Alpha--sialon ceramic doping composite rare earth and preparation method thereof

A technology for compounding rare earth and ceramics, which is applied in the field of α-sialon ceramics and its preparation, and can solve the problems of limiting the application of scandium oxide and the difficulty of obtaining Sc-α-sialon equivalents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

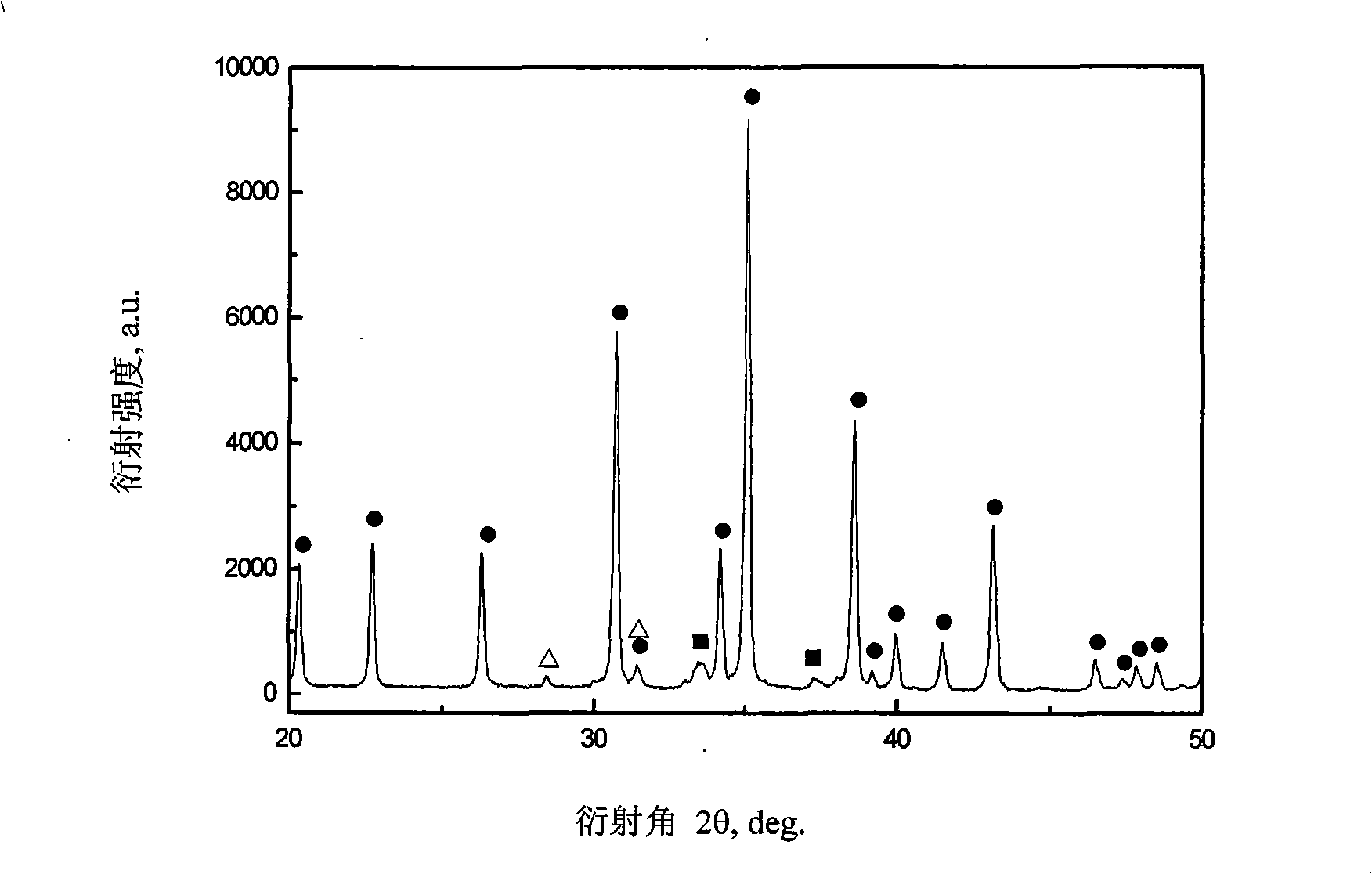

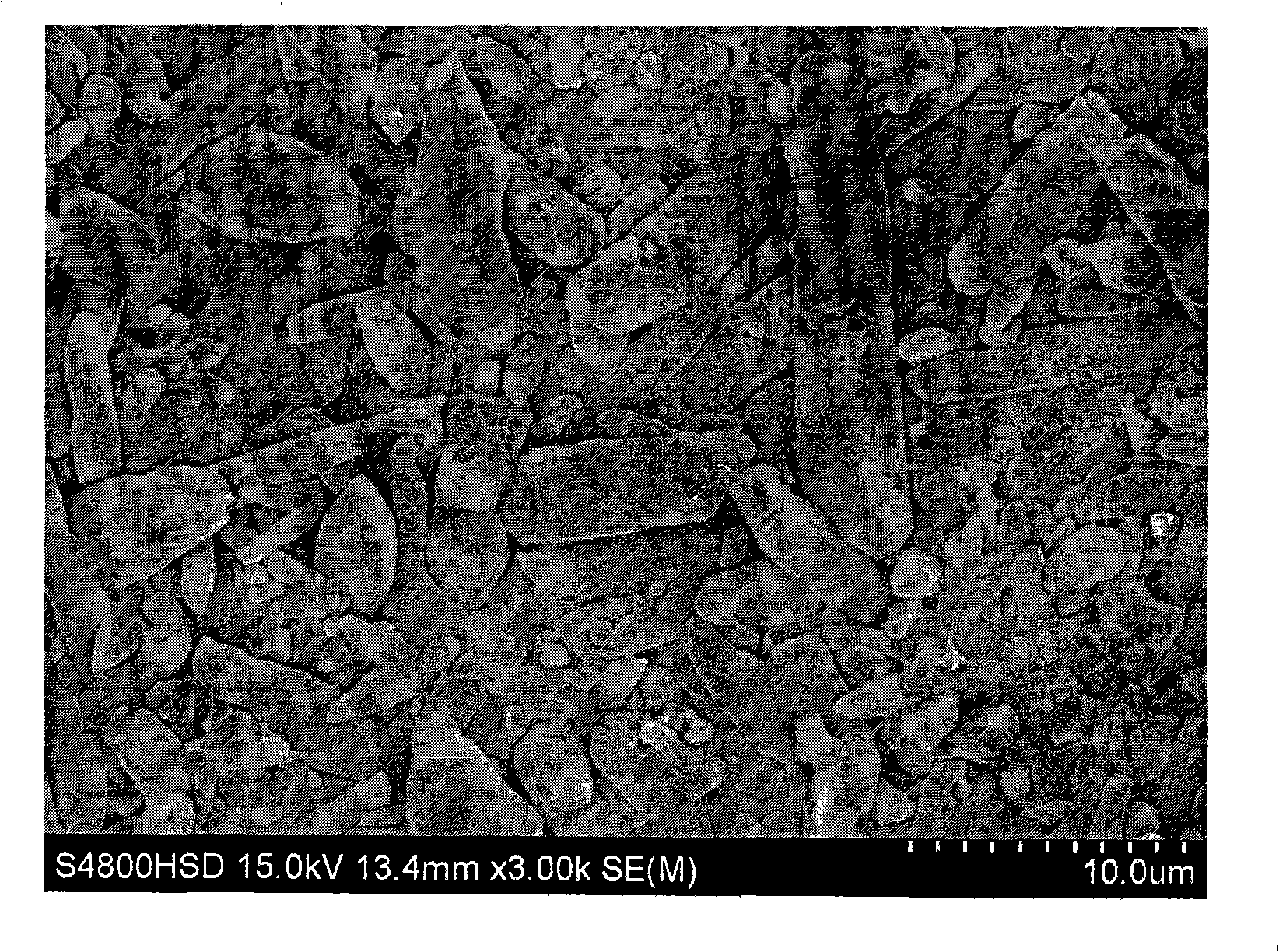

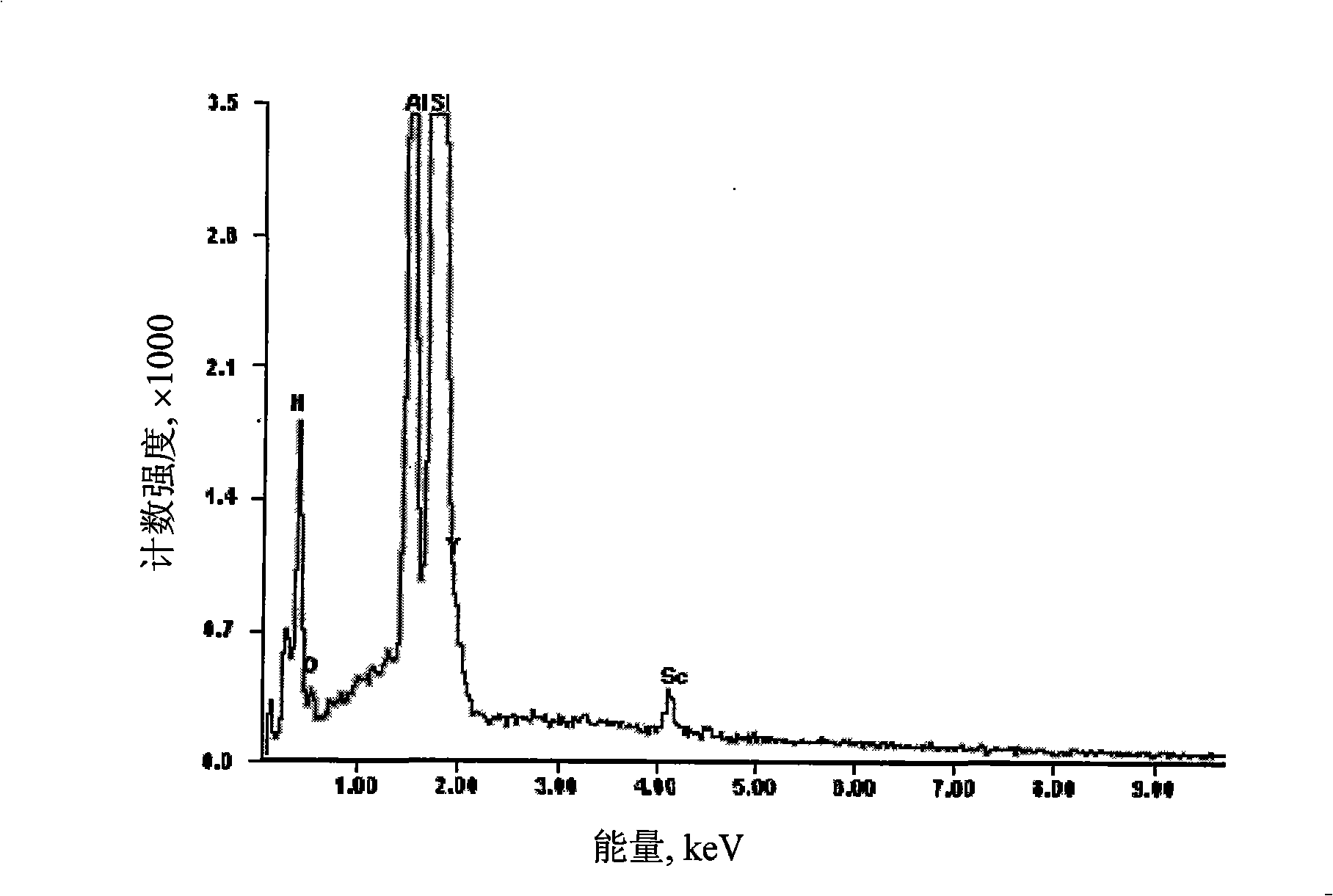

[0013] Embodiment 1: In this embodiment, the general formula of the α-sialon ceramic doped with composite rare earth is (Sc x R y )Si 12-(m+n) Al (m+n) O n N 16-n , where x+y=m / 3, 0≤x≤m / 3, 0≤y≤m / 3, 0

specific Embodiment approach 2

[0014] Embodiment 2: The difference between this embodiment and Embodiment 1 is that x=m / 3, y=0, and m=n=1 in the general formula. Others are the same as the first embodiment.

specific Embodiment approach 3

[0015] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in the general formula, x=y=m / 6, and m=n=1. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com