Method for preparing low-boron-doped high-conductivity hydrogenated amorphous silicon film

A hydrogenated amorphous silicon, high-conductivity technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of increasing the preparation cost of hydrogenated amorphous silicon thin films, relying on the initial structure of the thin film, etc. The effect of low deposition temperature and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

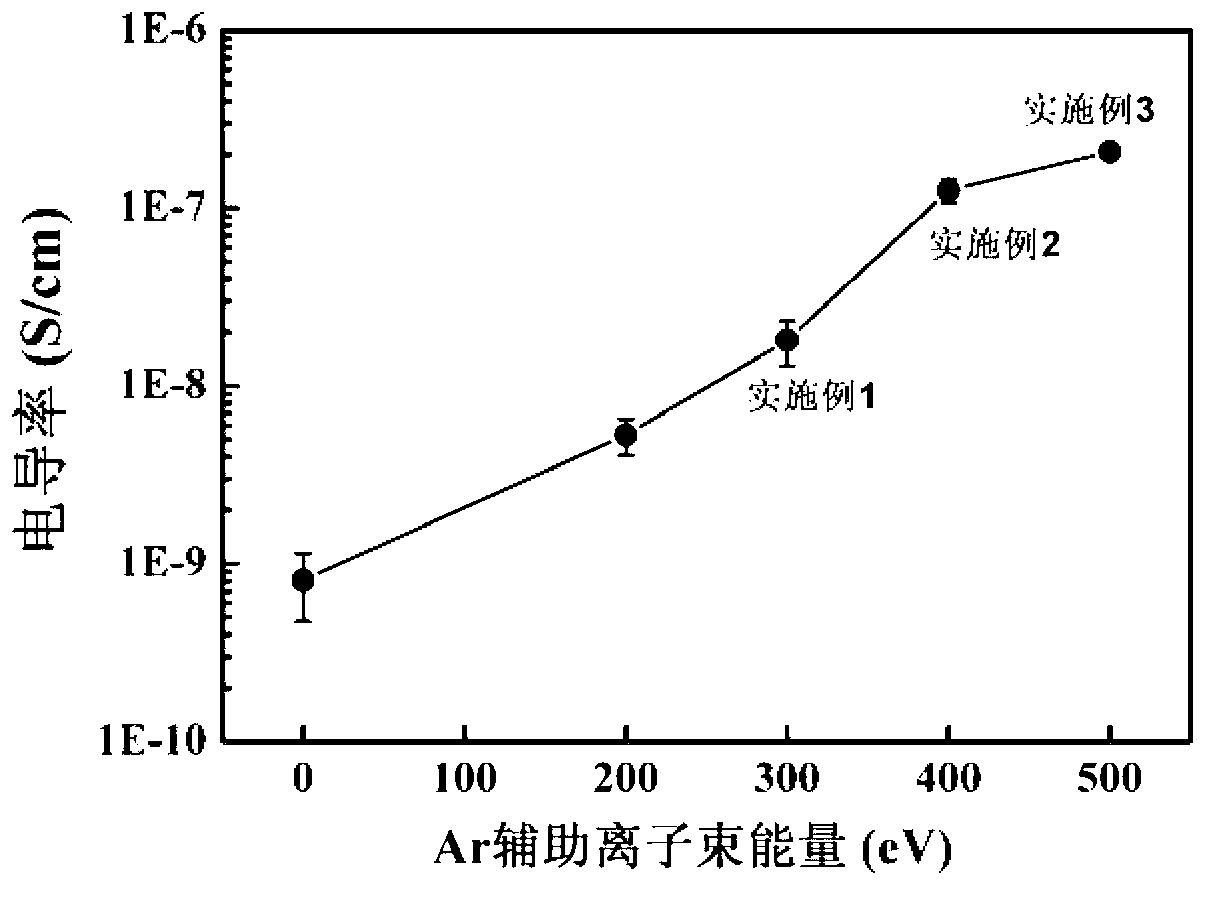

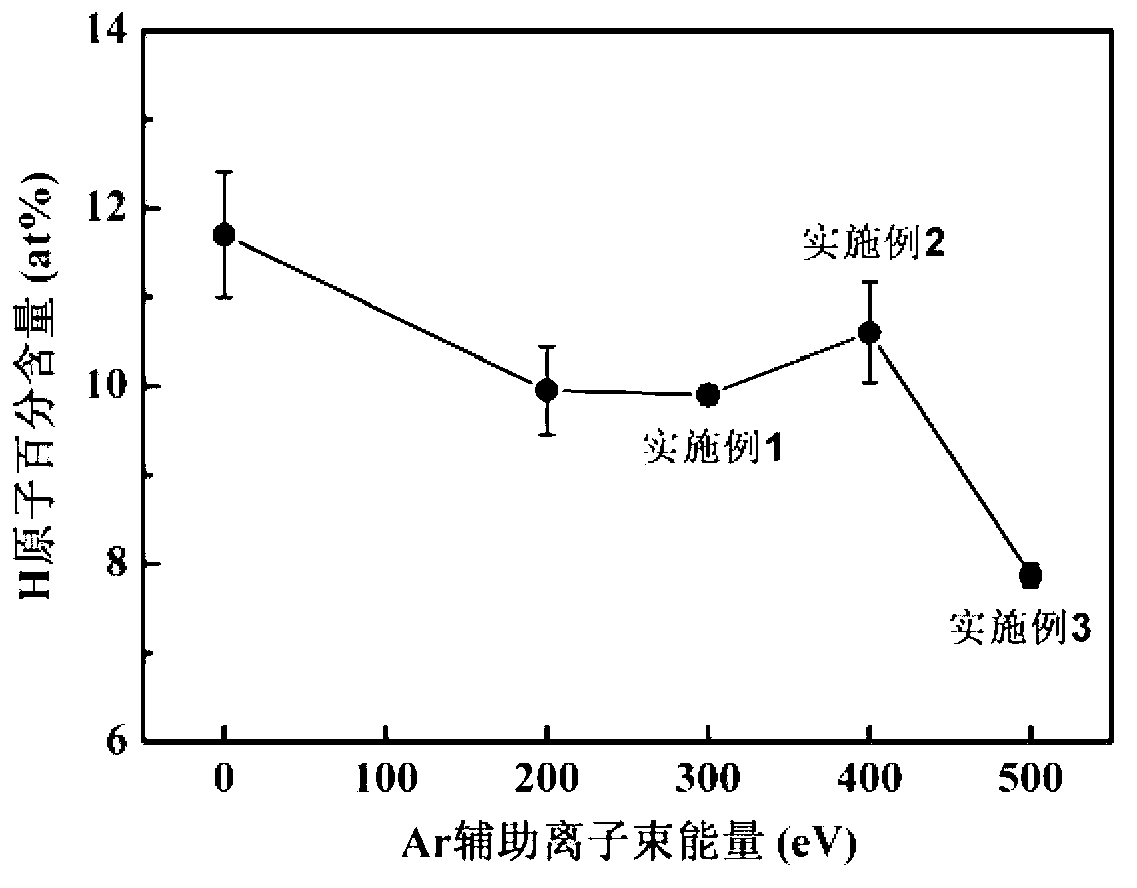

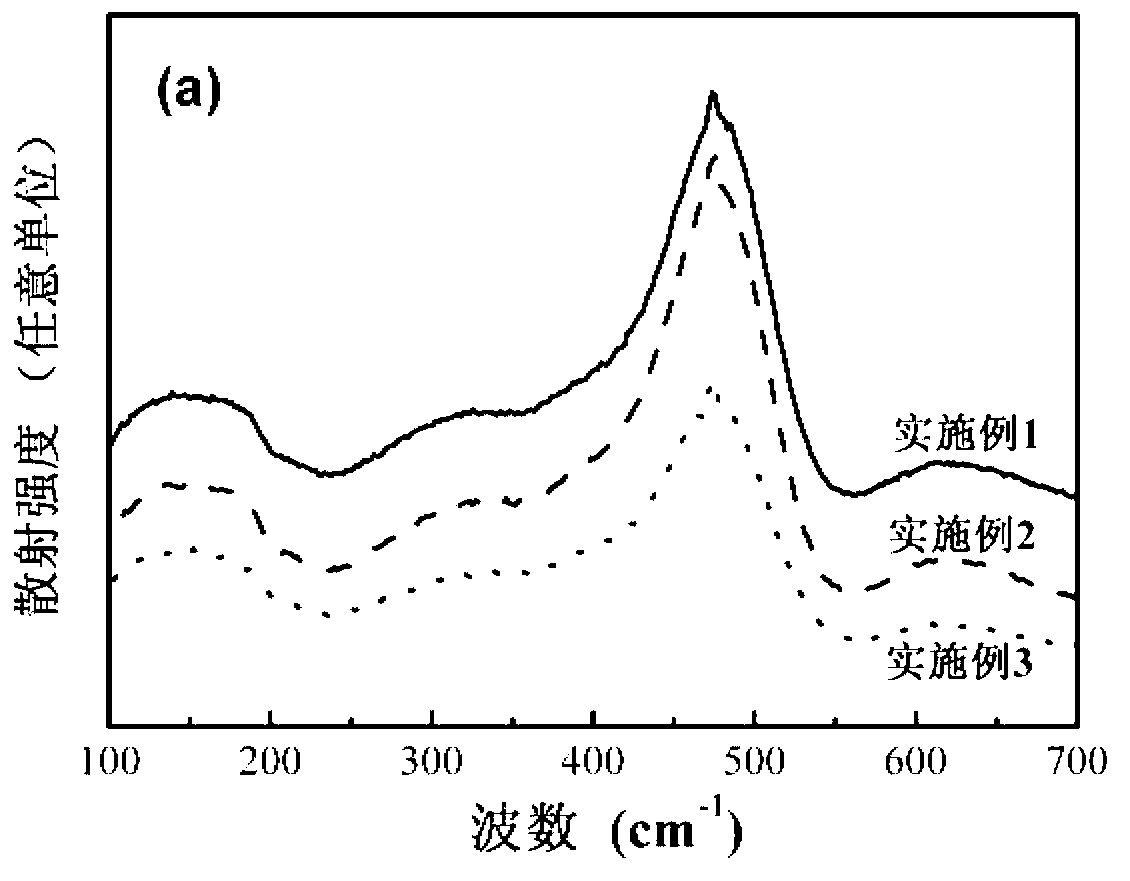

[0023] Example 1: Using ion beam assisted magnetron sputtering technology, sputtering with single crystal silicon with a boron atom doping amount of 0.1at% as a magnetron sputtering target, the background vacuum is 10 -5 Pa, the RF power is 150W, the sputtering gas is a mixed gas of argon and hydrogen, the flow ratio of argon and hydrogen in the mixed gas is 3:2, the total pressure of the sputtering gas is 0.15Pa, and the substrate temperature is 350°C , using high-purity argon as the auxiliary ion source to form an argon-assisted ion beam. The energy of the argon-assisted ion beam is 300eV, and the beam current is 15mA. The argon-assisted