Method for preparing silicon carbide porous ceramic using gelatin wrapping-freeze drying process

A drying process and porous ceramic technology, applied in the field of porous ceramics, can solve the problems such as difficult to obtain porosity, and achieve the effect of good high temperature performance and high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

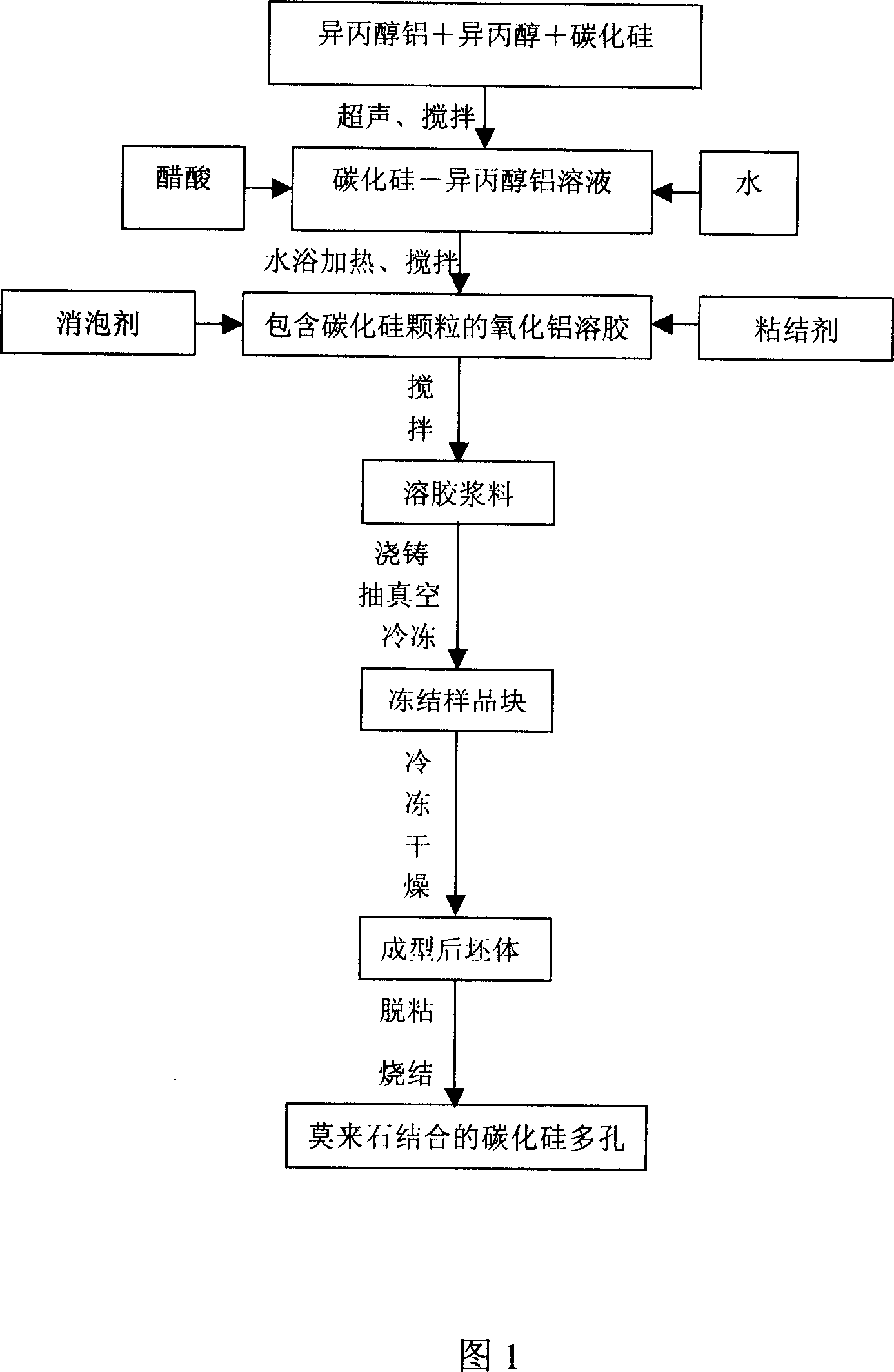

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described through specific implementation below, but the present invention is by no means limited to the embodiments. The process embodiment is shown in the table below:

[0024]

Reality

apply

example

silicon

pre-oxygenation

Office

reason

contain

quantity

(%

)

temperature

(℃

)

insulation

time

(h)

freeze-dried

drying time

(h)

frozen

to dry

pressure

(Pa

)

drying temperature

(℃)

(g / cm 3 )

(%)

Spend

(MPa)

1

No oxygen

change

25

1400

4

48 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com