Self-clean self-purification cement-based facing material and production method thereof

A facing material and self-purification technology, which is applied in the field of building materials, can solve the problems of affecting the aesthetic decoration effect, dust contamination, and easy frosting on the surface, etc., and achieves easy control of product quality, high bonding strength, and good durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

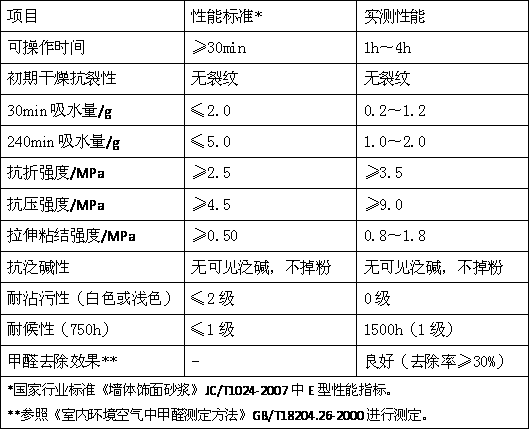

[0035] Embodiment 1: The self-cleaning self-purifying cement-based facing material that is used for building exterior wall surface layer decoration, its component and proportion (weight percentage) are: white Portland cement: 26, mineral admixture: 7, 20-30 mesh quartz sand: 10, 40-70 mesh quartz sand: 25, 70-100 mesh quartz sand: 24, diatomite: 2.8, zeolite: 2, nano-titanium dioxide: 0.5, EVA redispersible latex powder: 1.5 , Silicone water repellent 0.5, iron oxide red inorganic pigment: 0.3, other chemical additives 0.4. The performance results obtained by the detection test are shown in Table 2.

[0036] Table 2 Performance test results of self-cleaning and self-purifying cement-based facing materials in Example 1

[0037] project Measured performance Operational time 3h Initial drying crack resistance no crack 30min water absorption / g 0.4 240min water absorption / g 1.2 Flexural strength / MPa 4.4 Compressive strength / MPa 12.8 ...

Embodiment 2

[0038] Example 2: The self-cleaning and self-purifying cement-based facing material used for interior and exterior wall surface decoration of buildings, its components and proportioning (percentage by weight) are: white Portland cement: 22, mineral admixture: 10, 20-30 mesh quartz sand: 6, 40-70 mesh quartz sand: 25, 70-100 mesh quartz sand: 28, diatomite: 4, zeolite: 3, nano-titanium dioxide: 0.5, EVA redispersible latex powder: 0.7 , Silicone water repellent 0.3, iron oxide yellow inorganic pigment: 0.2, other chemical additives 0.3. The performance results obtained by the detection test are shown in Table 3.

[0039]

[0040] Table 3 Performance test results of self-cleaning and self-purifying cement-based facing materials in Example 2

[0041] project Measured performance Operational time 2.5h Initial drying crack resistance no crack 30min water absorption / g 0.6 240min water absorption / g 1.6 Flexural strength / MPa 4.0 Compres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com