ion beam hits the film while sputtering and depositing the film on the surface of the quartz glass substrate. On the surface, a-Si:H hydrogenated amorphous silicon film with high conductivity under low boron doping was obtained. After testing, the thickness of the film is 160nm, and the conductivity is (1.8±0.5)×10 -8 S cm -1 , H atom cont...

Embodiment 2

[0024] Embodiment 2: Using ion beam assisted magnetron sputtering technology, sputtering with single crystal silicon with a boron atom doping amount of 0.1 at% as a magnetron sputtering target material, the background vacuum degree is 10 -5 Pa, the RF power is 200W, the sputtering gas is a mixed gas of argon and hydrogen, the flow ratio of argon and hydrogen in the mixed gas is 3:2, the total pressure of the sputtering gas is 0.2Pa, and the substrate temperature is 300°C , using high-purity argon as the auxiliary ion source to form an argon-assisted ion beam. The energy of the argon-assisted ion beam is 400eV, and the beam current is 15mA. The argon-assisted ion beam hits the film while sputtering and depositing the film on the surface of the quartz glass substrate. On the surface, a-Si:H hydrogenated amorphous silicon film with high conductivity under low boron doping was obtained. After testing, the thickness of the film is 147nm, and the conductivity is (1.3±0.2)×10 -7 S c...

Embodiment 3

[0025] Embodiment 3: Using ion beam assisted magnetron sputtering technology, sputtering with single crystal silicon with a boron atom doping amount of 0.1at% as a magnetron sputtering target material, the background vacuum degree is 10 -5 Pa, the RF power is 250W, the sputtering gas is a mixed gas of argon and hydrogen, the flow ratio of argon and hydrogen in the mixed gas is 3:2, the total pressure of the sputtering gas is 0.25Pa, and the substrate temperature is 250°C , using high-purity argon as the auxiliary ion source to form an argon-assisted ion beam. The energy of the argon-assisted ion beam is 500eV, and the beam current is 15mA. The argon-assisted ion beam hits the film while sputtering and depositing the film on the surface of the quartz glass substrate. On the surface, a-Si:H hydrogenated amorphous silicon film with high conductivity under low boron doping was obtained. After testing, the thickness of the film is 129nm, and the conductivity is (2.1±0.2)×10 -7 S c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com