Patents

Literature

38results about How to "Make full use of the value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

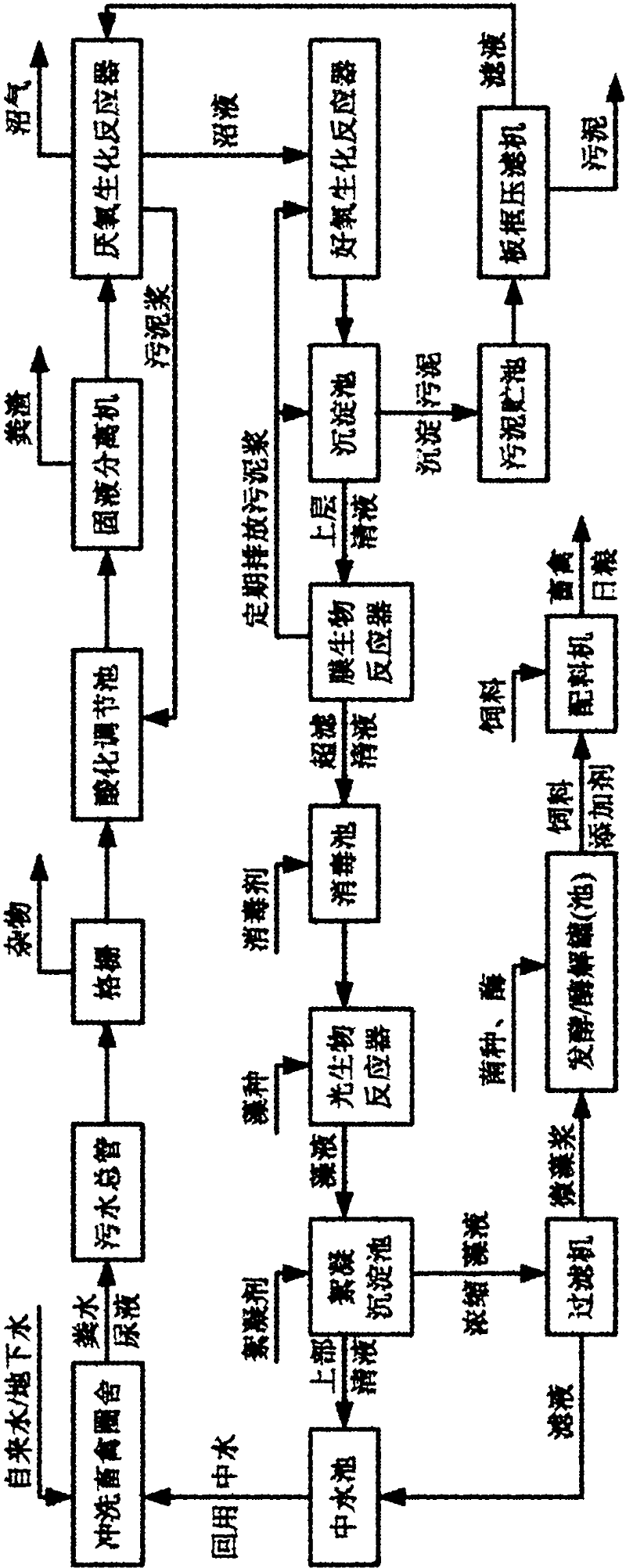

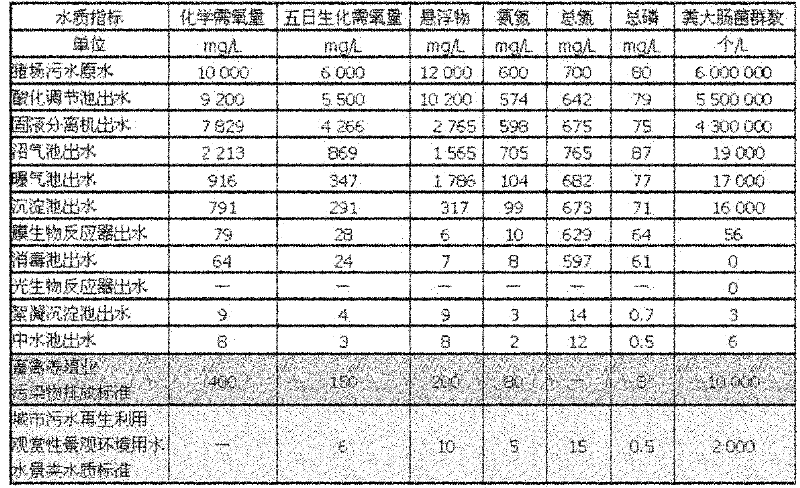

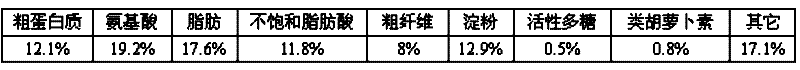

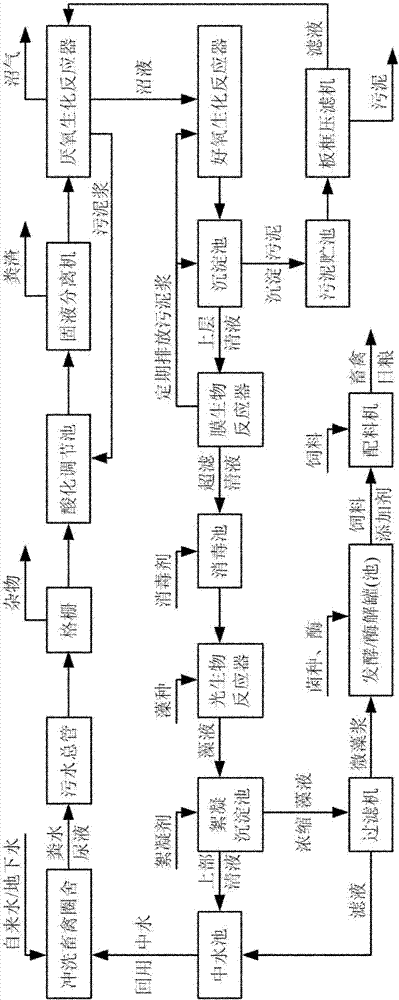

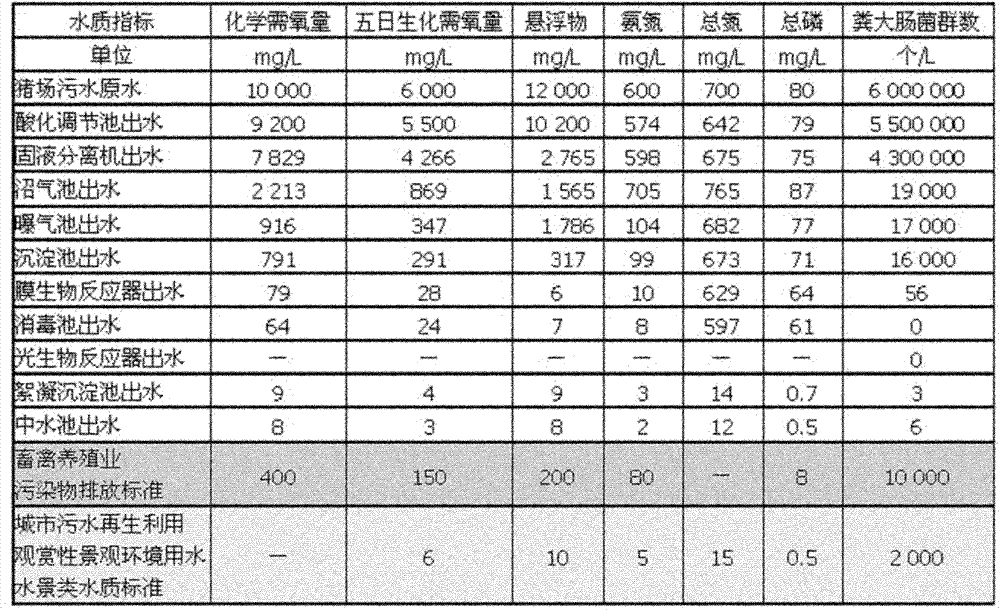

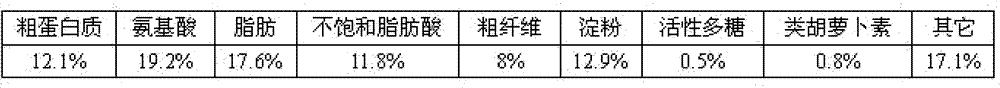

Method for producing feed additive from livestock and poultry breeding wastewater and purifying breeding wastewater to reclaimed water

InactiveCN102161550AReduce water consumptionAchieving zero emissionsWaste water treatment from animal husbandryAnimal feeding stuffUltrafiltrationSlurry

The invention relates to the fields of environmental technology and the breeding and processing of microalgae, in particular to a method for producing feed additive from livestock and poultry breeding wastewater and purifying breeding wastewater to reclaimed water. The method is characterized by comprising the following steps that: wastewater enters an acidification adjusting tank through a grille, and the acidified wastewater enters an anaerobic biochemical reactor for treatment and then enters an aerobic biochemical reactor; after the aerobic biochemical treatment, the obtained biogas slurry enters a settling tank for settling, the supernatant enters a membrane bioreactor for further aerobic treatment and is filtered by an ultrafiltration membrane, the generated ultrafiltration clear liquid is sterilized and neutralized and then enters a photobioreactor, algae are added into the photobioreactor to perform microalgae cultivation, and the algae liquid is discharged from the photobioreactor and then enters a flocculation and settling tank; and after flocculation and settling, the supernatant is used for water recycling, the concentrated algae liquid at the bottom enters a filter, and the separated microalgae slurry enters a fermentation / enzymolysis pot (tank) to perform fermentation / enzymolysis to be used as the feed additive. The invention has the advantages of high economic adaptability, zero discharge and the like.

