Synchronous grouting slurry for shield tunneling and preparation method thereof

A technology of simultaneous grouting and grouting, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of high material cost and difficult disposal of by-product desulfurized gypsum, and achieves improved later strength and obvious construction. and economic benefits as well as technological innovation, good flow filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

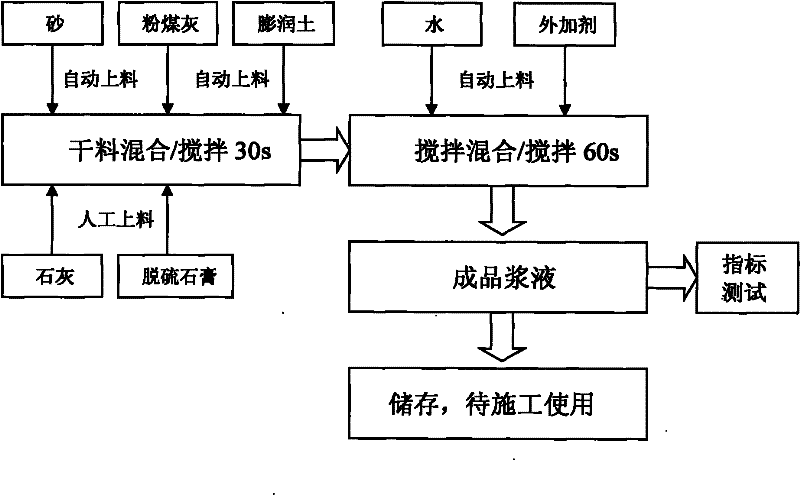

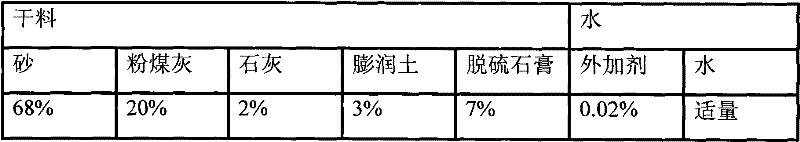

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with specific embodiments. The present invention takes a super-large-diameter earth pressure balance shield tunnel project as an example, and provides detailed implementation methods and processes, but the protection scope of the present invention is not limited to the following examples.

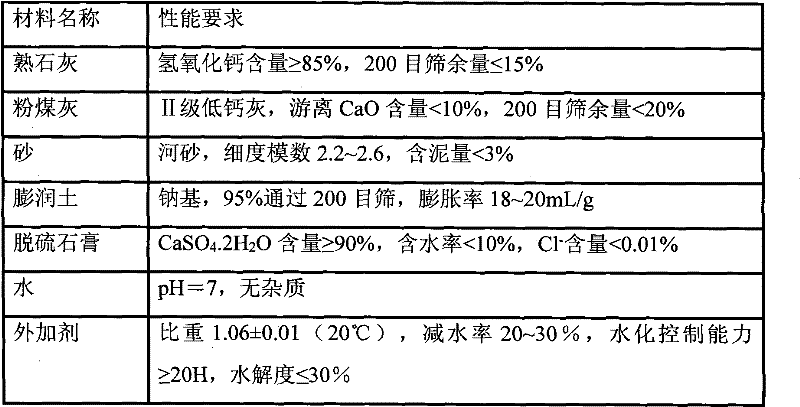

[0027] In this embodiment, a new type of synchronous grouting slurry for shield tunneling is used, whose components are different from traditional synchronous shield grouting materials. Waste - prepared from materials including desulfurized gypsum. The test report of the desulfurized gypsum material when it enters the site is as follows: List-4:

[0028] Table 4

[0029] Test items

Desulfurization gypsum

pH

6.42

8.56%

CaSO 4 .2H 2 o

95.32%

CaCO 3

0.25%

[0030] CaSO 3 .1 / 2H 2 o

0.0003%

CL-

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com