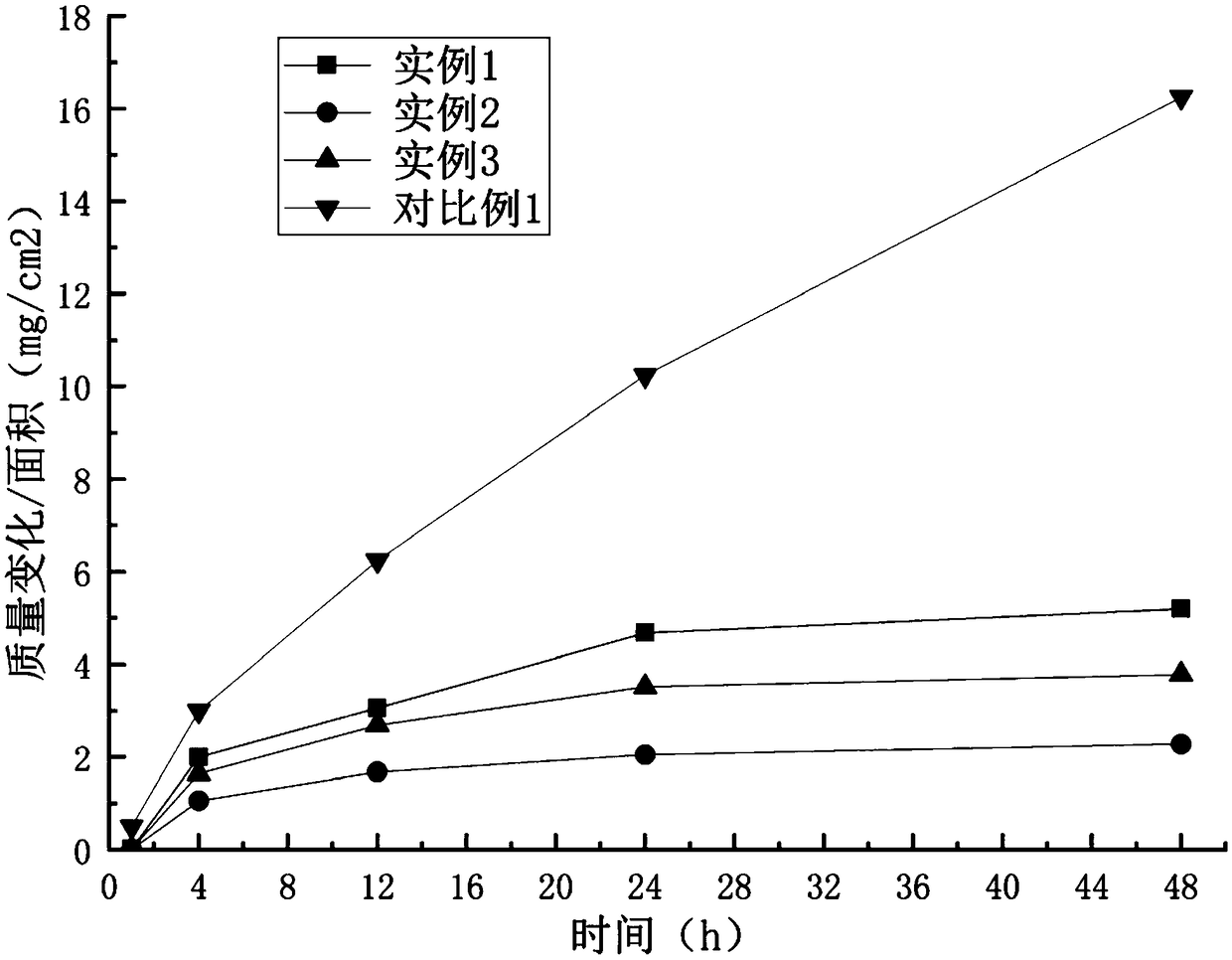

Embodiment 1

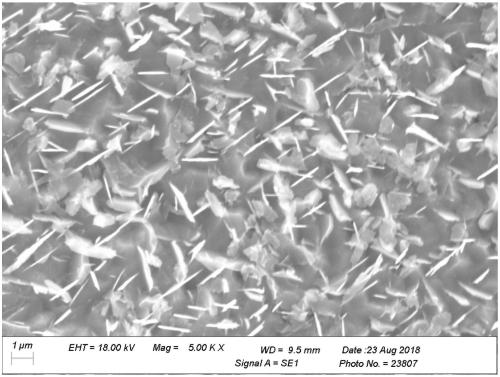

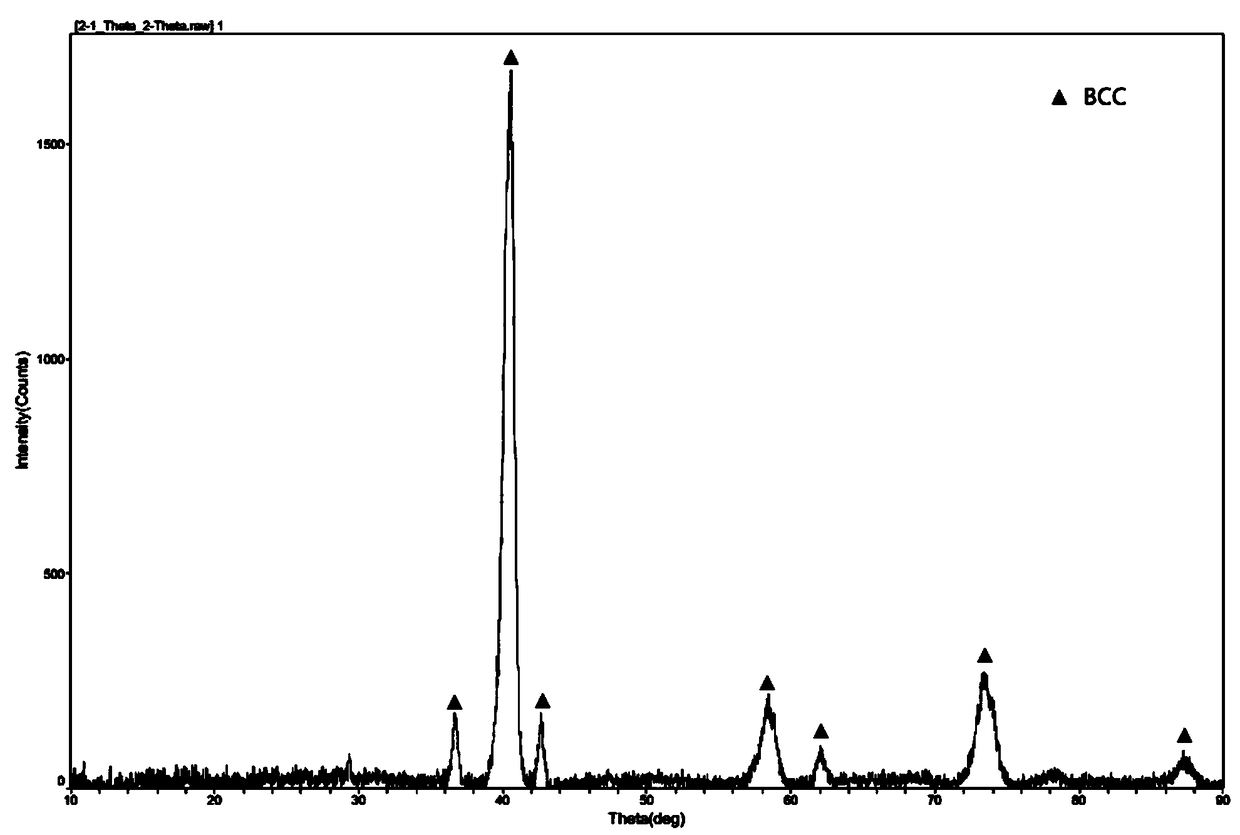

[0025] Ultrafine-grained Al-containing multi-principal element high-entropy alloy, composed of Al, Co, Cr, Fe, Ni, Ti and Nb, recorded as Al according to atomic ratio 20-x co 20 Cr 20 Fe 20 Ni 20 (Ti y Nb 1-y ) x , wherein x=10; y=0.5; said Al, Co, Cr, Fe, Ni, Ti and Nb are solid pure raw materials with a purity not lower than 99.5wt%.

[0026] The preparation method of the above-mentioned ultrafine-grained Al-containing multi-principal high-entropy alloy comprises the following steps:

[0027] Step (1): Al, Co, Cr, Fe, Ni, Ti and Nb elemental small particles are compounded according to the composition ratio;

[0028] Step (2): Put the prepared materials in step (1) in the melting furnace and close the furnace door (the low melting point is placed in the core of the raw material, and the high melting point is placed around the low melting point raw material to reduce the burning rate of elements), pump Vacuum to vacuum degree 3*10 -3 Pa, then filled with argon, this s...

Embodiment 2

[0033] Ultrafine-grained Al-containing multi-principal element high-entropy alloy, composed of Al, Co, Cr, Fe, Ni, Ti and Nb, recorded as Al according to atomic ratio 20-x co 20 Cr 20 Fe 20 Ni 20 (Ti y Nb 1-y ) x , wherein x=6; y=0.8; said Al, Co, Cr, Fe, Ni, Ti and Nb are solid pure raw materials with a purity not lower than 99.5wt%.

[0034] The preparation method of the above-mentioned ultrafine-grained Al-containing multi-principal high-entropy alloy comprises the following steps:

[0035] Step (1): Al, Co, Cr, Fe, Ni, Ti and Nb elemental small particles are compounded according to the composition ratio;

[0036] Step (2): Put the prepared materials in step (1) in the melting furnace, place the low melting point material in the core of the raw material, and place the high melting point material around the low melting point material to reduce the burning loss rate of elements, and close the furnace door , evacuated to a vacuum of 1×10 -3 Pa, then filled with argon,...

Embodiment 3

[0041] Ultrafine-grained Al-containing multi-principal element high-entropy alloy, composed of Al, Co, Cr, Fe, Ni, Ti and Nb, recorded as Al according to atomic ratio 20-x co 20 Cr 20 Fe 20 Ni 20 (Ti y Nb 1-y ) x , wherein x=15; y=0.2; said Al, Co, Cr, Fe, Ni, Ti and Nb are solid pure raw materials with a purity not lower than 99.5wt%.

[0042] The preparation method of the above-mentioned ultrafine-grained Al-containing multi-principal high-entropy alloy comprises the following steps:

[0043] Step (1): Al, Co, Cr, Fe, Ni, Ti and Nb elemental small particles are compounded according to the composition ratio;

[0044] Step (2): Put the prepared materials in step (1) in the melting furnace, place the low melting point material in the core of the raw material, and place the high melting point material around the low melting point material to reduce the burning loss rate of elements, and close the furnace door , evacuated to a vacuum degree of 5×10 -3 Pa, then filled wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com