Owner:蔡志武 +1

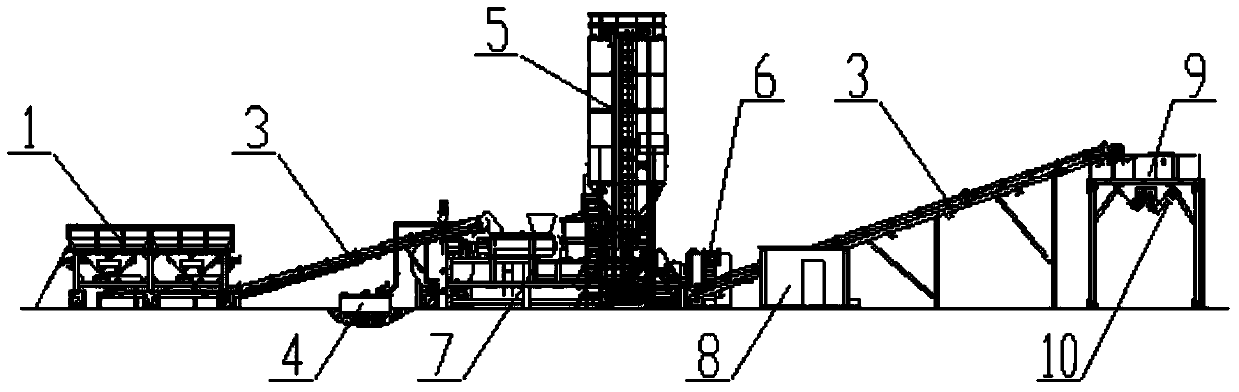

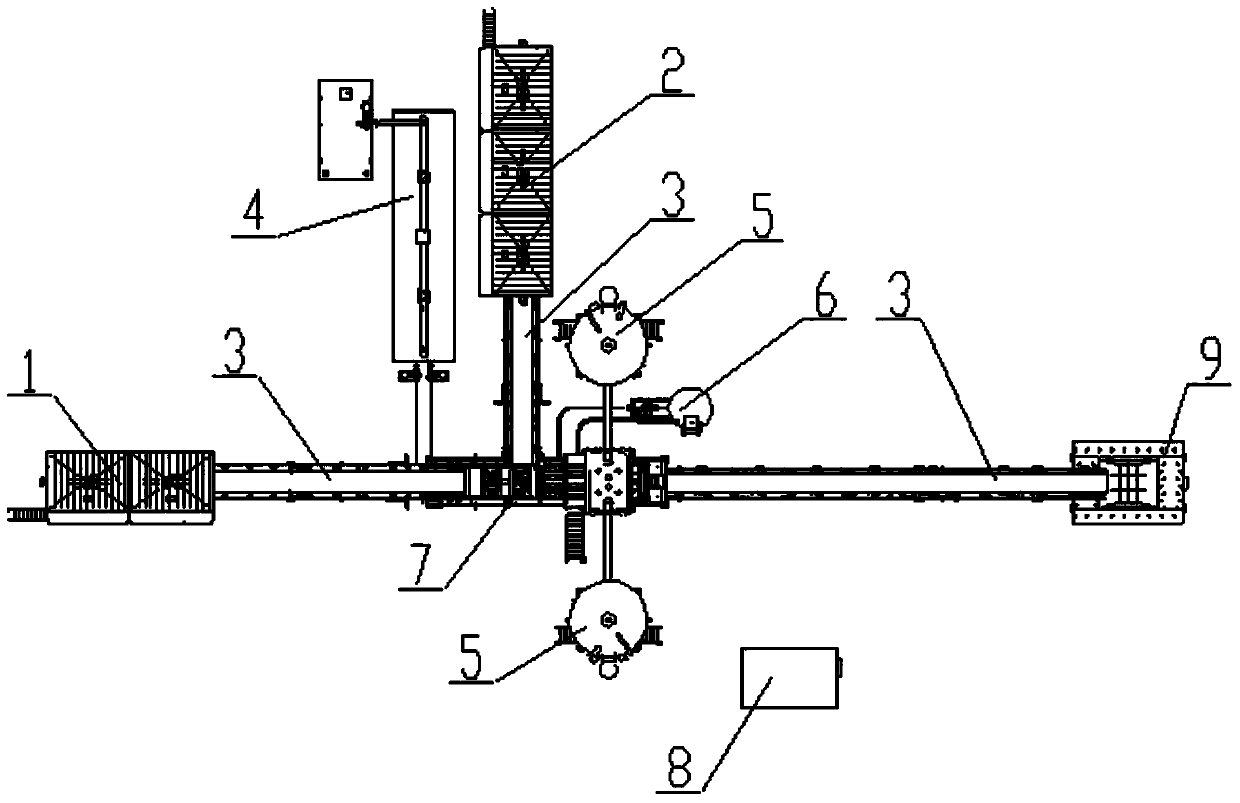

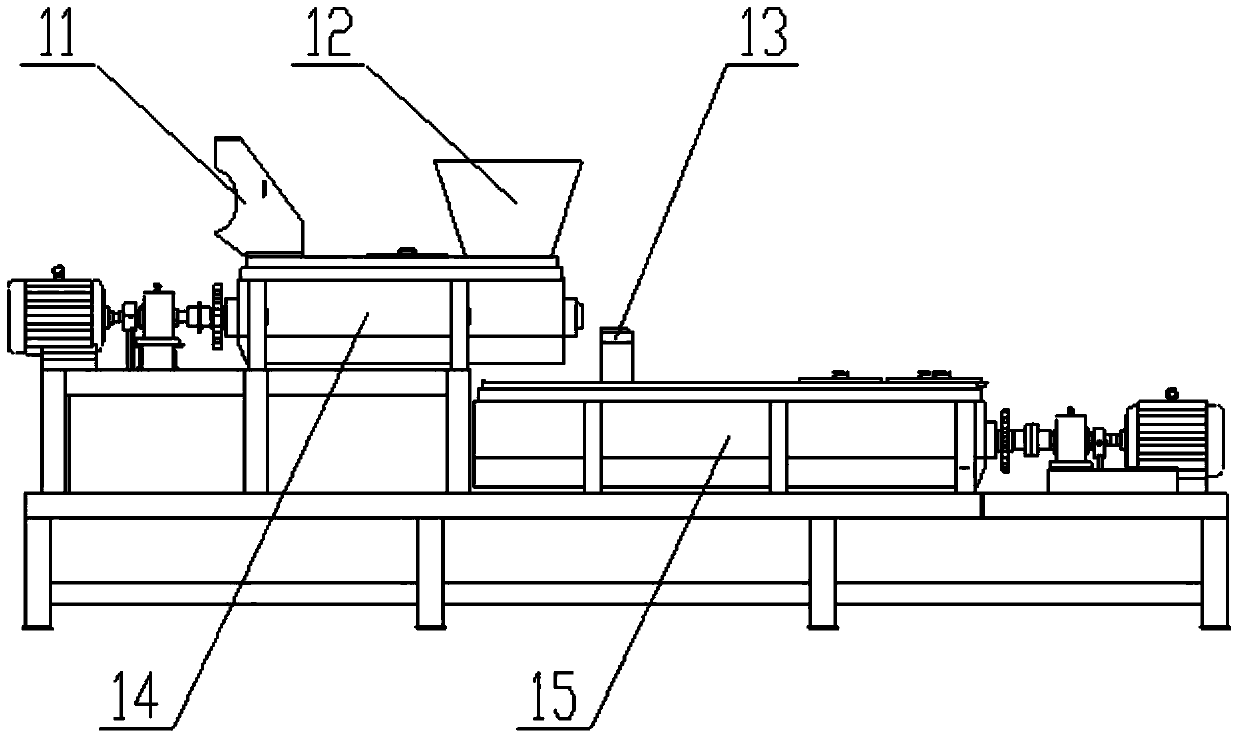

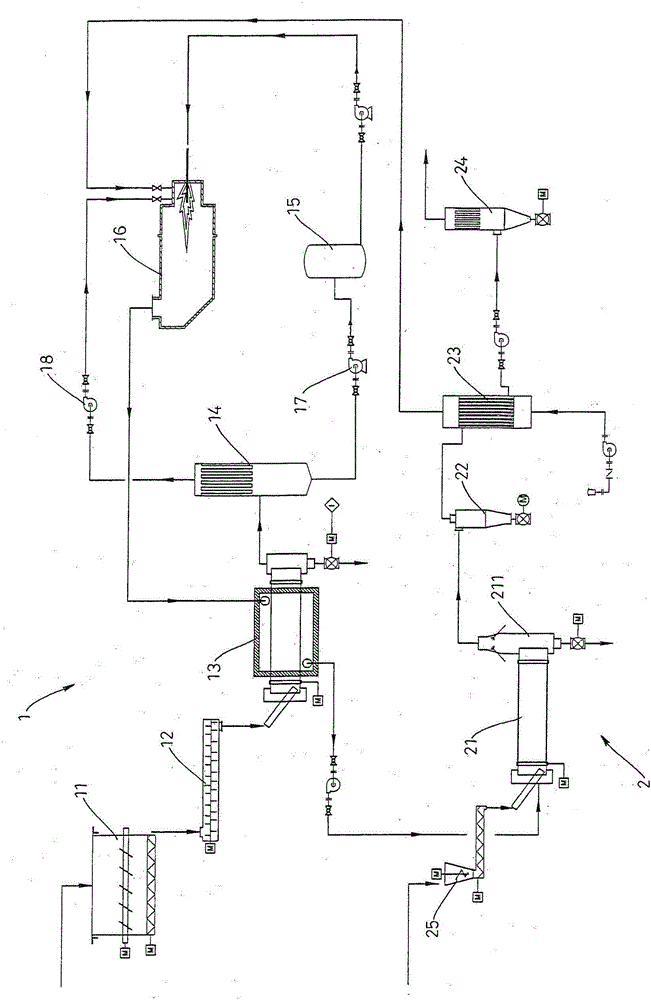

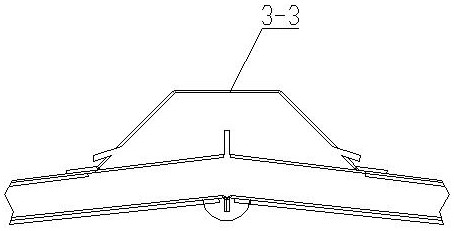

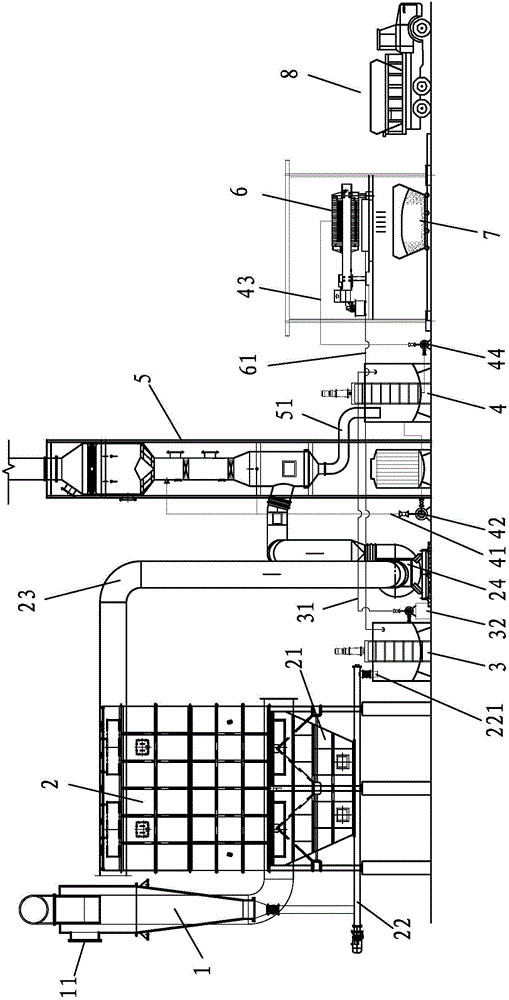

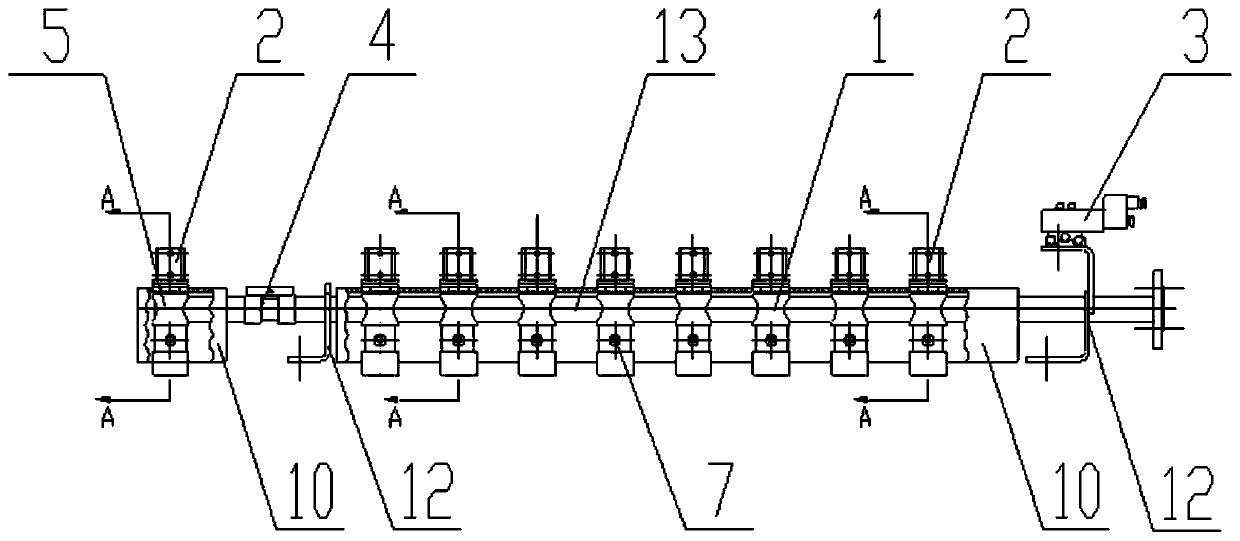

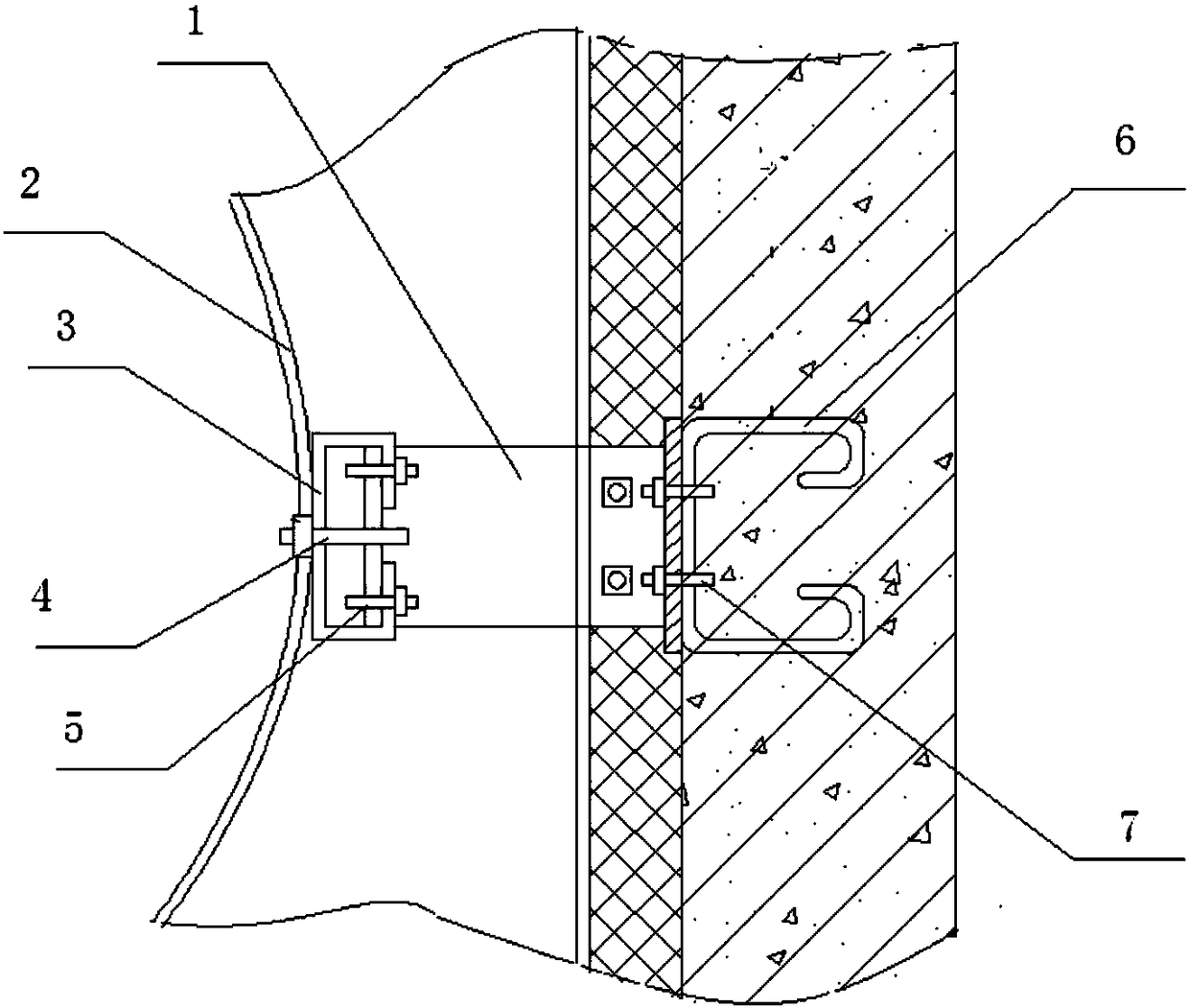

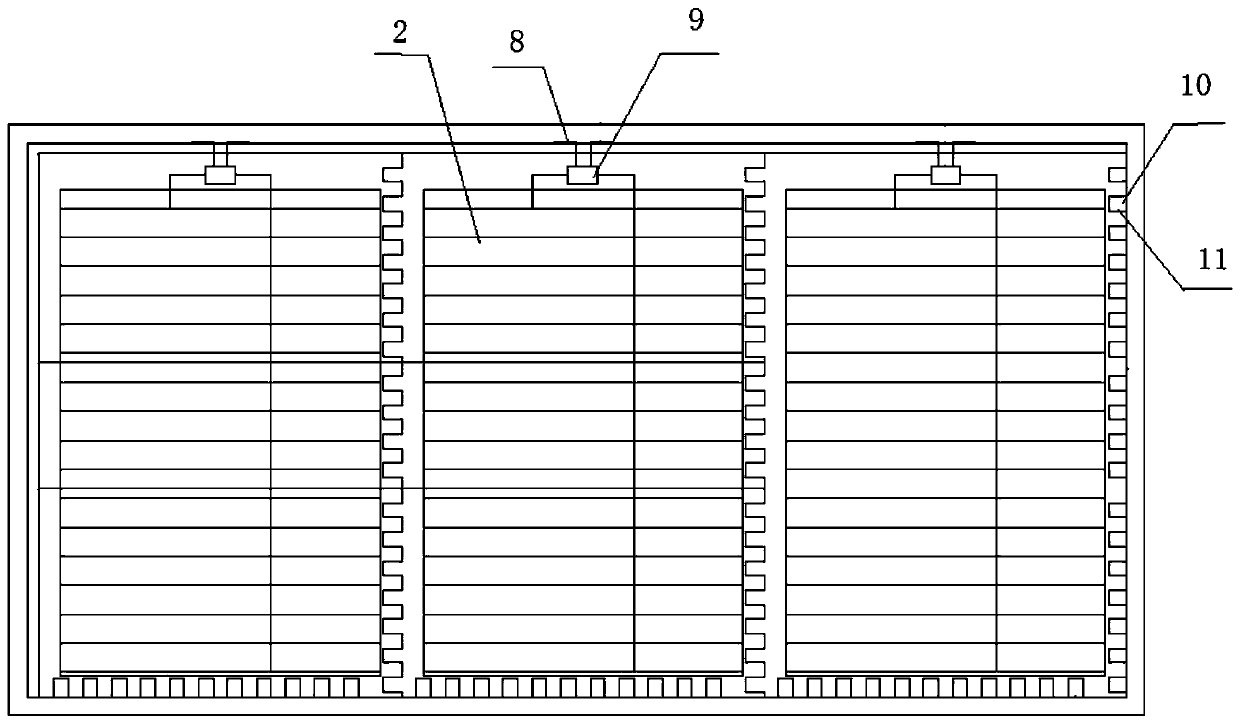

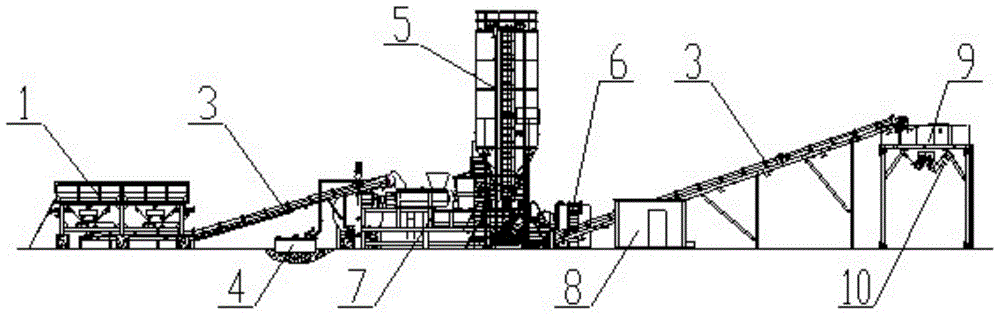

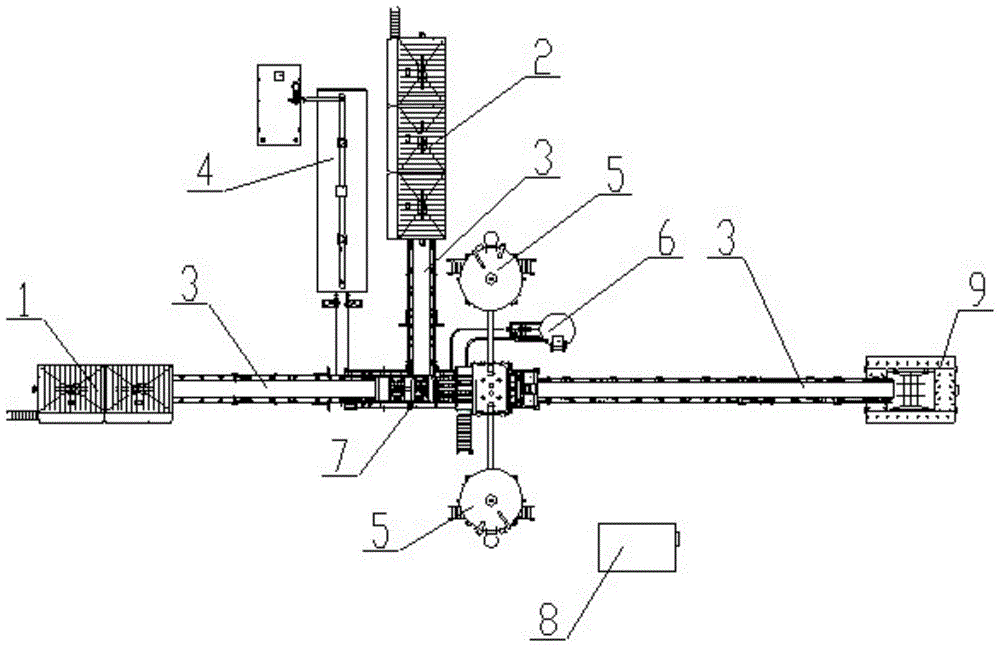

Feeding and blending technology and feeding and blending device for cold recycling of emulsified asphalt factory

ActiveCN103790093AMake full use of the valueUniform qualityRoads maintainenceRoad surfaceEngineering

The invention discloses a feeding and blending technology and a feeding and blending device for cold recycling of an emulsified asphalt factory. The stepped feeding and stepped blending technology is adopted, i.e. the technology comprises the steps of accurately gauging and matching new aggregate, feeding into a one-step stirring pot through a belt conveyor system, spraying a small quantity of water at a new aggregate inlet, pre-stirring, spraying a small quantity of emulsified asphalt, sufficiently blending, enabling the surface of the new aggregate to be packed with a small quantity of asphalt, adding asphalt pavement milling old material, cement and mineral powder, spraying water again, spraying the emulsified asphalt after pre-stirring again, and sufficiently blending, so that an emulsified asphalt regenerated finished material with characteristics of the paved asphalt pavement lower layer can be prepared. After the finished product material prepared by the construction technology and device for feeding and blending in a stepped way is used, the use value of the asphalt pavement milling old material can be sufficiently played, and the produced finished product material is stable in quality; when the material is used for paving roads, the road quality can be improved, and the service life of the roads can be prolonged.

