Maintaining method of dry fibers at roots of glass fiber reinforced plastic blades

A technology of blade root and glass fiber cloth, which is applied in the field of maintenance of fiberglass blade root dry fiber, can solve problems such as unreasonable design and maintenance scheme, unclear blade force structure, and blade root fracture, so as to save processing time and reduce scrap rate, increase the strength of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043]A maintenance method for dry fiber at the root of a fiberglass blade, characterized in that: the method includes ten steps, the first step is to inspect the dry fiber at the root of the blade, the second step is to polish the dry fiber at the root, the third step is to reinforce the inside of the root ring, and the second step is to The fourth step is to polish the dry fiber of the leaf root, the fifth step is to repair the fiberglass cloth of the leaf root, the sixth step is to lay the vacuum auxiliary material for the dry fiber repair of the leaf root, the seventh step is to repair the vacuum guide of the dry fiber of the leaf root, the eighth step The first step is to repair and pre-cure the dry fiber of the blade root, the ninth step is to remove the mold after repairing the dry fiber of the blade root, and the tenth step is to cure after repairing the dry fiber of the blade root.

Embodiment 2

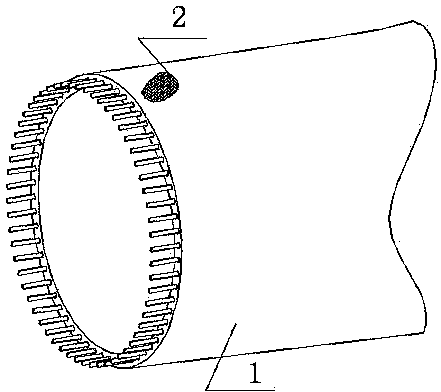

[0045] The maintenance method of the dry fiber at the root of the FRP blade described in embodiment 1 is characterized in that: the first step of inspecting the dry fiber at the root of the blade is to investigate the area and the number of layers of the dry fiber at the root of the blade; the second step is to polish The root dry fiber is to further accurately survey the number of dry fiber layers to provide data support for the formulation of maintenance plans; the third step of the internal reinforcement of the blade root ring is to repair the root of the blade if the number of dry fiber layers exceeds 44 layers. The inner side is reinforced to increase the strength of the blade root and reduce the risk of root fracture.

Embodiment 3

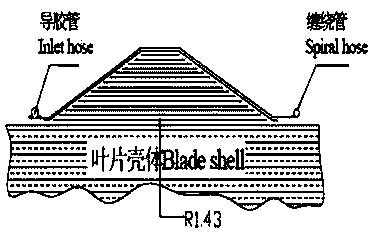

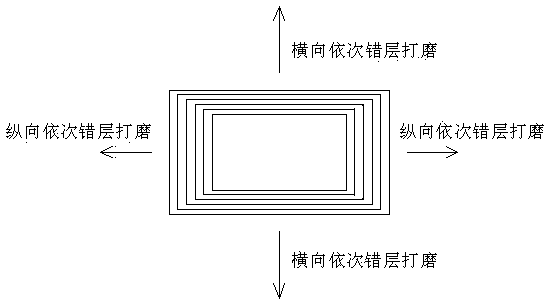

[0047] The maintenance method of the dry fiber at the root of the glass fiber reinforced plastic blade described in embodiment 1 is characterized in that: the fourth step of blade root dry fiber staggered grinding and staggered grinding is to make each layer of glass fiber layer misplaced to form a ladder shape, After the grinding is completed, count the layers of dry fibers to better increase the shear strength and bonding strength of the repair interface; the fifth step of blade root dry fiber repair fiberglass cloth laying is based on the steps of staggered grinding It is the basic principle of FRP maintenance to lay glass fiber cloth in dislocation layers. The cloth layer to be repaired is equal to the design layer of the defect. In addition, in order to better improve the repair strength, lay 1-5 more layers of glass cloth according to the actual situation. The position of the blade root bolt hole cannot be vertically staggered. Layers can only be horizontally staggered; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com