Owner:XUZHOU XCMG MAINTENANCE MACHINERY CO LTD

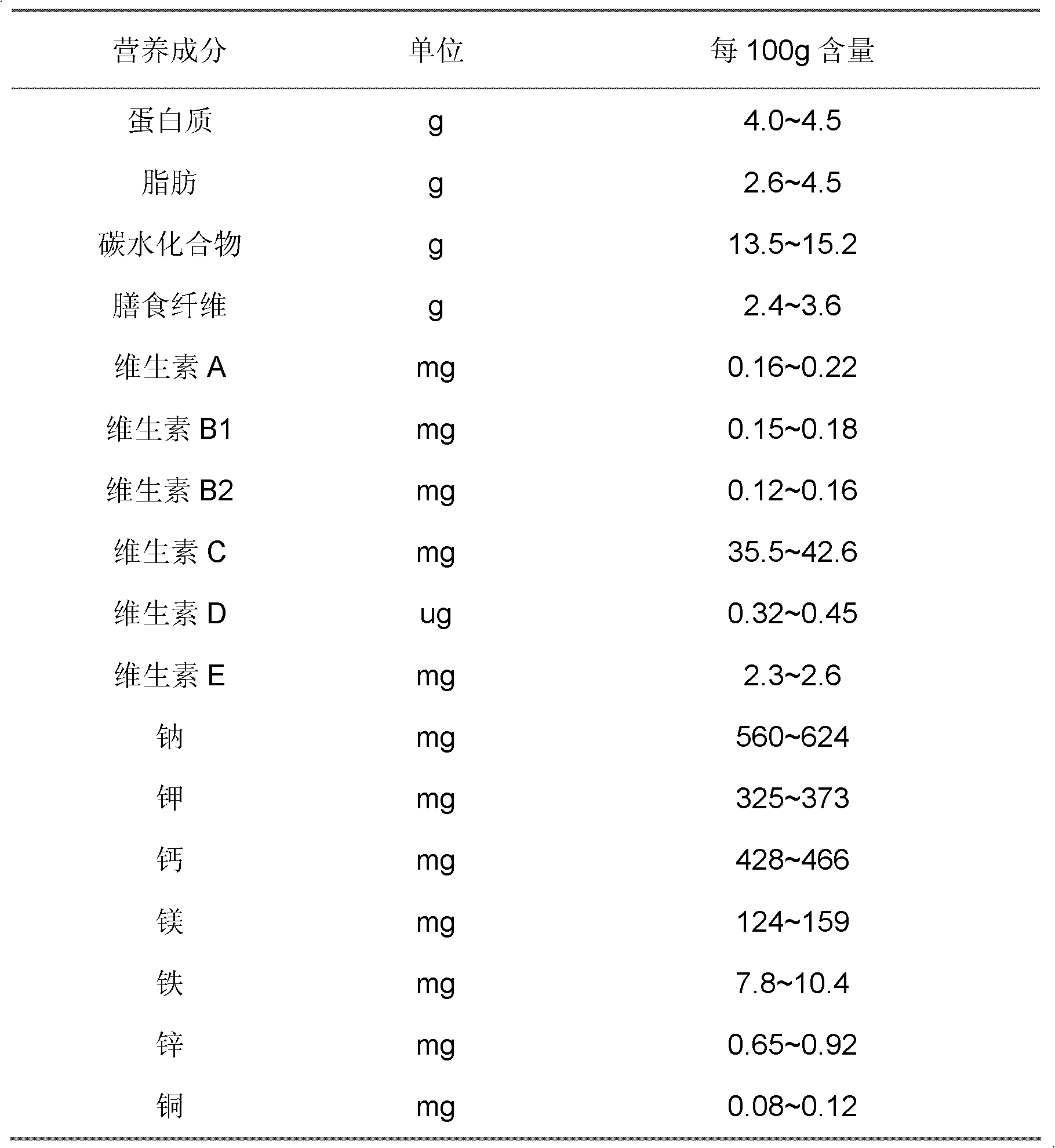

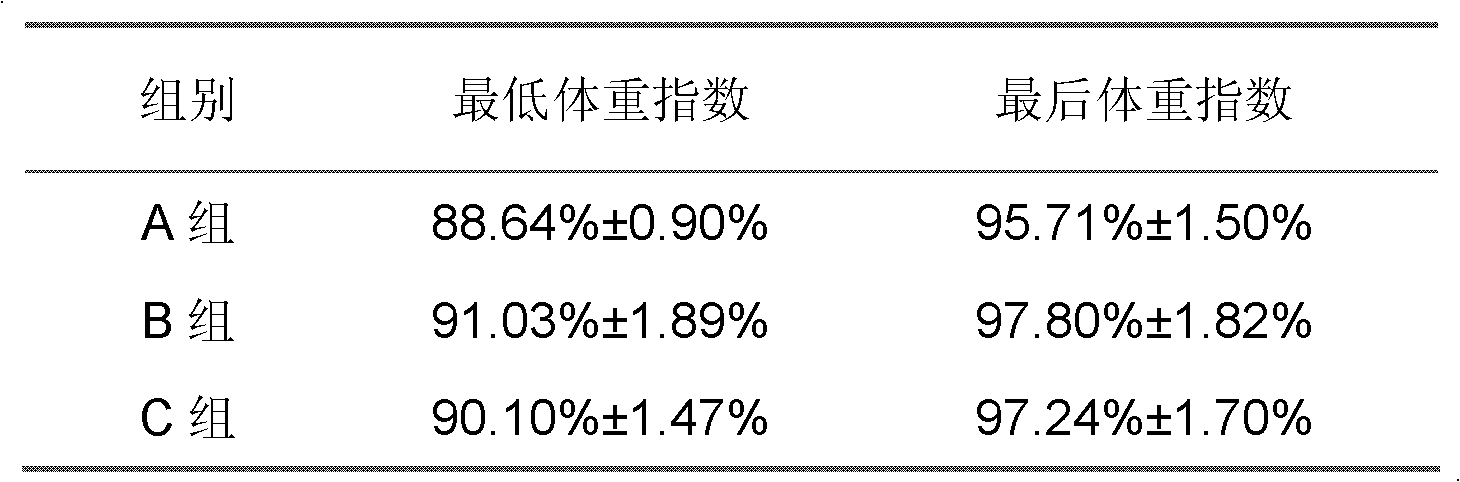

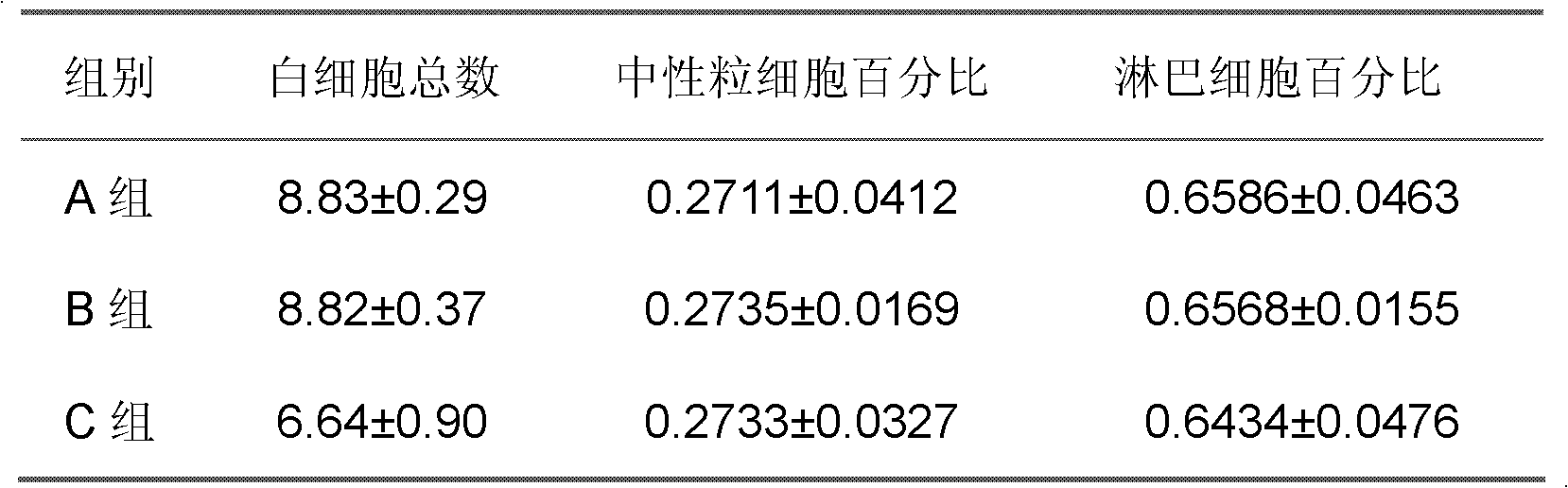

Salted egg white protein polypeptide containing enteral nutrition and preparation method thereof

InactiveCN102429149AHigh in nutrients and very comprehensiveRich in nutrientsFood preparationWater bathsAnimal science

The invention provides a salted egg white protein polypeptide containing enteral nutrition and a preparation method thereof, belonging to the field of nutritious foods. The enteral nutrition comprises the following components in percentage by mass: 2-5% of salted egg white protein polypeptide powder, 9-10% of fat, 15-20% of soy protein, 45-50% of maltodextrin, 5-10% of fruit and vegetable powder,2-5% of arginine, 7-12% of konjaku flour and 2-5% of oligosaccharide. The preparation method mainly comprises the following steps of: preparing salted egg white protein polypeptide powder, preparing salted egg white powder into an aqueous solution with pH of 7-9, heating for pretreating; adding protease, carrying out constant-temperature water bath enzymolysis on a condition of stable pH value; and finally, carrying out boiling water bath, cooling and centrifuging, treating supernate with activated carbon, and drying. The salted egg white protein polypeptide containing enteral nutrition provided by the invention has comprehensive nutrients, can be digested and absorbed easily, and can remarkably enhance immunity; the utilization value of salted egg white protein is realized completely. The effect of environment protection is realized and the processing cost of salted egg foods is reduced.

Owner:JILIN UNIV

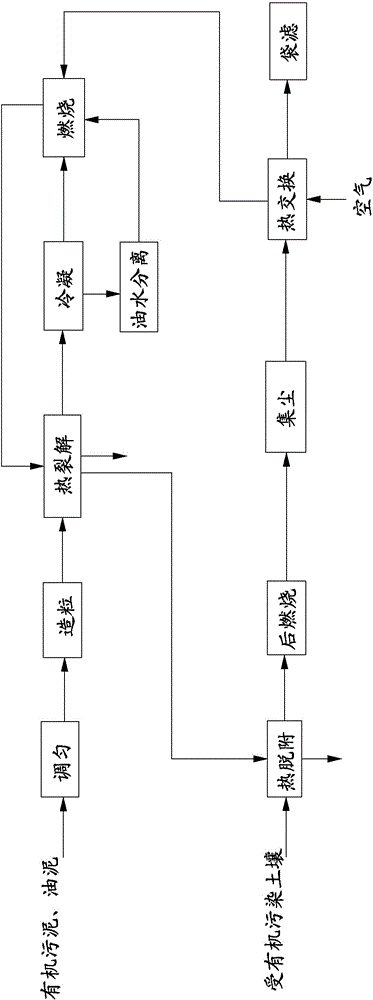

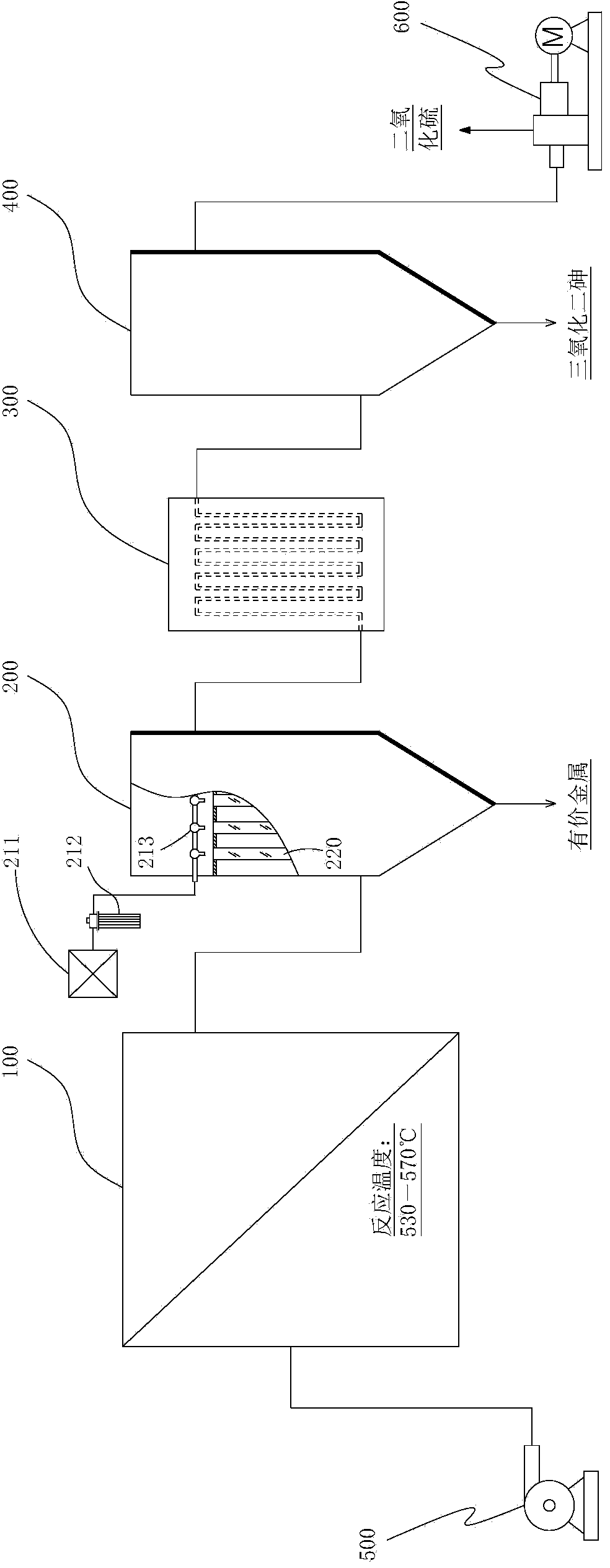

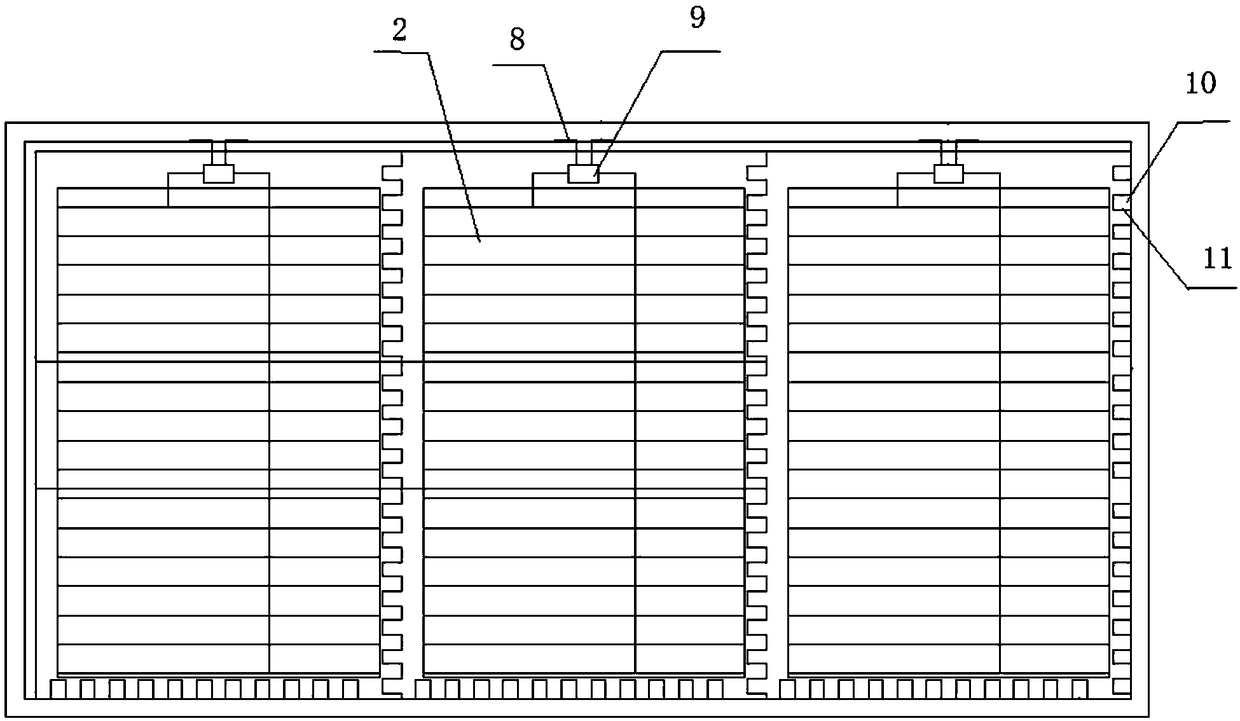

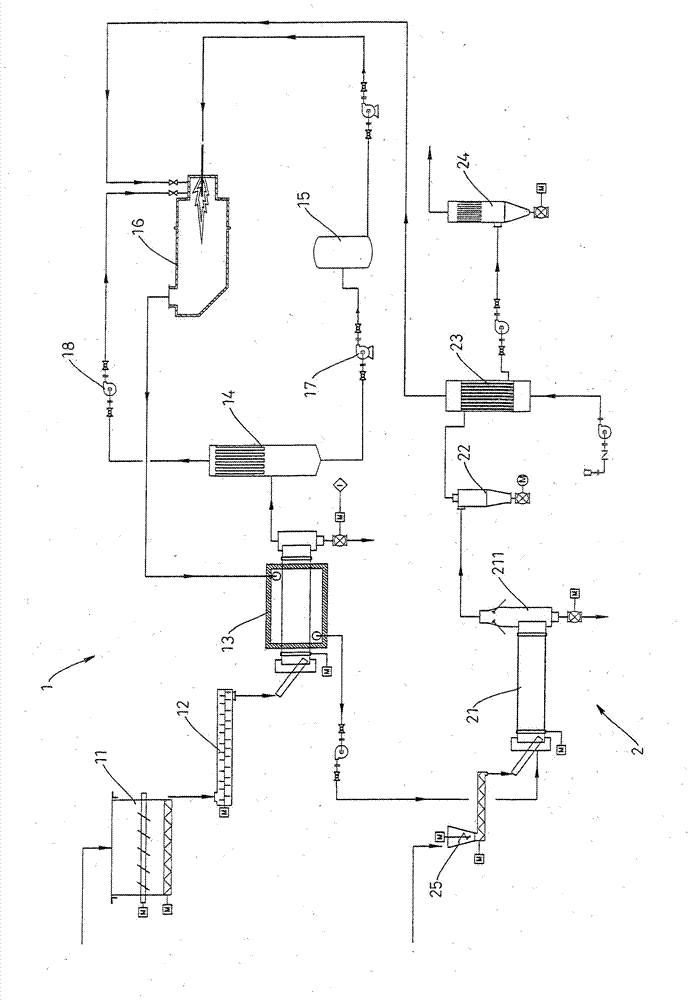

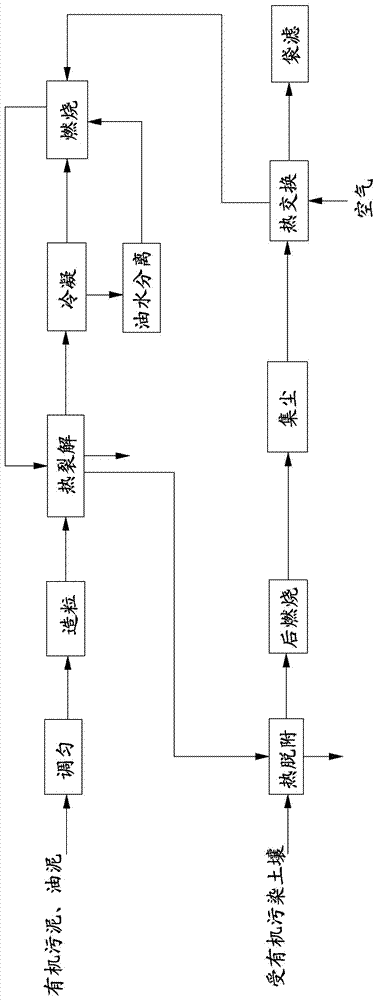

Oil mud cracking and polluted soil thermal desorption combination treatment system

ActiveCN105000767AImprove processing efficiencySave energySludge treatment by pyrolysisByproduct vaporizationAdditive ingredientPollution soil

The invention relates to an oil mud cracking and polluted soil thermal desorption combination treatment system, which comprises an oil mud thermal cracking treatment system and a polluted soil thermal desorption system. With the oil mud cracking and polluted soil thermal desorption combination treatment system of the present invention, the organic sludge and oil mud thermal cracking treatment and the organically-polluted soil thermal desorption treatment can be simultaneously performed, and the separated volatile organic ingredients are recovered and are subjected to combustion heating so as to be adopted as the heat source required by the thermal cracking reaction and the heat desorption reaction, such that the energy sources are effectively saved so as to reduce the treatment cost.

Owner:ENRESTEC

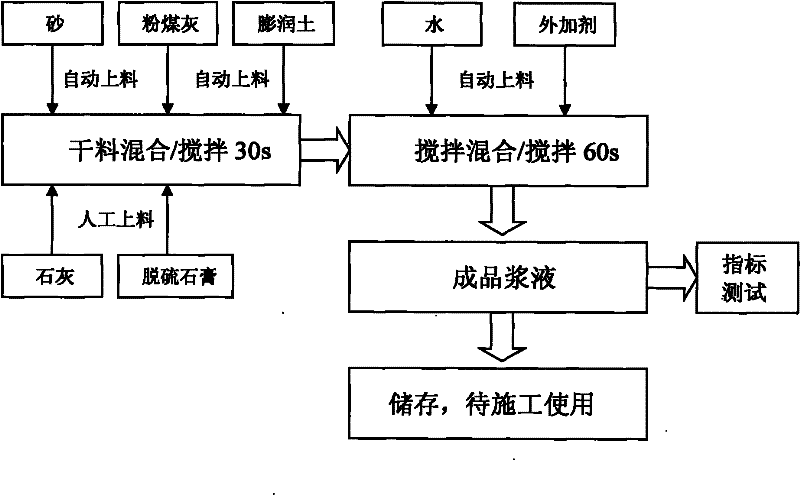

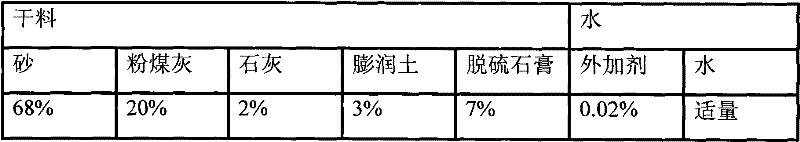

Synchronous grouting slurry for shield tunneling and preparation method thereof

InactiveCN102173699AAvoid adverse effectsReduce material costsSolid waste managementSpecific gravityIndustrial waste

The invention discloses synchronous grouting slurry for shield tunneling, which is prepared from materials including desulfurization gypsum generated in a smoke desulfurizing process of a thermal power plant. The slurry comprises the following dry material components in percentage by weight: 68 percent of sands, 20 percent of coal ash, 3 percent of bentonite, 2 percent of lime, and 7 percent of the desulfurization gypsum. The invention also provides a method for preparing the synchronous grouting slurry for field tunneling, which comprises the following steps of: weighing the sands, the coal ash, the bentonite, the lime and the desulfurization gypsum which form the dry materials; uniformly mixing and stirring the dry materials; adding proper water and additives; uniformly mixing and stirring; sampling an index of detection performance; and preparing to grout the finished product. By the method, industrial wastes of the thermal power plant are sufficiently utilized to achieve the effects of reducing slurry cost and reducing environmental pollution, the developing orientation of energy conservation and emission reduction is fulfilled, and the slurry has the advantages of high proportion, low denseness, high shearing resistance, good flow filling performance, improved later strength of slurry and the like and can be used as synchronous grouting slurry for shield tunneling.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD. +1

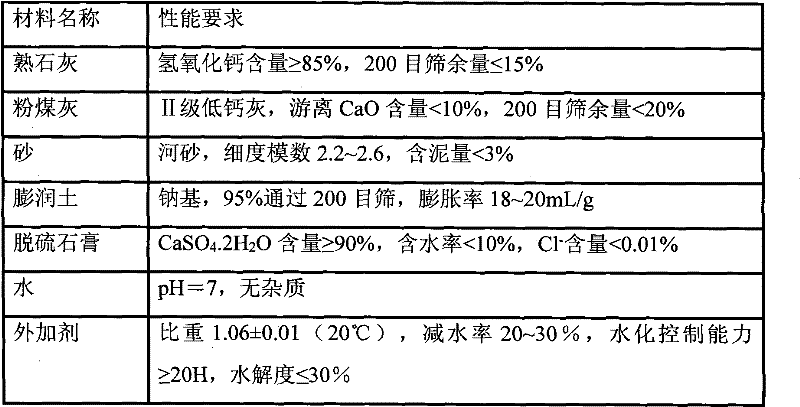

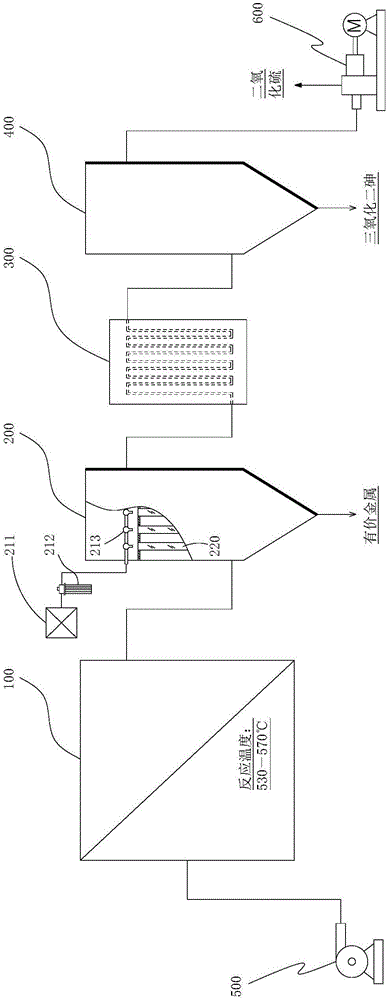

Treatment method for phosphoric acid arsenic-removed slag

The invention discloses a treatment method for phosphoric acid arsenic-removed slag, which can effectively separate and recycle arsenic and other valued metal of the phosphoric acid arsenic-removed slag. The method comprises the following steps: 1) adding the phosphoric acid arsenic-removed slag into an industrial kiln and feeding oxygen-containing gas to perform oxidizing roasting, wherein the reaction temperature is controlled to be 530 to 570 DEG C; 2) conveying high-temperature dust-containing kiln gas which contains As2O3 and SO2 and is generated in the reaction process, into a first flue gas filter, and collecting arsenic-removed valued metal-enriched dust, wherein the first flue gas filter adopts a high-temperature sintering resistant inorganic porous material filter element and the dust content of the kiln gas purified by the first flue gas filter is below 10 to 20 mg / m<3>; 3) conveying the kiln gas purified by the first flue gas filter into a dividing wall type heat exchanger to enable the temperature of the kiln gas to be reduced to be below 150 DEG C; and 4) conveying the kiln gas at the outlet of the dividing wall type heat exchanger into a second flue gas filter, and collecting As2O3-enriched dust, wherein the dust content of the kiln gas purified by the second flue gas filter is below 10 to 20 mg / m<3>.

Owner:CHENGDU INTERMENT TECH

Technology and system for removing dust and sulfur by using coal ash

InactiveCN103599691AAchieve emission standardsAchieve recyclingSolid waste disposalDispersed particle separationChemical reactionSurface-active agents

The invention discloses a technology for removing dust and sulfur by using coal ash. The technology mainly comprises the following steps: (1) leading flue gas with the coal ash, which is generated after burning, into a cyclone dust collector, wherein the coal ash mainly comprises glass bead bodies, spongy porous particles and calcium oxide powder; (2) separating the glass bead bodies and the spongy porous particles adsorbing SO2, which are contained in the flue gas, from the flue gas by using the cyclone dust collector; and (3) feeding the flue gas sent out from the cyclone dust collector into a desulfurizing tower, so that the flue gas and a water circulating liquid containing a surface active agent are subjected to physical and chemical reactions so as to realize the removal of sulfur in the flue gas. The system for removing dust and sulfur by using coal ash comprises the cyclone dust collector, the desulfurizing tower and a circulating pool. The removal of sulfur in the flue gas is realized by using activating oxides contained in the flue gas through the related physical and chemical reactions, so that the up-to-standard release of the treated clean flue gas is realized. The whole technological process is concise, extremely reasonable and optimal; and the desulfurized coal ash can be reused, so that the comprehensive cyclic utilization of the coal ash is realized, and the utility value of the coal ash is fully exerted.

Owner:JINJIANG MEICHUANG ENVIRONMENTAL PROTECTION EQUIP

Preparation method for preparing chitosan by utilizing snow crab shells

ActiveCN111138563AMake full use of the valueAvoid the three wastesOrganic compound preparationCarboxylic acid salt preparationEnvironmental engineeringCitric acid

A preparation method for preparing chitosan by utilizing snow crab shells relates to the technical field of preparation methods of high-viscosity chitosan, and particularly belongs to a preparation method for preparing chitosan by utilizing fresh snow crab shells. Crab shell pretreatment: taking 200 parts (by mass) of fresh snow crab shells, and crushing the fresh snow crab shells; decalcifying the crab shells: adding 600-1000 parts by mass of a citric acid solution with the mass percent concentration of 5-10% into the crab shells, soaking for 6-15 hours, filtering, washing the crab shells obtained by filtering by using water as a washing solution, and combining washing residual liquid with a filtrate to obtain a mixture for storage; extracting organic calcium: filtering the mixture through a plate frame, and drying filter residues to obtain calcium citrate; and collecting the residual mixed solution for later use after subsequent treatment. Three wastes are avoided in the whole production process, and zero waste, zero emission and high-value utilization are realized. A high-temperature strong-alkali deproteinization procedure is not needed, so that energy conservation, environmental protection and stable product quality are realized. The product has high viscosity and good quality.

Owner:SHANDONG MEIJIA GROUP

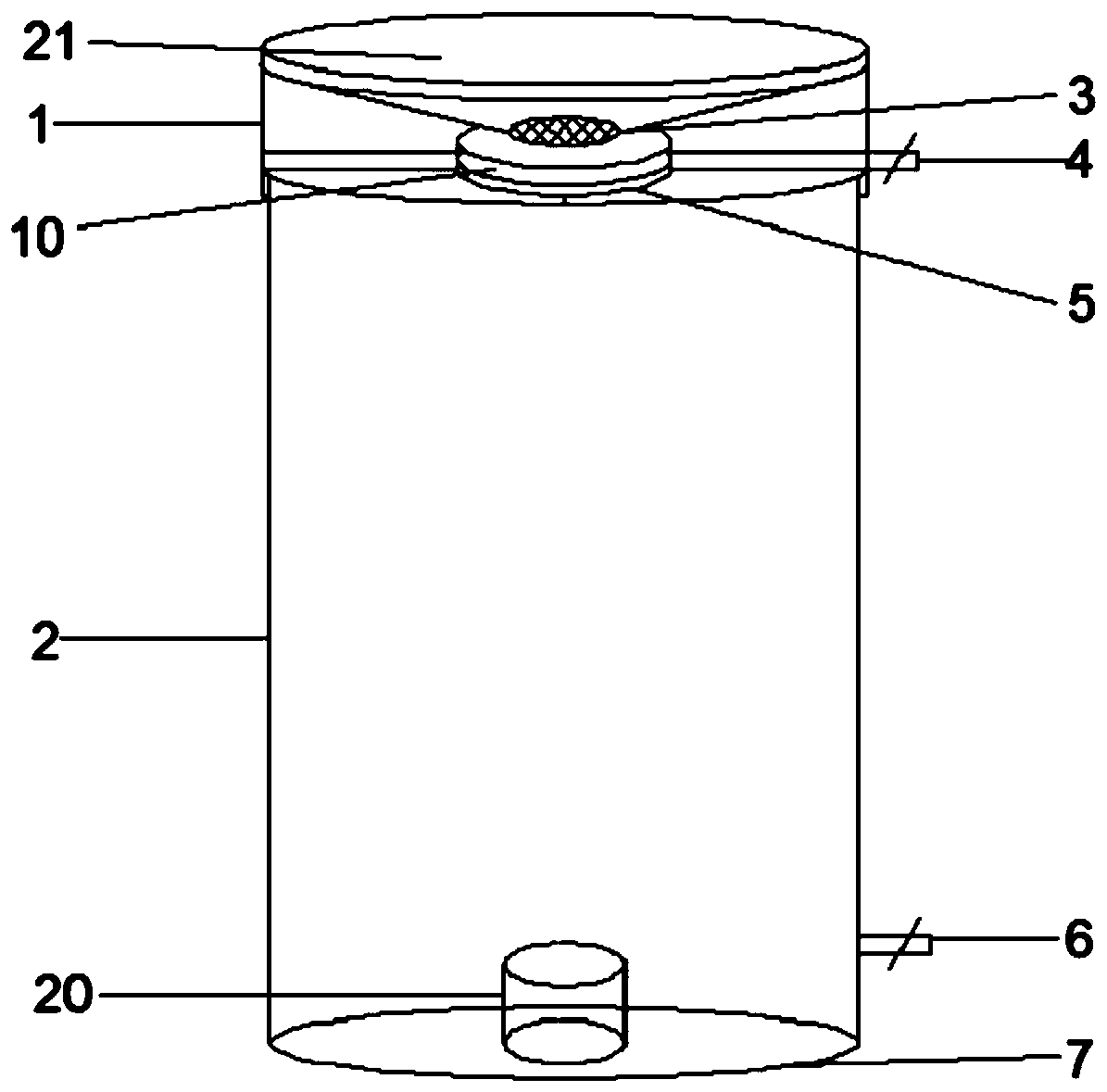

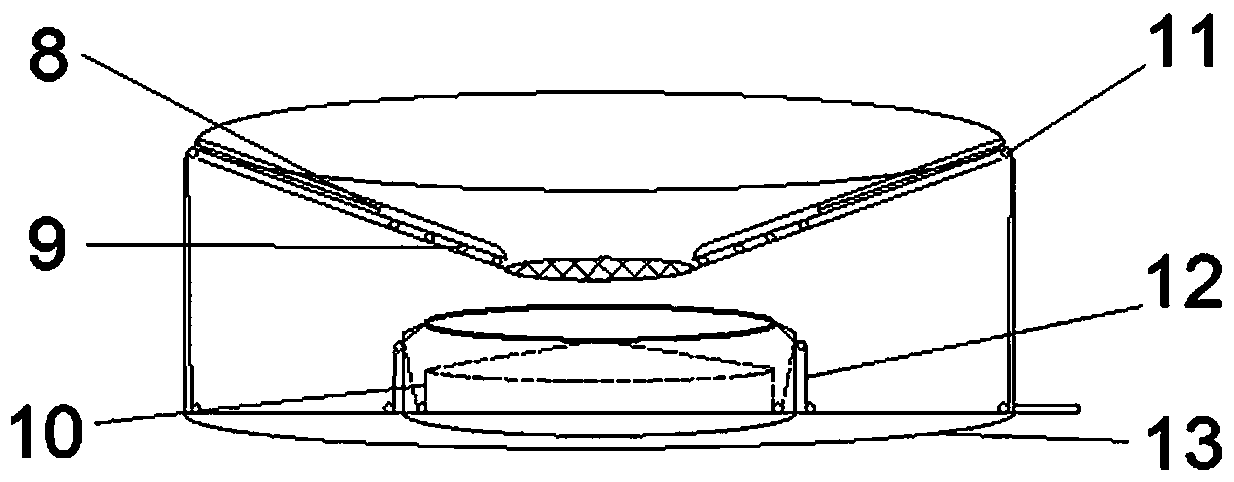

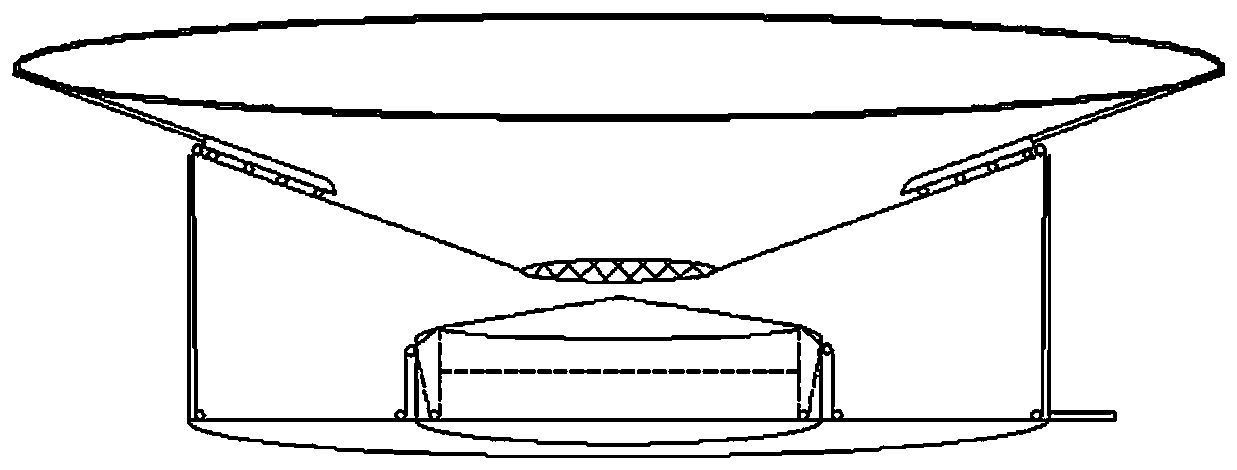

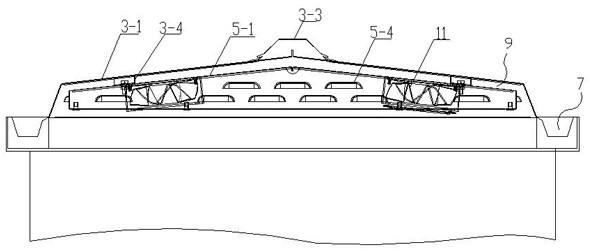

Rainwater collecting bucket device and rainwater collecting method

PendingCN108222123AMake full use of the valueEasy to assembleGeneral water supply conservationDrinking water installationRainwater harvestingEngineering

The invention discloses a rainwater collecting bucket device. The device is characterized in that a rainwater bucket cover comprises a rainwater collecting plate, a first rainwater collector and a first rainwater drain outlet; the rainwater collecting plate is fixed to the top of the rainwater bucket cover, and a rainwater filer opening is formed in the rainwater collecting plate; the first rainwater collector is located on the lower portion of the rainwater collecting plate, an opening is formed in the top of the first rainwater collector, a conical floating block is arranged in the first rainwater collector, a linkage is arranged between the conical floating block and the rainwater collecting plate, and the rainwater collecting area of the rainwater collecting plate changes along with the height of the conical floating block; the first rainwater drain outlet is formed in the side wall of the rainwater bucket cover, and the first rainwater collector is connected to the first rainwaterdrain outlet through a first rainwater drain slim tube. Accordingly, by means of the modular detachable structure, assembling, disassembling and cleaning are facilitated; polluted first rainwater isrejected, a larger area of rainwater is collected, the rainwater use value is fully played, other power input is not needed, energy conservation and discharge reduction are achieved, and the landscapeeffect is achieved.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Green energy-saving split mounting type roof

InactiveCN111794453AExtended service lifeImprove ventilationRoof covering using slabs/sheetsBatteries circuit arrangementsThermodynamicsCooling effect

The invention relates to an assembled roof, and particularly relates to a green energy-saving split mounting type roof. The green energy-saving split mounting type roof comprises a roof bearing structure, roof split mounting plates, a rainwater collecting unit and a top cover ventilation unit; the roof split mounting plates are laid on the upper surface of the roof bearing structure; the top coverventilation unit covers the upper part of the roof bearing structure; the top cover ventilation unit comprises an outer top cover and an inner top cover, and the inner top cover is arranged below theouter top cover; solar power generation panels are movably mounted on the outer surface of the outer top cover; and the rainwater collecting unit is laid on the periphery of the outer edge of the topcover ventilation unit. The roof is assembled, the construction time is short, operation is convenient and fast, and practicability is high; the roof is simple in structure, overhead and ventilation,has a better cooling effect than a solid material heat insulation roof, can insulate heat in the daytime and is easy to dissipate heat at night, the problem of low utilization rate of natural energyis solved, and the purposes of greenness and energy conservation are achieved.

Owner:河北地质大学

Wet desulphurization technology and system using coal ash

InactiveCN103599688AAchieve recyclingMake full use of the valueCombination devicesSulfur dioxideFlue gas

The invention discloses a wet desulphurization technology and system using coal ash. The wet desulphurization technology using coal ash mainly comprises the following steps: (1) collecting superfine coal ash in flue gas which is generated after boiler combustion, and conveying the collected superfine coal ash to a liquid preparation tank; (2) fully reacting activating oxides in the superfine coal ash with a certain proportion of water in the liquid preparation tank so as to obtain an alkaline solution; (3) conveying the alkaline solution to a desulphurization circulating pool; and (4) enabling the alkaline solution in the desulphurization circulating pool to circularly flow between a desulphurization tower and the desulphurization circulating pool so as to realize the removal of sulfur in the flue gas. The wet desulphurization system using coal ash comprises a dust collector, the liquid preparation tank, the desulphurization circulating pool and the desulphurization tower. According to the technology and the system, the removal of sulfur in the flue gas is realized by directly using the activating oxides contained in the coal ash. The desulfurized coal ash solid liquid generated after desulphurization can be reused, so that the comprehensive cyclic utilization of the coal ash is realized, and the utility value of the coal ash is fully exerted; and the wet desulphurization technology and system using the coal ash are particularly suitable for the removal of sulfur of sulfur dioxide in flue gas of small and medium-sized industrial pulverized coal boilers with the raw coal sulfur content of below 1.0%.

Owner:JINJIANG MEICHUANG ENVIRONMENTAL PROTECTION EQUIP

Piping exchange station used for oil depot tank field cargo access system

ActiveCN103552971AMake full use of the valueImprove work efficiencyLiquid transferring devicesControl valvesOil terminal

The invention relates to a piping exchange station used for an oil depot tank field cargo access system. The piping exchange station comprises a base body, wherein a loading and unloading boat control valve, a storage tank control valve, a cargo delivery control valve and a cargo delivery pipeline control valve are arranged on the base body. The piping exchange station has the advantages that the free combination can be realized according to the in-site requirements for realizing cargo access operation, the work efficiency is greatly improved, and the utilization value of pipelines and equipment stored in a depot region can be sufficiently realized.

Owner:江苏丽天石化码头有限公司

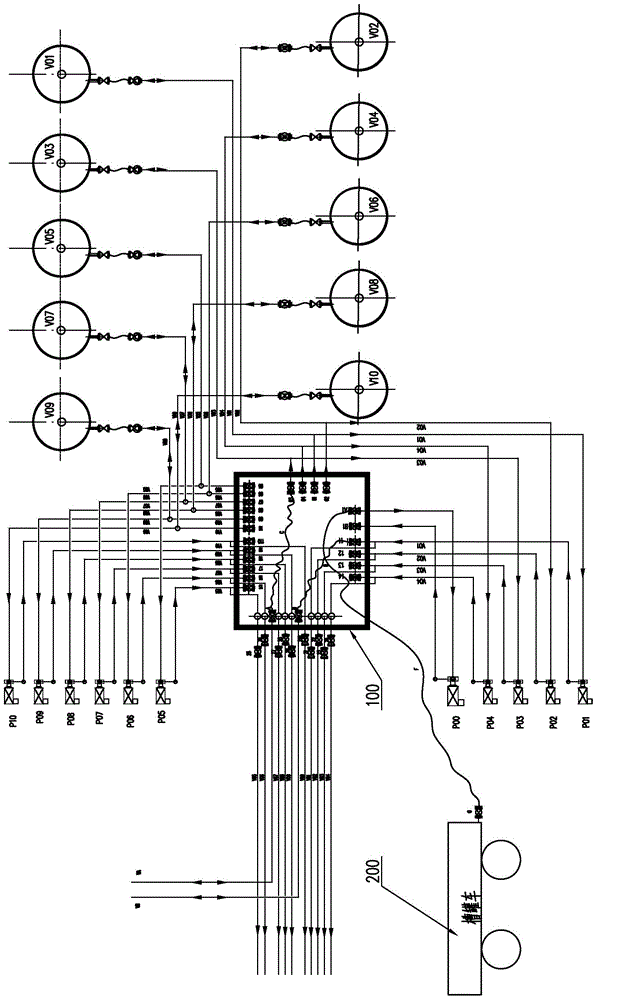

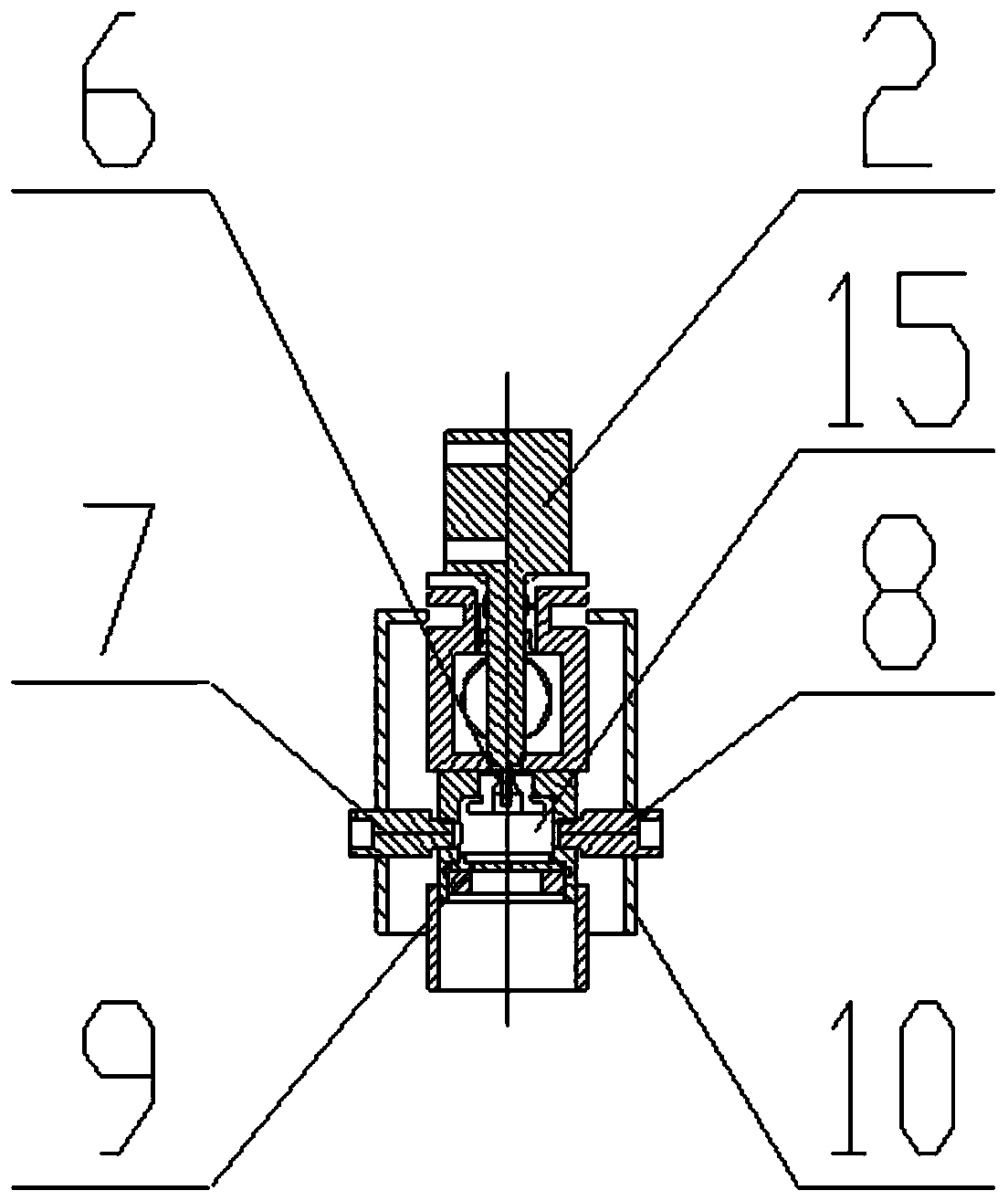

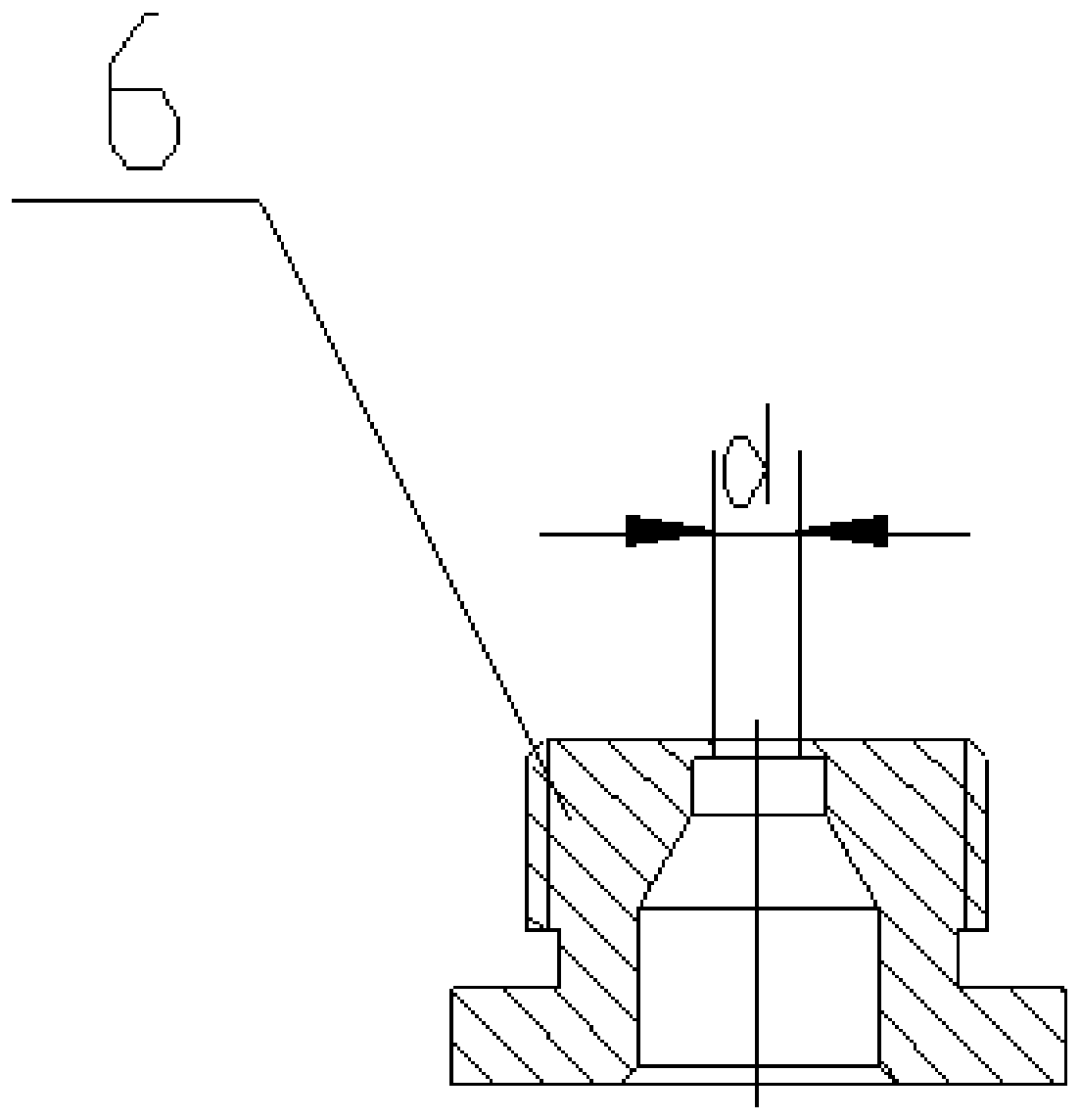

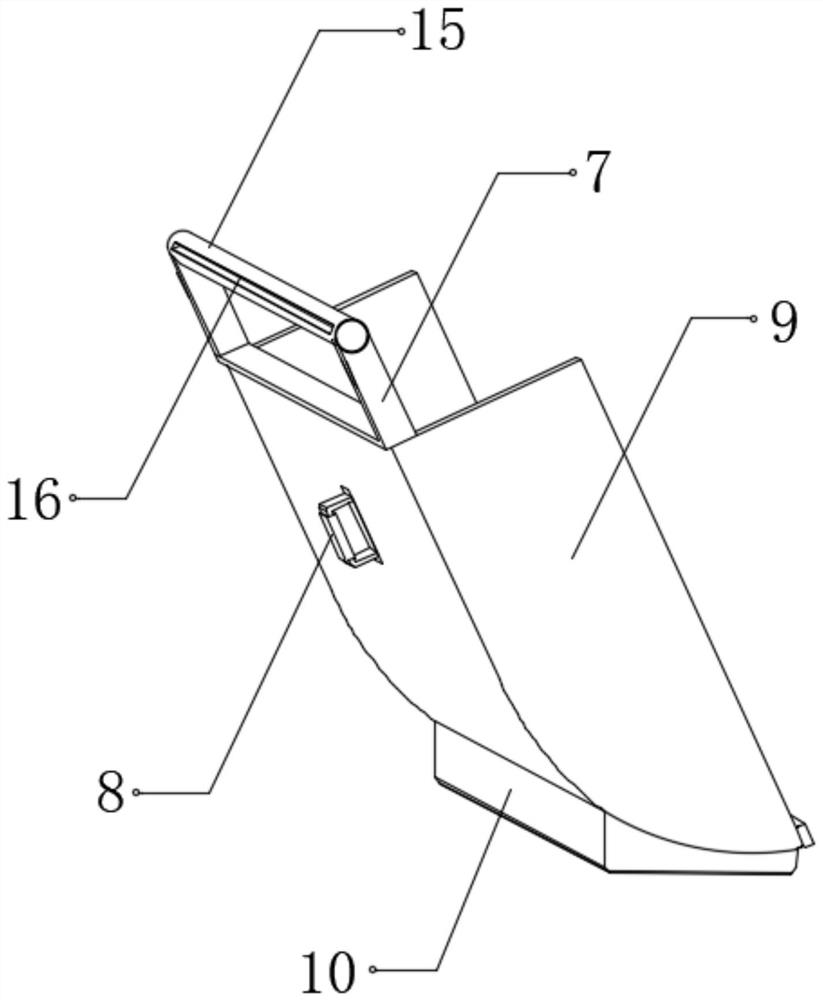

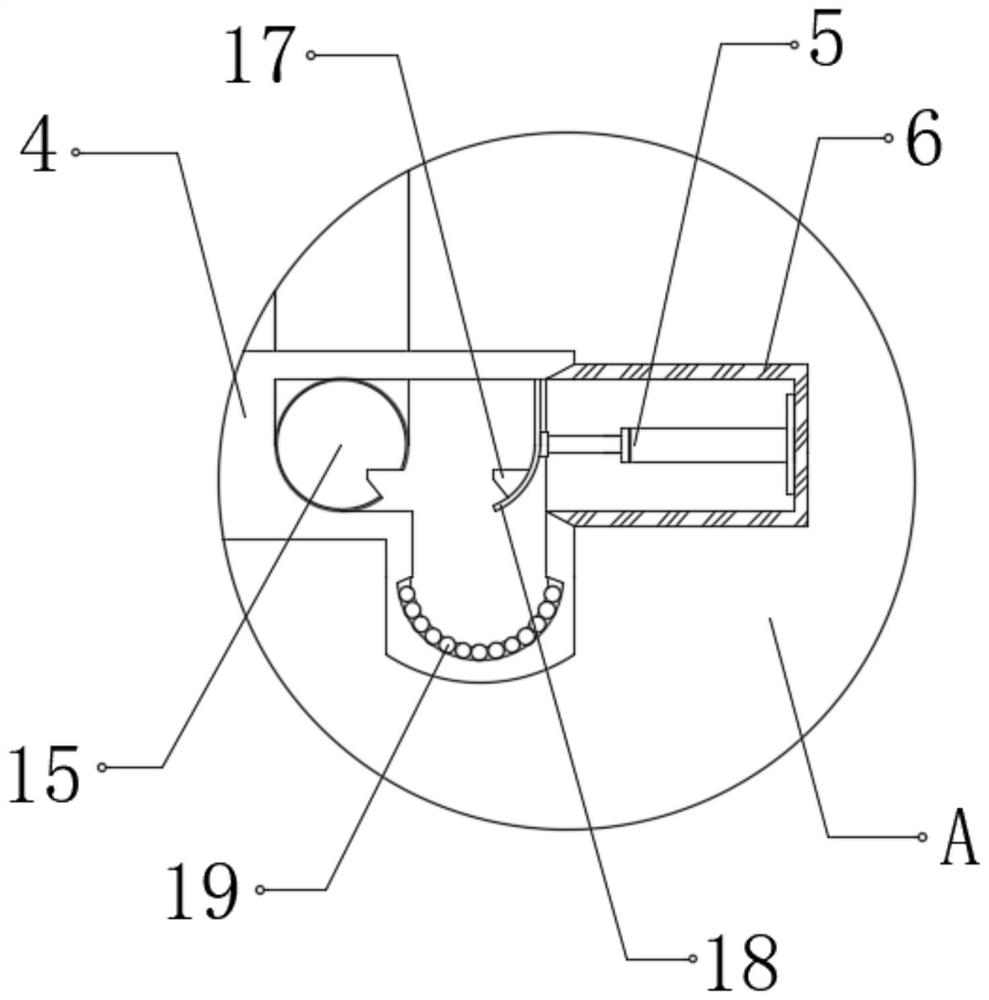

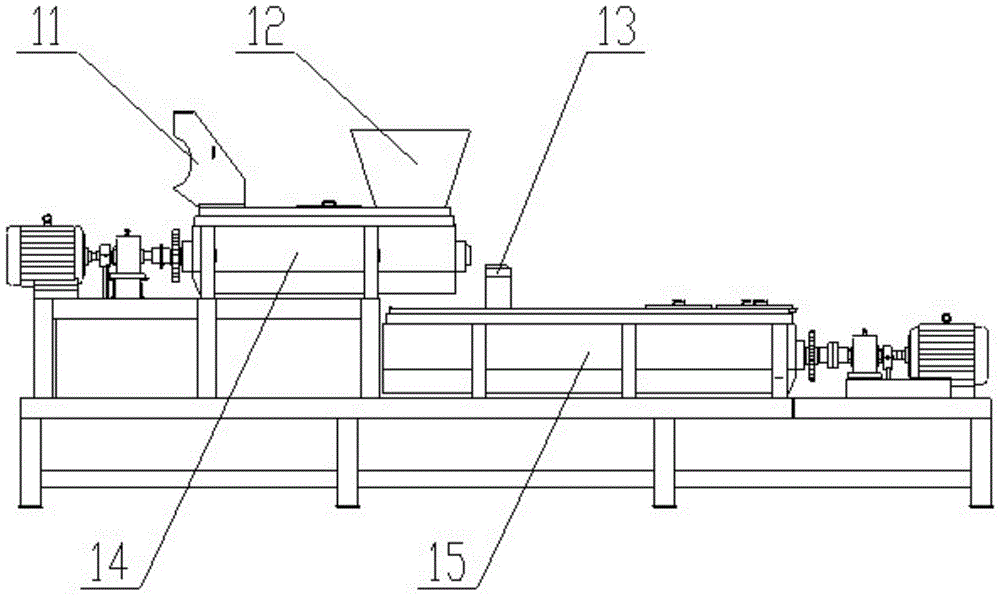

Foamed asphalt integrated foaming beam for foamed asphalt cold-recycling plant mixing equipment

PendingCN111576142AFinished material quality is stableImprove road qualityRoads maintainenceProcess engineeringAsphalt

The invention discloses a foamed asphalt integrated foaming beam for foamed asphalt cold-recycling plant mixing equipment. The beam comprises a foamed asphalt spraying beam connected with an asphalt conveying pipeline, and a plurality of asphalt foaming devices are equidistantly and uniformly distributed on the foamed asphalt spraying beam; an inlet end of a matrix hot asphalt nozzle is connectedwith the foamed asphalt spraying beam, and an outlet end of the matrix hot asphalt nozzle is connected with a top end of the asphalt foaming cavity; a gas nozzle and a water nozzle are arranged on a group of opposite side surfaces of the asphalt foaming cavity; a foamed asphalt nozzle is arranged at a bottom end of the asphalt foaming cavity; an air cylinder is arranged on the asphalt foaming device; the output end of the air cylinder is contacted with the matrix hot asphalt nozzle; and the air cylinder, the air nozzle and the water nozzle are connected with an electromagnetic valve. The air cylinder timely switches on and switches off asphalt, and the foaming cavity with a high-pressure air and high-pressure water opposite blowing function effectively forms foamed asphalt. And the asphaltfoaming device continuously sprays foamed asphalt into a stirrer and fully stirs the foamed asphalt with a cold-wet premixed mixture to form a high-quality cold-mixed foamed asphalt mixture.

Owner:XUZHOU XCMG MAINTENANCE MACHINERY CO LTD

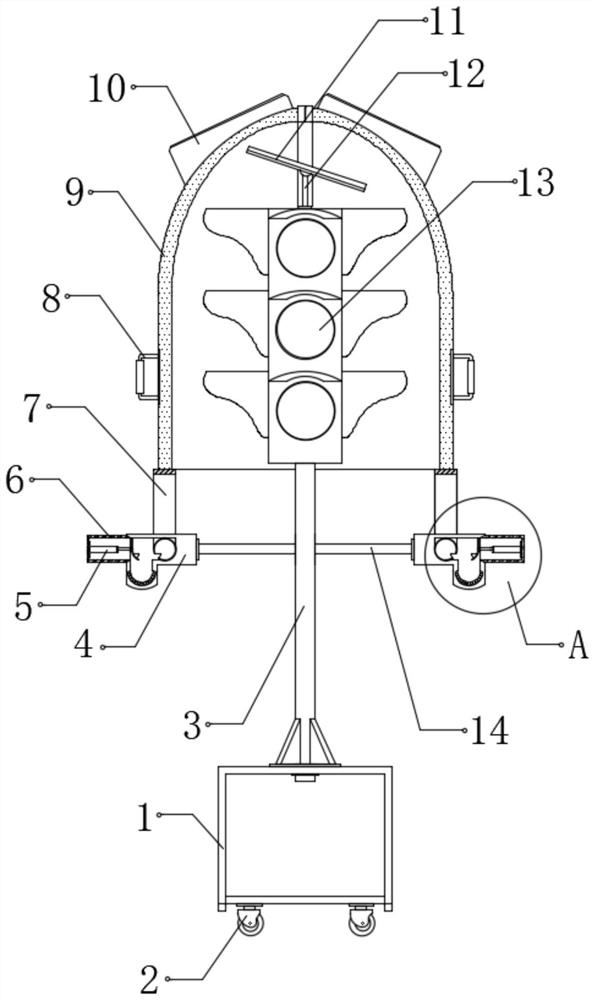

Mobile signal lamp

InactiveCN111785054AMake full use of the valueAvoid damageRoad vehicles traffic controlMechanical engineeringSignal lamp

The invention discloses a mobile signal lamp that comprises a case, universal wheels and a signal lamp; the four universal wheels are installed at the bottom of the case in a rectangular shape; the signal lamp is arranged above the case, the middle position of the top of the case is connected with a lamp pole through a bolt, the signal lamp is fixedly connected to the top of the lamp pole, connecting rods are welded to the two sides of the top of the lamp pole, clamping grooves are fixedly connected to the ends, away from each other, of the two connecting rods, and the clamping grooves are arranged to be in an L shape. In use, two shields close, the positioning mechanism is used for positioning the shield and the rotating shaft, the signal lamp in the shield is prevented from being damagedby accidental collision; during use, the push rod motor drives the clamping plate to retract into the box body and the rotating shaft to slide into the bottom of the clamping groove, and the shield is turned over, so that the bottom of the shield touches the ground to support and reinforce the signal lamp, the utilization value of the shield is brought into full play, and normal work of the signal lamp is not affected.

Owner:周天健

Waste kitchen grease absorption liquid for VOC waste gas treatment, and absorption method and separation and recovery method thereof

InactiveCN111151098AHigh boiling pointChemically stableGas treatmentDispersed particle separationExhaust fumesEnvironmental engineering

The invention belongs to the technical field of VOC waste gas treatment, and particularly relates to a waste kitchen grease absorption liquid for VOC waste gas treatment, and an absorption method anda separation and recovery method thereof. The waste kitchen grease absorption liquid comprises, by mass, 20-50% of waste kitchen grease, 40-75% of white oil and 4-12% of calcium chloride. The absorption method comprises the following steps: introducing air containing VOC waste gas into the waste kitchen grease absorption liquid, continuously stirring, and carrying out ultrasonic oscillation. The separation and recovery method is characterized in that the waste kitchen grease absorption liquid absorbing the VOC waste gas for more than 24 h is subjected to vacuum condensation. The waste kitchengrease absorption liquid provided by the invention is low in viscosity, good in absorption effect, high in practicability, low in cost, easy to separate and recover, recyclable, not prone to catchingfire, simple to operate, safe to use and suitable for large-scale application of VOC waste gas treatment.

Owner:义乌韦陀环保科技有限公司

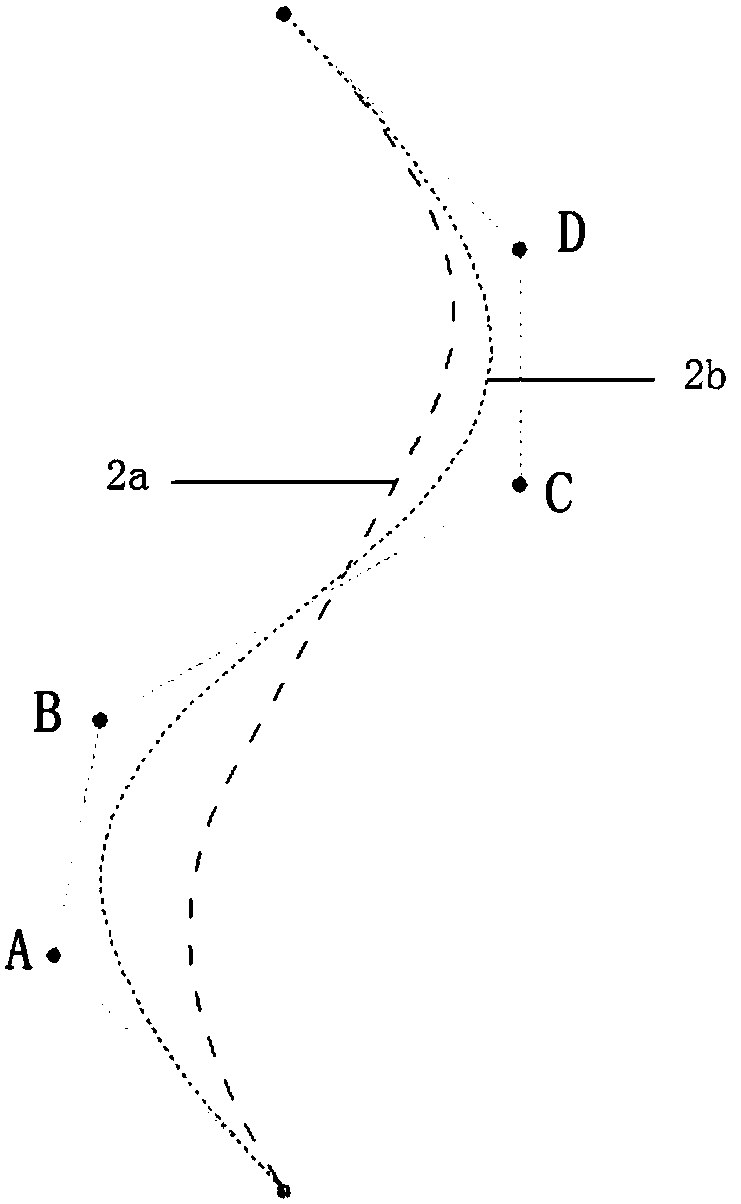

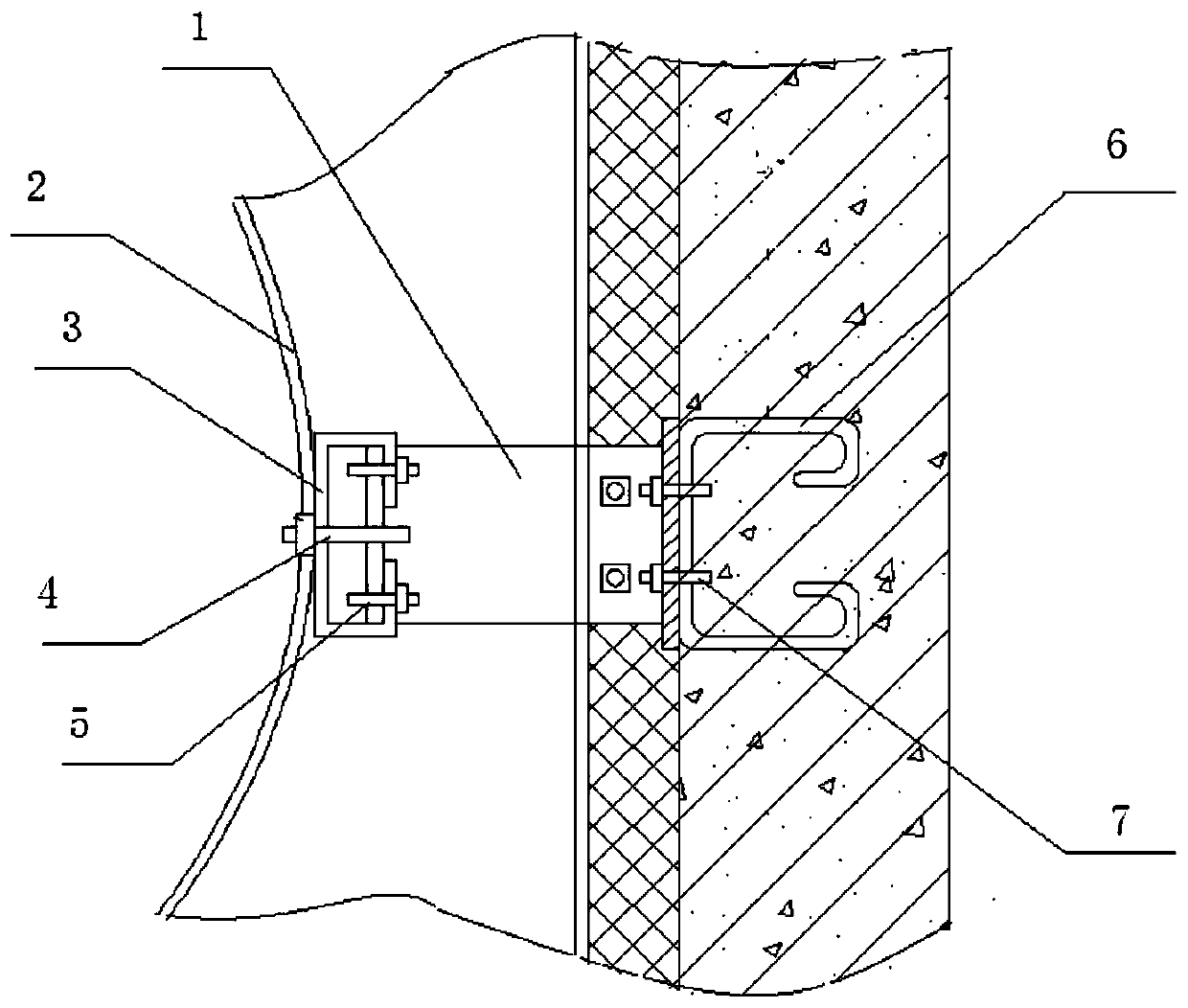

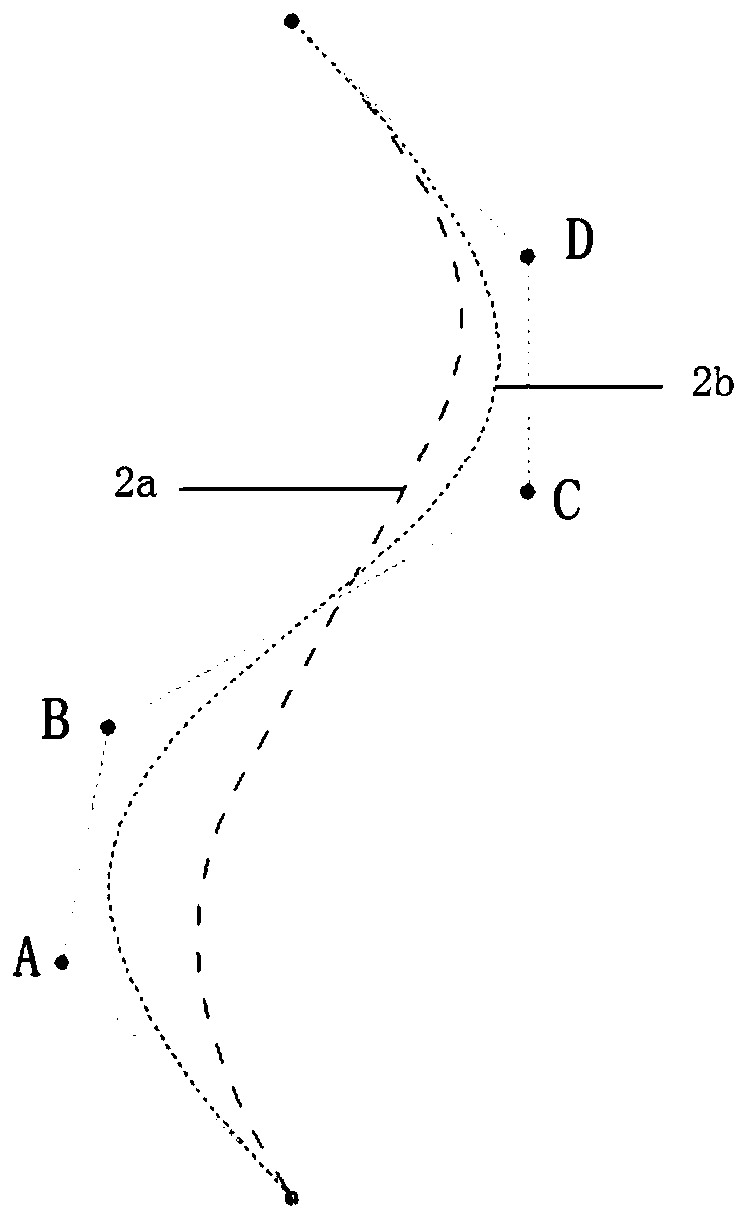

Manufacture method of curved surface film photovoltaic building surface and adopted surface module

ActiveCN108322146AReduce the difficulty of on-site installationImprove construction efficiencyPhotovoltaic supportsClimate change adaptationSheet filmEngineering

The invention discloses a manufacture method of a curved surface film photovoltaic building surface and an adopted surface module, and aims at providing a manufacture method capable of reducing the construction difficulty and improving the construction efficiency and a surface module. The manufacture method comprises the following steps: designing an initial curved surface model; performing optimization design by taking the maximum solar irradiation absorbing amount as a target, so as to obtain an optimized curved surface model; dividing the optimized curved surface into a plurality of modules; printing a hard curved surface back plate according to a 3D printing technology according to patterns of divided modules, and sequentially overlapping and fixing a first flexible film clamping piece, a flexible film solar cell, a second flexible film clamping piece and a flexible waterproof transparent plastic film on the printed hard curved surface back plate, and packaging an edge; performingsite mounting on each finished product surface module; finally splicing adjacent modules, so as to accomplish the construction of a complete building surface facade. The method greatly reduces the site mounting difficulty, and improves the construction efficiency.

Owner:TIANJIN UNIV

Combination treatment system of oil sludge cracking and thermal desorption of polluted soil

ActiveCN105000767BImprove processing efficiencySave energySludge treatment by pyrolysisByproduct vaporizationCombustionAdditive ingredient

A combined treatment system for oil sludge cracking and thermal desorption of polluted soil, comprising: an oil sludge thermal cracking treatment system and a polluted soil thermal desorption treatment system. By this, thermal cracking treatment of organic sludge and oil sludge and thermal desorption treatment of organically polluted soil can be carried out at the same time, and the volatile organic components separated from them can be recovered, heated by combustion, and provided as thermal cracking reaction and heat The heat source required for the desorption reaction can effectively save energy, thereby reducing the treatment cost.

Owner:ENRESTEC

Organic agent for disinfecting banana continuous cropping obstacle diseased soil and application thereof

ActiveCN107135699AEliminate barriers to continuous croppingMake full use of the valueOrganic fertilisersSoil conditioning compositionsRoot systemDisease

The invention relates to an organic agent for disinfecting banana continuous cropping obstacle diseased soil and usage, and the method comprises the steps of mixing dry plant powders like reed, potato vine, straw, wheat straw, pea straw, bagasse, bean dregs, broad bean straw and corn straw with molasses, wherein the weight percentage of the molasses is 0-100%, and the dry plant powder and the molasses are packaged respectively before being use in order. The usage method comprises the steps of digging out the root of banana ground with continuous cropping obstacles and removing the straw; spreading the dry plant powder or the molasses in a preset proportion uniformly on the ground and plowing the ground with a rotocultivator; burying the plant powder and the molasses in a soil cultivated horizon in a mixing way; watering uniformly the ground by 30-80 ton of water per Mu to keep the soil wet; covering the ground to isolate the soil from the air; controlling the soil temperature between 25-50 DEG C and an oxido reduction potential below 60mv; and removing the covered film after maintaining an anaerobic strong reduction state for 3-4 weeks. According to the method, continuous cropping obstacle of the banana ground can be effectively eliminated; and incidence of disease where insect disease is infected by banana soil is greatly reduced.

Owner:云南丽然农业科技发展有限公司

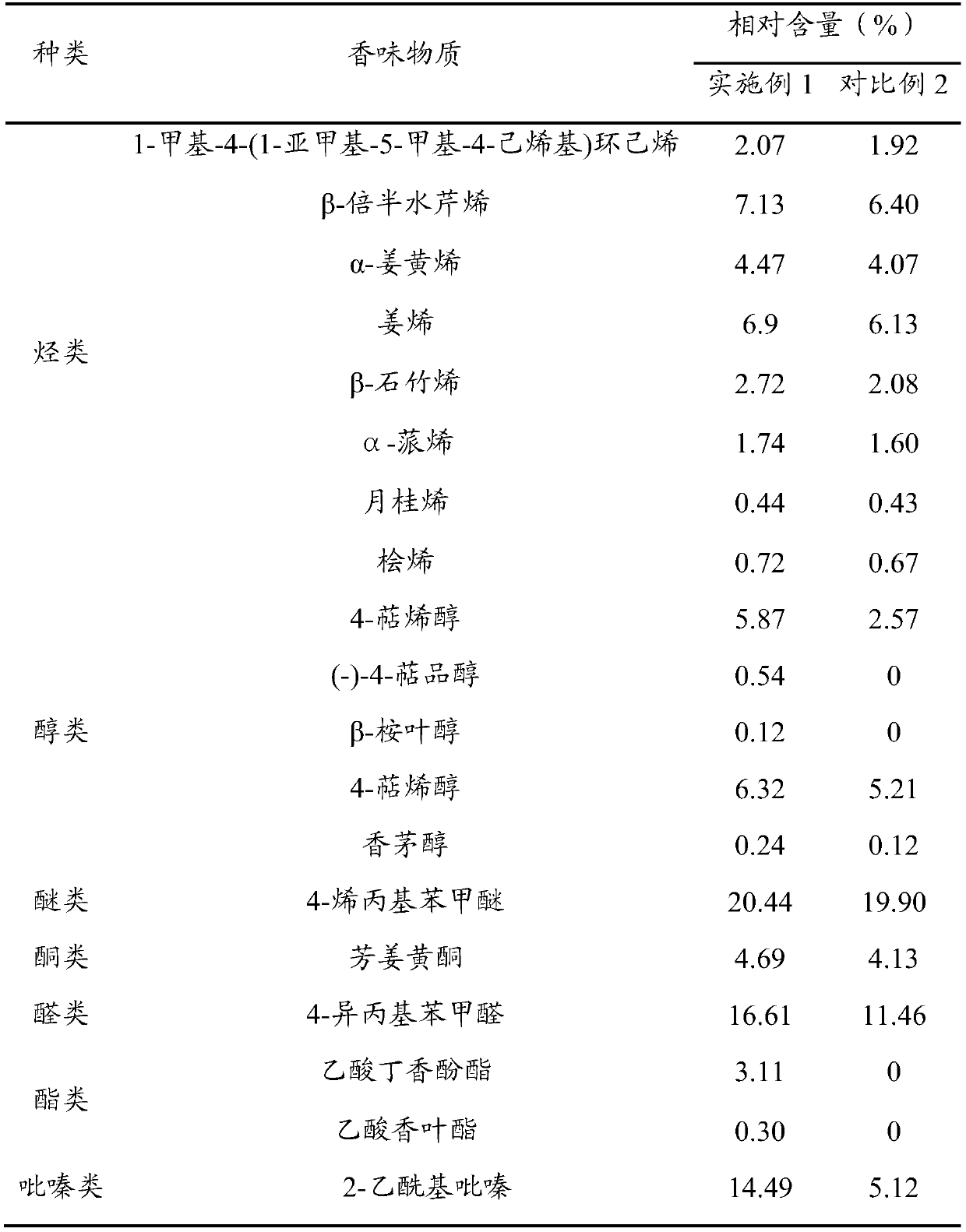

Method for preparing curry beef tallow hotpot condiment by utilizing embedding technology and low-temperature grease extracting technology

The invention provides a preparation method of a curry beef tallow hotpot condiment. The preparation method comprises the following steps: frying garlic, onion, pickled chili, Indian chili powder, mixed spice powder, curry powder, curry flavor sauce and dried small shrimps with beef tallow to obtain a fried product; carrying out heat preservation on the fried product and performing extracting at alow temperature to obtain an extracted product; mixing the extracted product with modified starch and maltodextrin, performing emulsifying and homogenizing, and carrying out microcapsule embedding toobtain an embedded product; and mixing the embedded product with edible salt, white granulated sugar, beef powder and a yeast extract, performing stirring, taking a formed mixture out from a pot, performing packaging and performing rapid cooling at a low temperature to obtain the curry beef tallow hotpot condiment. According to the preparation method provided by the invention, the aroma of various seasonings can be fused into grease and bioactive substances of the various seasonings are kept, so that the taste and aroma layering sense is richer. Meanwhile, the beef tallow is used as a main flavor raw material of a formula and is also used as an extracting agent; the food raw material modified starch and the maltodextrin are embedded and then are rapidly cooled and molded into a solid state; and the embedding effect is more stable and the quality guarantee time is long.

Owner:内蒙古草原红太阳食品股份有限公司

Method for recycling overdue waste medicine compound ferrous sulfate preparation and waste lithium foil in old lithium battery

ActiveCN108550941AReduce the impactMake full use of the valueWaste accumulators reclaimingBattery recyclingSulfateNew energy

The invention discloses a method for recycling overdue waste medicine compound ferrous sulfate preparation and waste lithium foil in an old lithium battery, and belongs to the technical field of the new energy material. The overdue waste medicine compound ferrous sulfate preparation and waste lithium foil in the old lithium battery is recycled in a LiFePO4 / C way, and then manufactured as an electrode plate by taking the LiFePO4 / C as an electrode active material, the electrode plate is assembled into a button simulate lithium ion battery under an anhydrous and oxygen-free condition, and the electrochemical performance is tested. Through the method disclosed by the invention, the waste is turned into the wealth, the process is simple, a new path and a new scheme are provided for recycling the overdue waste medicine compound ferrous sulfate preparation and the waste lithium foil, the ecological hazard on the environment by the overdue waste medicine compound ferrous sulfate preparation and the waste lithium foil is reduced, and the development of the circular economy and the sustainable policy is promoted.

Owner:KUNMING UNIV OF SCI & TECH

Treatment method of phosphoric acid dearsenic slag

The invention discloses a treatment method for phosphoric acid arsenic-removed slag, which can effectively separate and recycle arsenic and other valued metal of the phosphoric acid arsenic-removed slag. The method comprises the following steps: 1) adding the phosphoric acid arsenic-removed slag into an industrial kiln and feeding oxygen-containing gas to perform oxidizing roasting, wherein the reaction temperature is controlled to be 530 to 570 DEG C; 2) conveying high-temperature dust-containing kiln gas which contains As2O3 and SO2 and is generated in the reaction process, into a first flue gas filter, and collecting arsenic-removed valued metal-enriched dust, wherein the first flue gas filter adopts a high-temperature sintering resistant inorganic porous material filter element and the dust content of the kiln gas purified by the first flue gas filter is below 10 to 20 mg / m<3>; 3) conveying the kiln gas purified by the first flue gas filter into a dividing wall type heat exchanger to enable the temperature of the kiln gas to be reduced to be below 150 DEG C; and 4) conveying the kiln gas at the outlet of the dividing wall type heat exchanger into a second flue gas filter, and collecting As2O3-enriched dust, wherein the dust content of the kiln gas purified by the second flue gas filter is below 10 to 20 mg / m<3>.

Owner:CHENGDU INTERMENT TECH

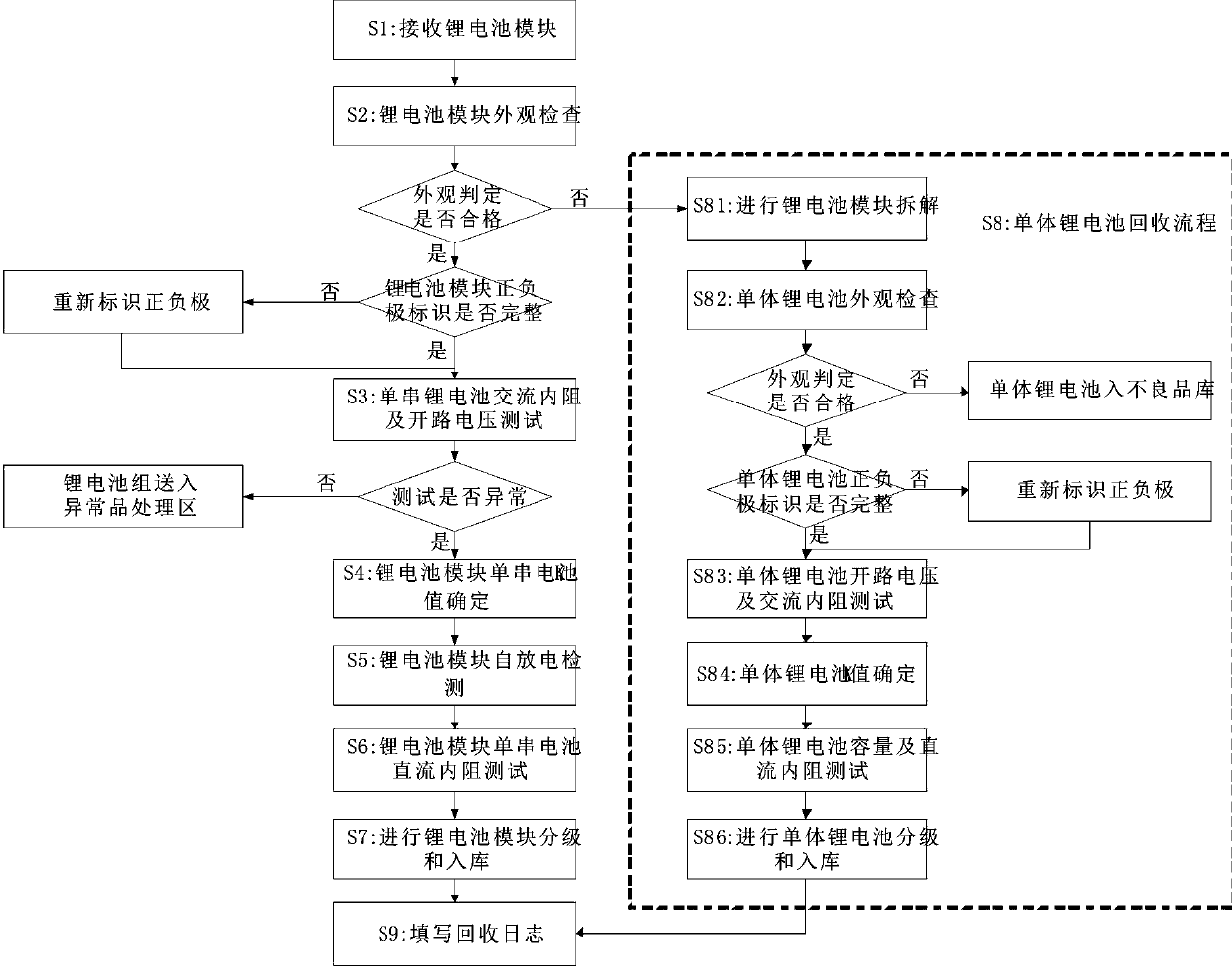

Method for recycling waste lithium battery module

InactiveCN111430833AAchieve recyclingImprove recycling ratesWaste accumulators reclaimingSortingProcess engineeringEnvironmental engineering

The invention discloses a method for recycling a waste lithium battery module, which and realizes the recycling of the waste lithium battery module and gives full play to the utilization value of other waste energy. According to the method, the waste lithium battery modules are firstly subjected to recoveryrecycling test, the waste lithium battery modules which do not meet the standard are disassembled into single lithium batteries, and the recoveryrecycling test is performed again , so that the recoveryrecycling utilization rate of the waste lithium battery modules is improved; in the recycling test process, test results and battery bar codes are bound one by one, and confusion of recyclable lithium battery modules and defective products is avoided; and after the recoveryrecycling test isfinished, the lithium batteries are classified and warehoused, so that the waste lithium batteries can be graded and effectively used.

Owner:洛阳捷鑫能源科技有限公司

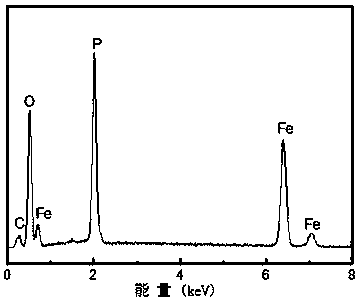

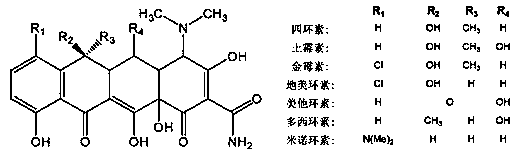

A New Application of Recovery of Expired Tetracycline Antibiotic Drugs

ActiveCN108172758BMake full use of the valueThe recycling application process is simple and practicalFinal product manufactureElectrode collector coatingNew energyNonwoven fabric

The invention discloses an application method of expired tetracycline antibiotics and belongs to the technical field of new energy materials. In the present invention, the expired tetracycline antibiotics are ground into powder, mixed with a conductive agent and a binder to obtain an electrode material mixture, and the electrode material mixture is added to N-methylpyrrolidone solvent, and stirred evenly to obtain an electrode slurry; the electrode slurry Evenly coated on the surface of the current collector, vacuum-dried to obtain the electrode sheet; the electrode sheet is used as the working electrode, lithium foil or sodium foil is used as the counter electrode and reference electrode, and porous polypropylene film, polyethylene film, glass fiber or non-woven fabric is The diaphragm is assembled into a lithium-ion rechargeable battery or a sodium-ion rechargeable battery under anhydrous and oxygen-free conditions. The invention is environmentally friendly, has strong practicability, and is low in cost. The expired tetracycline antibiotic medicine is used in the field of new energy materials for the first time, and a new way and a new scheme are provided for recycling and using the expired antibiotic medicine.

Owner:KUNMING UNIV OF SCI & TECH

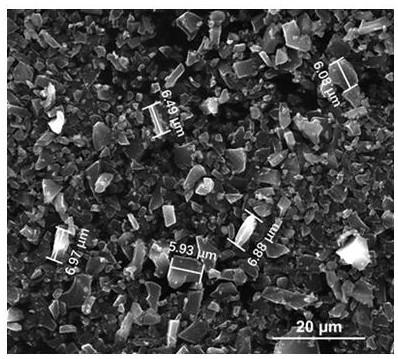

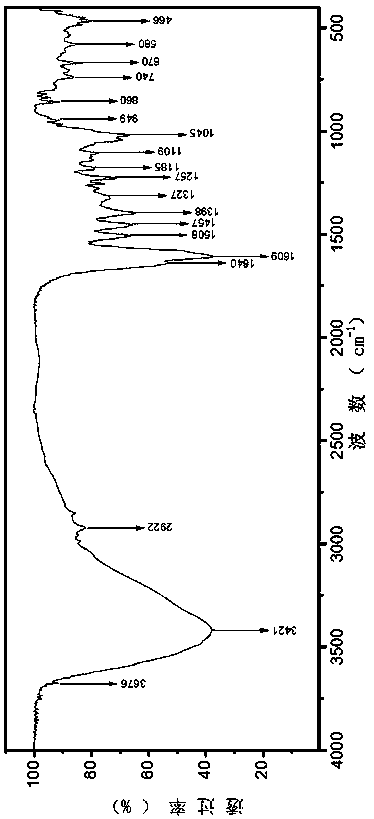

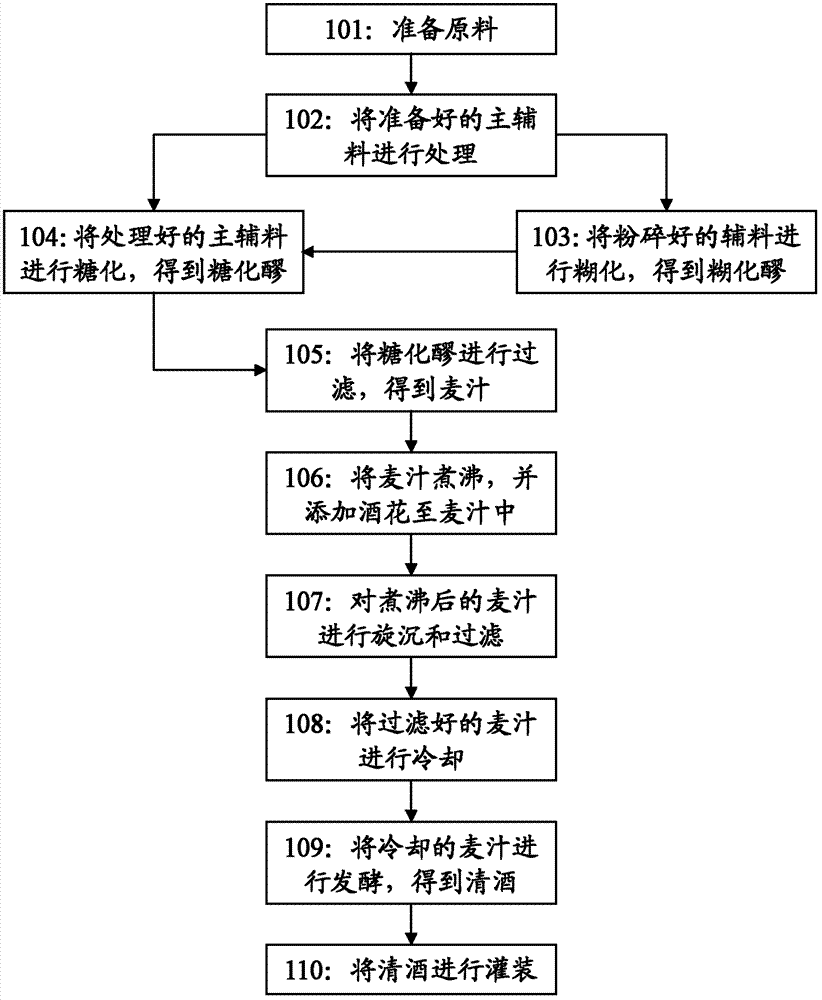

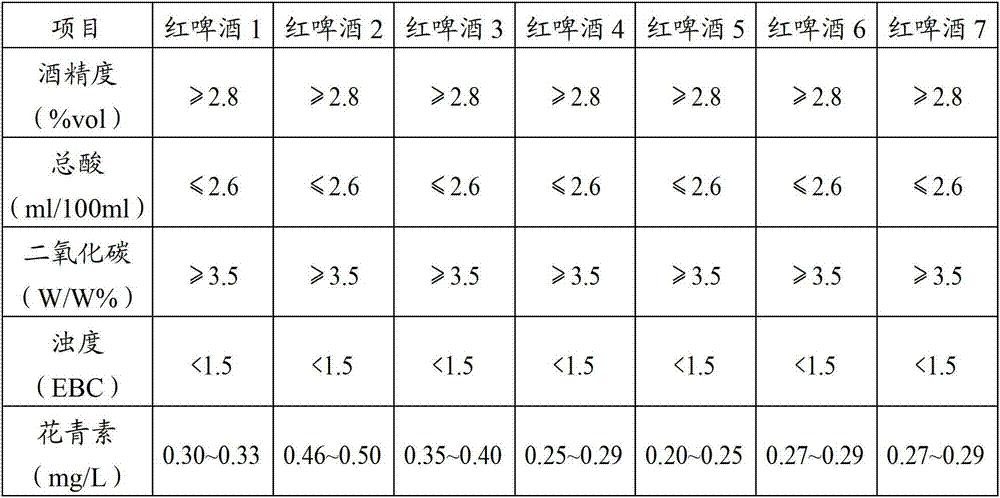

Functional beer and brewing method thereof

InactiveCN102250701BIncrease contentReduce damageMicroorganism based processesBeer brewingNutrientChemistry

The invention discloses a functional beer and a brewing method thereof. The brewing method of the functional beer uses malt, rice, hops, yeast and a raw material containing anthocyanin, and comprises the steps of: pulverizing, pasting, saccharifying, filtering, boiling, adding the hops, carrying out rotary settling, cooling, pre-fermenting, after-fermenting and storing in a cold condition to obtain the functional beer in which the content of anthocyanin is 0.2-0.5 mg / L. By the brewing method disclosed by the invention, the beer containing purple sweet potato is produced, the content of nutrient anthocyanin in the functional beer is improved, and simultaneously, the beer is easy to store and preserve and has a better taste due to a certain antibacterial effect of purple sweet potato pigment.

Owner:JIANGHAN UNIVERSITY

Method for producing feed additive from livestock and poultry breeding wastewater and purifying breeding wastewater to reclaimed water

InactiveCN102161550BReduce water consumptionAchieving zero emissionsWaste water treatment from animal husbandryAnimal feeding stuffUltrafiltrationSlurry

The invention relates to the fields of environmental technology and the breeding and processing of microalgae, in particular to a method for producing feed additive from livestock and poultry breeding wastewater and purifying breeding wastewater to reclaimed water. The method is characterized by comprising the following steps that: wastewater enters an acidification adjusting tank through a grille, and the acidified wastewater enters an anaerobic biochemical reactor for treatment and then enters an aerobic biochemical reactor; after the aerobic biochemical treatment, the obtained biogas slurry enters a settling tank for settling, the supernatant enters a membrane bioreactor for further aerobic treatment and is filtered by an ultrafiltration membrane, the generated ultrafiltration clear liquid is sterilized and neutralized and then enters a photobioreactor, algae are added into the photobioreactor to perform microalgae cultivation, and the algae liquid is discharged from the photobioreactor and then enters a flocculation and settling tank; and after flocculation and settling, the supernatant is used for water recycling, the concentrated algae liquid at the bottom enters a filter, and the separated microalgae slurry enters a fermentation / enzymolysis pot (tank) to perform fermentation / enzymolysis to be used as the feed additive. The invention has the advantages of high economic adaptability, zero discharge and the like.

Owner:蔡志武 +1

Preparation method of chitosan produced from snow crab shell

ActiveCN111138563BMake full use of the valueAvoid the three wastesOrganic compound preparationCarboxylic acid salt preparationGlycanEnvironmental engineering

The invention discloses a method for preparing chitosan by using snow crab shells, relates to the technical field of preparation methods for high-viscosity polysaccharides, and in particular belongs to a method for preparing chitosan by using fresh snow crab shells. Crab shell pretreatment: take 200 parts ("parts" are in mass units, the same below) fresh snow crab shells and crush them; crab shell decalcification: add 600-1000 parts of citric acid solution with a mass percentage concentration of 5-10% to the crab shells , soaked for 6 to 15 hours, filtered, and water was used as a washing liquid to wash the filtered crab shells, and the washing residual liquid was combined with the filtrate to obtain a mixture for retention; extracting organic calcium: filtering the mixture through a plate frame, and drying the filter residue to obtain calcium citrate; The remaining mixed liquid is collected for reuse after subsequent treatment; the three wastes are eliminated in the entire production process, and zero waste, zero discharge, and high-value utilization are realized. Without high temperature and strong alkali deproteinization process, energy saving, environmental protection, and stable product quality. The product has high viscosity and good quality.

Owner:SHANDONG MEIJIA GROUP

Piping exchange station for the incoming and outgoing system of the oil depot tank area

ActiveCN103552971BMake full use of the valueImprove work efficiencyLiquid transferring devicesLine tubingMarine engineering

The invention relates to a piping exchange station for the import and export system of an oil depot tank area, which includes a base body on which a loading and unloading ship control valve, a storage tank control valve, a delivery pump control valve and a delivery pipeline control valve are installed. The invention can freely combine incoming and outgoing goods according to on-site requirements, greatly improves work efficiency, and can fully utilize the utilization value of storage equipment and pipelines in the warehouse area.

Owner:江苏丽天石化码头有限公司

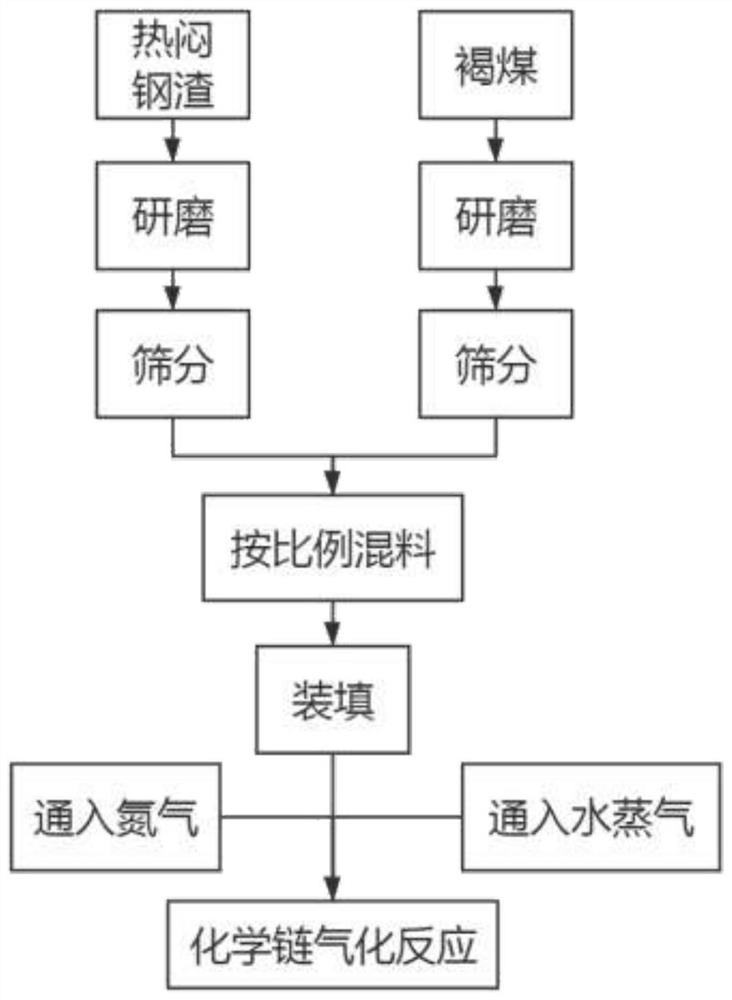

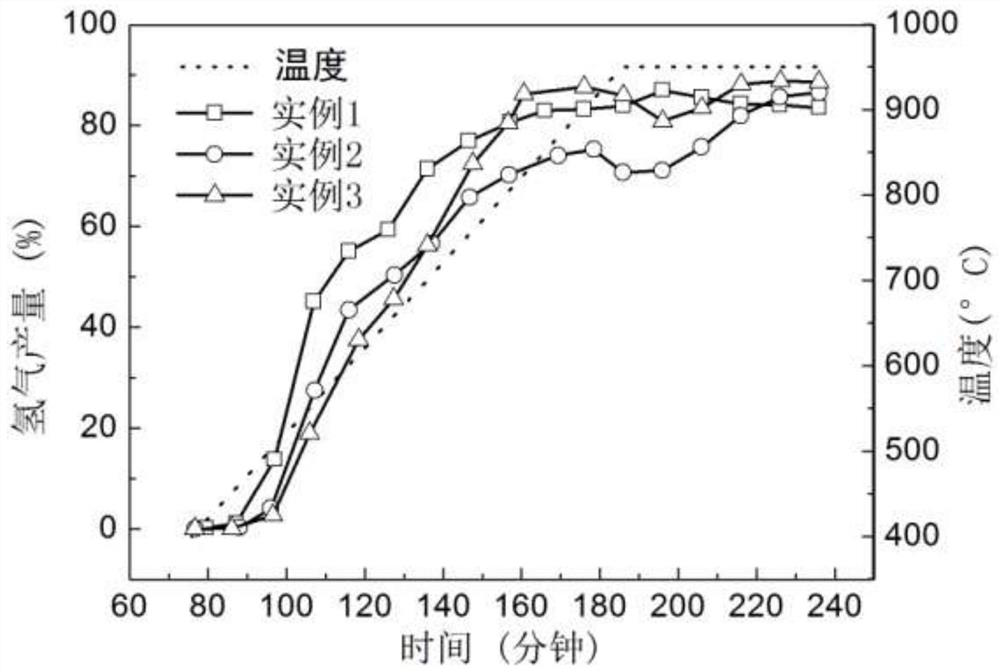

Method for producing hydrogen through lignite chemical looping gasification based on steel slag oxygen carrier

PendingCN113150834AWide variety of sourcesSimple processEnergy inputGasification processes detailsThermodynamicsSlag

The invention discloses a method for producing hydrogen through lignite chemical looping gasification based on a steel slag oxygen carrier, which comprises the following steps: step 1, respectively grinding steel slag and lignite, and conducting screening to be 120 meshes or less; 2, weighing the steel slag and the lignite according to the mass percentage; 3, conducting dry mixing for 15-20 min in a three-dimensional mixing machine; 4, filling a reactor with the mixed material, so as to enable the gas to be in full contact with the material and capable of passing through the material; and 5, introducing water vapor into the reactor in a nitrogen atmosphere, and continuously conducting reacting at 900-950 DEG C to obtain hydrogen. The method has the advantages that the pyrolytic steel slag is used as the oxygen carrier, the water vapor is introduced to react with the lignite in the nitrogen atmosphere to produce the hydrogen, the process flow is simple, the operation cost is low, and the raw material source is wide; and elements such as iron, magnesium, aluminum and calcium in the pyrolytic steel slag are fully utilized, on one hand, the efficiency of chemical chain gasification hydrogen production can be promoted, on the other hand, part of steel slag can be consumed, and reduction and resource utilization of industrial solid waste are achieved.

Owner:KUNMING UNIV OF SCI & TECH

Method for making curved thin-film photovoltaic building skin and skin module used

ActiveCN108322146BReduce the difficulty of on-site installationImprove construction efficiencyPhotovoltaic supportsClimate change adaptationComputer moduleEngineering

The invention discloses a manufacture method of a curved surface film photovoltaic building surface and an adopted surface module, and aims at providing a manufacture method capable of reducing the construction difficulty and improving the construction efficiency and a surface module. The manufacture method comprises the following steps: designing an initial curved surface model; performing optimization design by taking the maximum solar irradiation absorbing amount as a target, so as to obtain an optimized curved surface model; dividing the optimized curved surface into a plurality of modules; printing a hard curved surface back plate according to a 3D printing technology according to patterns of divided modules, and sequentially overlapping and fixing a first flexible film clamping piece, a flexible film solar cell, a second flexible film clamping piece and a flexible waterproof transparent plastic film on the printed hard curved surface back plate, and packaging an edge; performingsite mounting on each finished product surface module; finally splicing adjacent modules, so as to accomplish the construction of a complete building surface facade. The method greatly reduces the site mounting difficulty, and improves the construction efficiency.

Owner:TIANJIN UNIV

A feeding and mixing process and equipment for emulsified asphalt plant cold recycling

ActiveCN103790093BMake full use of the valueUniform qualityRoads maintainenceRoad surfaceEngineering

The invention discloses a feeding and blending technology and a feeding and blending device for cold recycling of an emulsified asphalt factory. The stepped feeding and stepped blending technology is adopted, i.e. the technology comprises the steps of accurately gauging and matching new aggregate, feeding into a one-step stirring pot through a belt conveyor system, spraying a small quantity of water at a new aggregate inlet, pre-stirring, spraying a small quantity of emulsified asphalt, sufficiently blending, enabling the surface of the new aggregate to be packed with a small quantity of asphalt, adding asphalt pavement milling old material, cement and mineral powder, spraying water again, spraying the emulsified asphalt after pre-stirring again, and sufficiently blending, so that an emulsified asphalt regenerated finished material with characteristics of the paved asphalt pavement lower layer can be prepared. After the finished product material prepared by the construction technology and device for feeding and blending in a stepped way is used, the use value of the asphalt pavement milling old material can be sufficiently played, and the produced finished product material is stable in quality; when the material is used for paving roads, the road quality can be improved, and the service life of the roads can be prolonged.

Owner:XUZHOU XCMG MAINTENANCE MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com